Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "Defect minimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

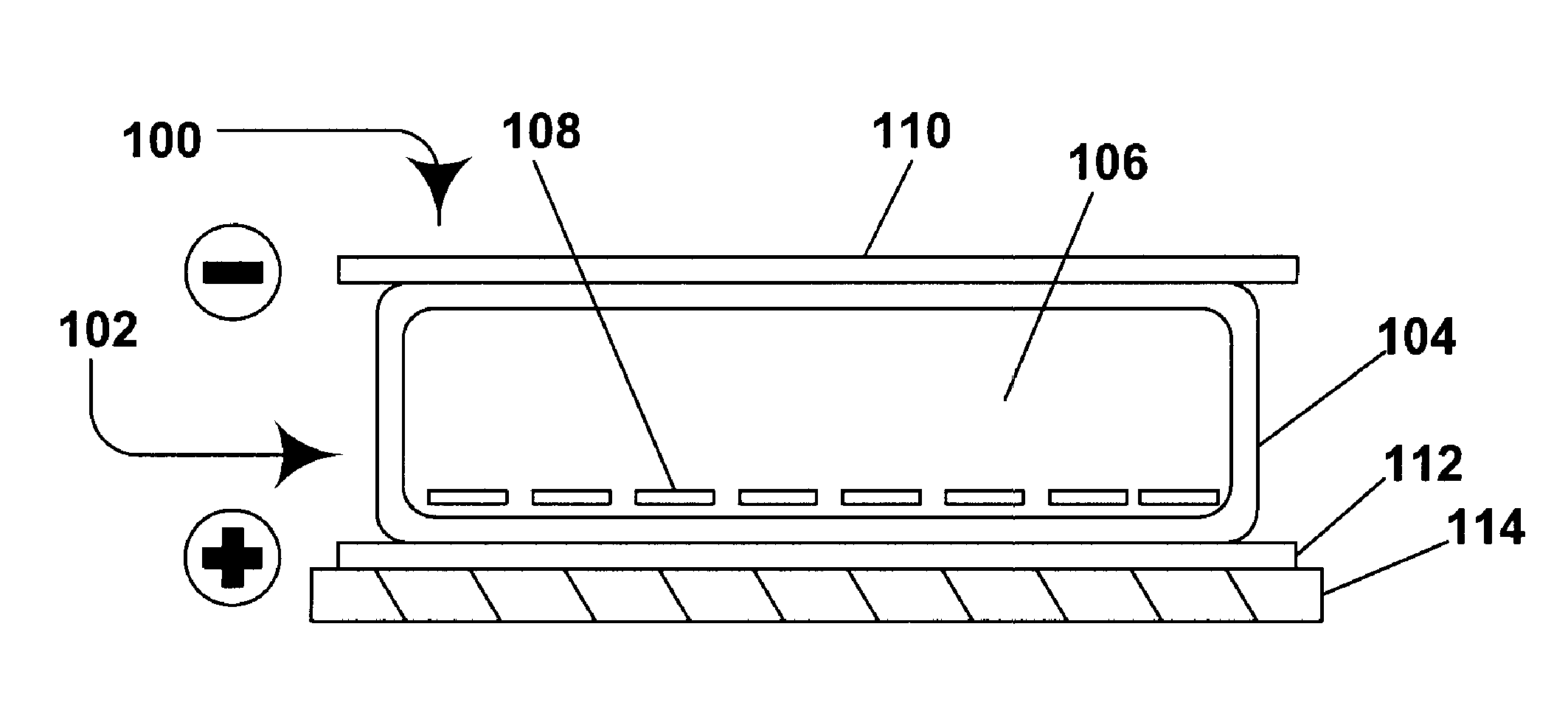

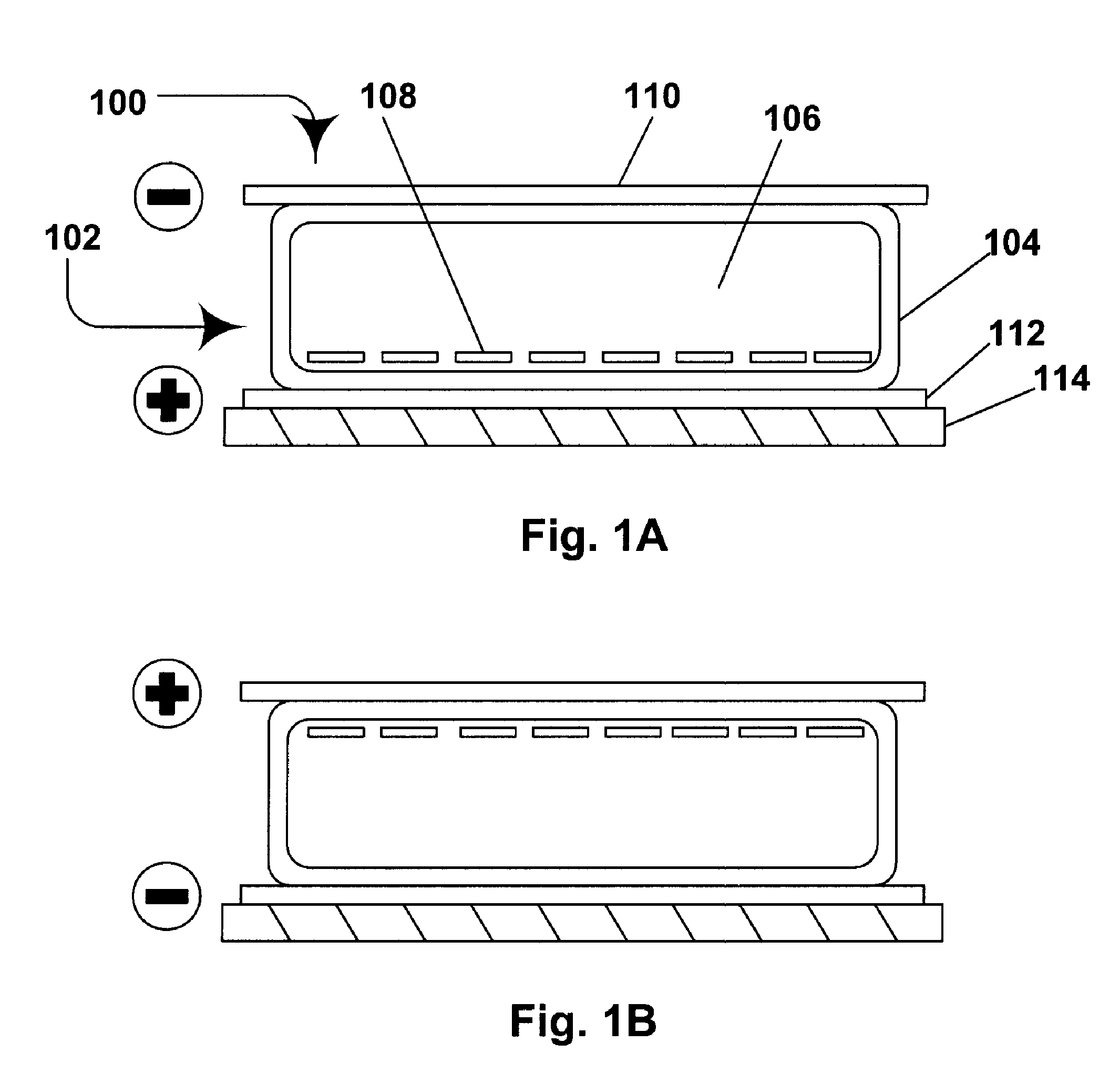

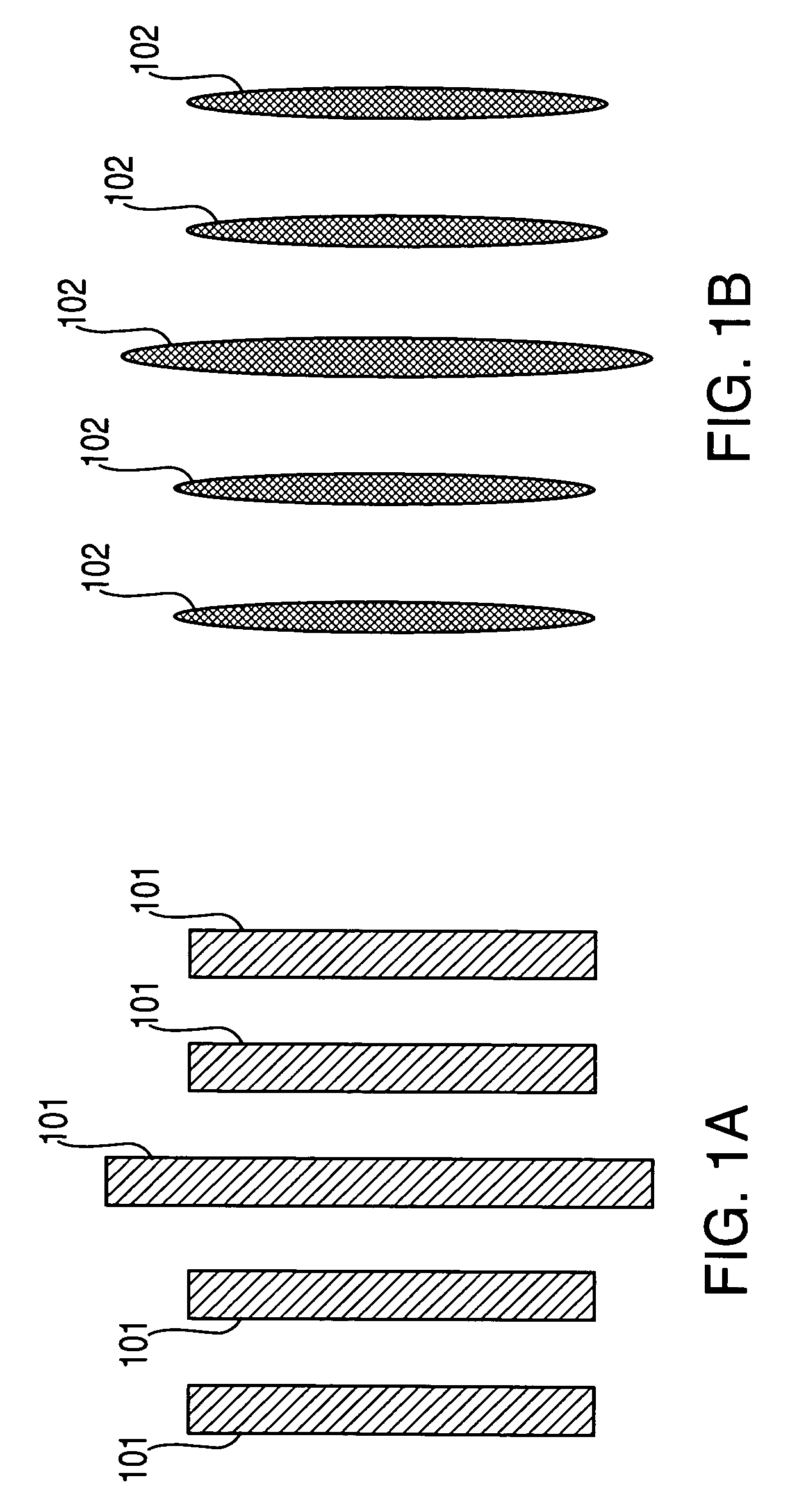

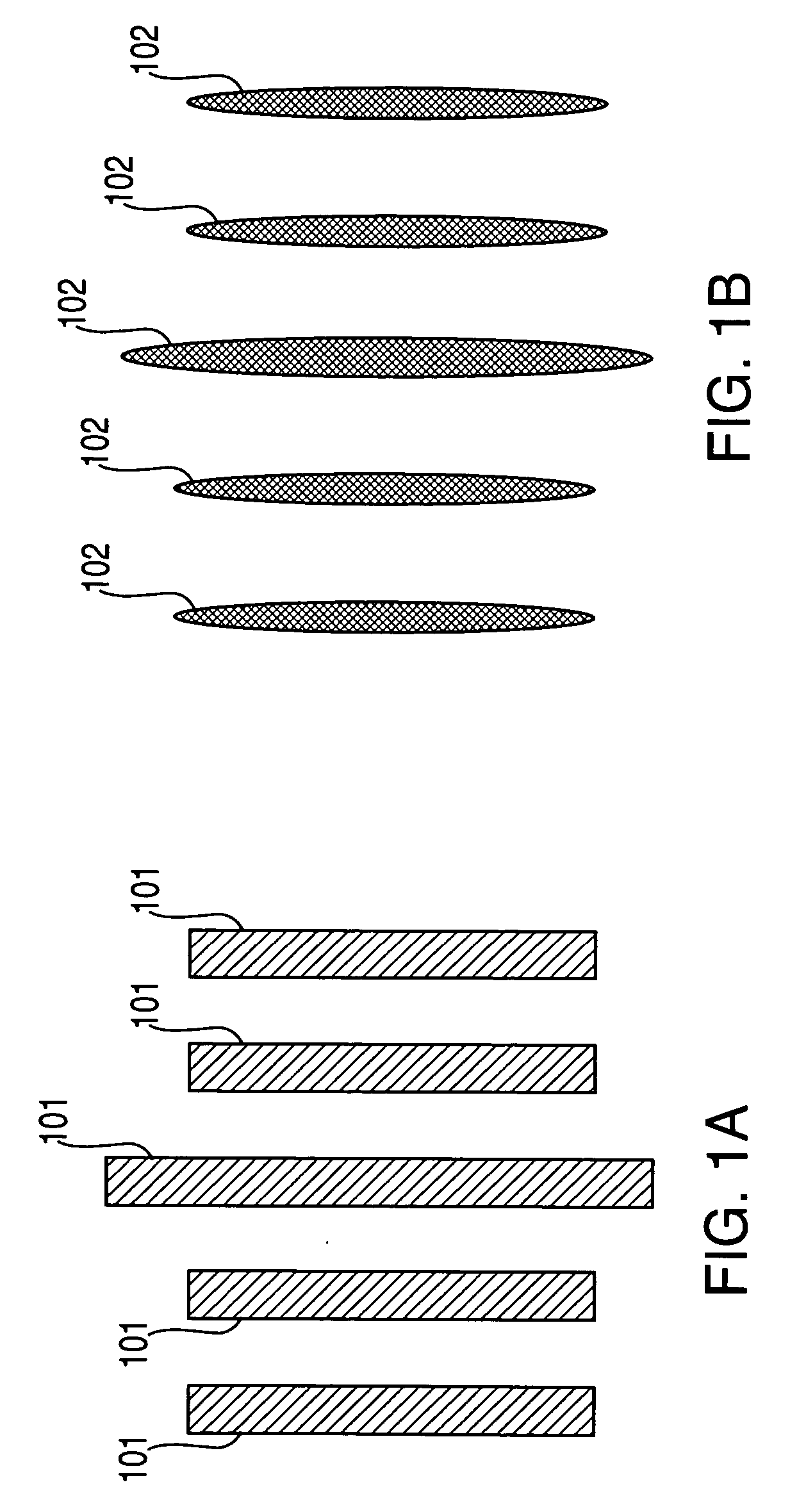

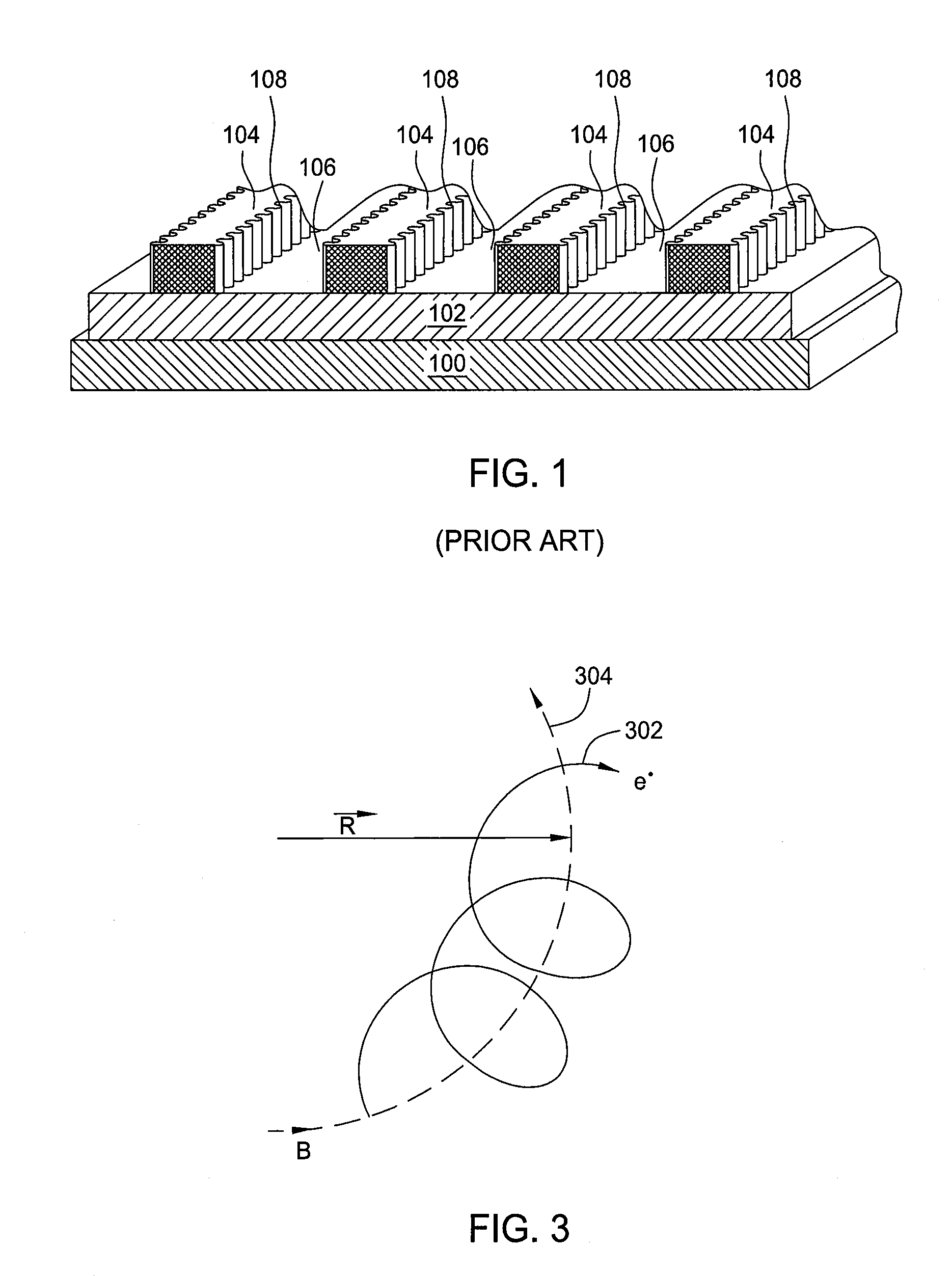

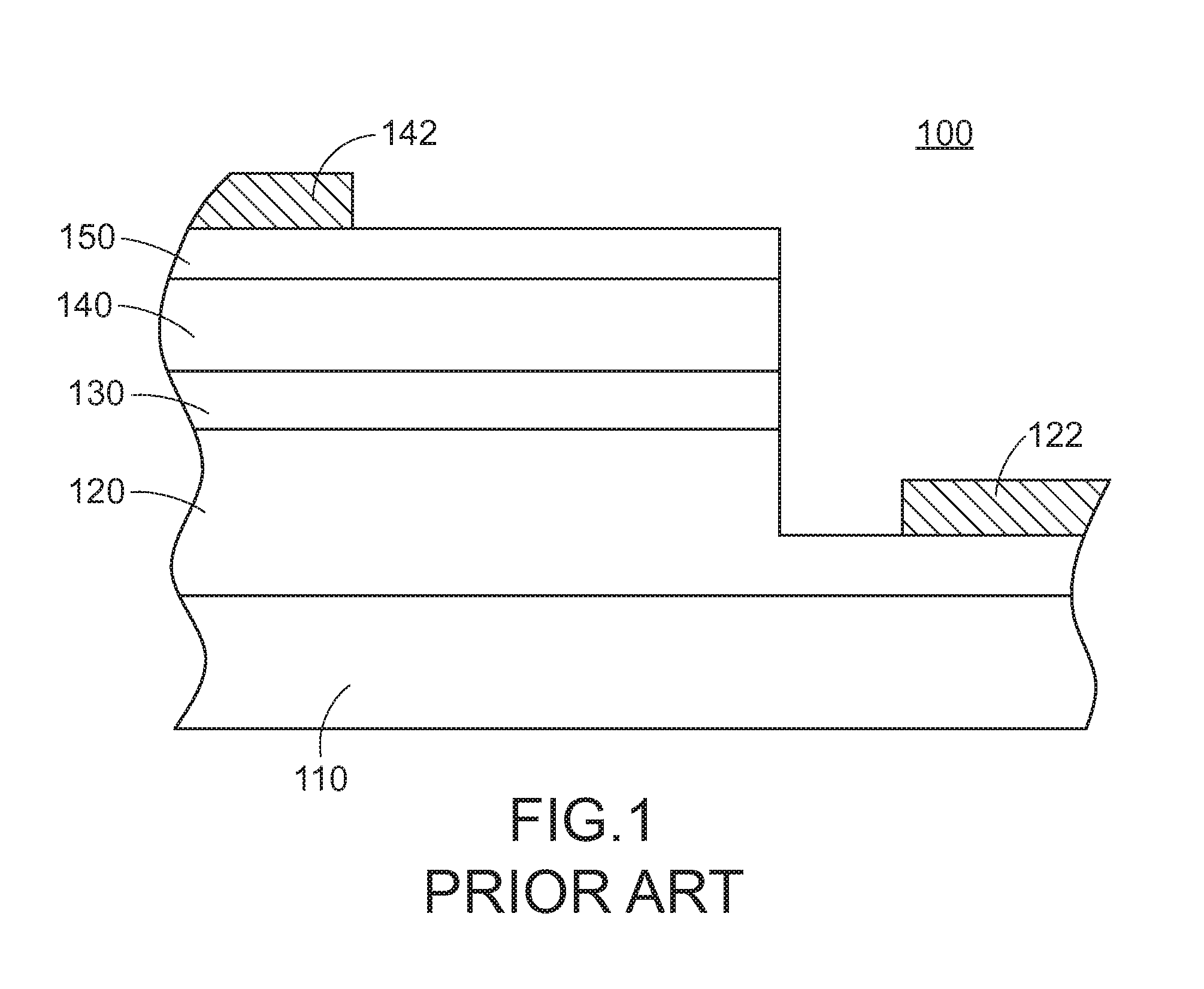

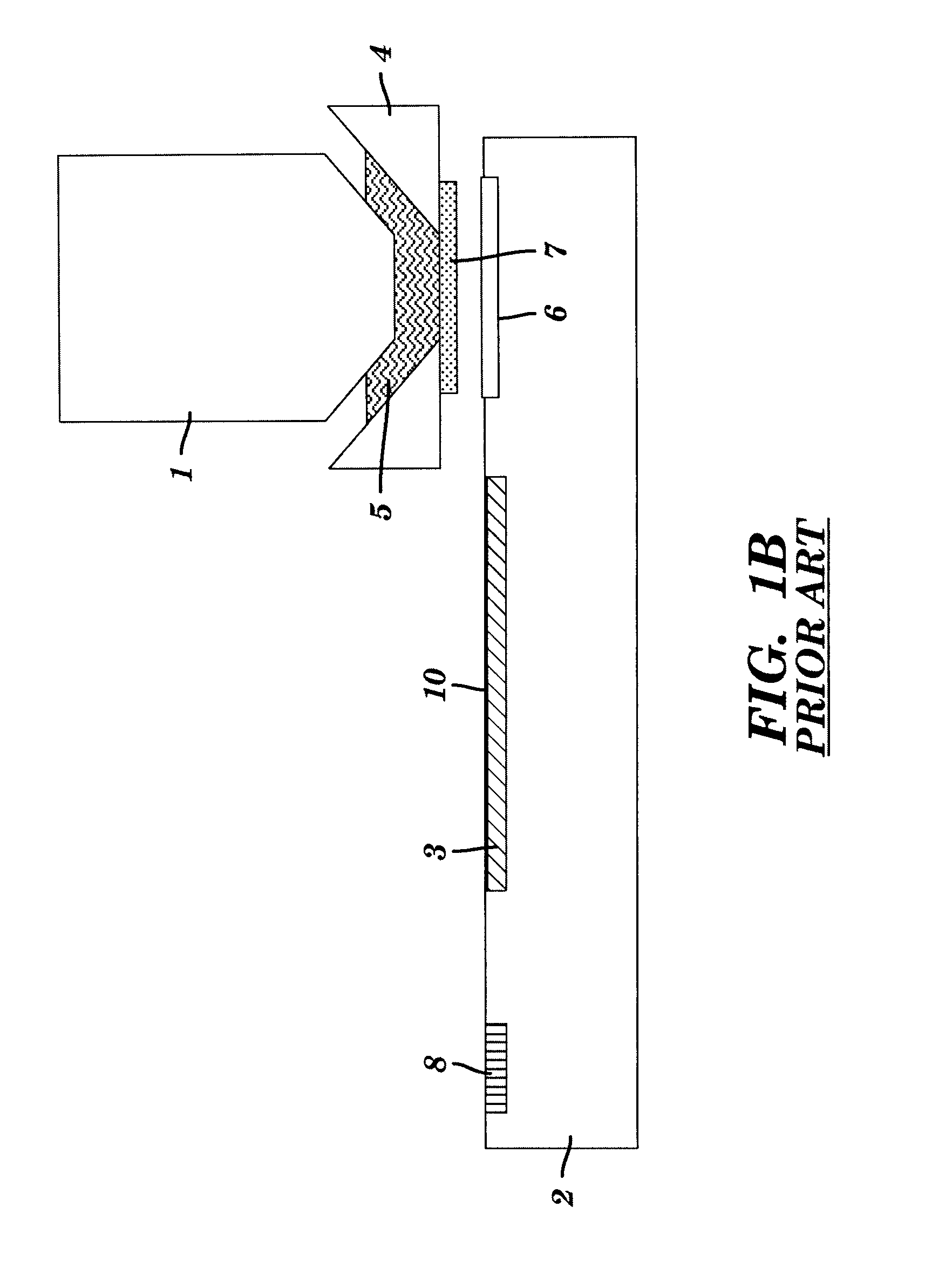

Electrophoretic media containing specularly reflective particles

ActiveUS20040094422A1Good flexibilityImprove uniformitySludge treatmentStatic indicating devicesElectrophoresisSpecular reflection

An electrophoretic medium (100) comprises at least one type of particle (108) suspended in a suspending fluid (106) and capable of moving therethrough on application of an electric field to the medium, the particles (108) including at least one electrophoretically mobile specularly reflective particle.

Owner:E INK CORPORATION

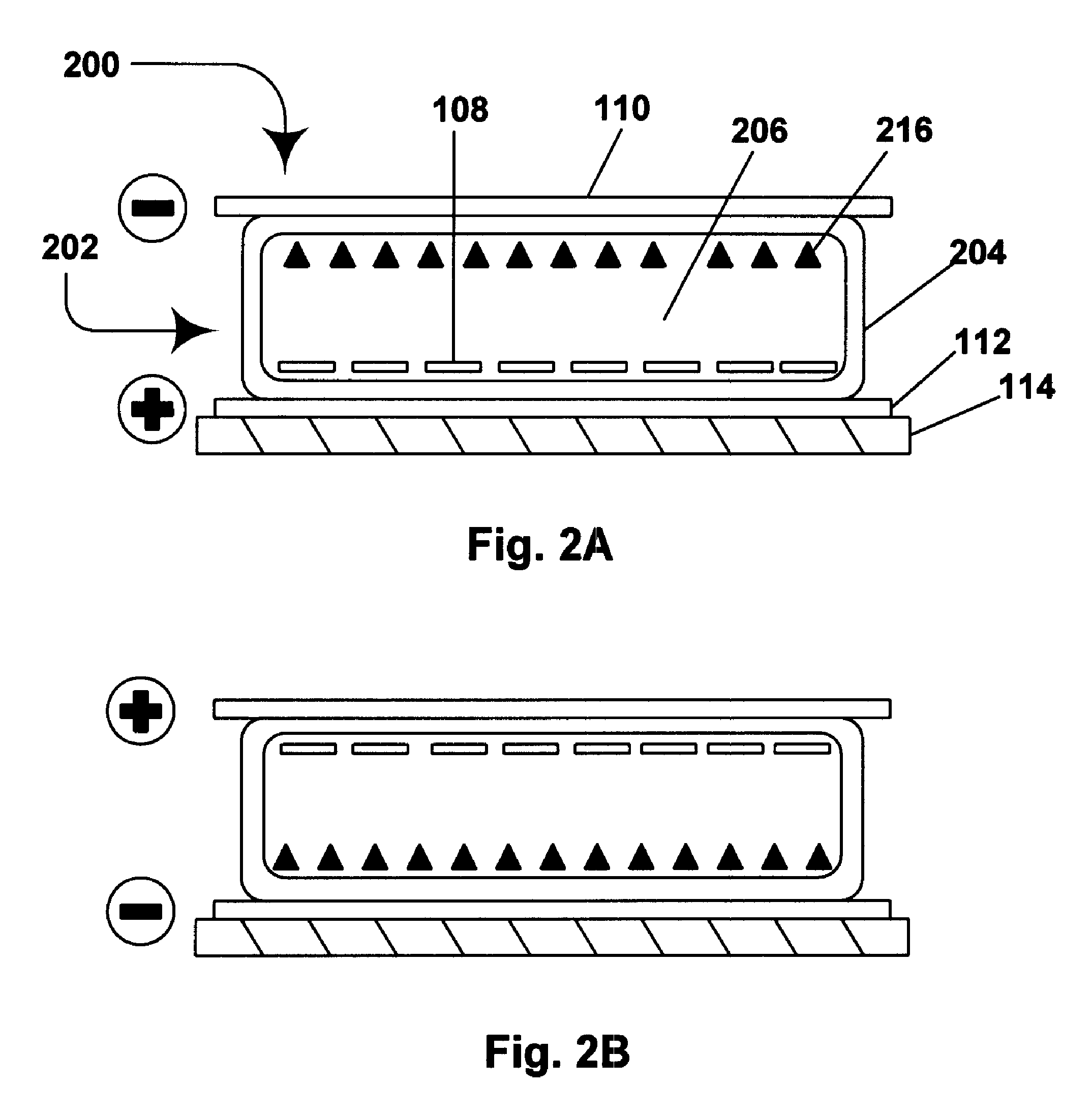

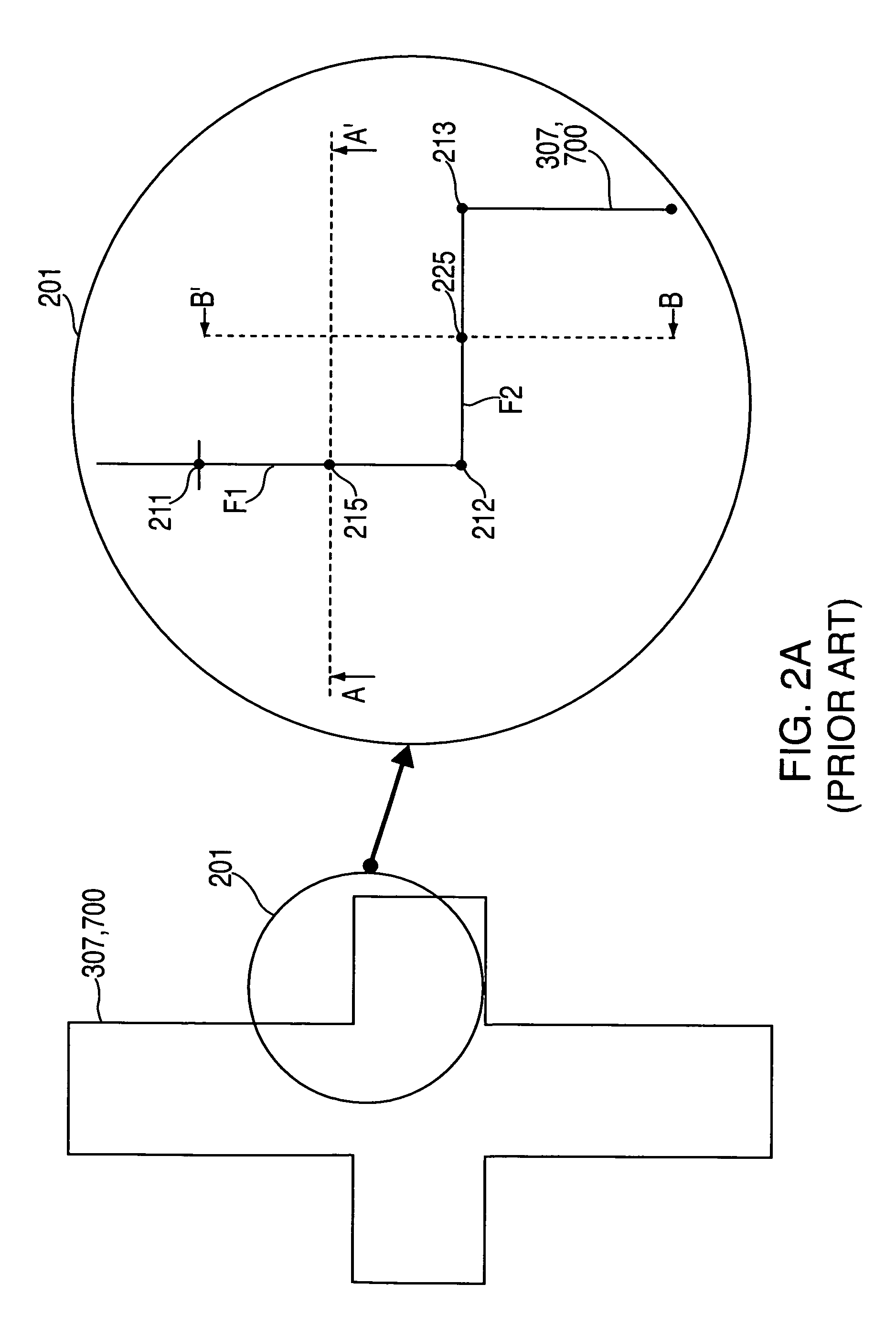

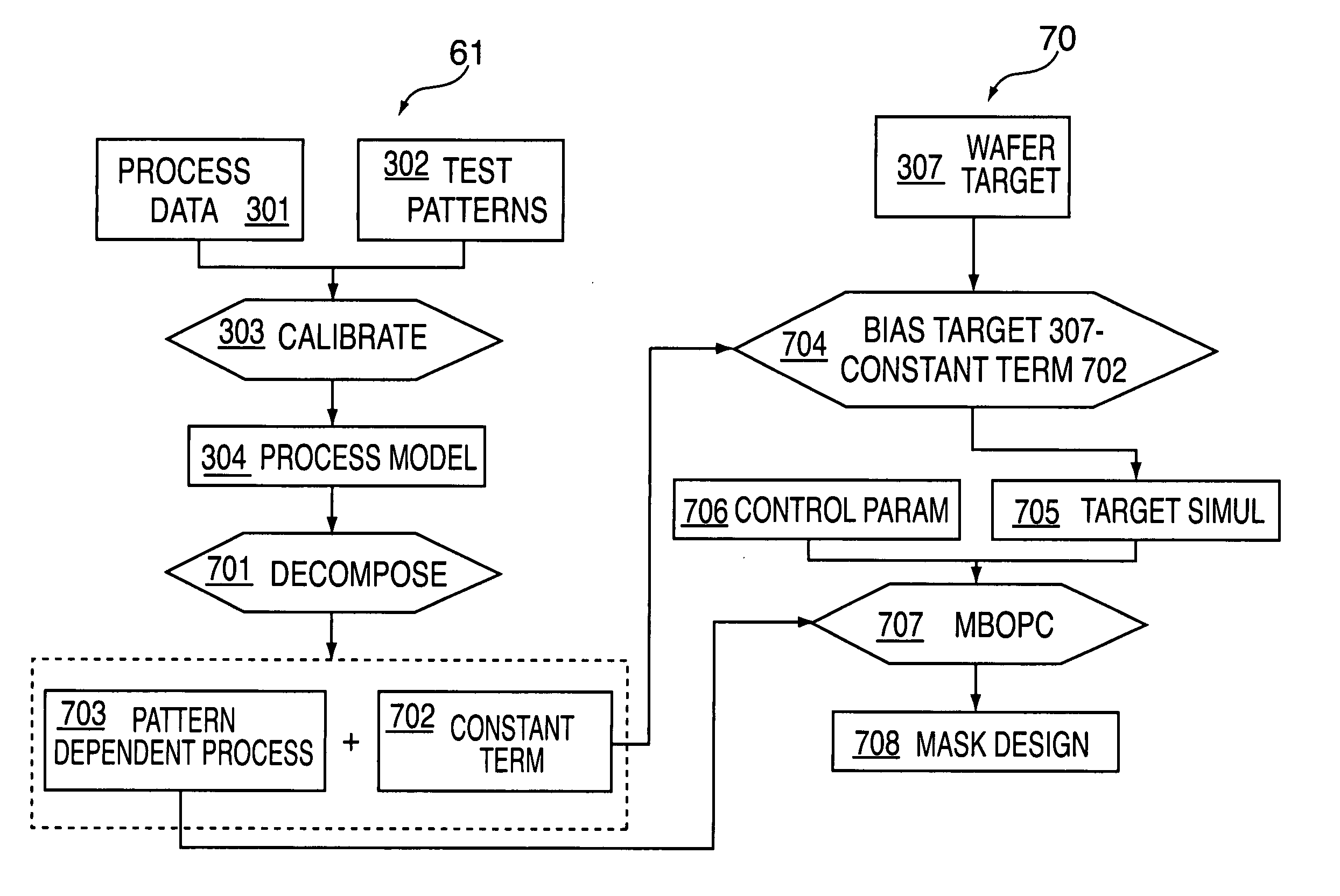

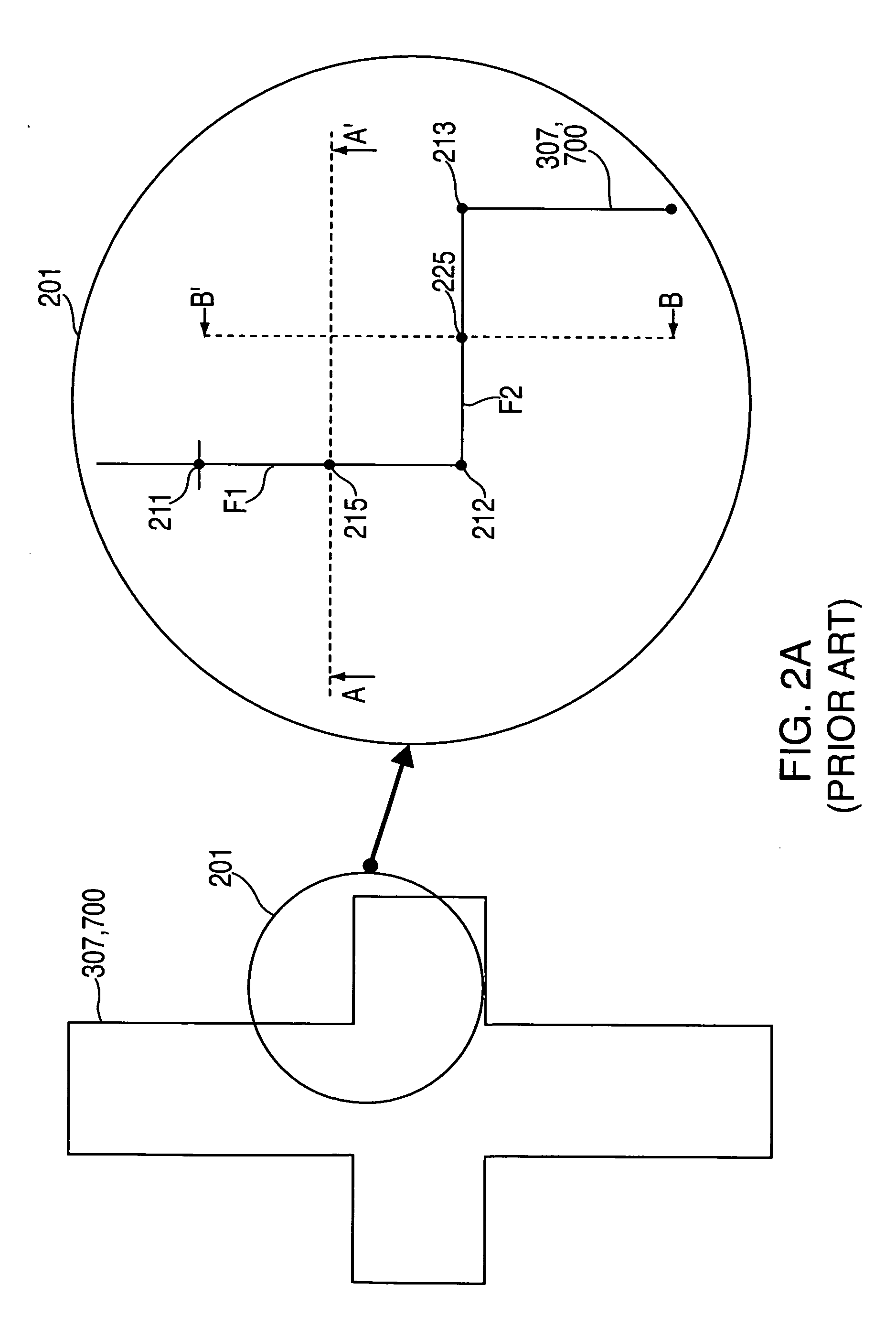

Method for improving optical proximity correction

ActiveUS7350183B2Improve variationDefect minimizationPhotomechanical apparatusOriginals for photomechanical treatmentLine widthComputer science

Owner:GLOBALFOUNDRIES U S INC

Method for improving optical proximity correction

ActiveUS20060101370A1Improve variationDefect minimizationPhotomechanical apparatusOriginals for photomechanical treatmentOptical proximity correctionPattern correlation

A method for performing model based optical proximity correction (MBOPC) and a system for performing MBOPC is described, wherein the process model is decomposed into a constant process model term and a pattern dependent portion. The desired wafer target is modified by the constant process model term to form a simulation target that is used as the new target within the MBOPC process. The pattern dependent portion of the model is used as the process model in the MBOPC algorithm. This results final mask designs that result in improved across-chip line width variations, and a more robust MBOPC process.

Owner:GLOBALFOUNDRIES US INC

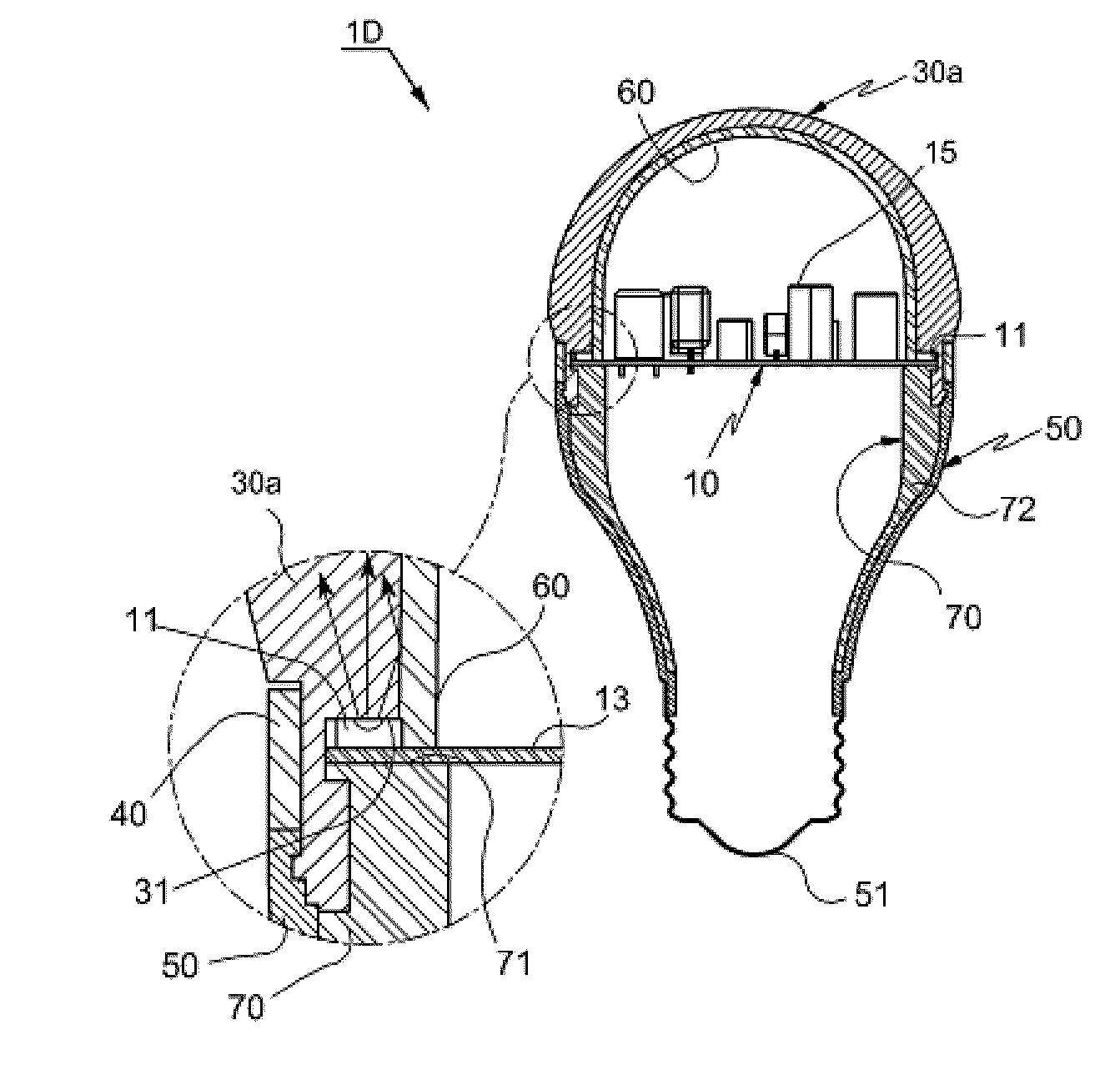

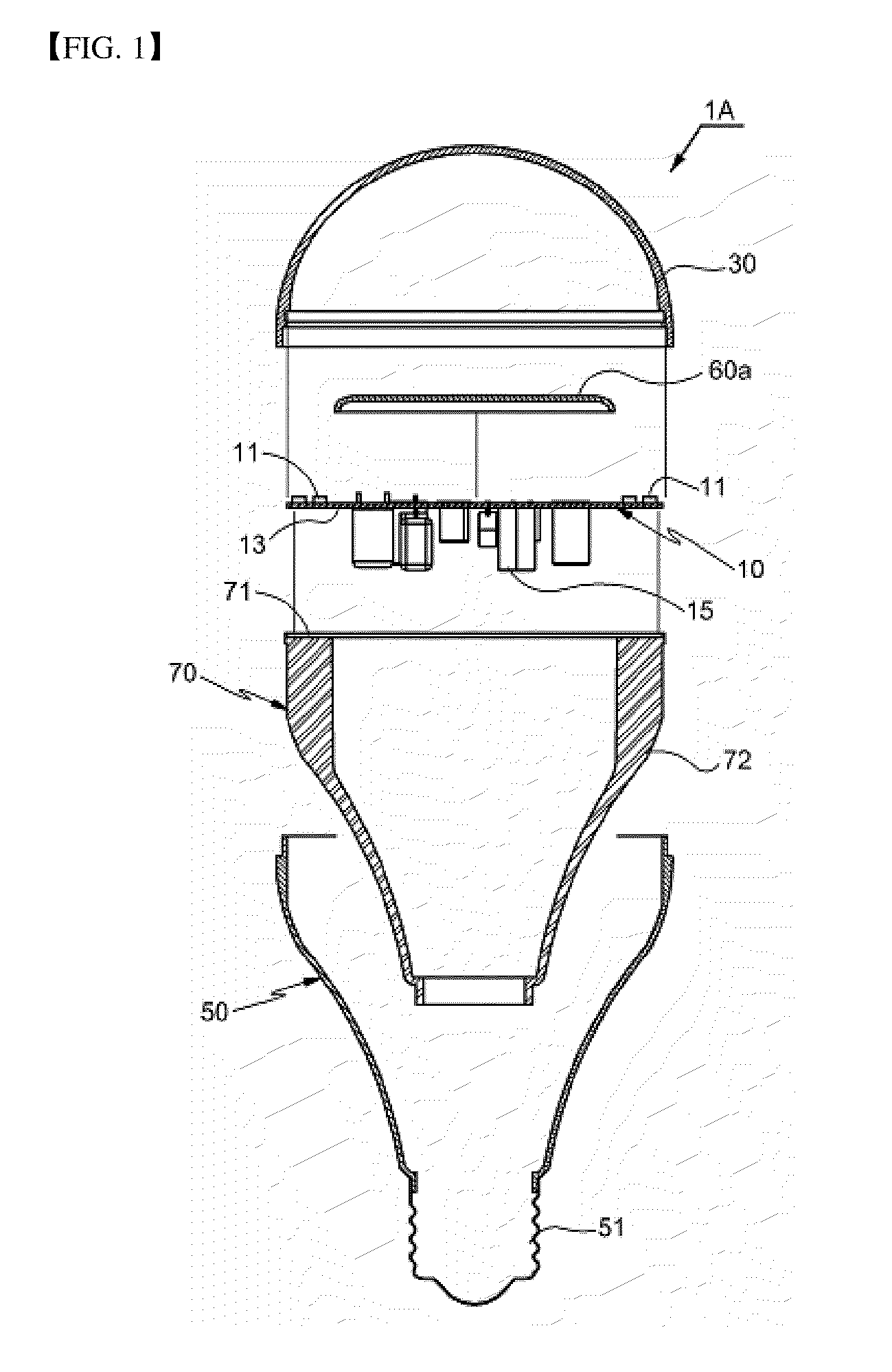

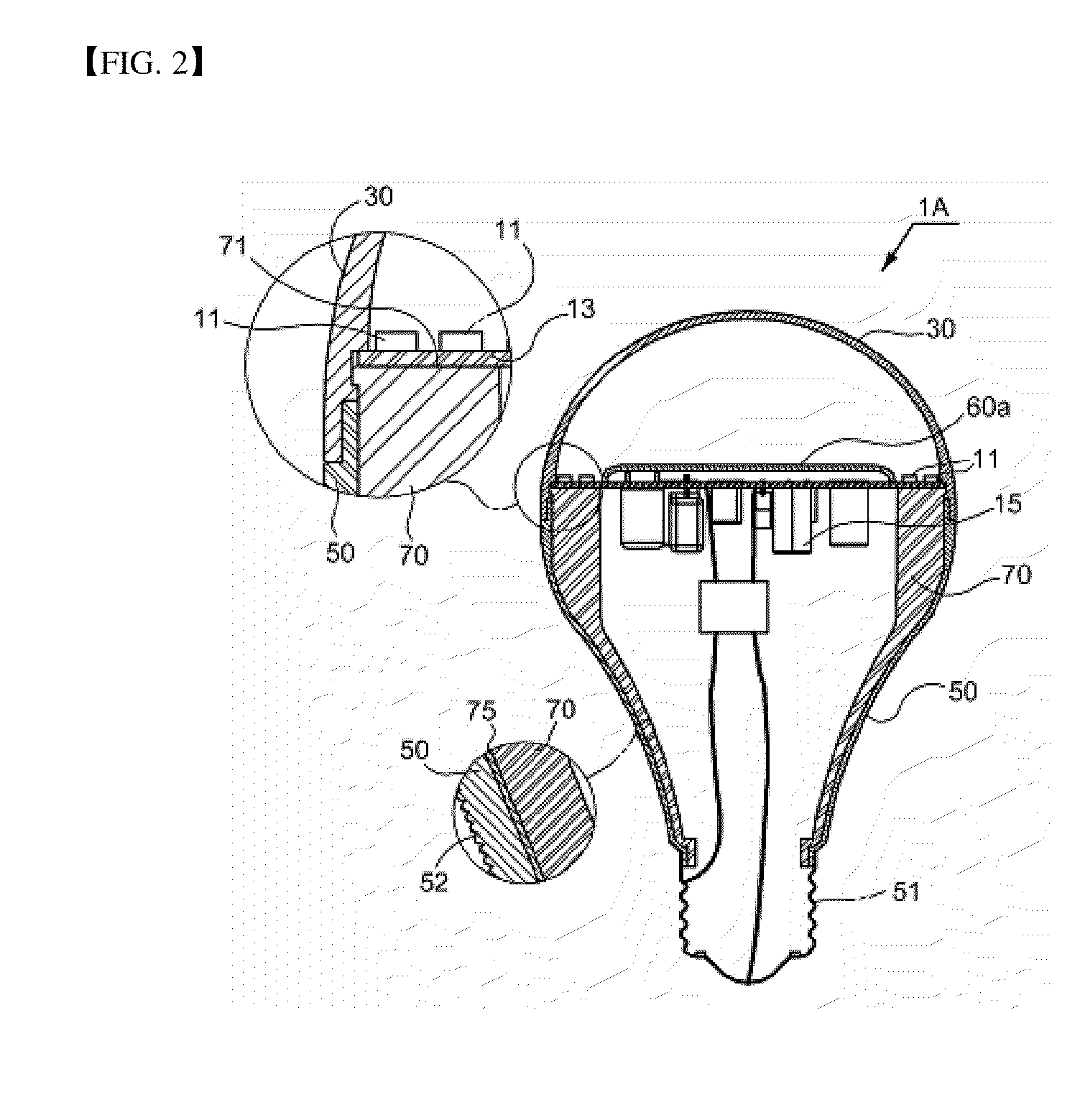

LED lamp

InactiveUS20110101861A1Increase emission rateConstant gainPoint-like light sourceElongate light sourcesEngineeringPolycarbonate

The present invention relates to an LED lamp in which, because the lamp has therein a heat dissipation transfer member and the power source base thereof is made of materials including polycarbonate, etc. with a high emission rate of radiation so as to enhance its surface heat dissipation constant, the power source base has sufficient heat dissipation performance and, thus, a separate insulation circuit is not necessary, thereby improving reliability and productivity of the lamp as well as reducing the cost of manufacturing.To this end, the present invention provides an LED lamp comprising one or more LEDs mounted on a PCB, a floodlight cover that transmits light from the LEDs, and a power source base coupled to the floodlight cover and having a terminal at one end thereof, wherein the power source base is made of an insulation material; and the LED lamp also comprises a heat dissipation transfer member that has a heat sink in contact with the PCB on which the LEDs are mounted, and is formed and installed so as to overlap with and be in tight contact with the inner face of either the power source base or the floodlight cover or both.

Owner:YOO YOUNG HO +1

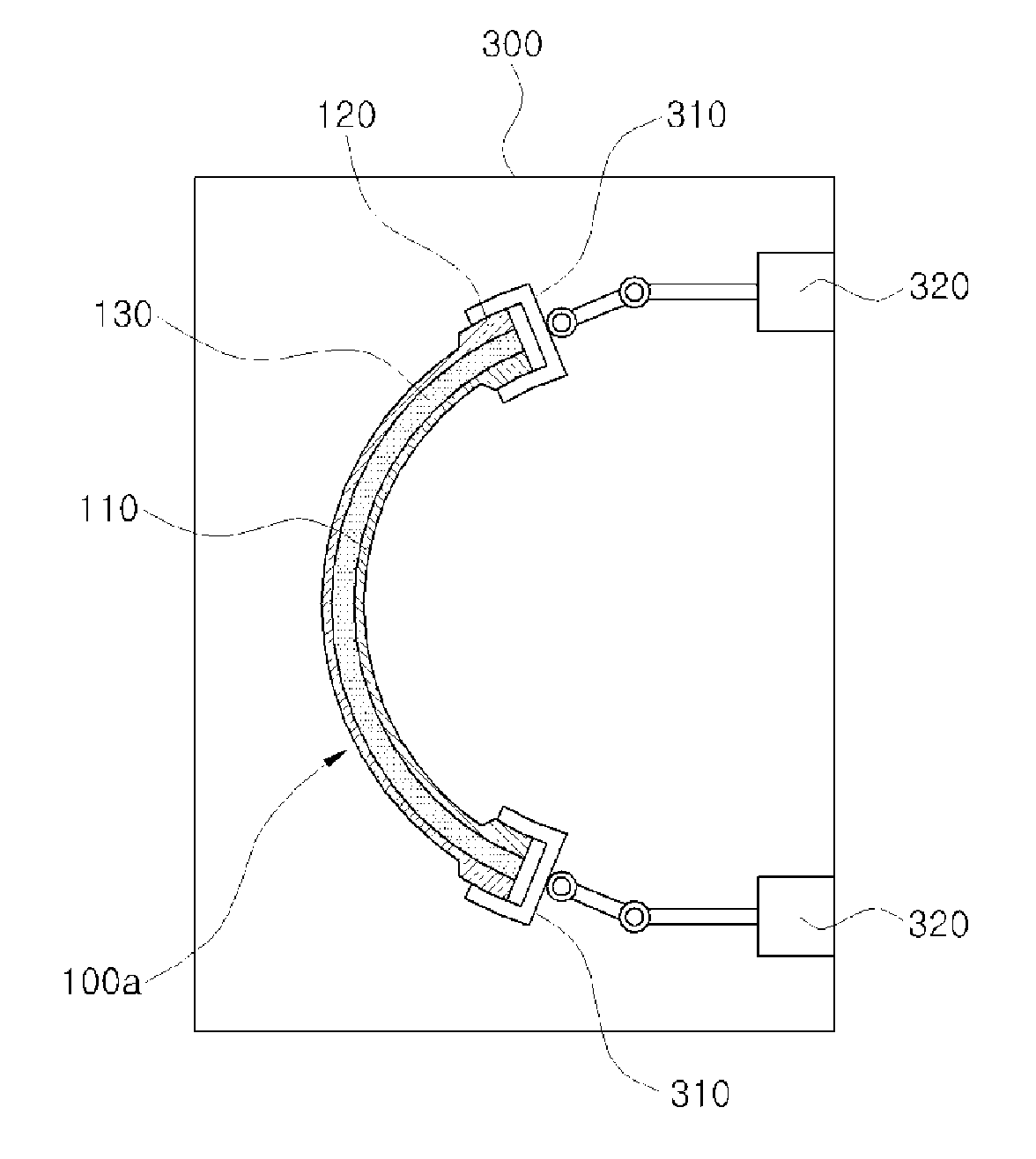

Etching device, curved display panel manufacturing apparatus comprising same, method for manufacturing curved display panel using same, and curved display panel manufactured by same

InactiveUS20140354938A1Defects of the curved display panel due to this can be minimizedDefect minimizationLamination ancillary operationsSemiconductor/solid-state device manufacturingSpray nozzleCurve shape

The present invention provides a curved display manufacturing method which can prevent phenomenon that outer surface edges of substrates are broken or pared unevenly while etchant is being injected, a curved display panel manufacturing using the same, and a curved display panel manufactured by the same. For this, a curved display panel manufacturing apparatus includes: an etching portion for partially paring outer portions of a first substrate and a second substrate such that thicknesses thereof are reduced to predetermined thicknesses; and a bending portion for bending the partially pared flat liquid crystal panel to a desired curved shape. The etching portion includes: at least one edge protection cover which is disposed on outer surface edge of the first substrate and the second substrate; and an injection nozzle which injects etchant to outer surfaces of the first substrate and the second substrate and to the edge protection cover.

Owner:TOVIS

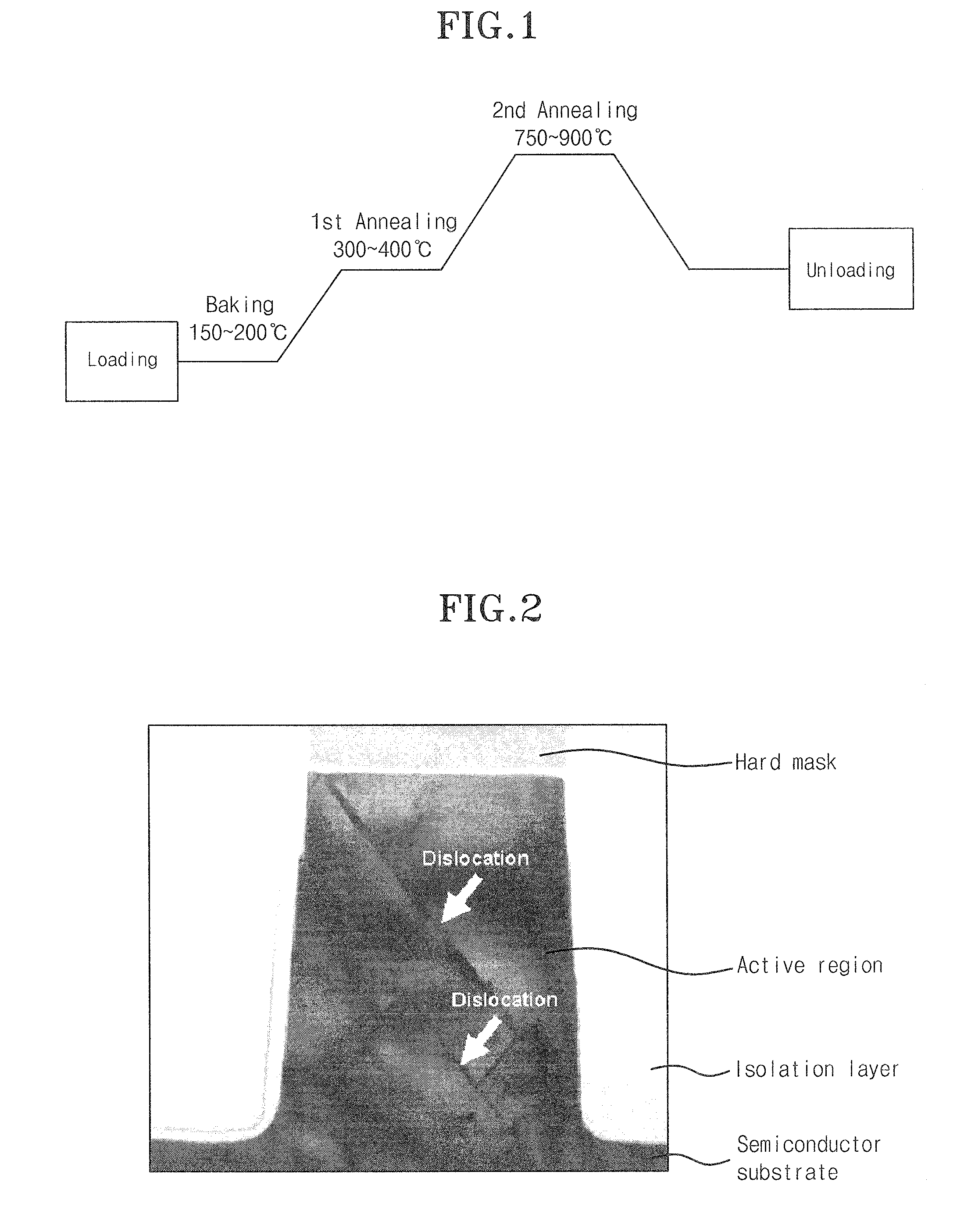

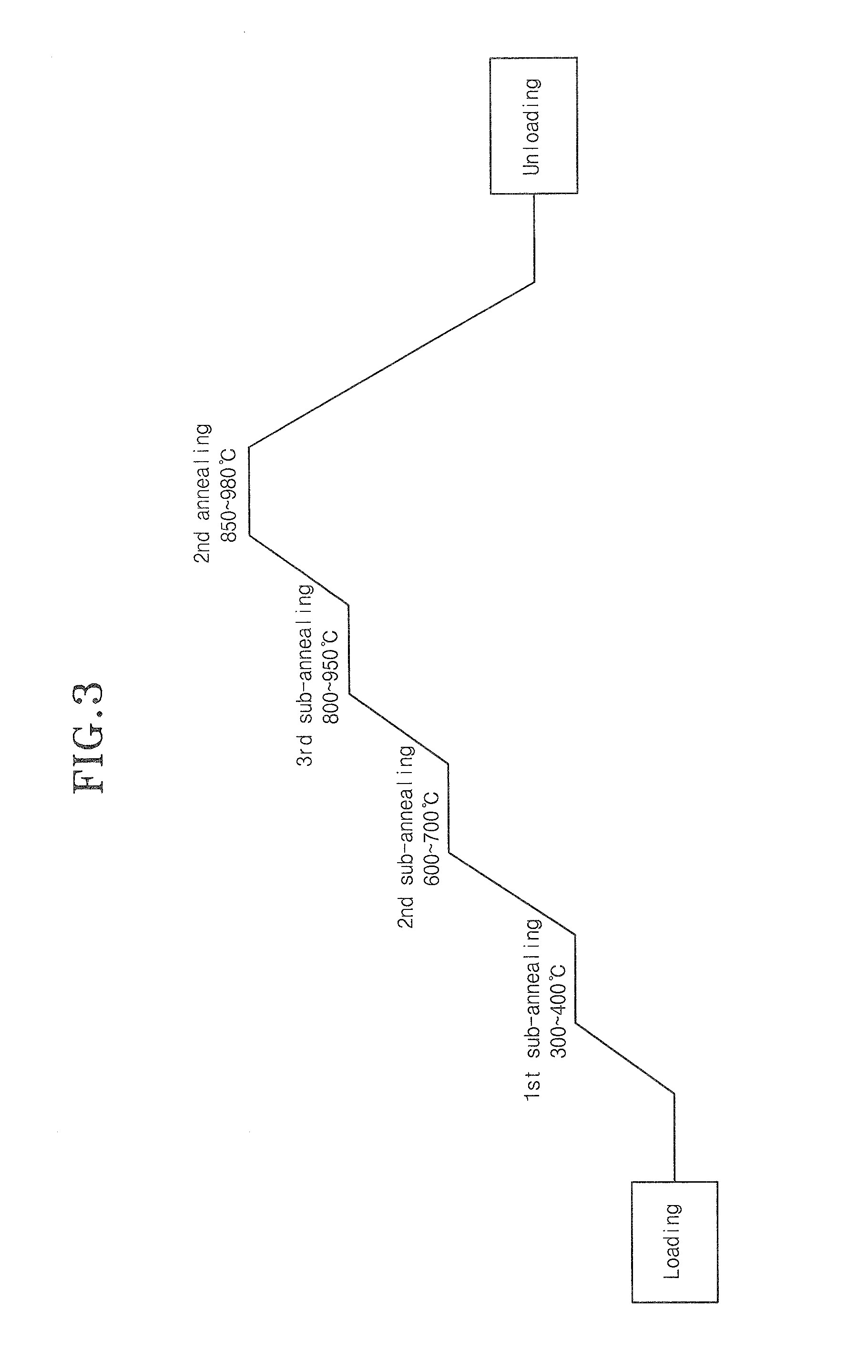

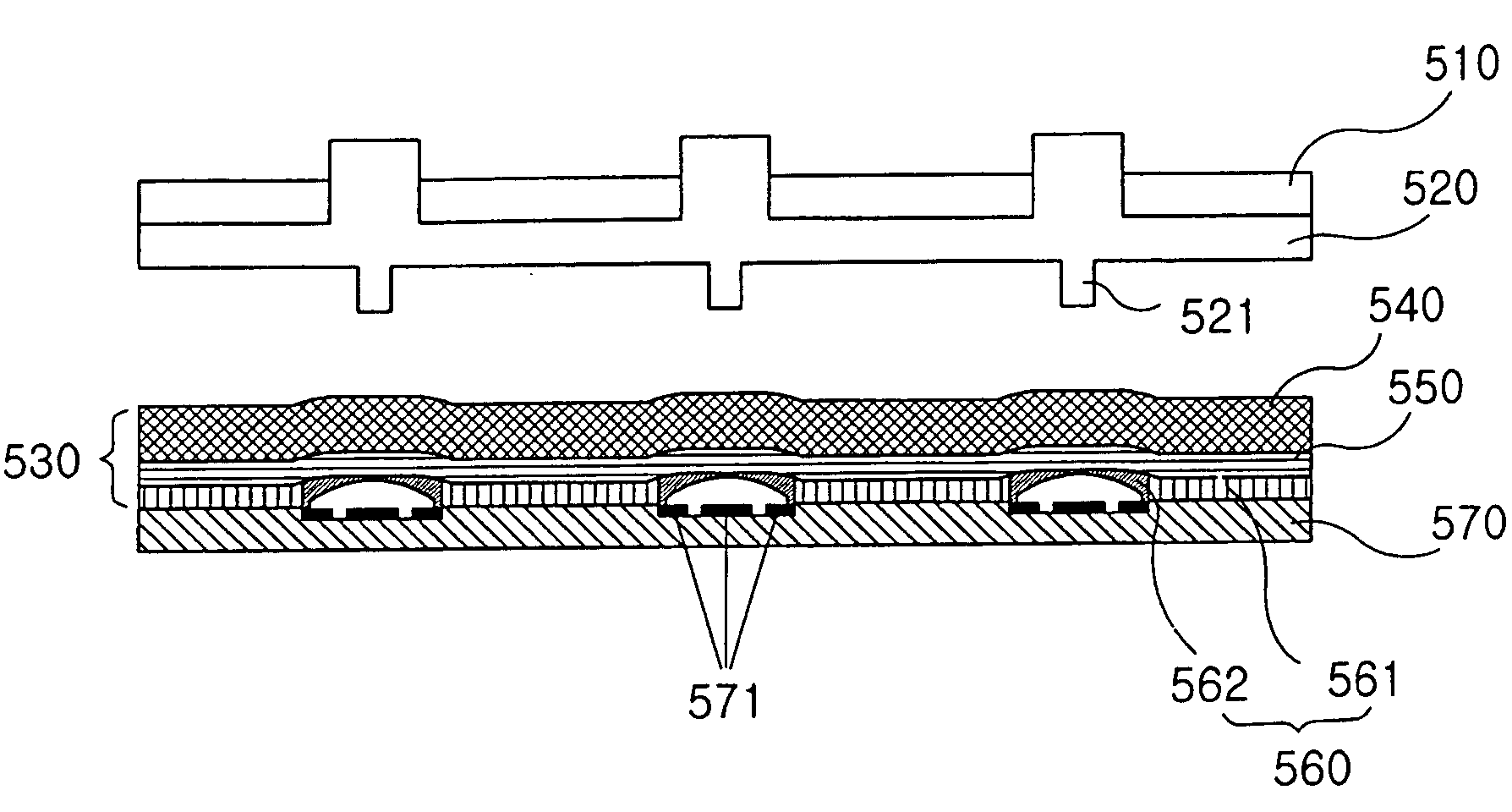

Method for forming device isolation structure of semiconductor device using annealing steps to anneal flowable insulation layer

InactiveUS20090035917A1Prevent orDefect minimizationTransistorSemiconductor/solid-state device detailsInsulation layerSemiconductor

A method for forming a device isolation structure of a semiconductor device using at least three annealing steps to anneal a flowable insulation layer is presented. The method includes the steps of forming a hard mask pattern on a semiconductor substrate having active regions exposing a device isolation region of the semiconductor substrate; etching the device isolation region of the semiconductor substrate exposed through the hard mask pattern, and therein forming a trench; forming a flowable insulation layer to fill a trench; first annealing the flowable insulation layer at least three times; second annealing the first annealed flowable insulation layer; removing the second annealed flowable insulation layer until the hard mask pattern is exposed; and removing the exposed hard mask pattern.

Owner:SK HYNIX INC

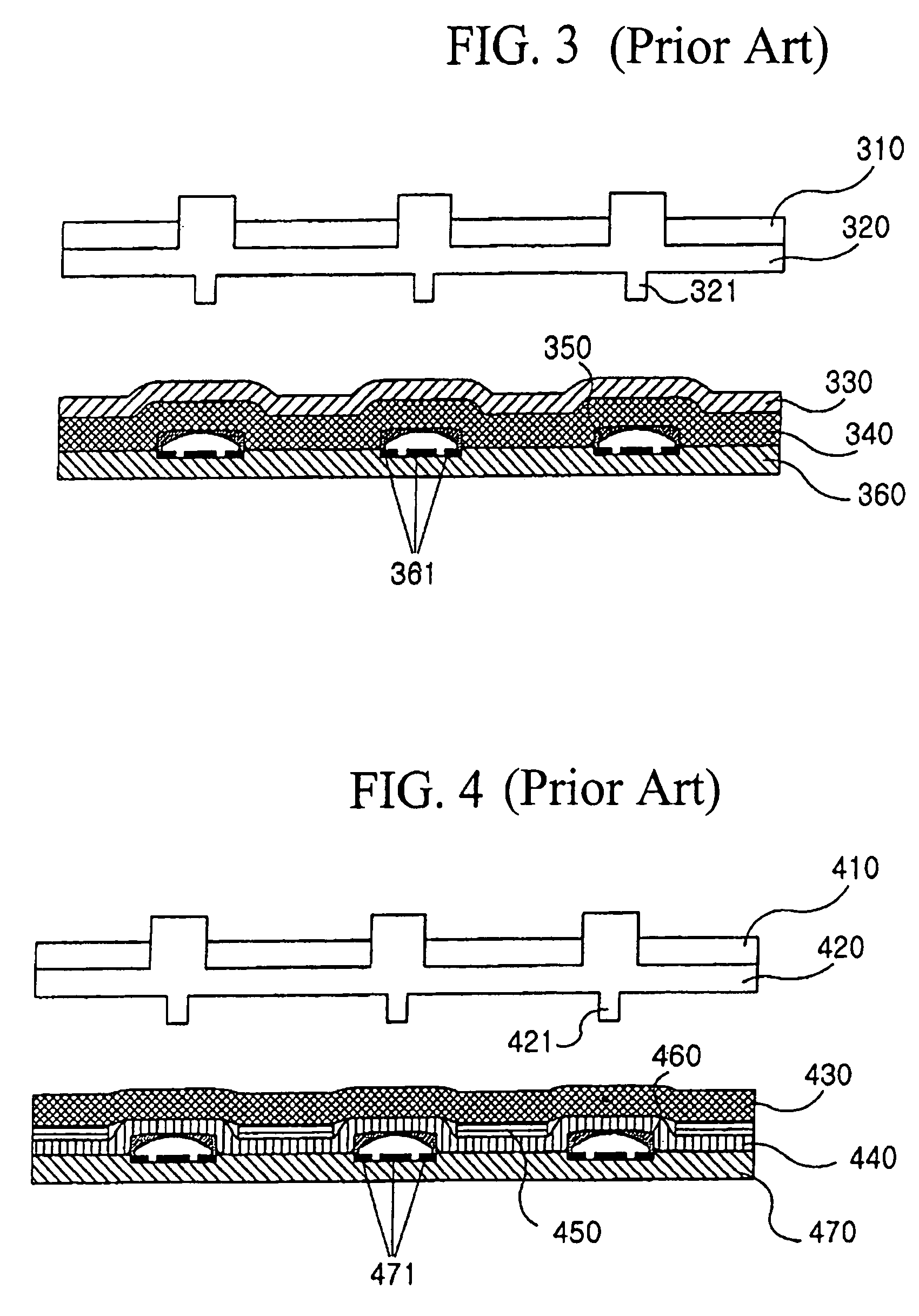

Electroluminescent metal dome keypad

InactiveUS7019242B2Improving click senseReduce operating loadContact surface shape/structureLegendsEngineeringPrinted circuit board

The present invention relates to an EL metal dome keypad which comprises a plurality of domes which are disposed at positions corresponding to fixed contact terminals of a printed circuit board and are brought into contact with or separated from the fixed contact terminals by means of elastic deformation; a base tape which is laminated on the printed circuit board, has a plurality of holes formed at positions corresponding to the domes, and is used to mount the domes to the printed circuit board by inserting and holding the domes into the formed holes; double-sided adhesive tape which is laminated in the base tape and the domes inserted into and held to the holes formed in the base tape, and used to attach and hold the base tape and the dome thereon; and an EL sheet which is attached and laminated on the double-sided adhesive tape.

Owner:KBF

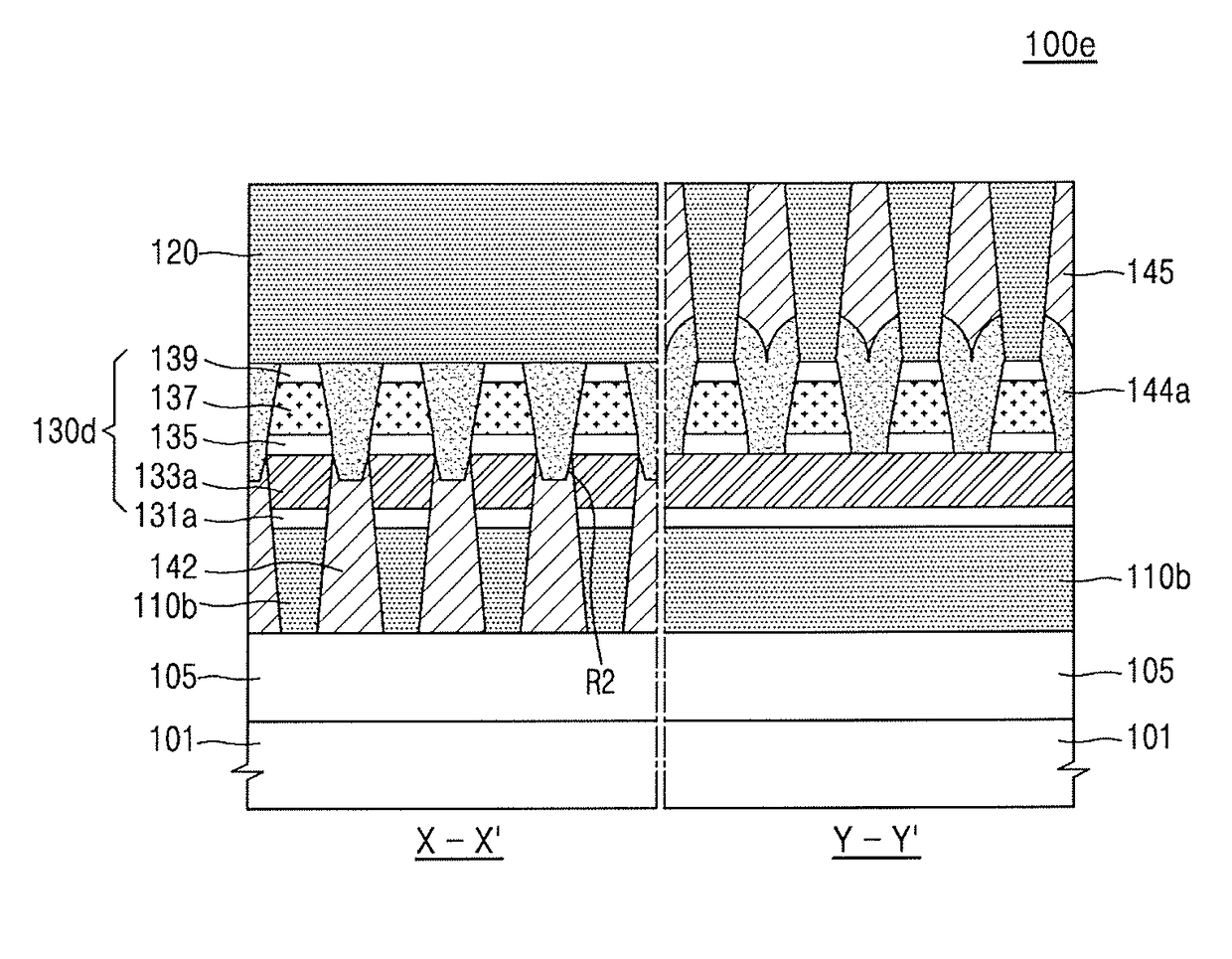

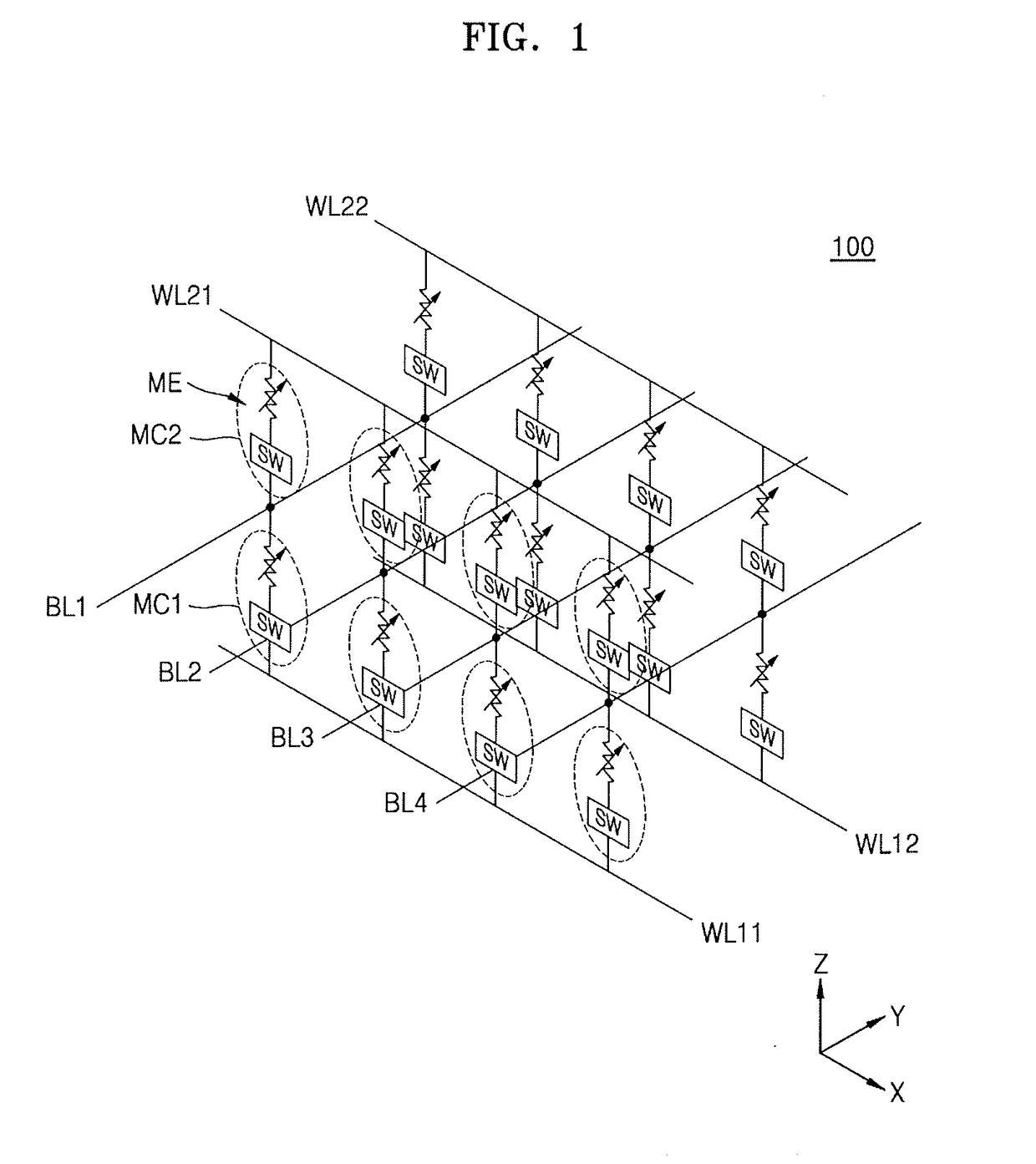

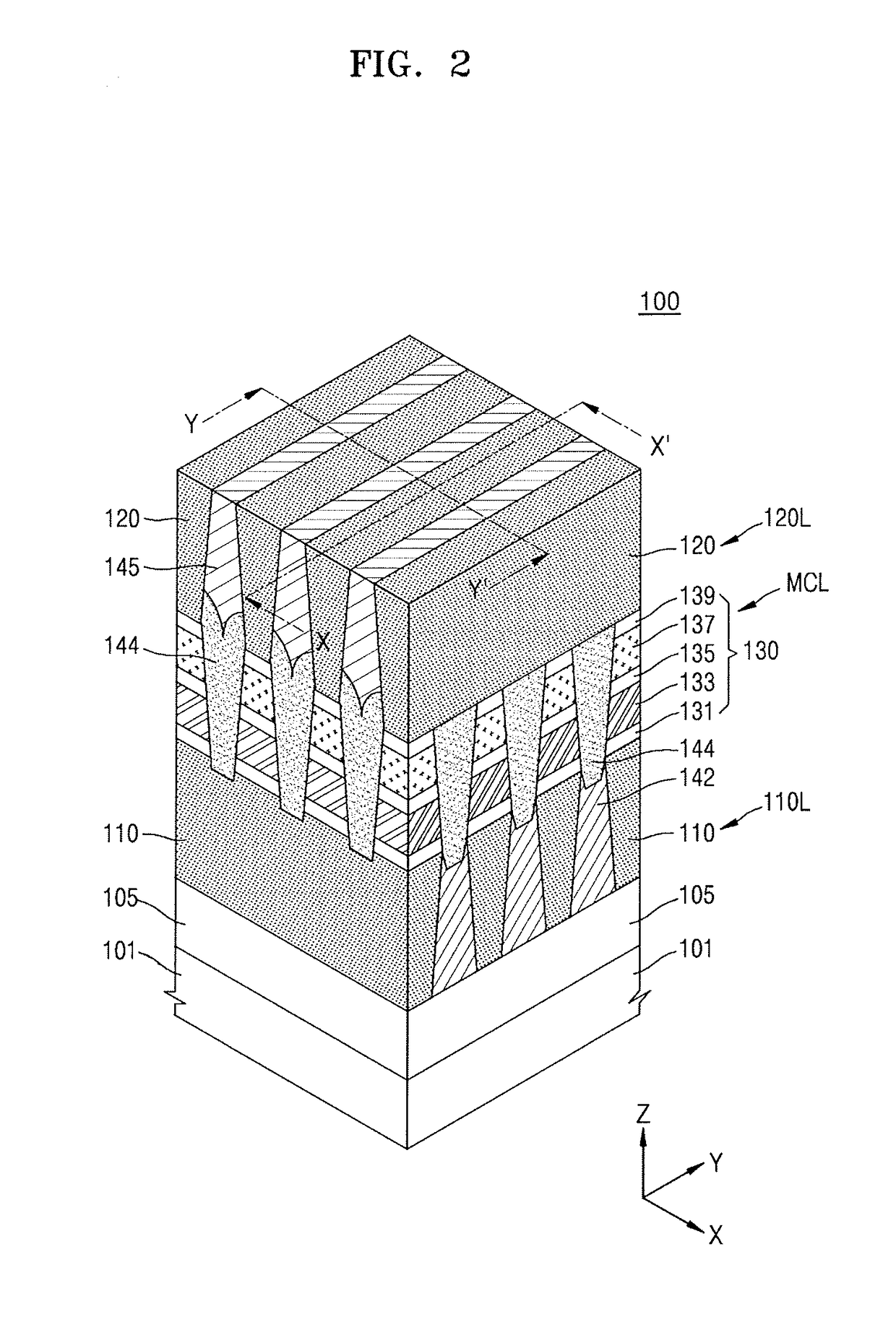

Memory device and method of manufacturing the same

ActiveUS20170244031A1Improve reliabilityDefect minimizationSolid-state devicesSemiconductor devicesInsulation layerEngineering

Provided are a memory device and a method of manufacturing the same. Memory cells of the memory device are formed separately from first electrode lines and second electrode lines, wherein the second electrode lines over the memory cells are formed by a damascene process, thereby avoiding complications associated with CMP being excessively or insufficiently performed on an insulation layer over the memory cells.

Owner:SAMSUNG ELECTRONICS CO LTD

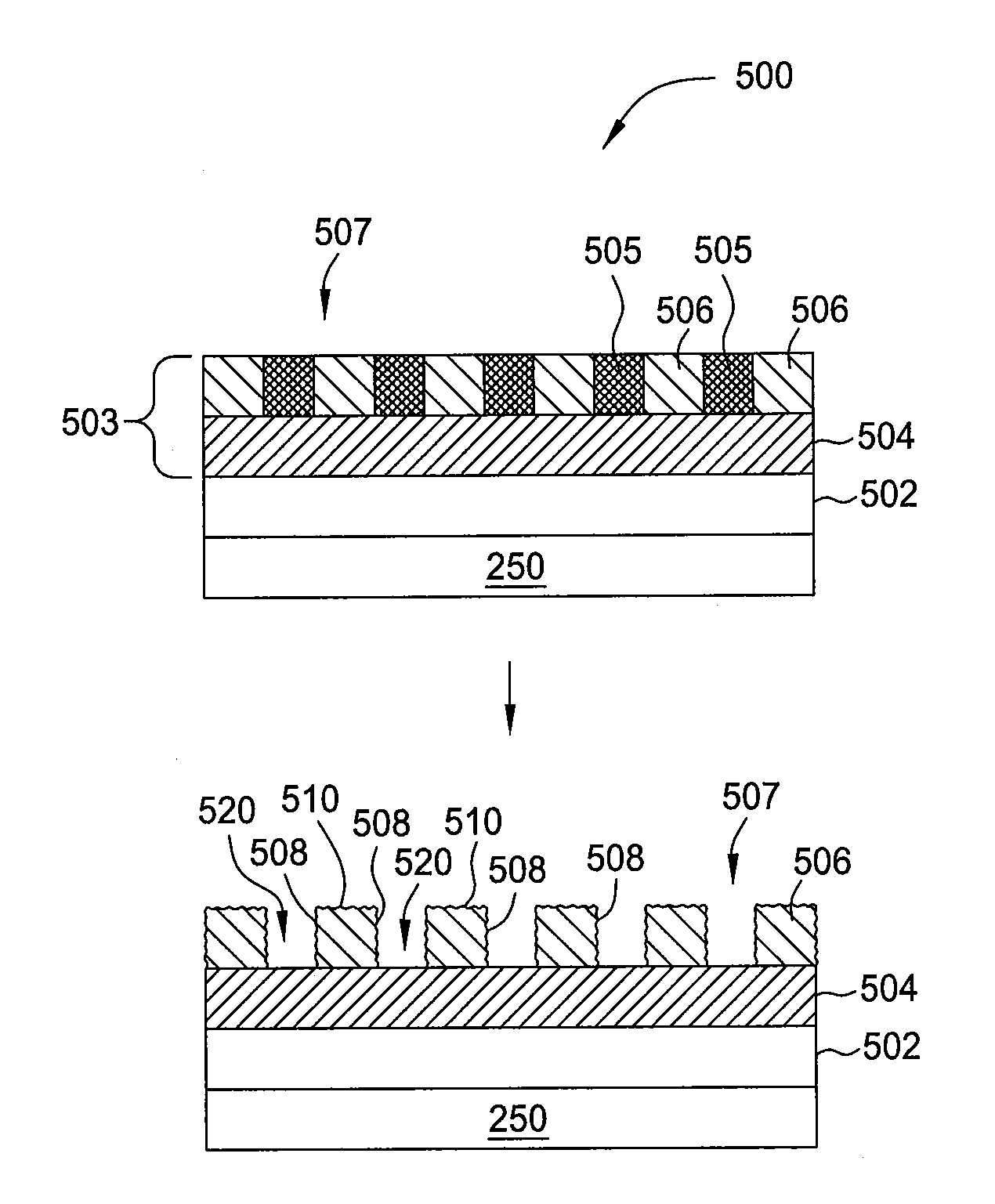

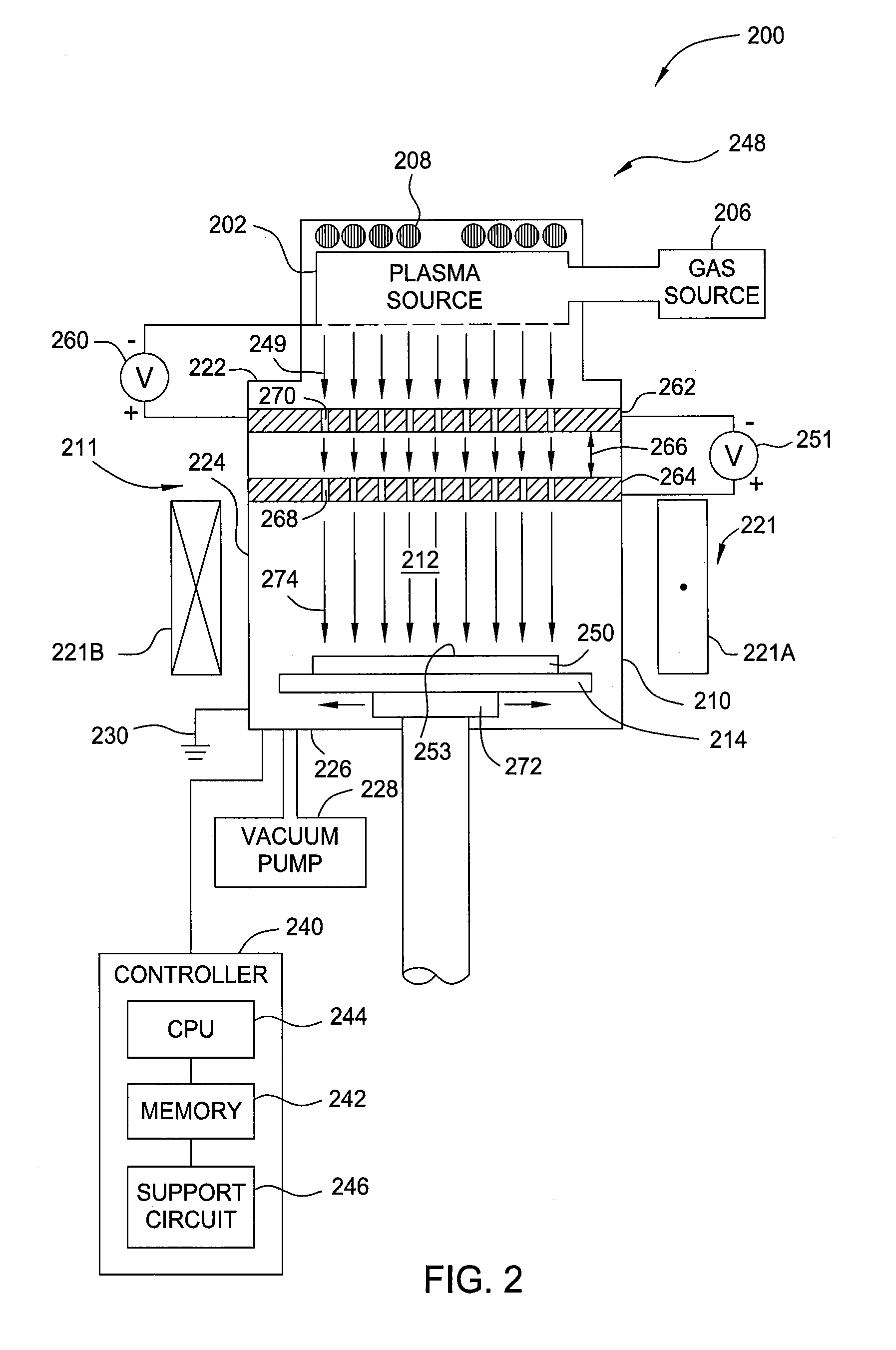

Methods and apparatus for performing multiple photoresist layer development and etching processes

ActiveUS20120322011A1Minimize process defectDefect minimizationPhotosensitive materialsPhotoprinting processesLine widthPhotoresist

The present invention provides methods and an apparatus controlling and minimizing process defects in a development process, and modifying line width roughness (LWR) of a photoresist layer after the development process, and maintaining good profile control during subsequent etching processes. In one embodiment, a method for forming features on a substrate includes developing and removing exposed areas in the photosensitive layer disposed on the substrate in the electron processing chamber by predominantly using electrons, removing contaminants from the substrate by predominantly using electrons, and etching the non-photosensitive polymer layer exposed by the developed photosensitive layer in the electron processing chamber by predominantly using electrons.

Owner:APPLIED MATERIALS INC

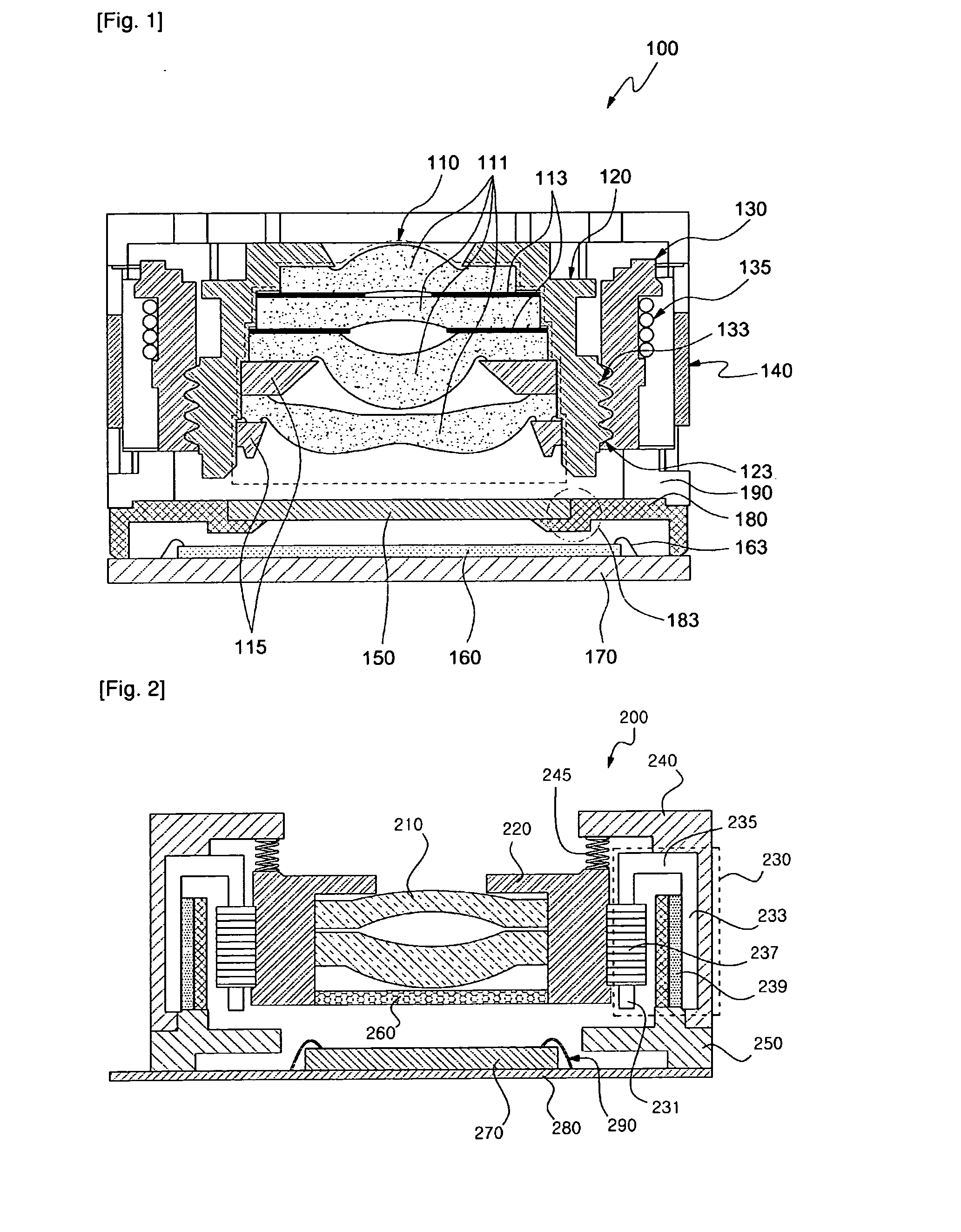

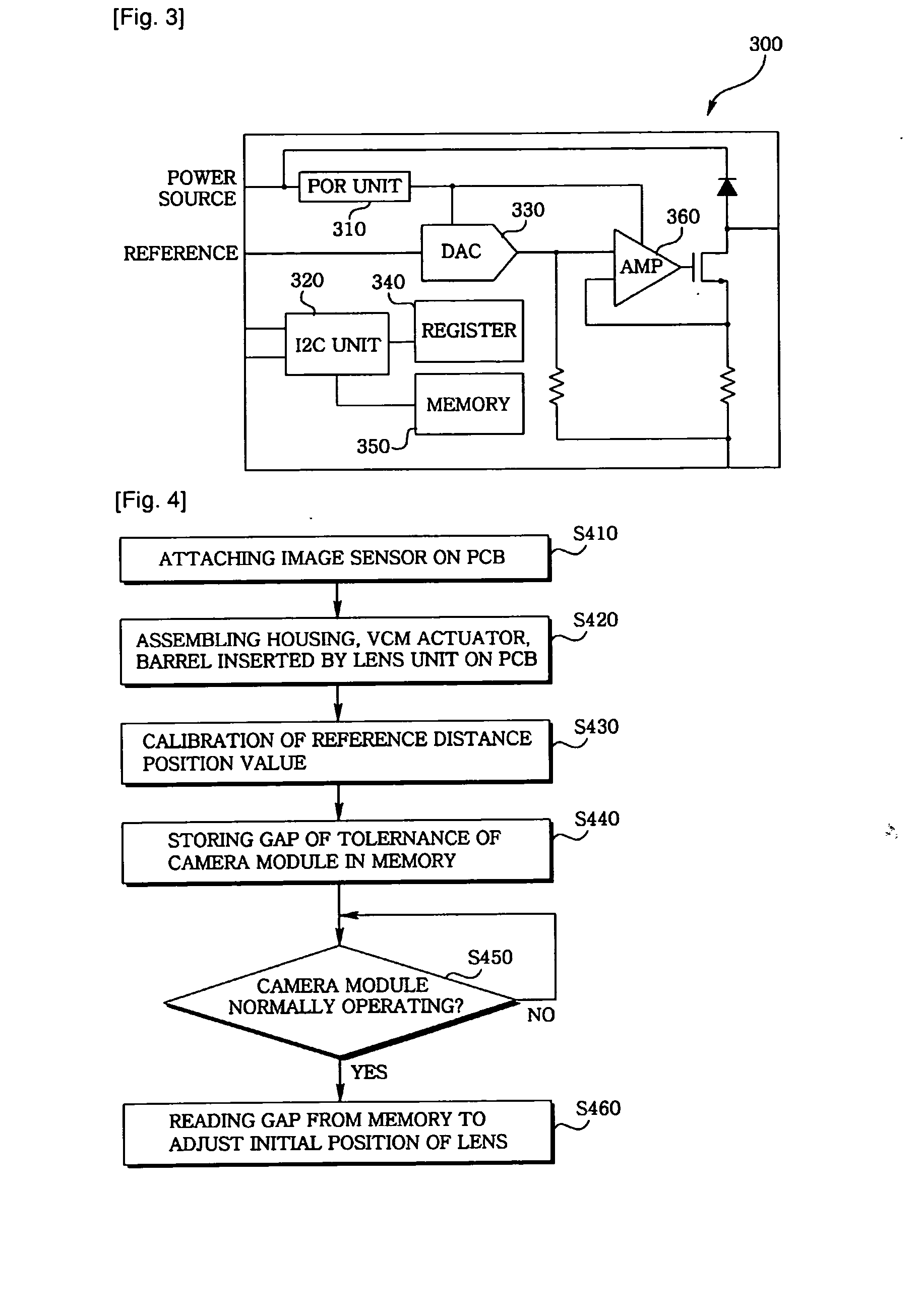

Camera module

ActiveUS20130070148A1Defect minimizationReduce assembly processTelevision system detailsColor television detailsCamera lensPhysics

The present invention relates to a camera module having an auto focus function, the module including a lens unit having at least one lens, a barrel into which the lens unit is inserted, and connected by a VCM (Voice Coil Motor) actuator, and an image sensor discretely positioned from the lens unit to convert light having passed the lens unit to an electrical signal, where the VCM actuator includes a gap of a reference distance position value which is a position of an object catering to a lens focal length according to the camera module, and information on a focus-met lens position value, and adjusts an initial position of the lens by using the gap of reference distance position value of the lens position value during operation of the camera module.

Owner:LG INNOTEK CO LTD

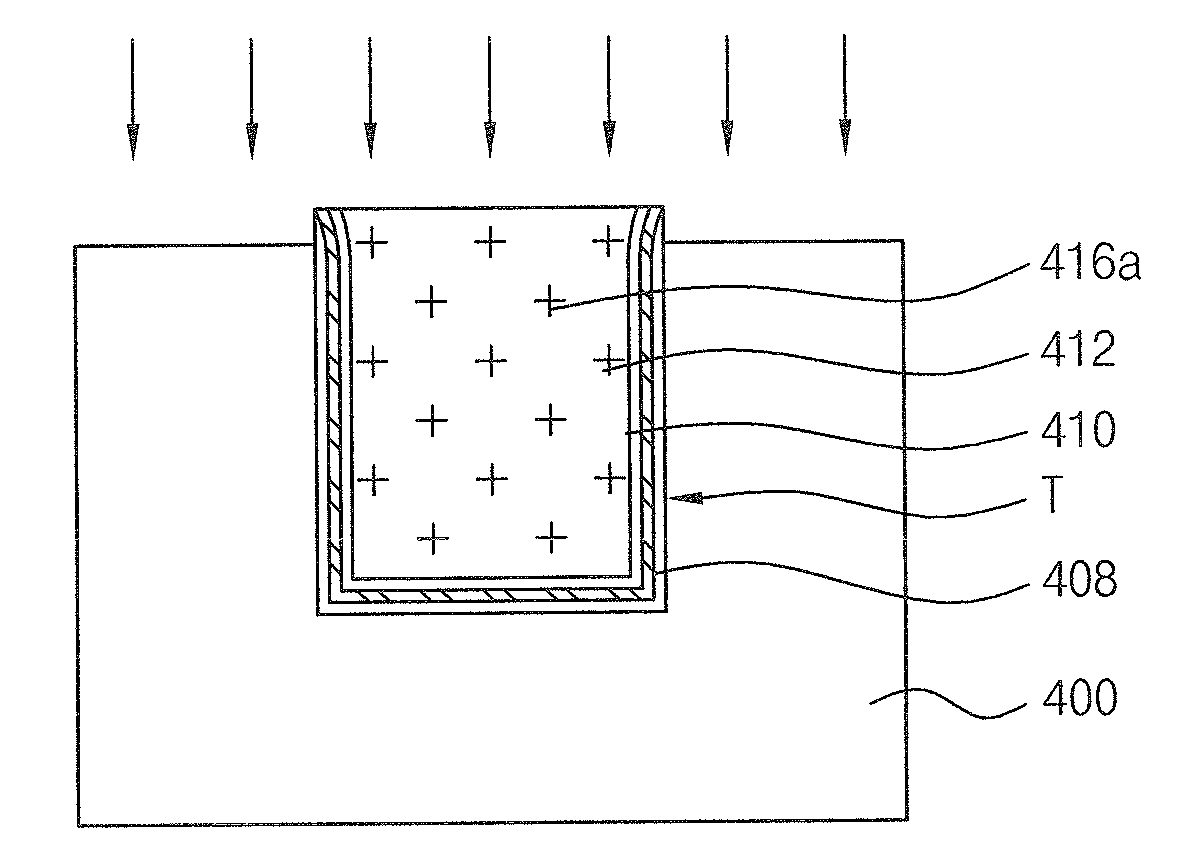

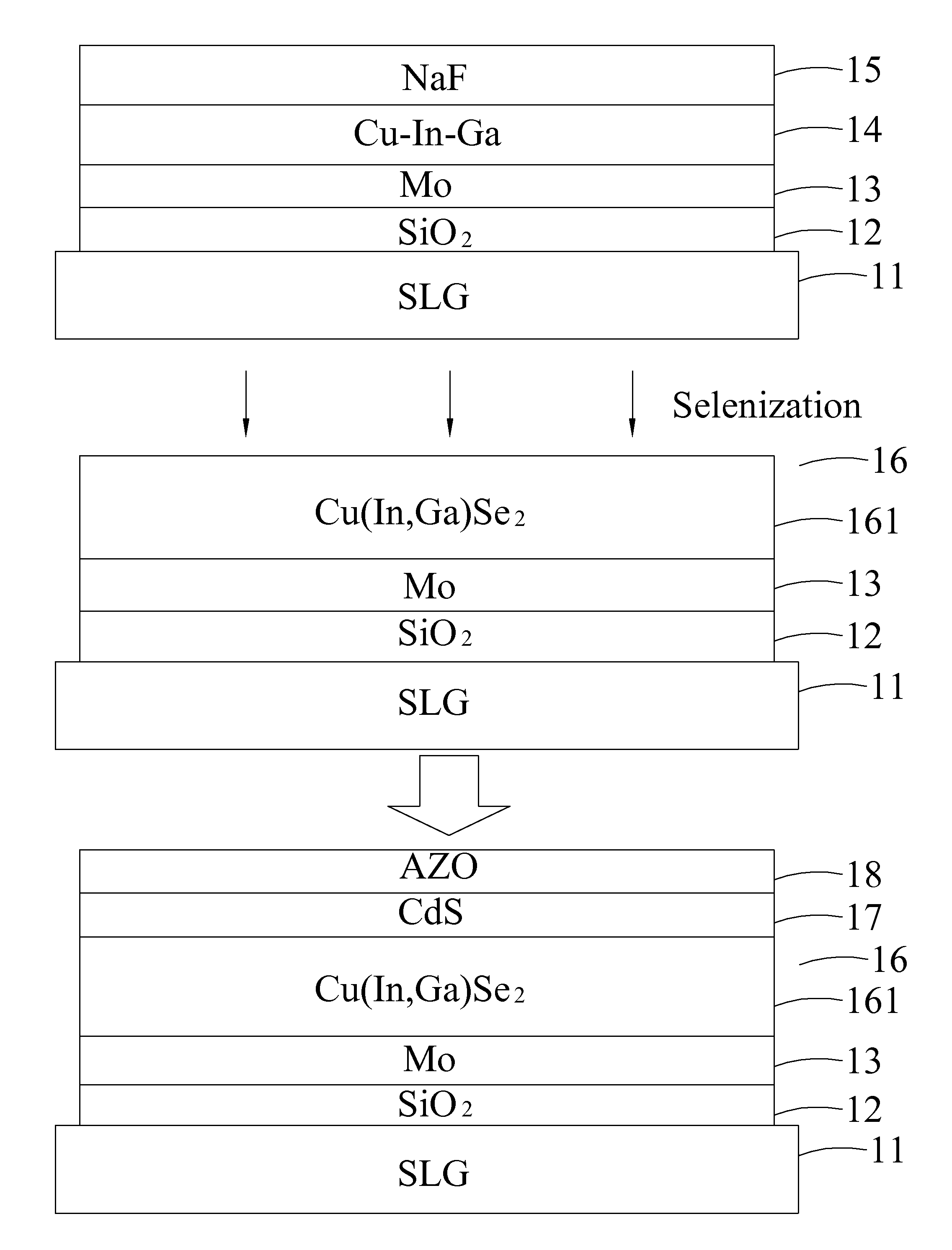

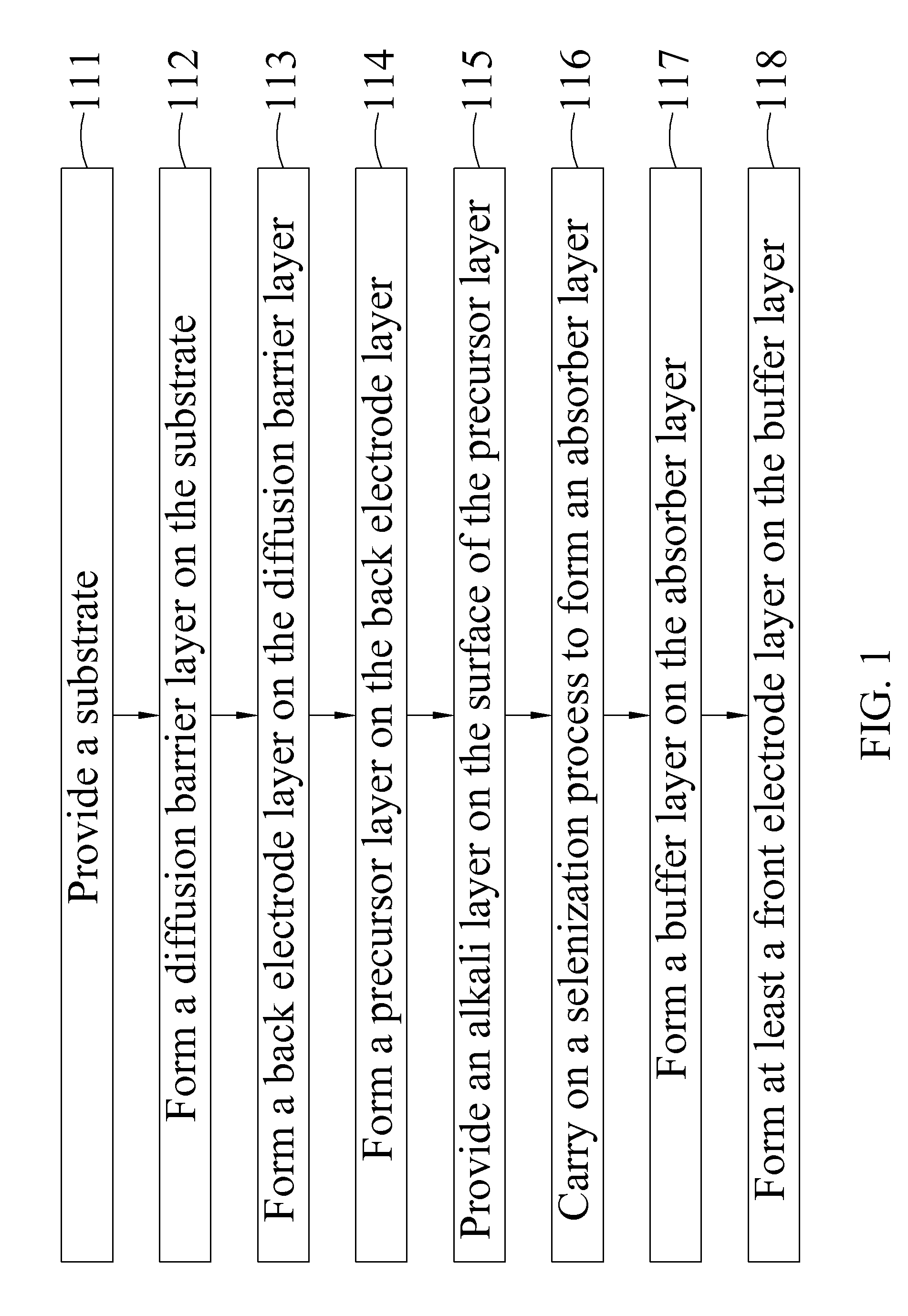

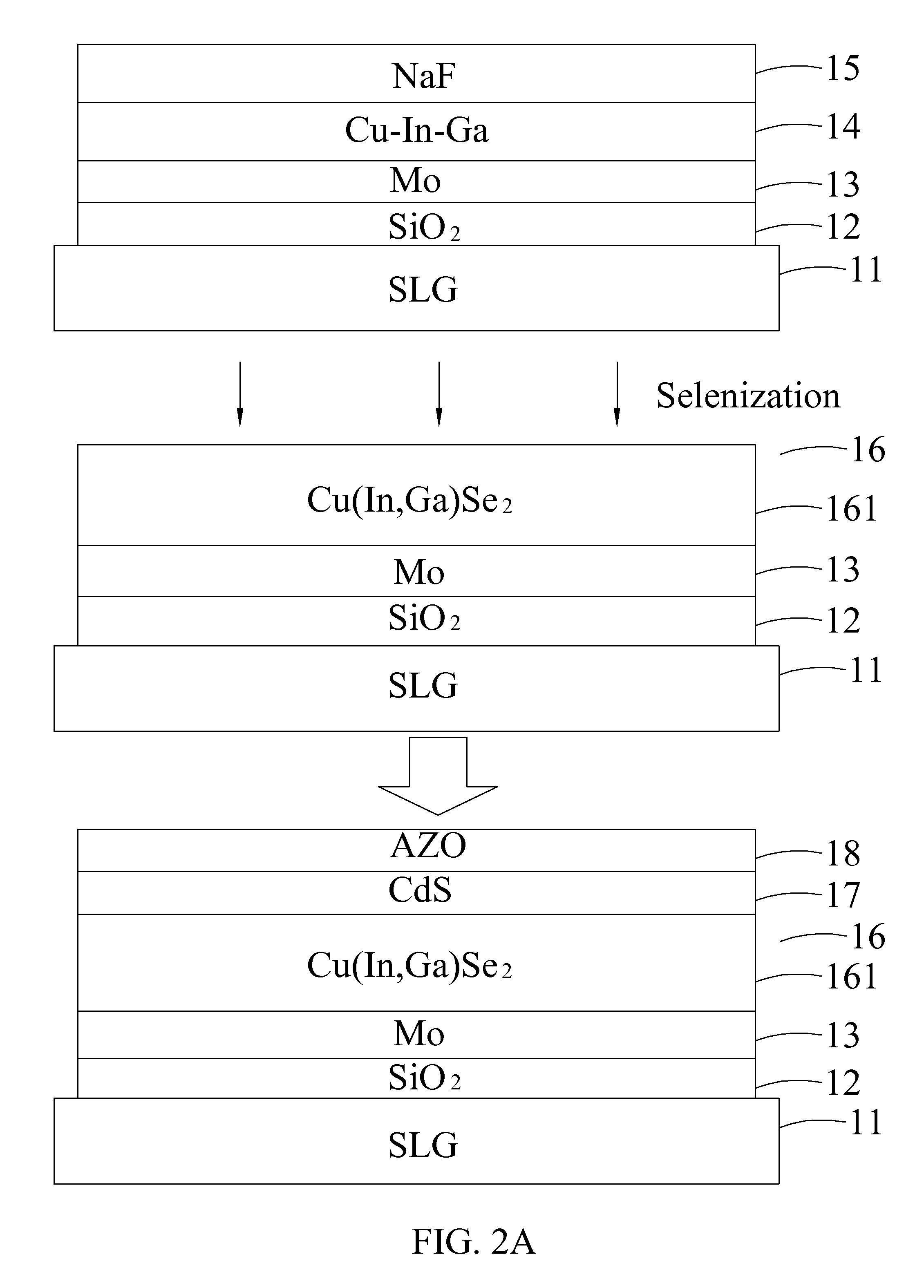

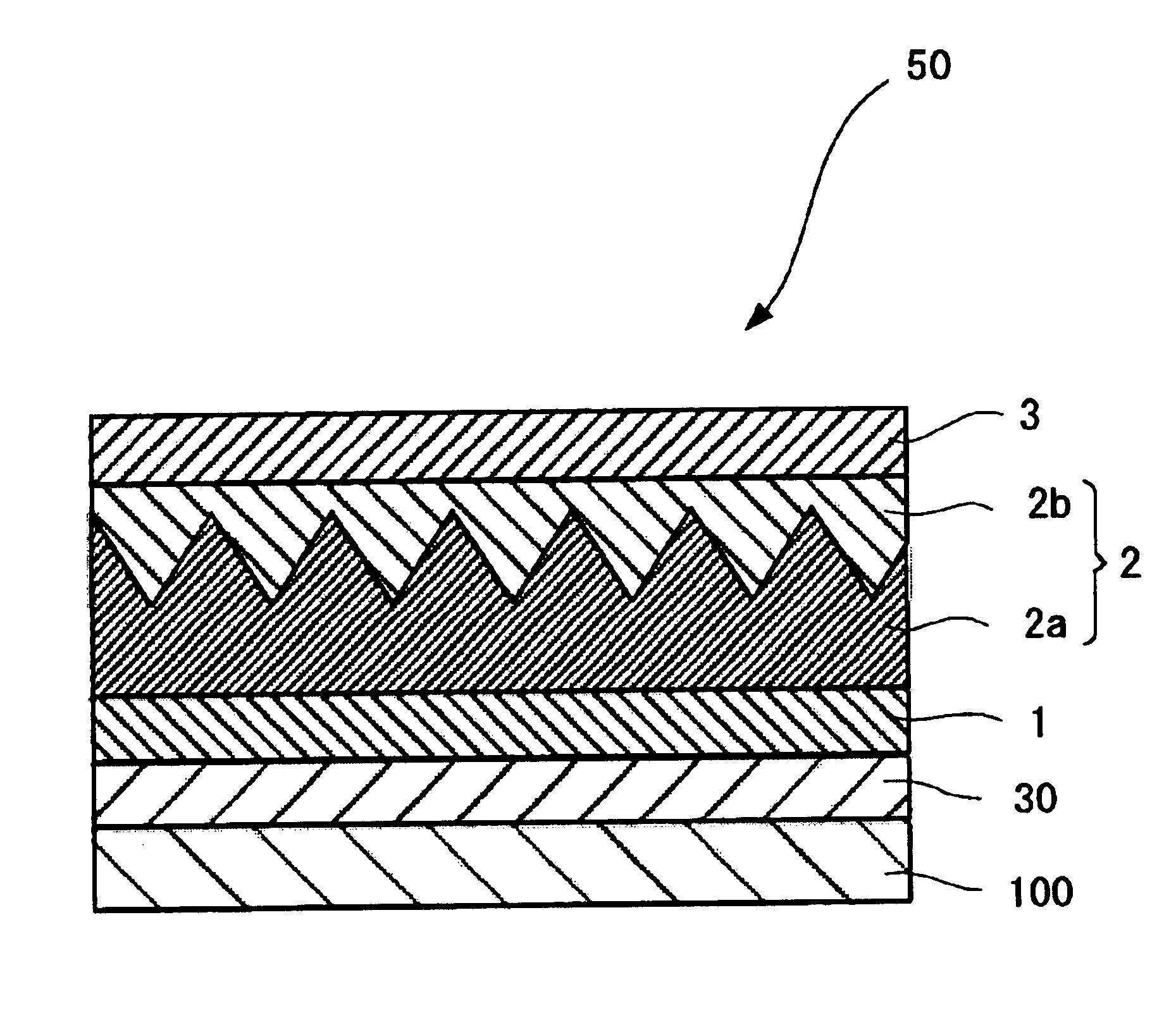

Thin-film solar cell and manufacturing method thereof

InactiveUS20120132281A1Effectively control contentReduce grain boundaryFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion barrierMetal

A thin-film solar cell and a manufacturing method thereof are disclosed. The method of manufacturing the thin-film solar cell includes the steps of providing a substrate; forming a diffusion barrier layer on the substrate; forming a back electrode layer on the diffusion barrier layer; forming a precursor layer on the back electrode layer, and the precursor layer including at least Cu, In and Ga; providing an alkali layer on an upper surface of the precursor layer, and the alkali layer being formed of Li, Na, K, Rb, Cs, or an alkali metal compound; providing a selenization process for the precursor layer and the alkali layer to form an absorber layer, such that an atomic percentage concentration of the alkali metal in the absorber layer is ranged between 0.01%˜10%; forming at least a buffer layer on the absorber layer; and forming at least a front electrode layer on the buffer layer.

Owner:NEXPOWER TECH

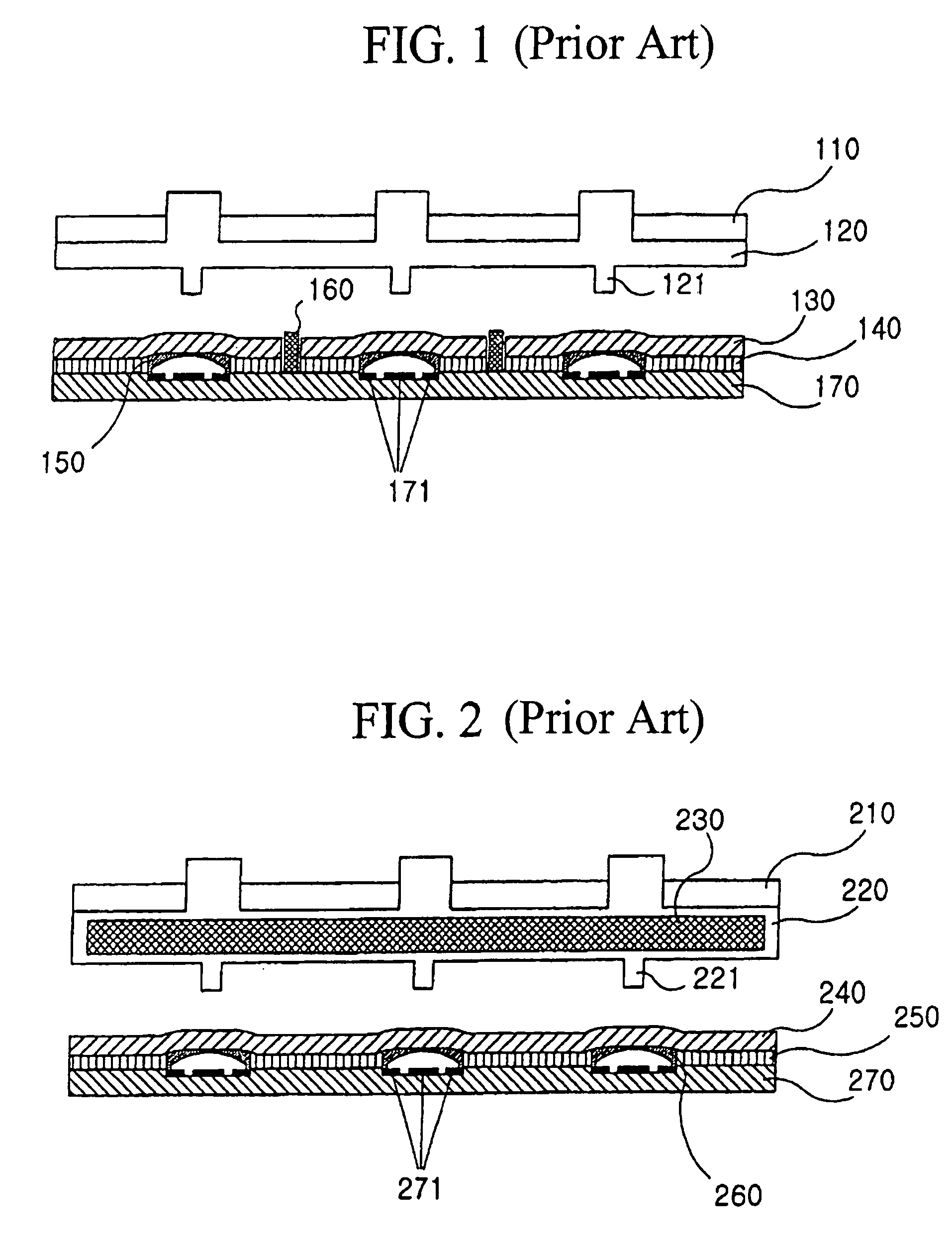

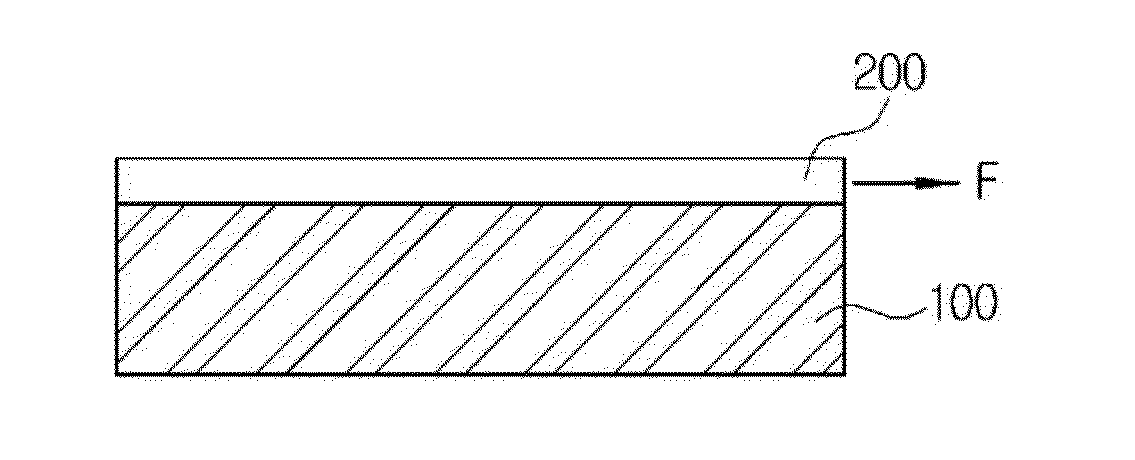

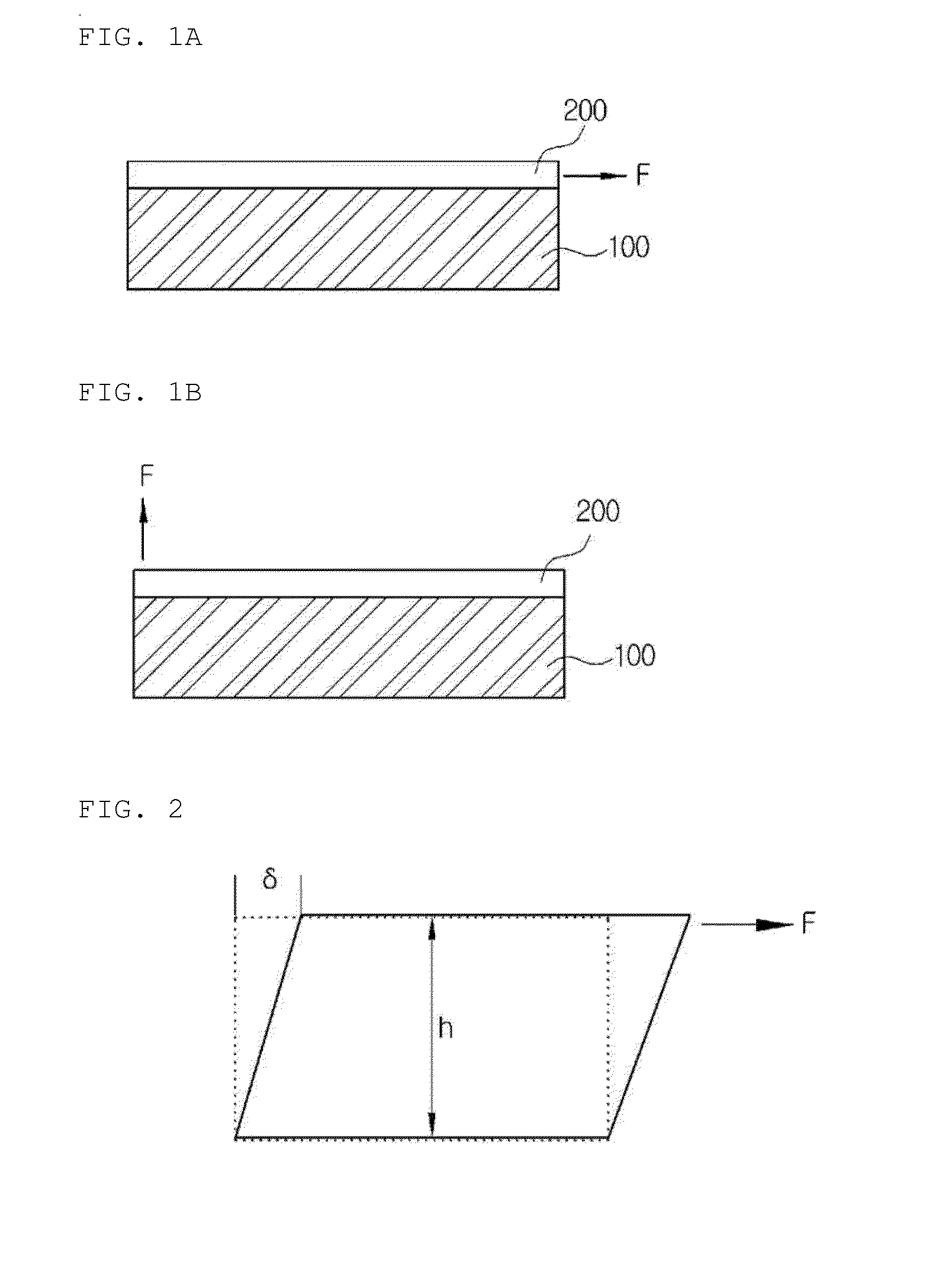

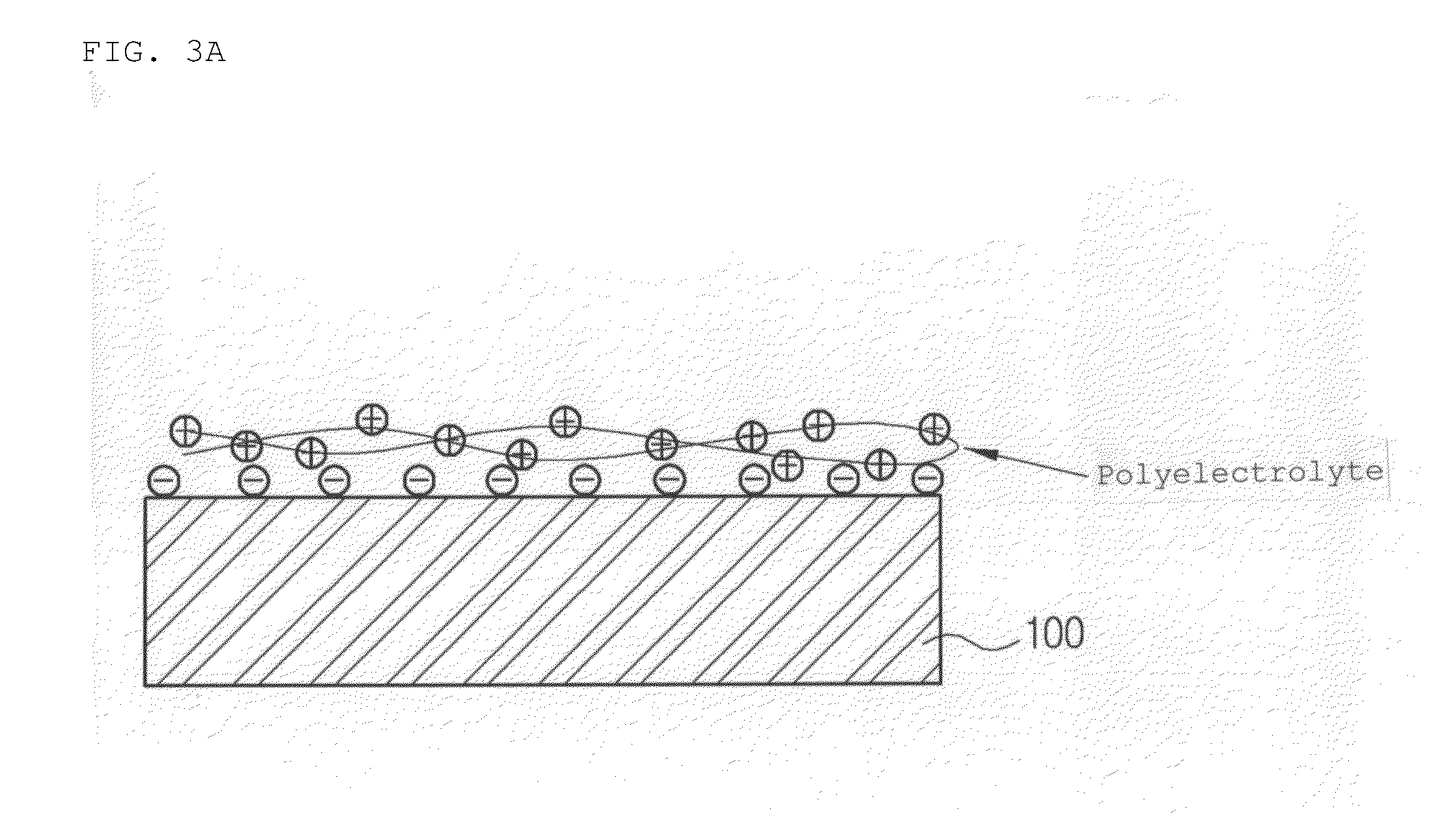

Supporting substrate for manufacturing flexible informaiton display device using temporary bonding/debonding layer, manufacturing method thereof, and flexible information display device

InactiveUS20150060869A1High resolutionAvoid low process precisionLiquid surface applicatorsElectric shock equipmentsDisplay deviceEngineering

Disclosed are a supporting substrate for manufacturing a flexible information display device using a temporary bonding / debonding layer, a manufacturing method thereof, and a flexible information display device. A supporting substrate for manufacturing a flexible information display device, the supporting substrate comprising: a temporary bonding / debonding layer having a thickness in a range of 0.1 nm to 1000 nm and comprising an adhesive material bonded to the supporting substrate through Van der Waals bonding force. Provided is a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

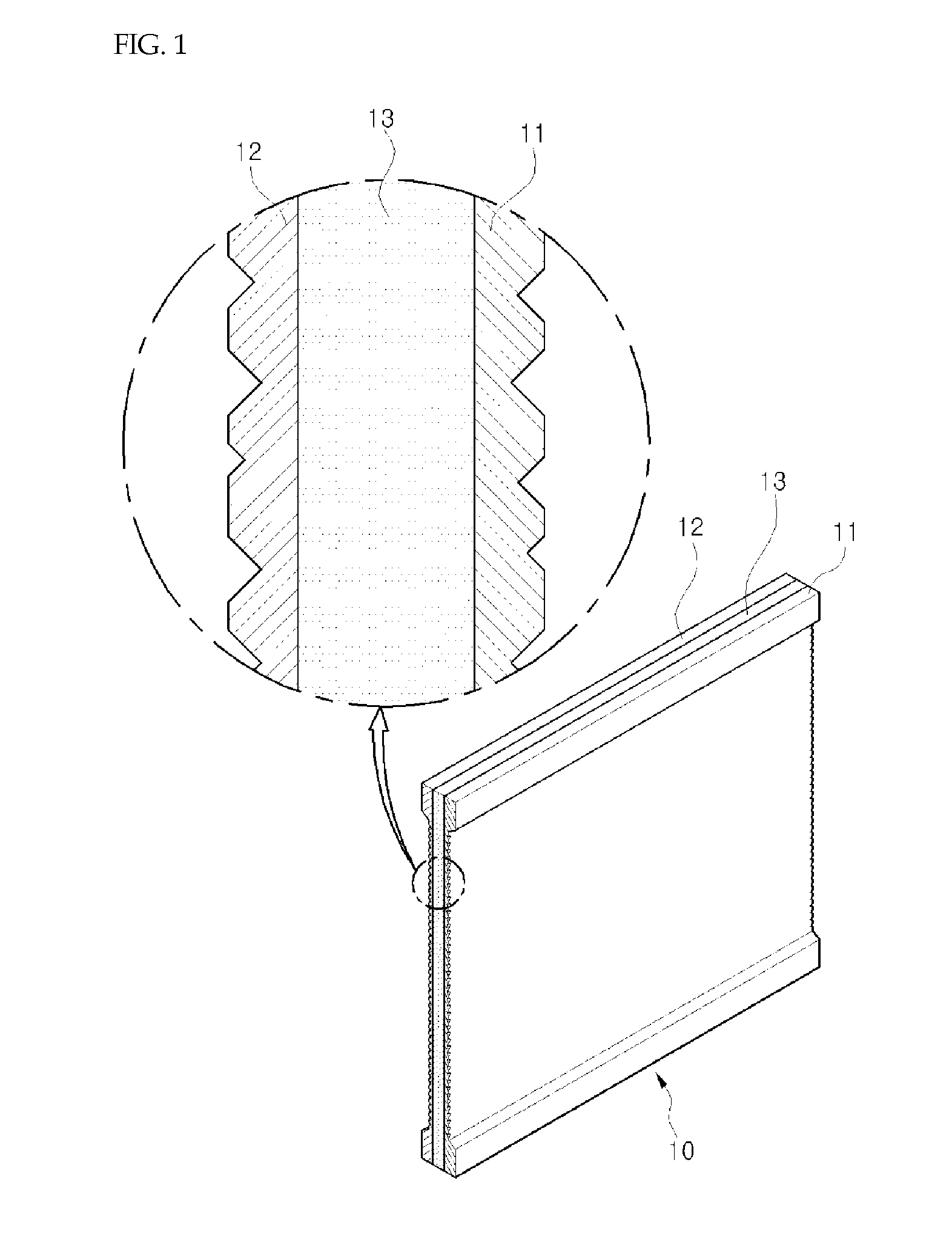

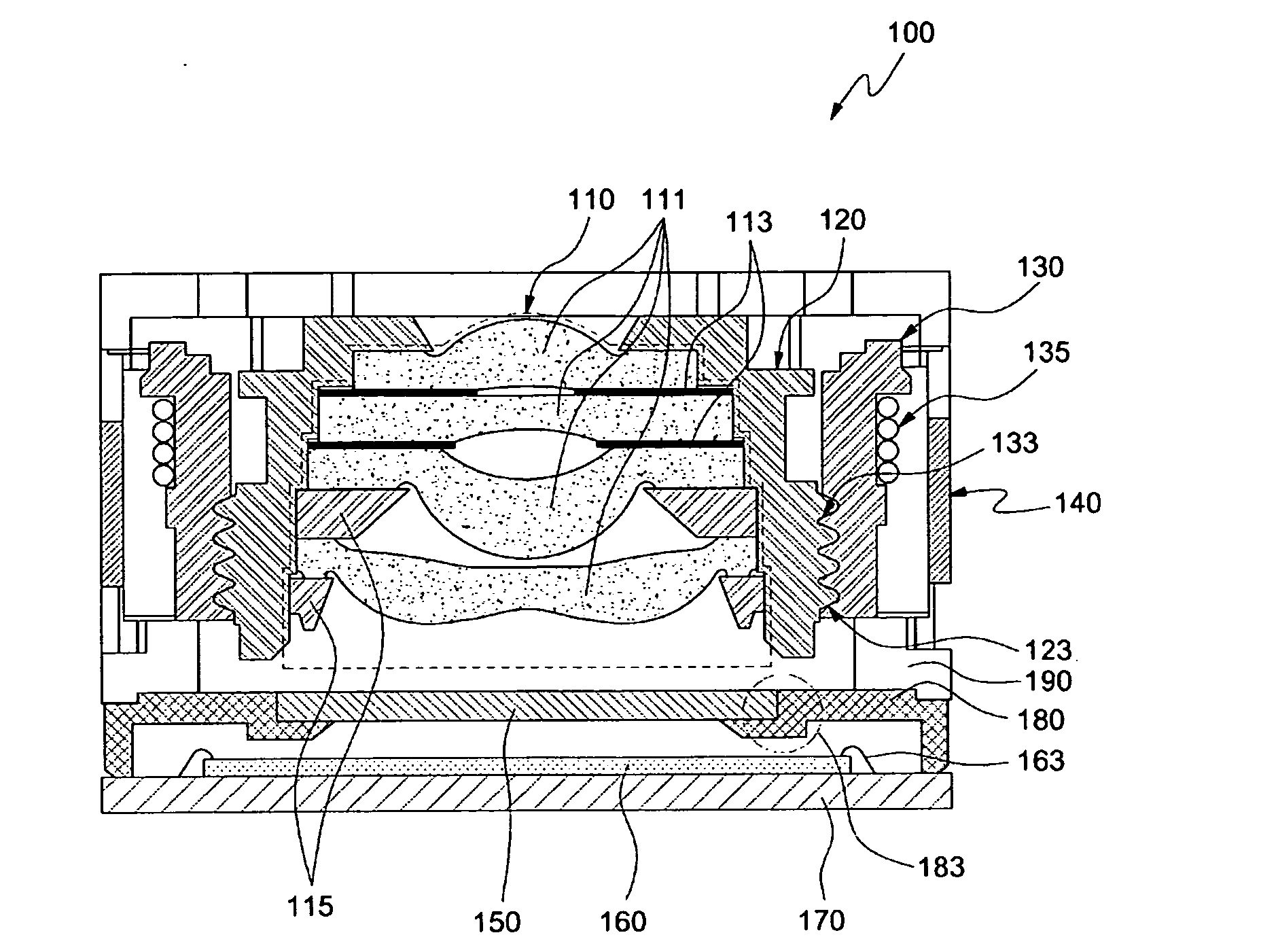

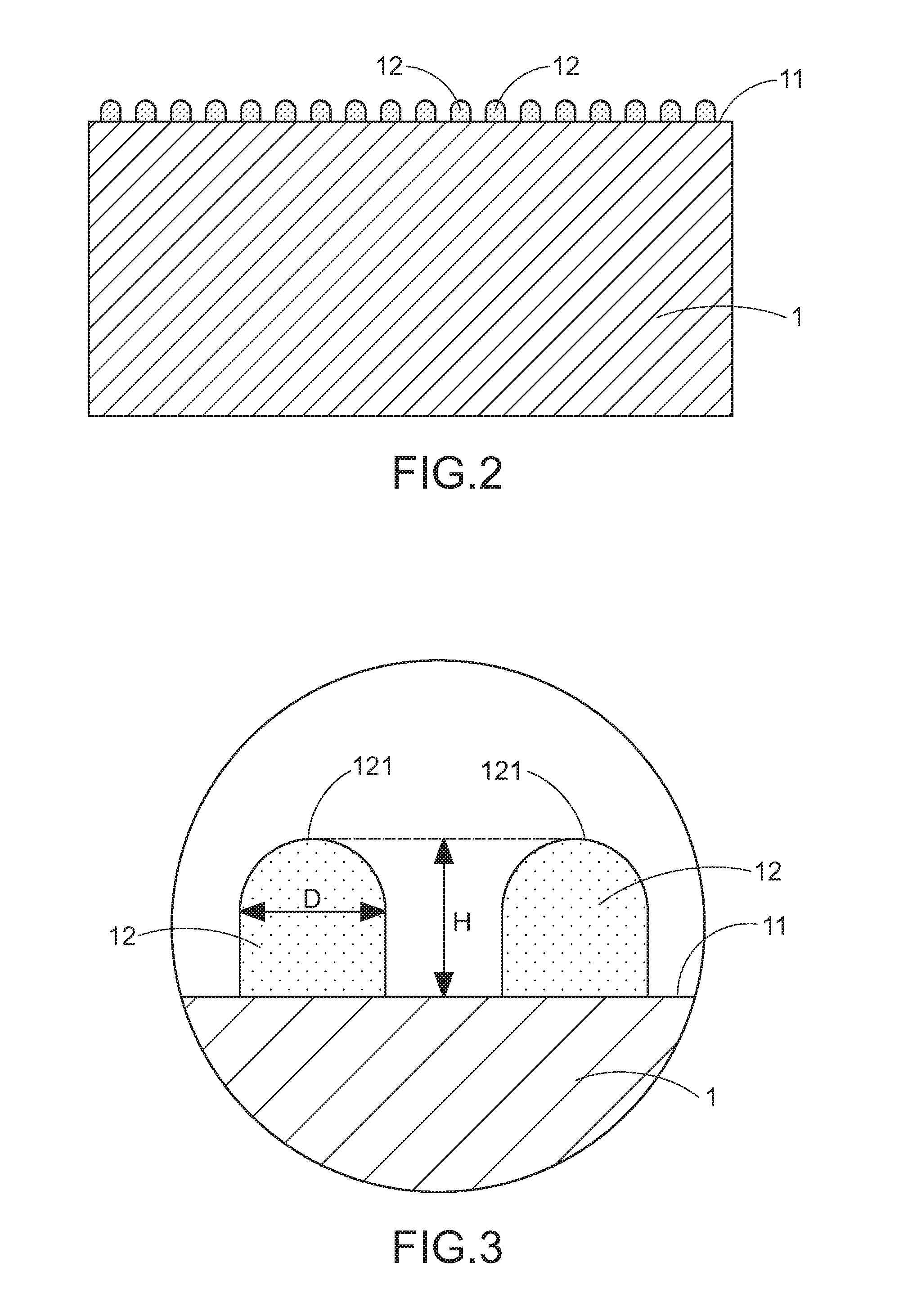

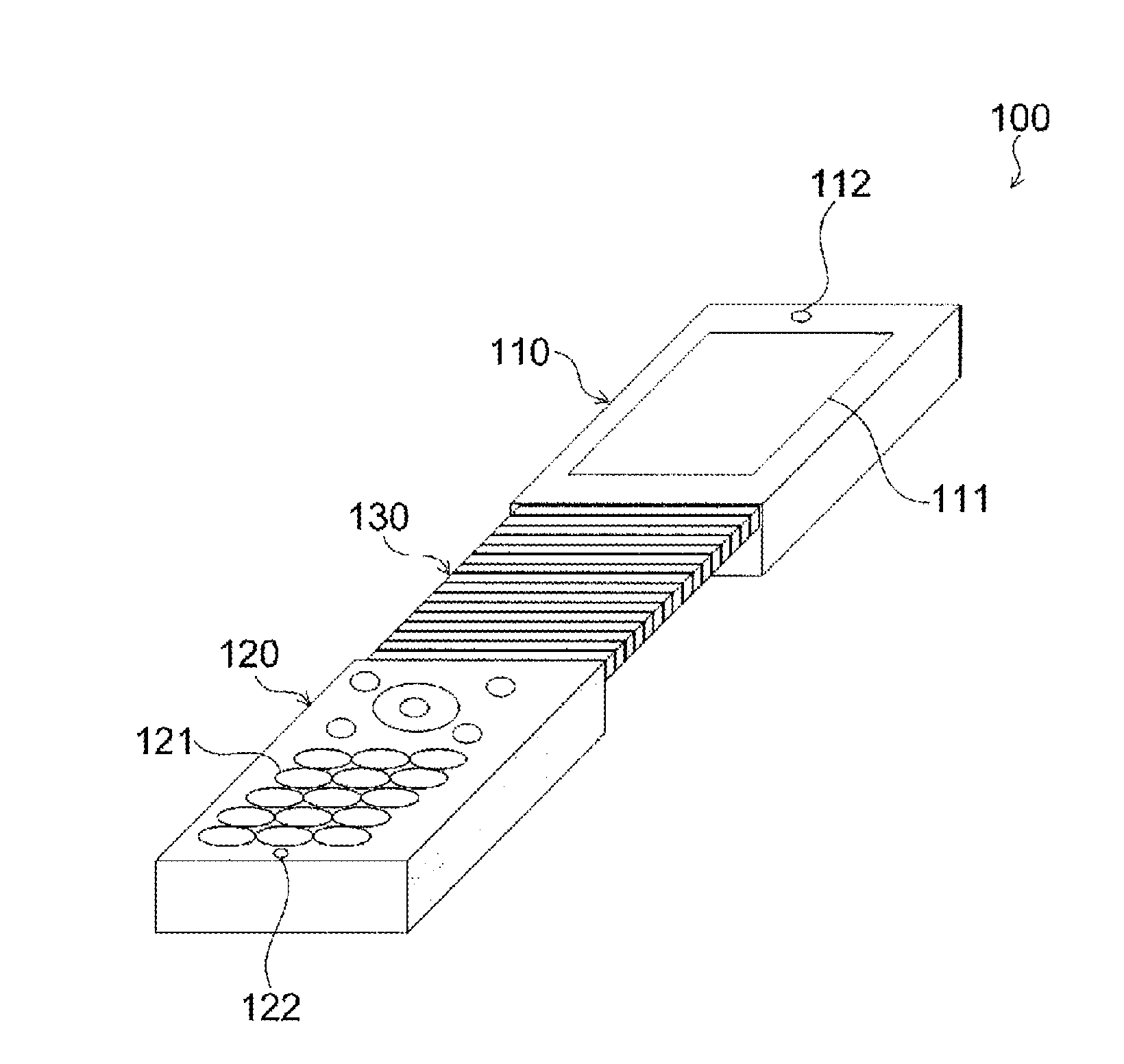

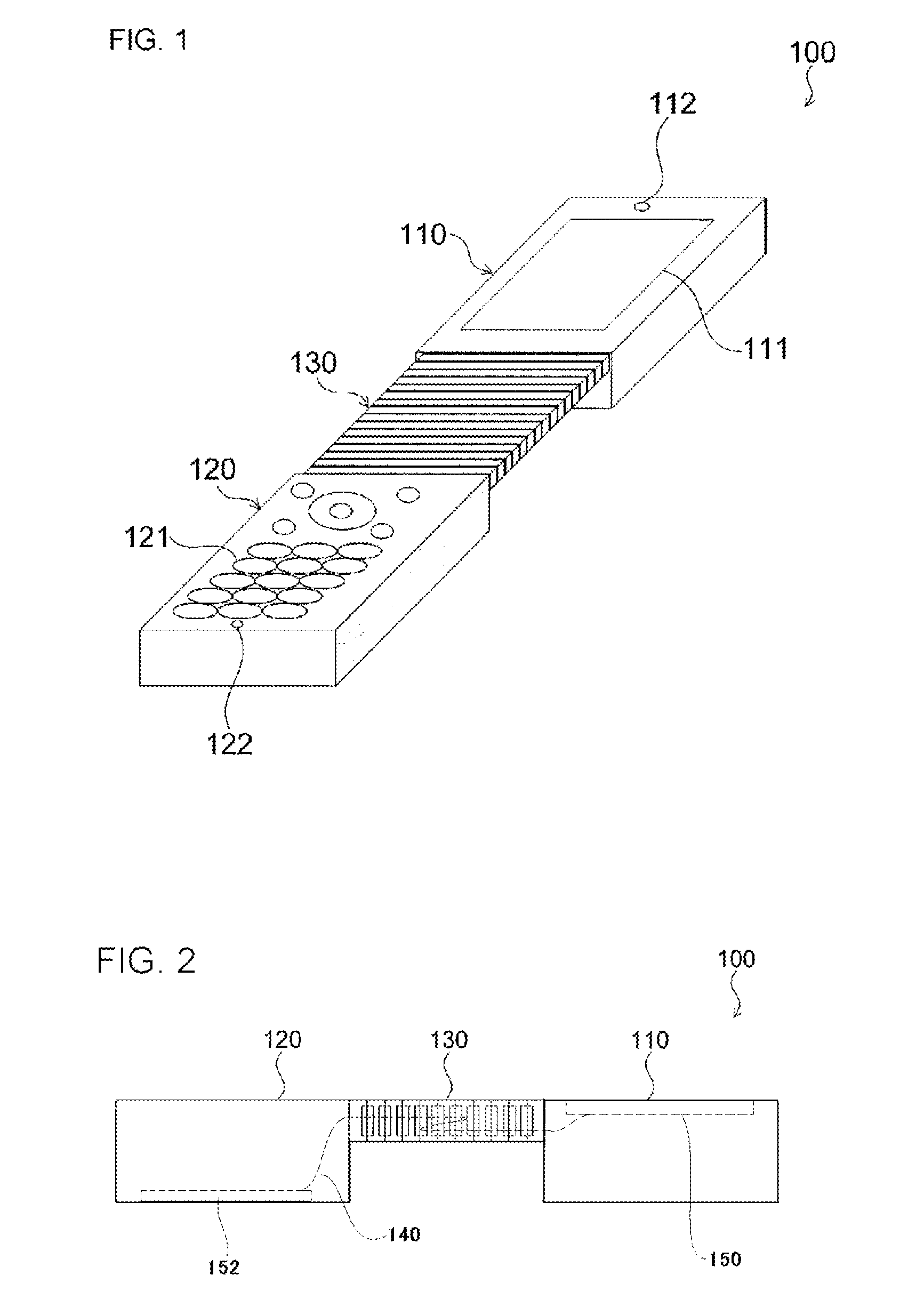

Nano-patterned substrate and epitaxial structure

InactiveUS20110024880A1Defect minimizationReduce defectsSemiconductor/solid-state device manufacturingSemiconductor devicesMetallurgy

A nano-patterned substrate includes a plurality of nano-particles or nanopillars on an upper surface thereof. A ratio of height to diameter of each of the nano-particles or each of the nanopillars is either greater than or equal to 1. Particularly, a ratio of height to diameter of the nanopillars is greater than or equal to 5. Each of the nano-particles or each of the nanopillars has an arc-shaped top surface. When an epitaxial growth process is applied onto the nano-patterned substrate to form an epitaxial layer, the epitaxial layer has very low defect density. Thus, a production yield of fabricating the subsequent device can be improved.

Owner:EPISTAR CORP +1

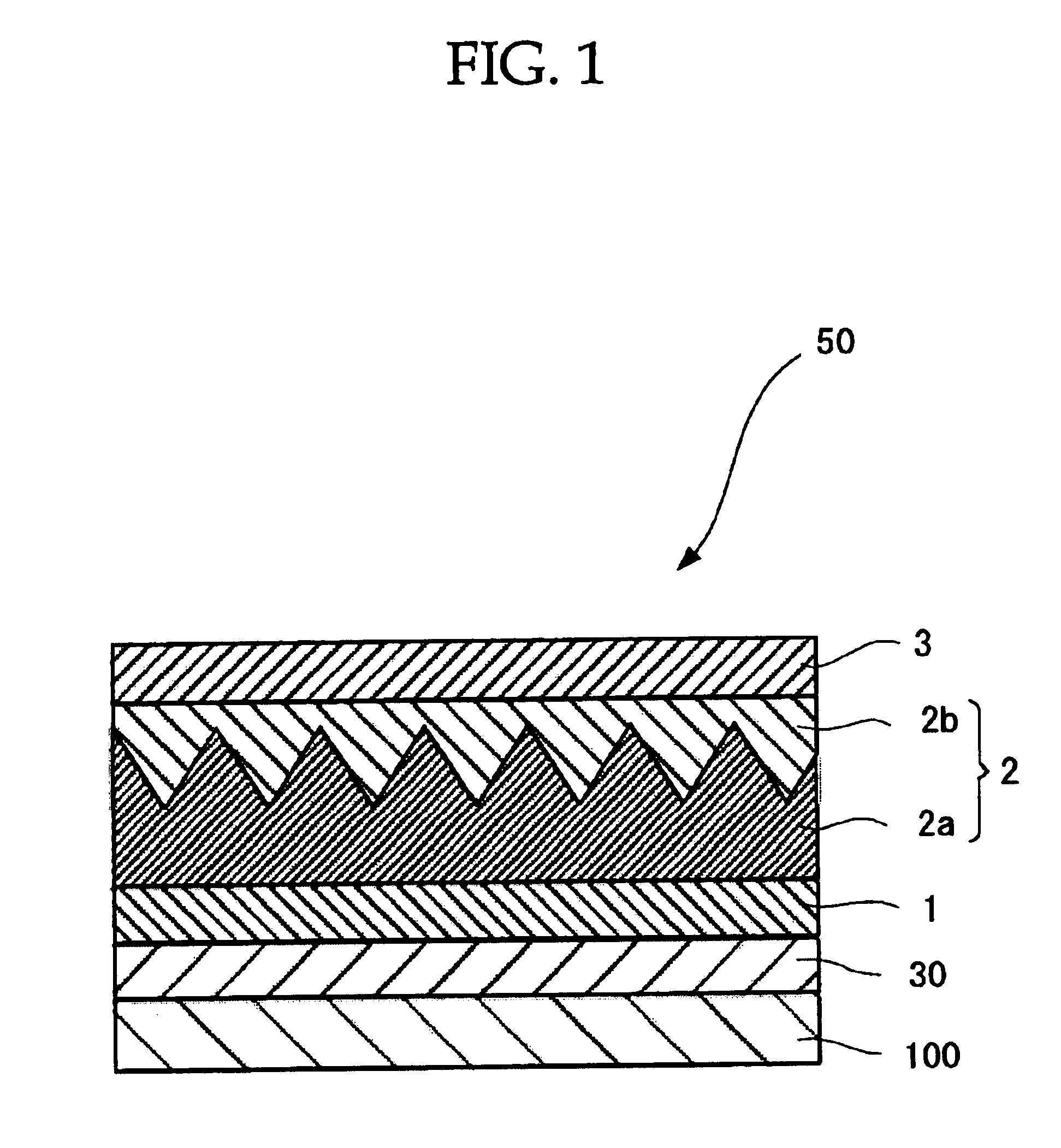

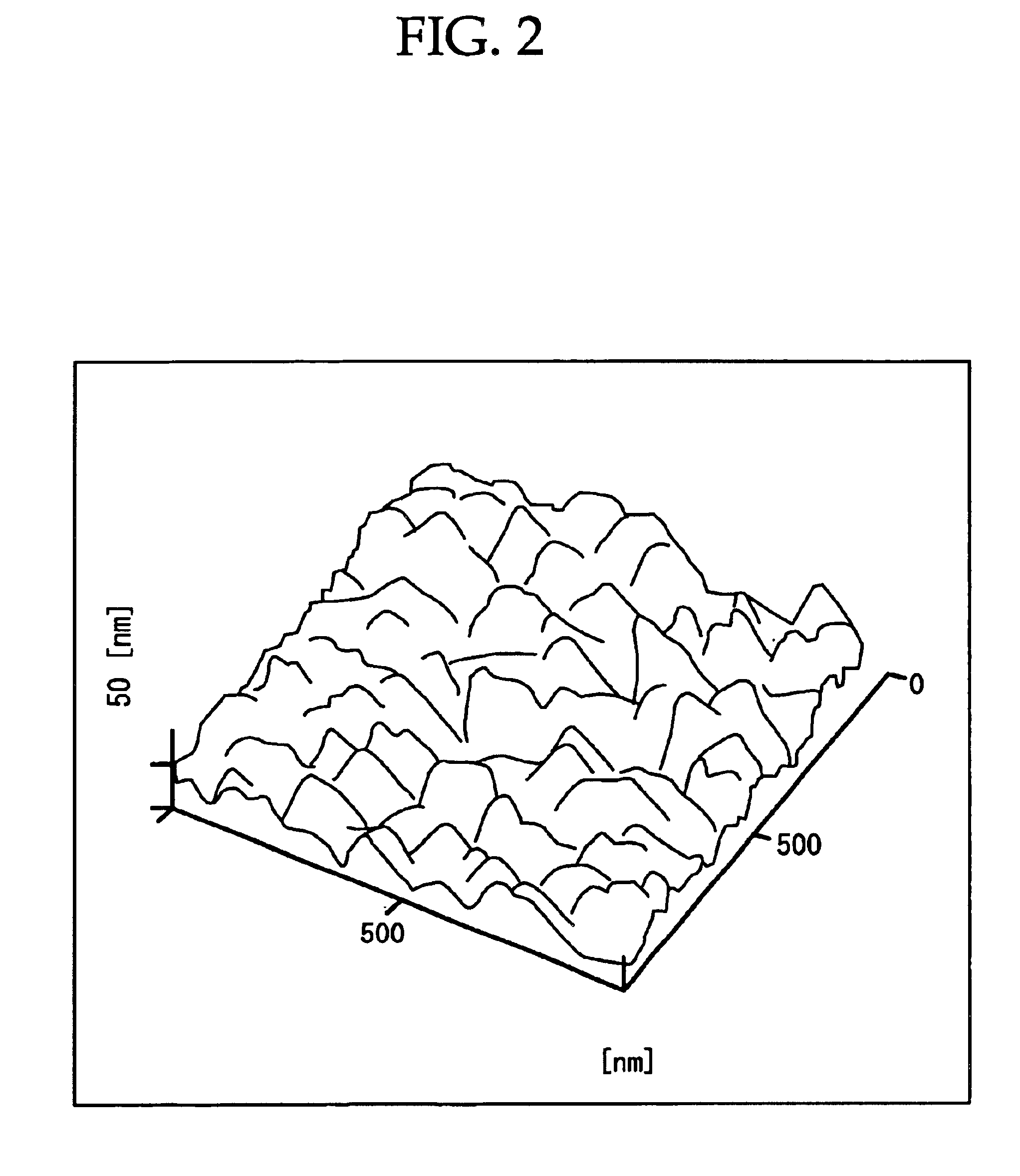

Ferroelectric capacitor, process for production thereof and semiconductor device using the same

InactiveUS6855974B2Reduce fatigueEfficient productionSolid-state devicesVacuum evaporation coatingCapacitanceSurface roughness

A ferroelectric capacitor includes a pair of electrodes, and at least one ferroelectric held between the pair of electrodes, in which the ferroelectric includes a first ferroelectric layer having a surface roughness (RMS) determined with an atomic force microscope of 10 nm or more; and a second ferroelectric layer being arranged adjacent to the first ferroelectric layer and having an RMS of 5 nm or less. A process produces such a ferroelectric capacitor by forming a first ferroelectric layer on or above one of a pair of electrodes at a temperature equal to or higher than a crystallization temperature at which the first ferroelectric layer takes on a ferroelectric crystalline structure, and forming a second ferroelectric layer on the first ferroelectric layer at a temperature lower than a crystallization temperature at which the second ferroelectric layer takes on a ferroelectric crystalline structure.

Owner:FUJITSU LTD

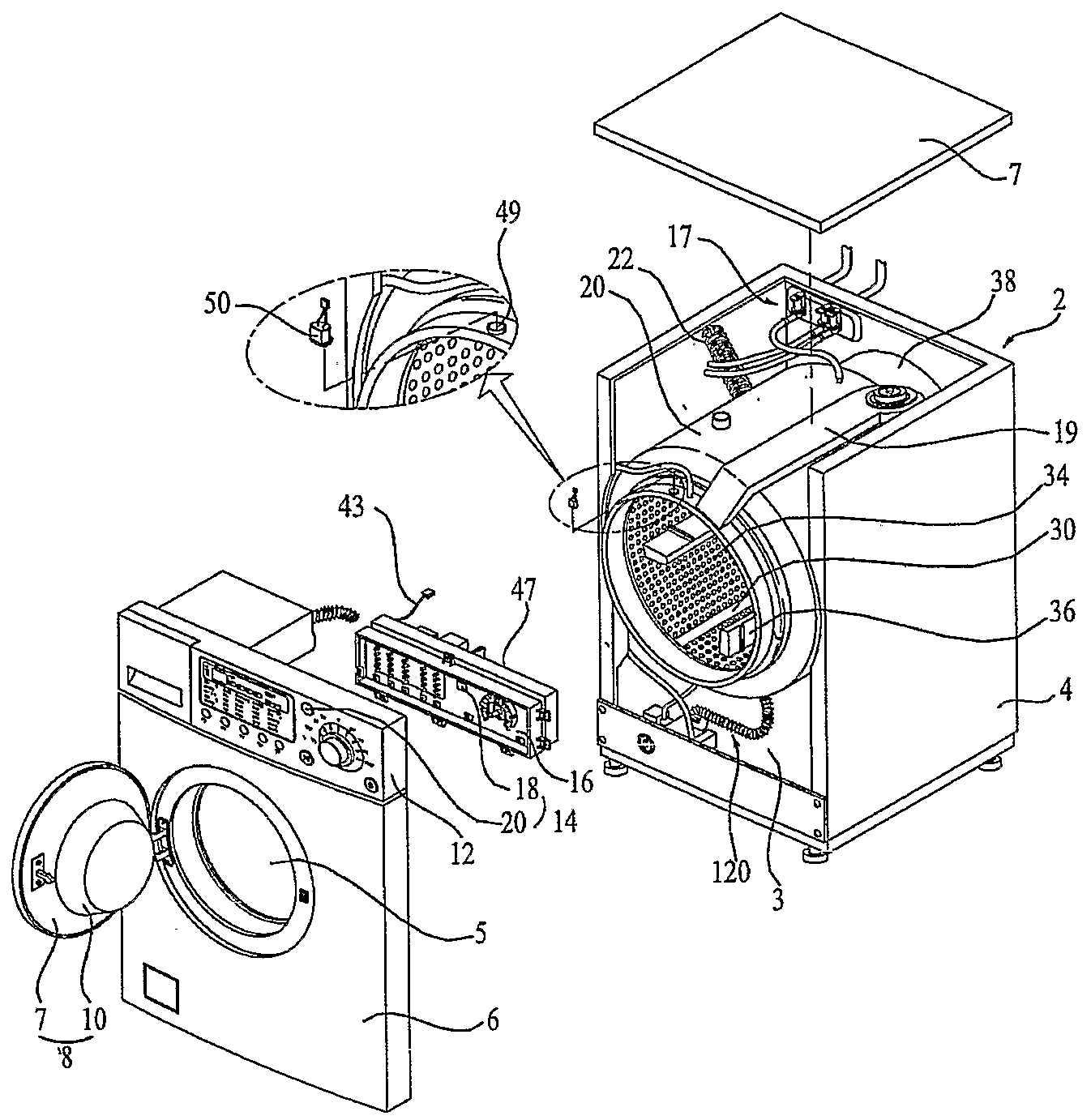

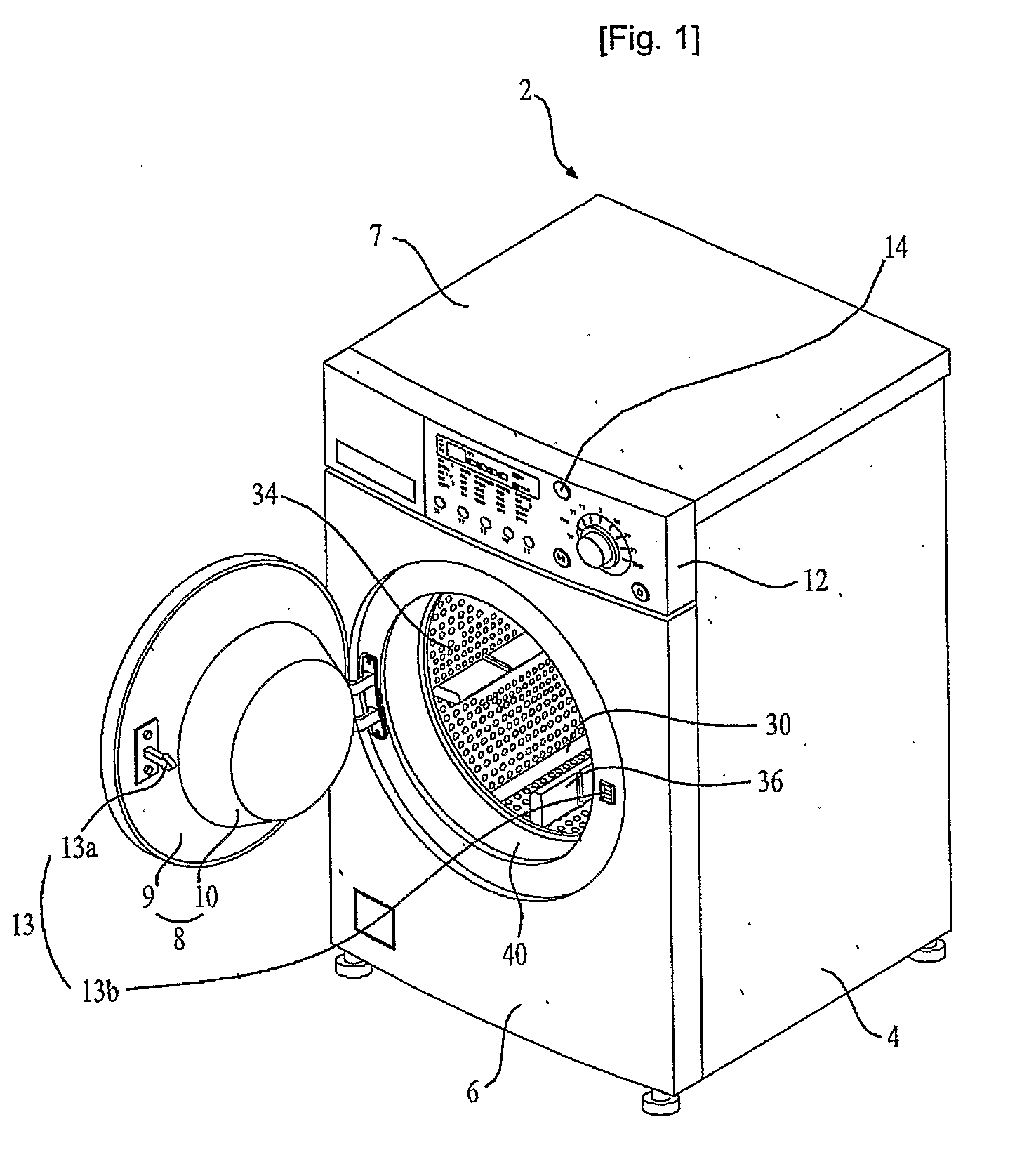

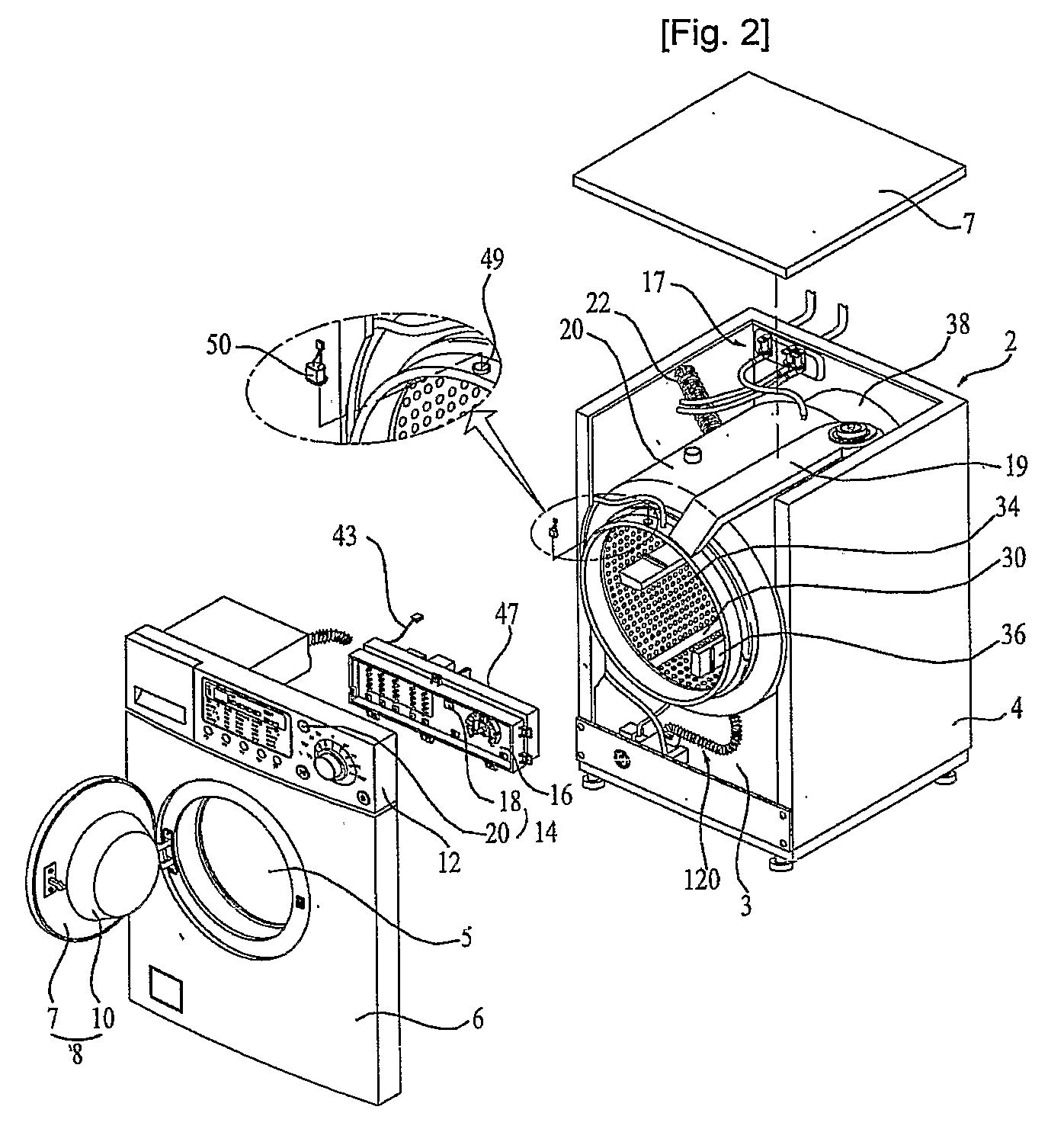

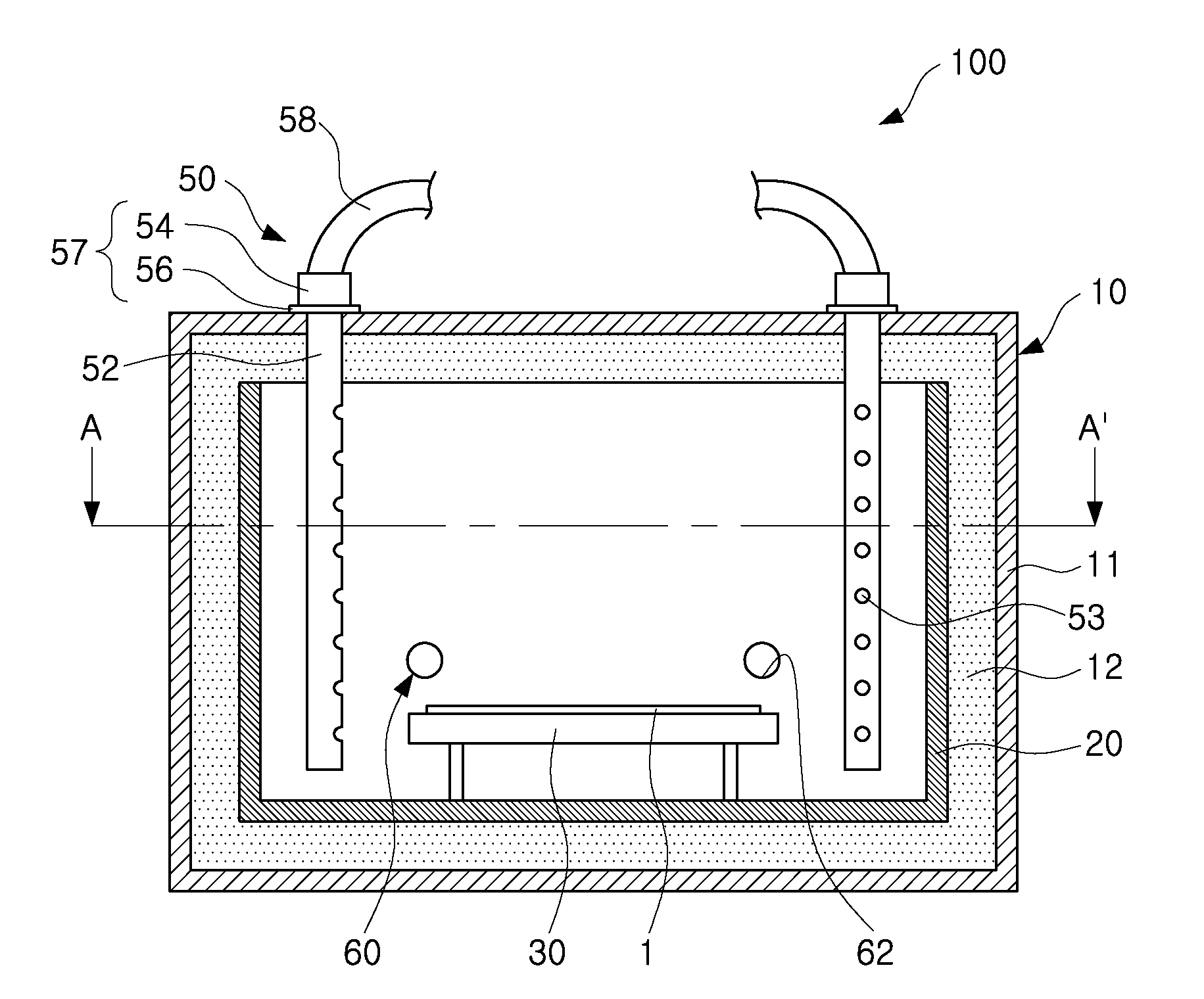

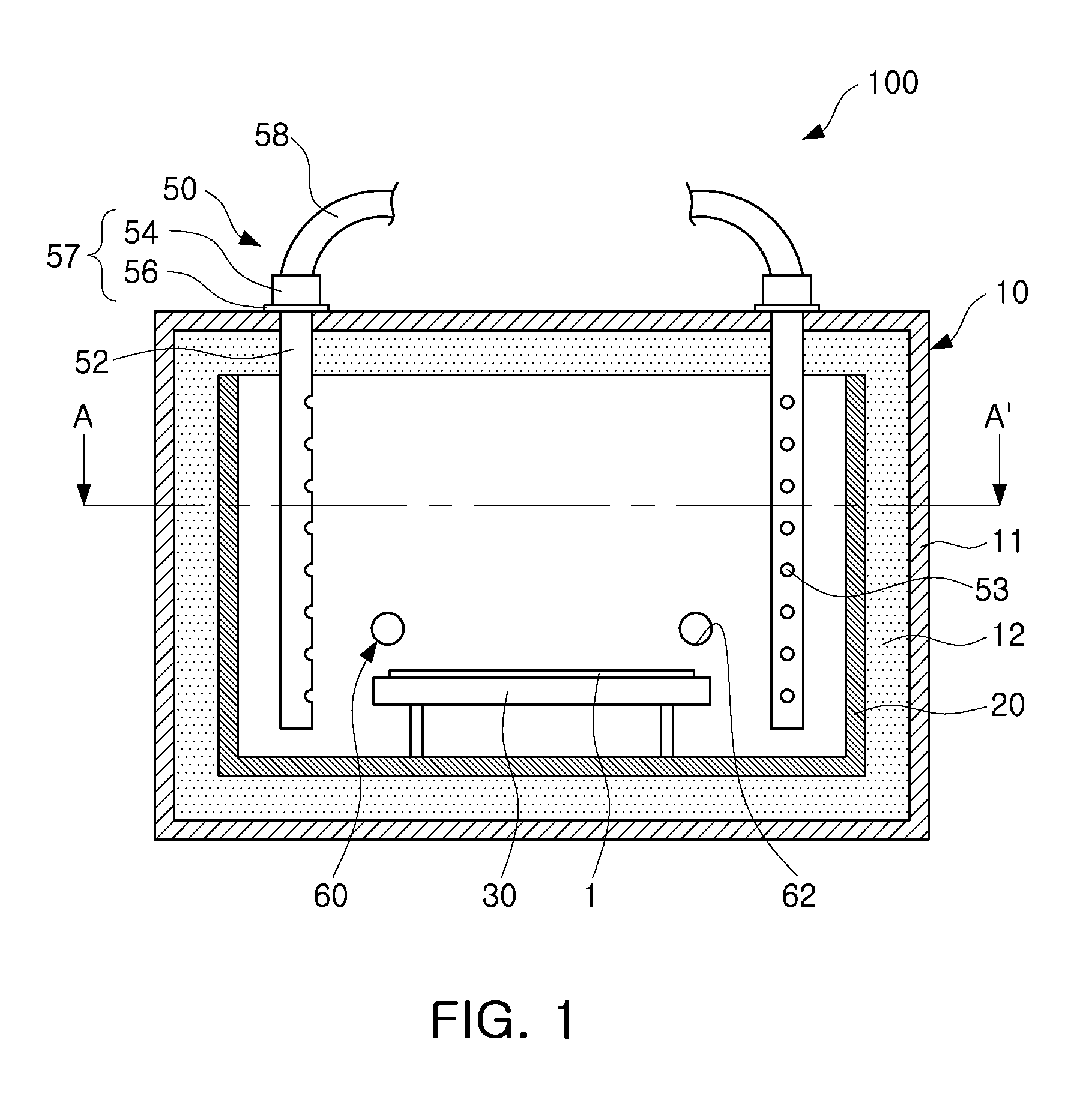

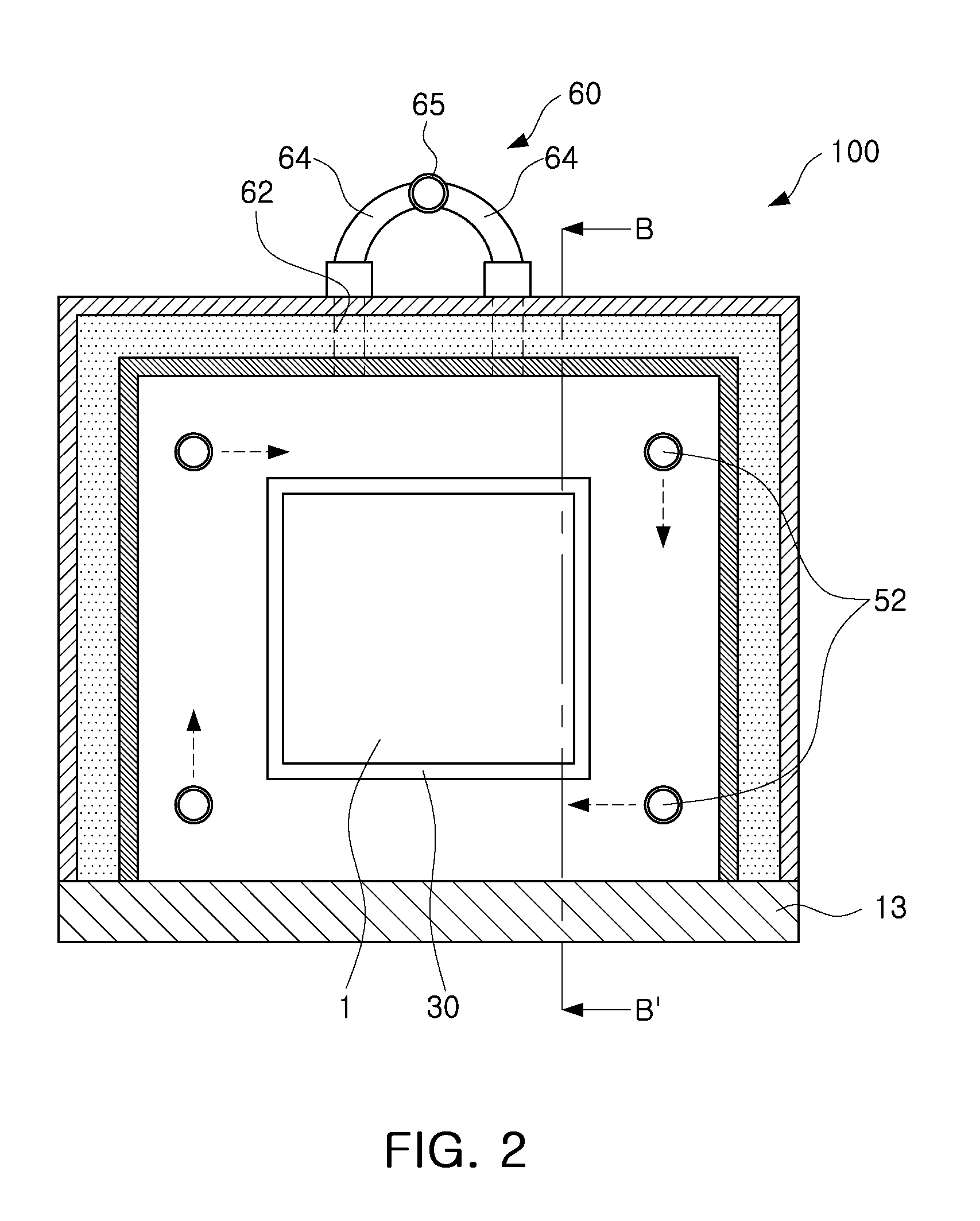

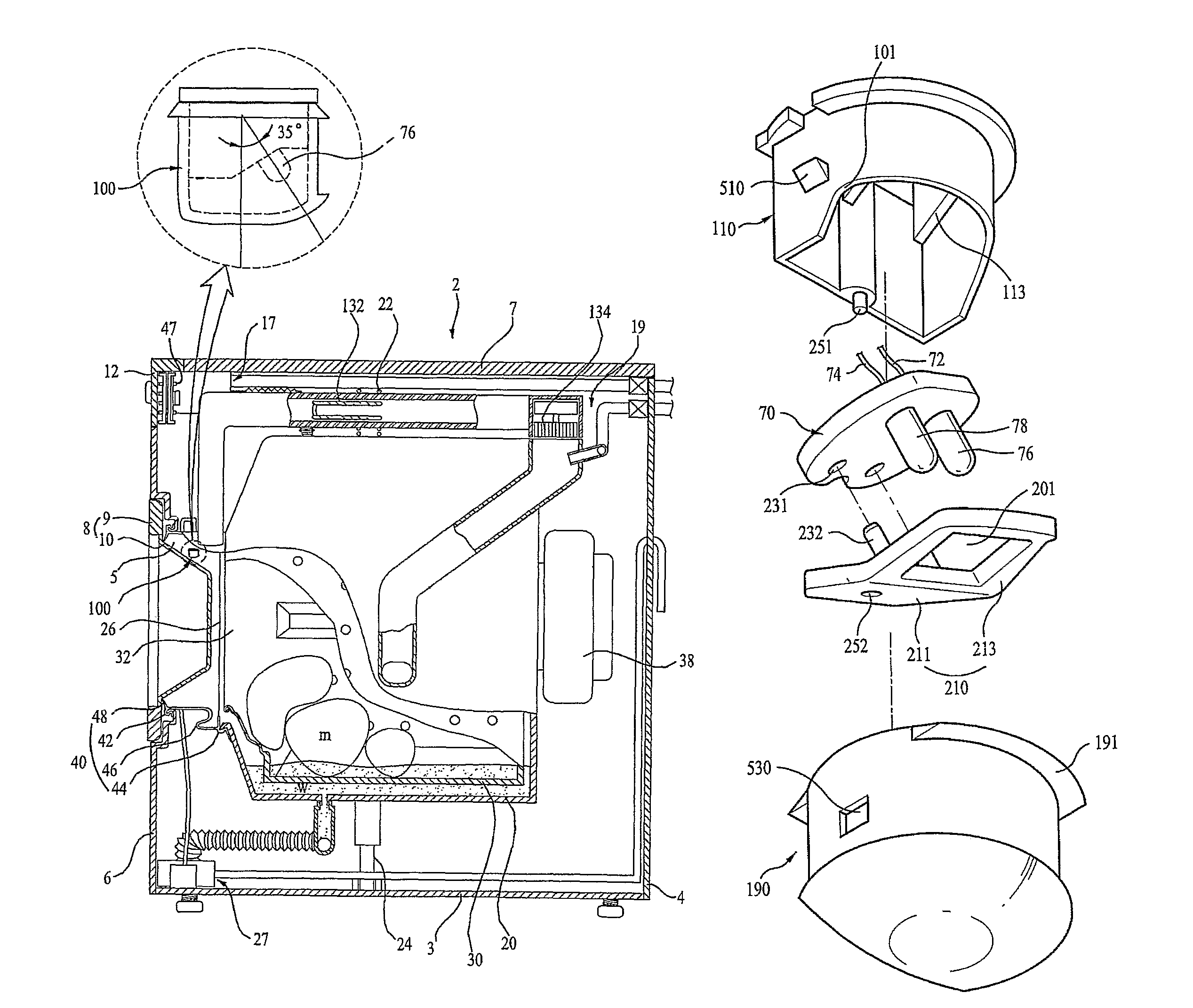

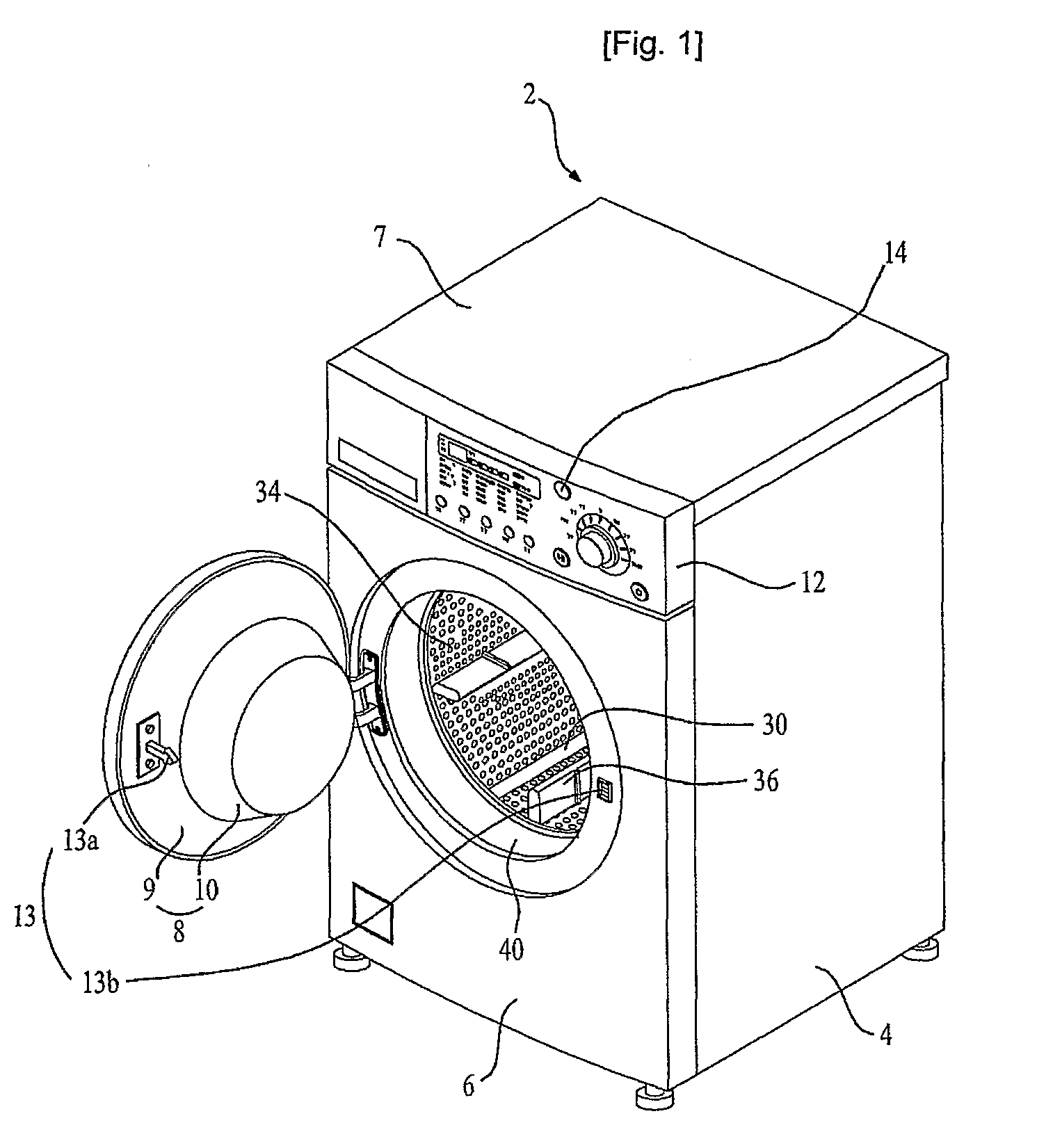

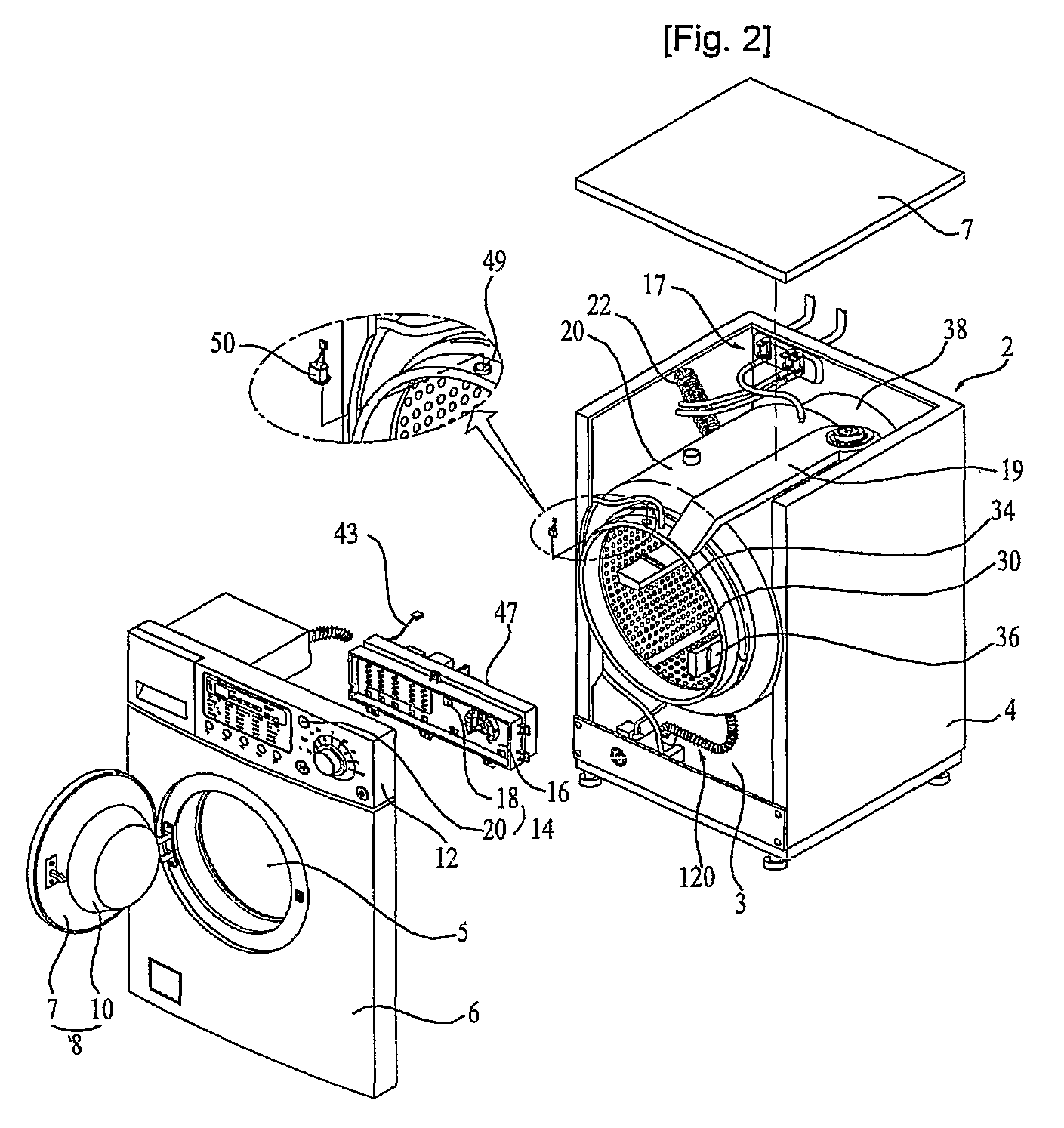

Washing machine having lamp device and control method of the same

ActiveUS20090153057A1Long life-timeStrong against vibrationLighting support devicesPoint-like light sourceEngineeringEffect light

The present invention relates to washing machines, and more particularly, to a washing machine having a lamp device with LED (76,78) mounted to a gasket (40) for lighting an inside of the washing machine, and a method for controlling the same. For this the present invention provides a washing machine including a cabinet (2) having a door (8) on a front, a tub (20) in the tub for holding washing water, a drum (30) rotatably mounted in the tub (20), a gasket (40) mounted to connect openings of the door (8) and the tub (20), and a lamp device (50) provided to the gasket (40). Moreover the present invention provides a method for controlling a washing machine including a first step for turning on LEDs (76,78) in a lamp device (50) for lighting an inside of the washing machine upon reception of an order of turning on a lighting through an LED input unit (14), and a second step for turning off the LEDs (76,78) upon reception of an order of turning off the lighting through the LED input unit (14) after the first step.

Owner:LG ELECTRONICS INC

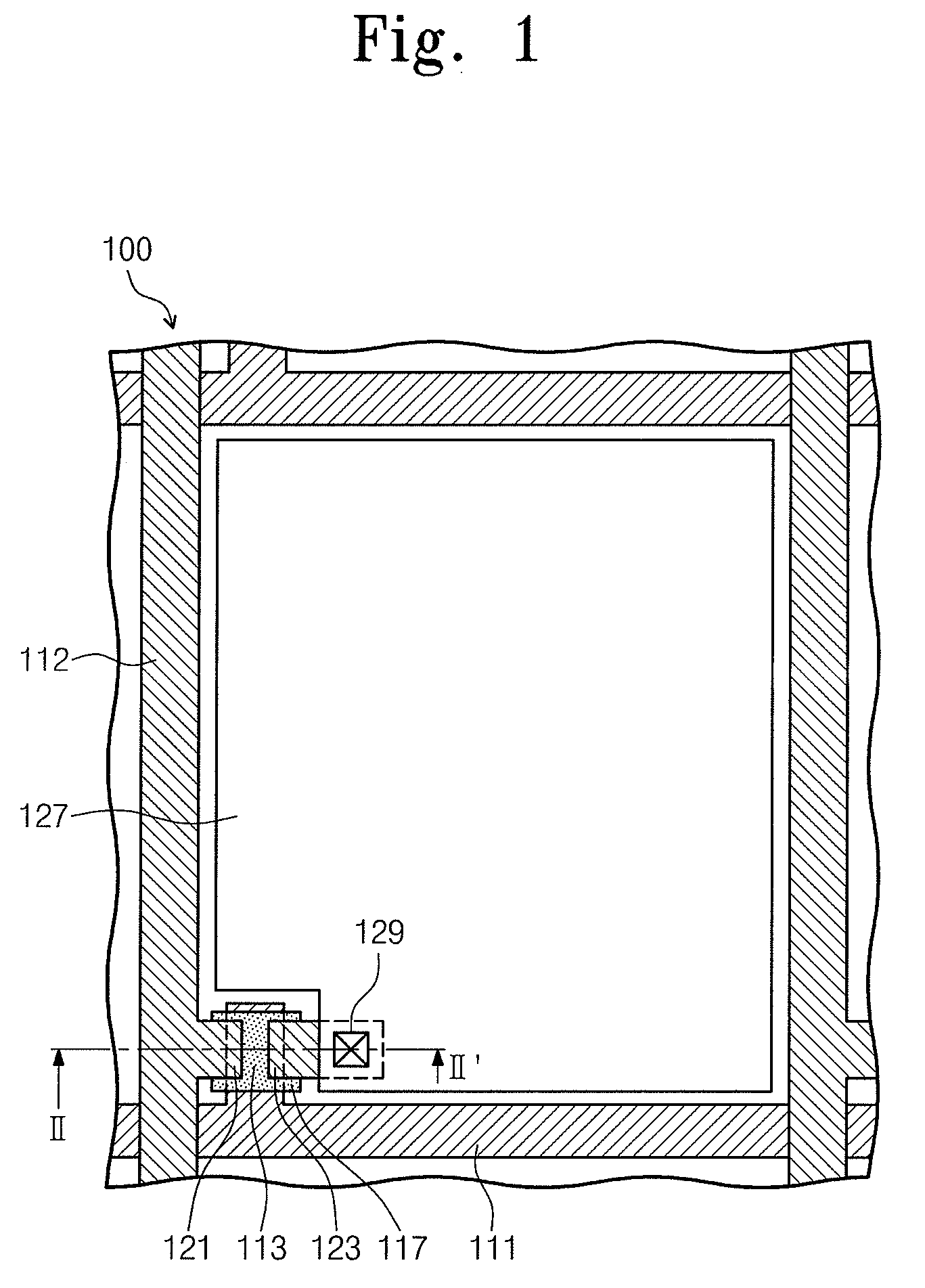

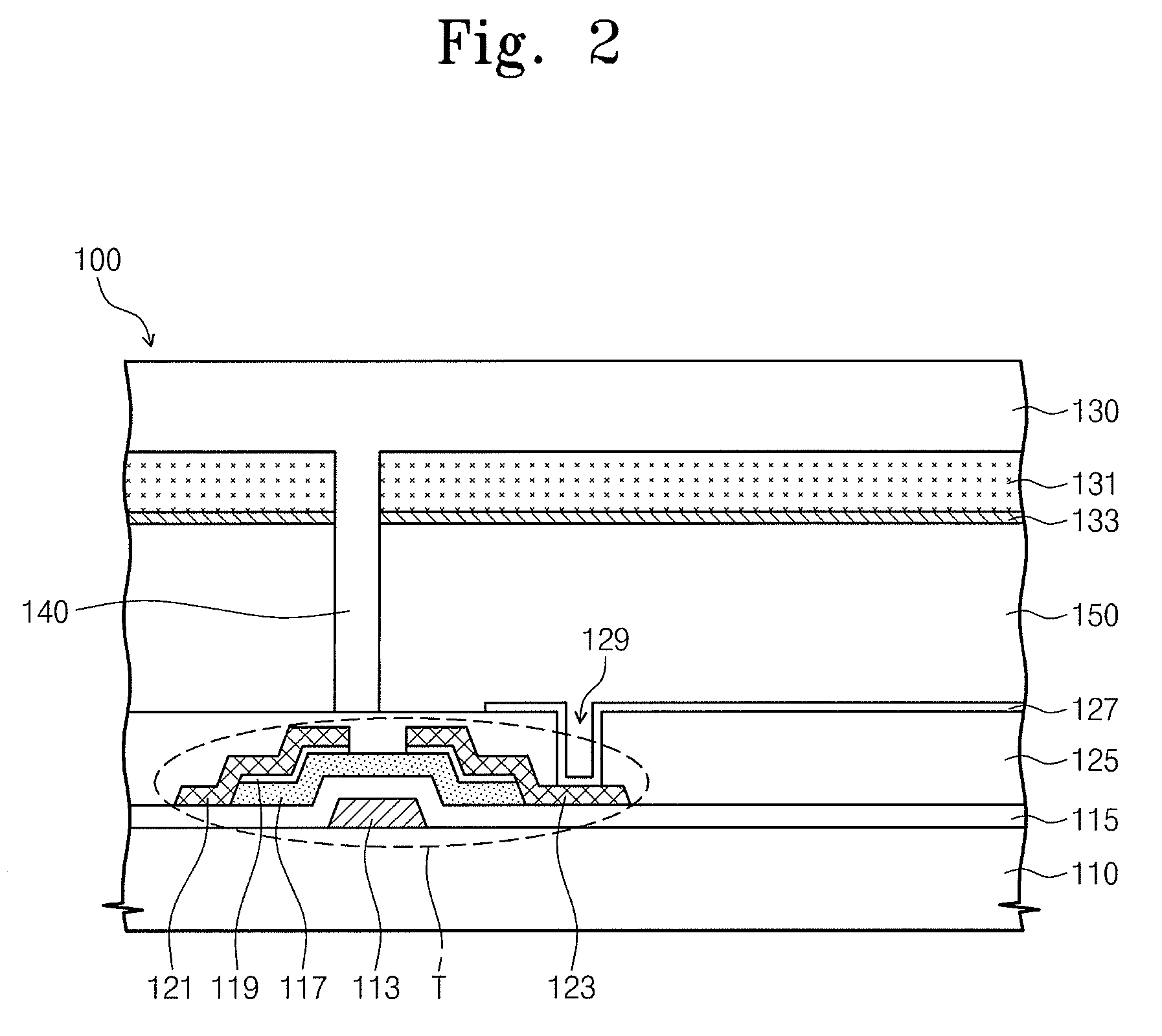

Display apparatus and method of fabrication the same

InactiveUS20100053535A1Simplify the manufacturing processFabrication efficiency can be improvedCircuit susbtrate materialsNon-linear opticsEngineeringElectrical and Electronics engineering

Owner:SAMSUNG ELECTRONICS CO LTD

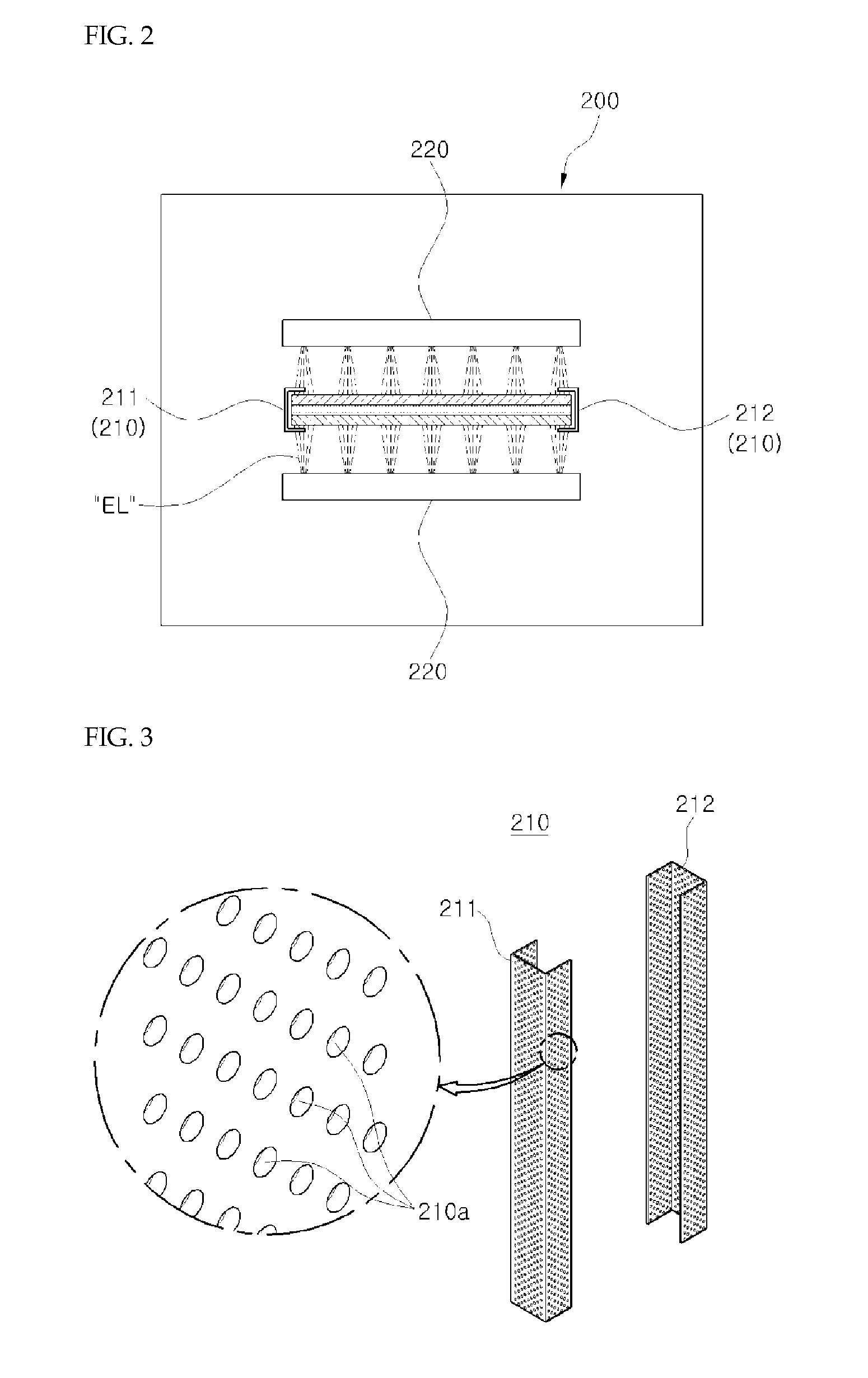

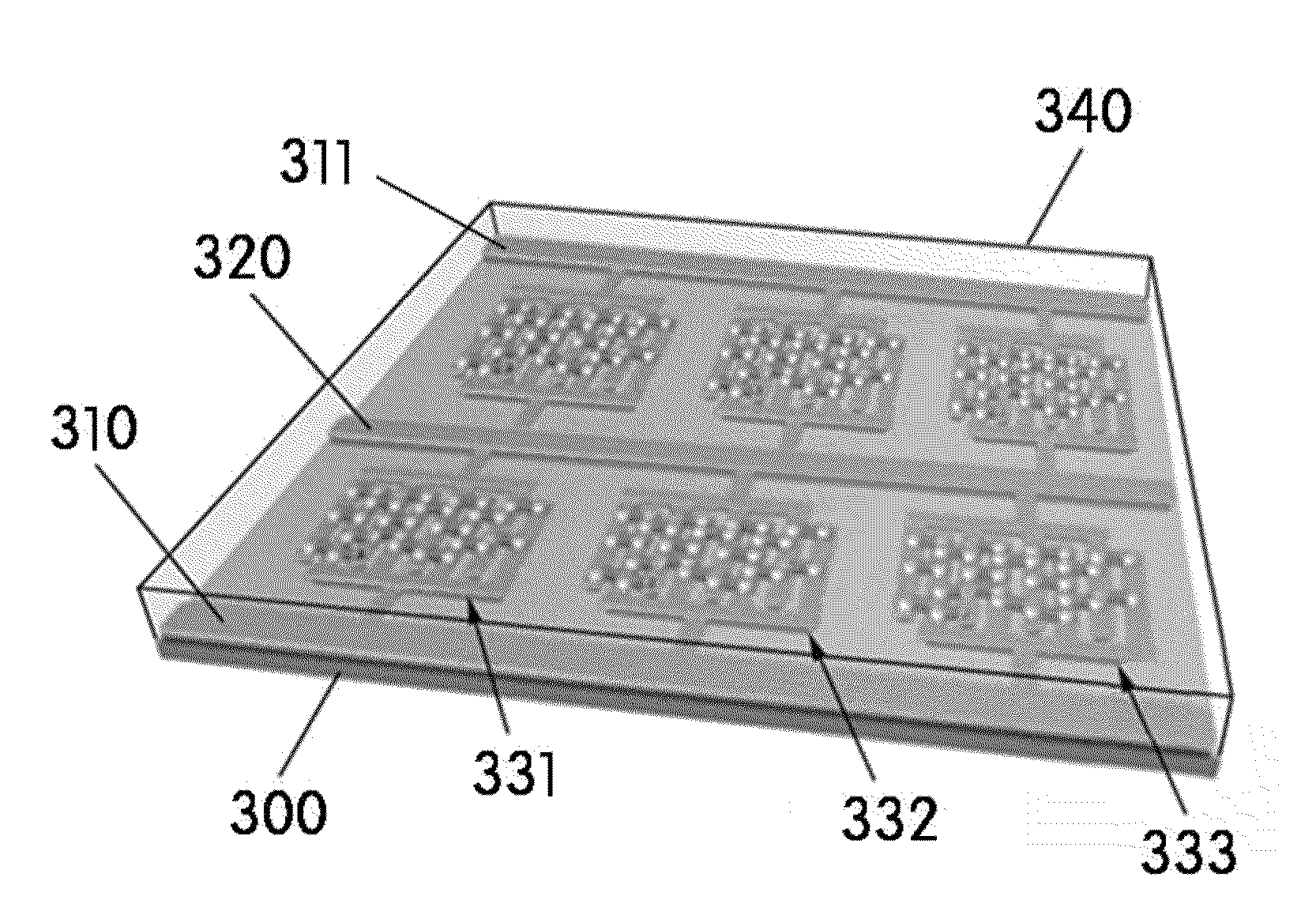

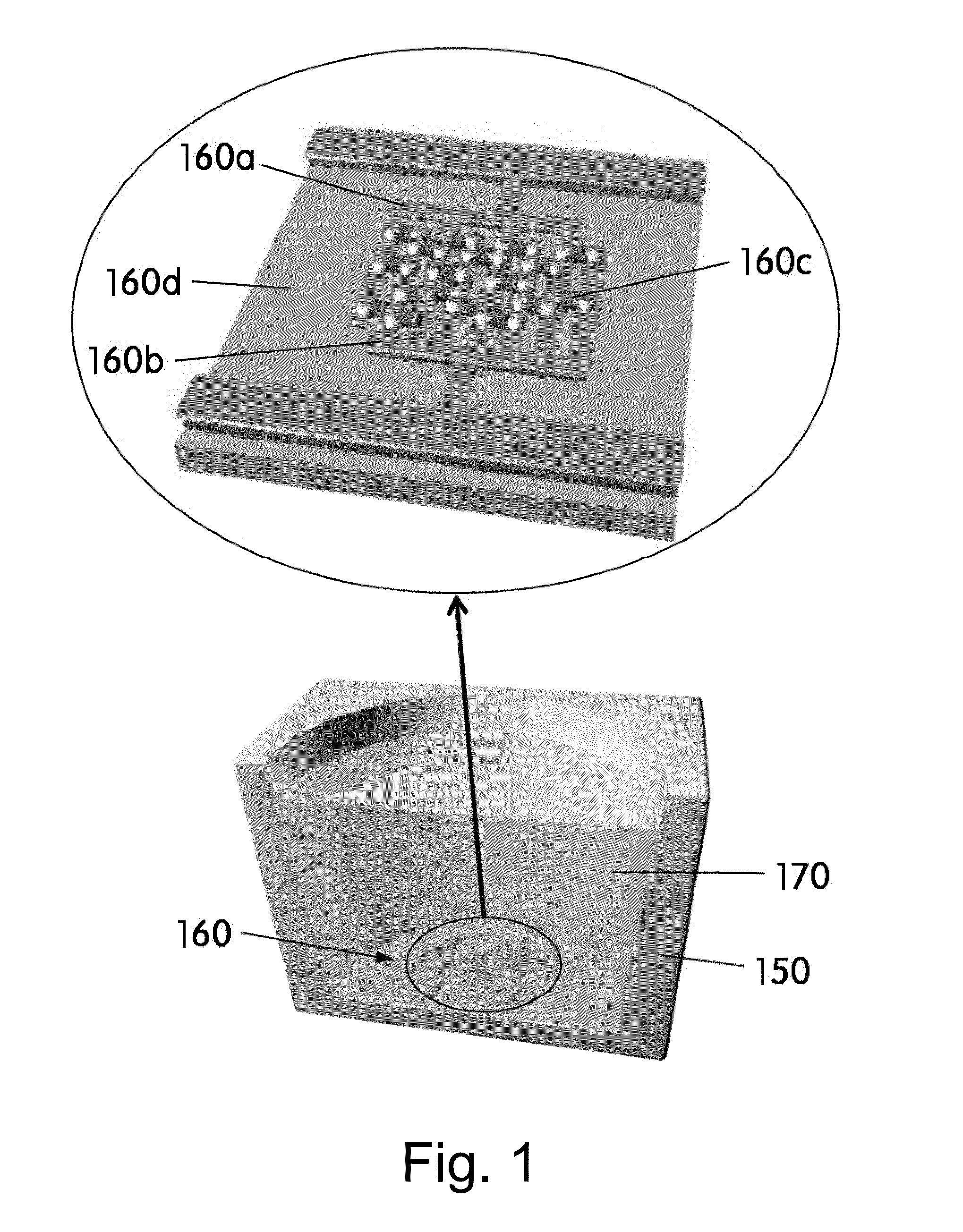

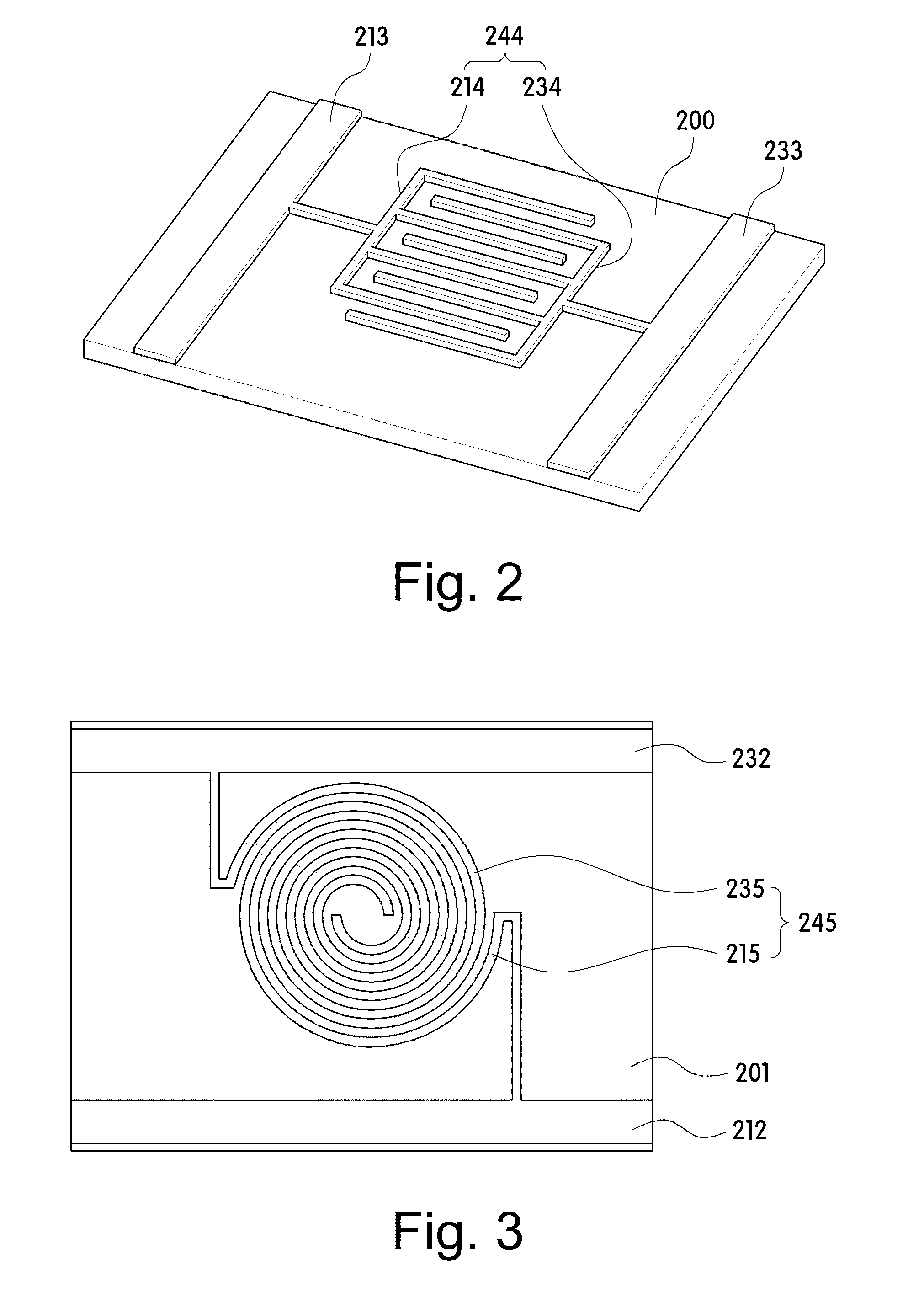

LED lamp using ultra-small LED electrode assembly

ActiveUS20160172339A1Light extraction efficiency be improveFunctional deteriorationFinal product manufacturePrinted circuit aspectsDirectivityLead electrode

Provided is an LED lamp using a nano-scale LED electrode assembly. The LED lamp using the nano-scale LED electrode assembly may solve limitations in which, when a nano-scale LED device according to the related art stands up and is three-dimensionally coupled to an electrode, it is difficult to allow the nano-scale LED device to stand up, and when the nano-scale LED devices are coupled to one-to-one correspond to electrodes different from each other, product quality is deteriorated. Thus, the nano-scale LED device having a nano unit may be connected to the two electrodes different from each other without causing defects, and light extraction efficiency may be improved due to the directivity of the nano-scale LED devices connected to the electrodes. Furthermore, deterioration in function of the LED lamp due to the defects of a portion of the nano-scale LEDs provided in the LED lamp may be minimized, and the LED lamp may have a flexible structure and shape by using the nano-scale LED electrode assembly of which a portion is deformable according to the used purpose or position of the LED lamp.

Owner:SAMSUNG DISPLAY CO LTD

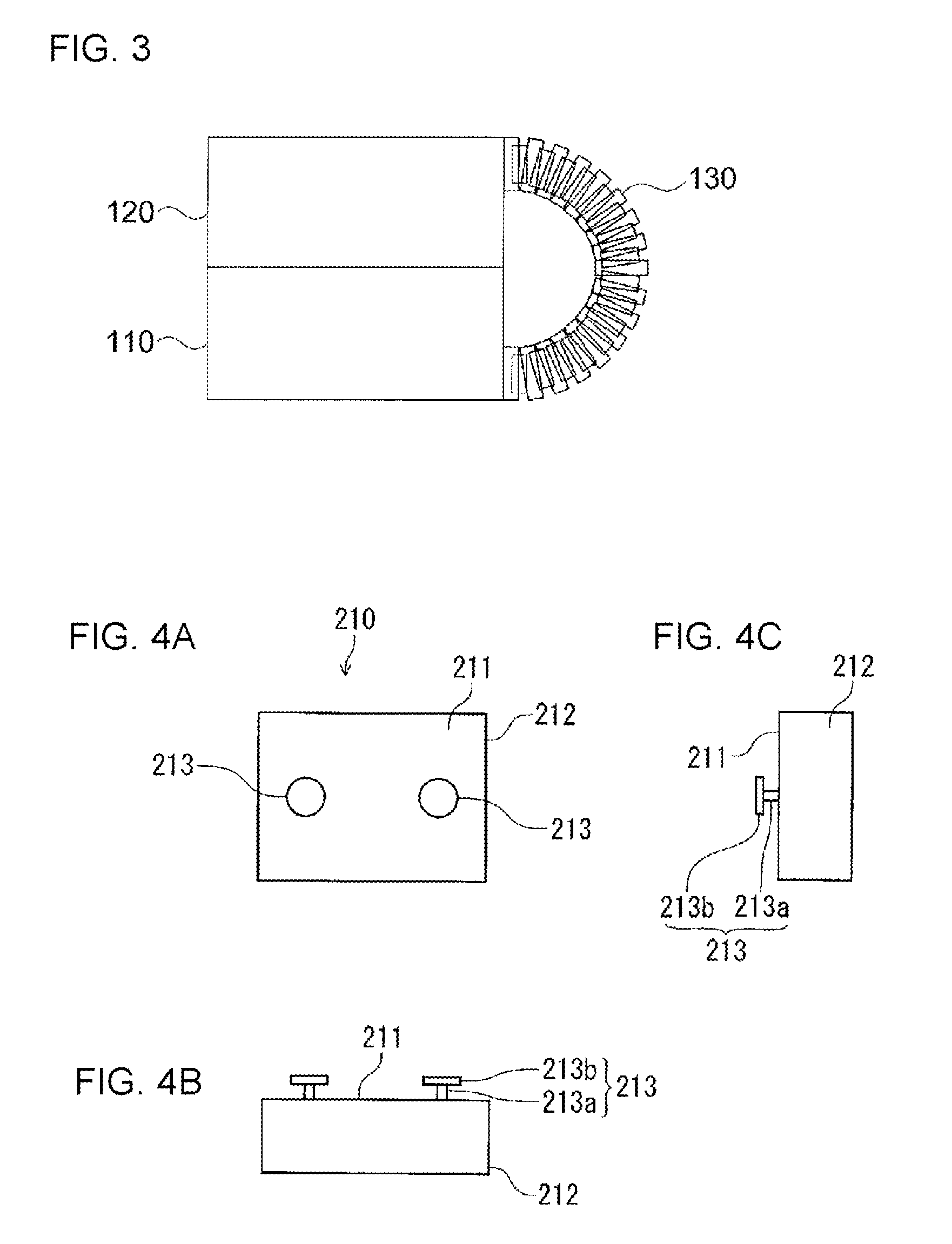

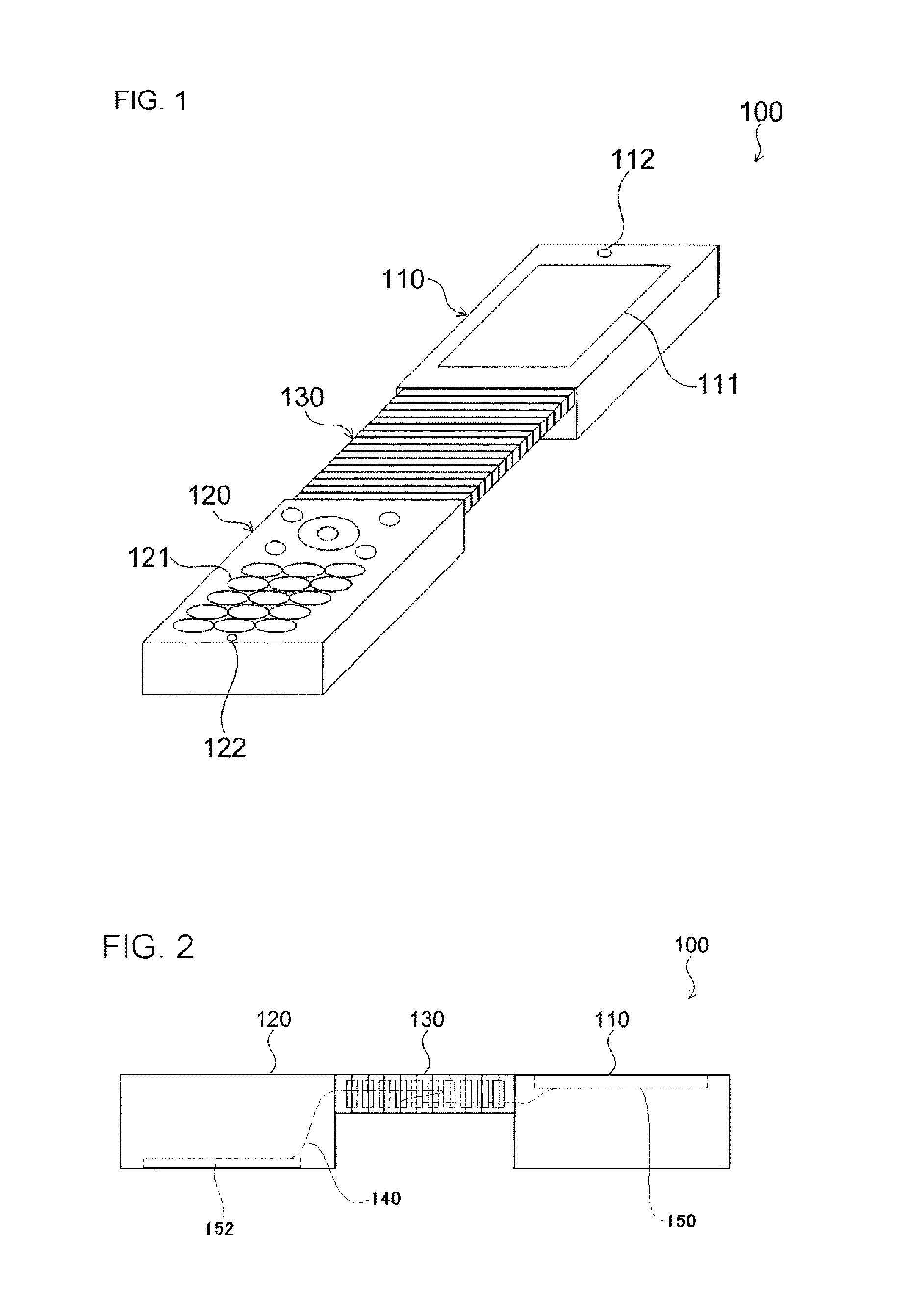

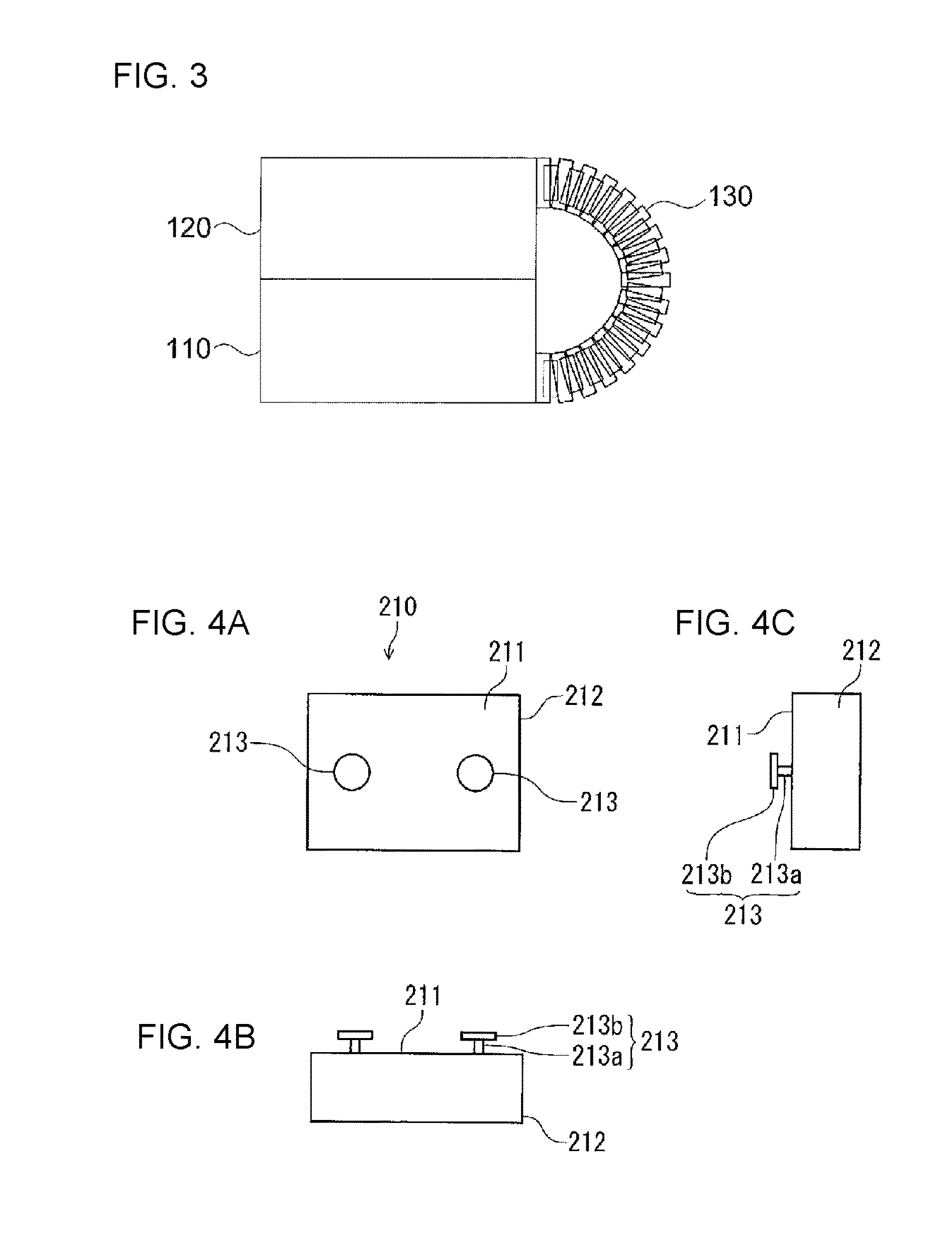

Folding portable device and connecting mechanism

InactiveUS20100144406A1Great resistanceMinimize defectSubstation equipmentDetails for portable computersFlexible electronicsPrinted circuit board

A folding portable device is provided, in which a connecting mechanism that mechanically connects a first housing and a second housing to each other includes a plurality of first members including a first plane and two engaging pieces provided on the first plane, and a plurality of second members including a second plane, an engaging groove provided on the second plane for the engaging piece to be slidably fitted, and a stopper. The first member is engaged with one of the second members by means of one of the two engaging pieces, and with another second member adjacent to the one second member by means of the other of the two engaging pieces, and the connecting mechanism includes therein a hollow portion formed along an extending direction of the engaging groove, and the hollow portion includes therein the flexible printed circuit board.

Owner:LENOVO INNOVATIONS LTD HONG KONG

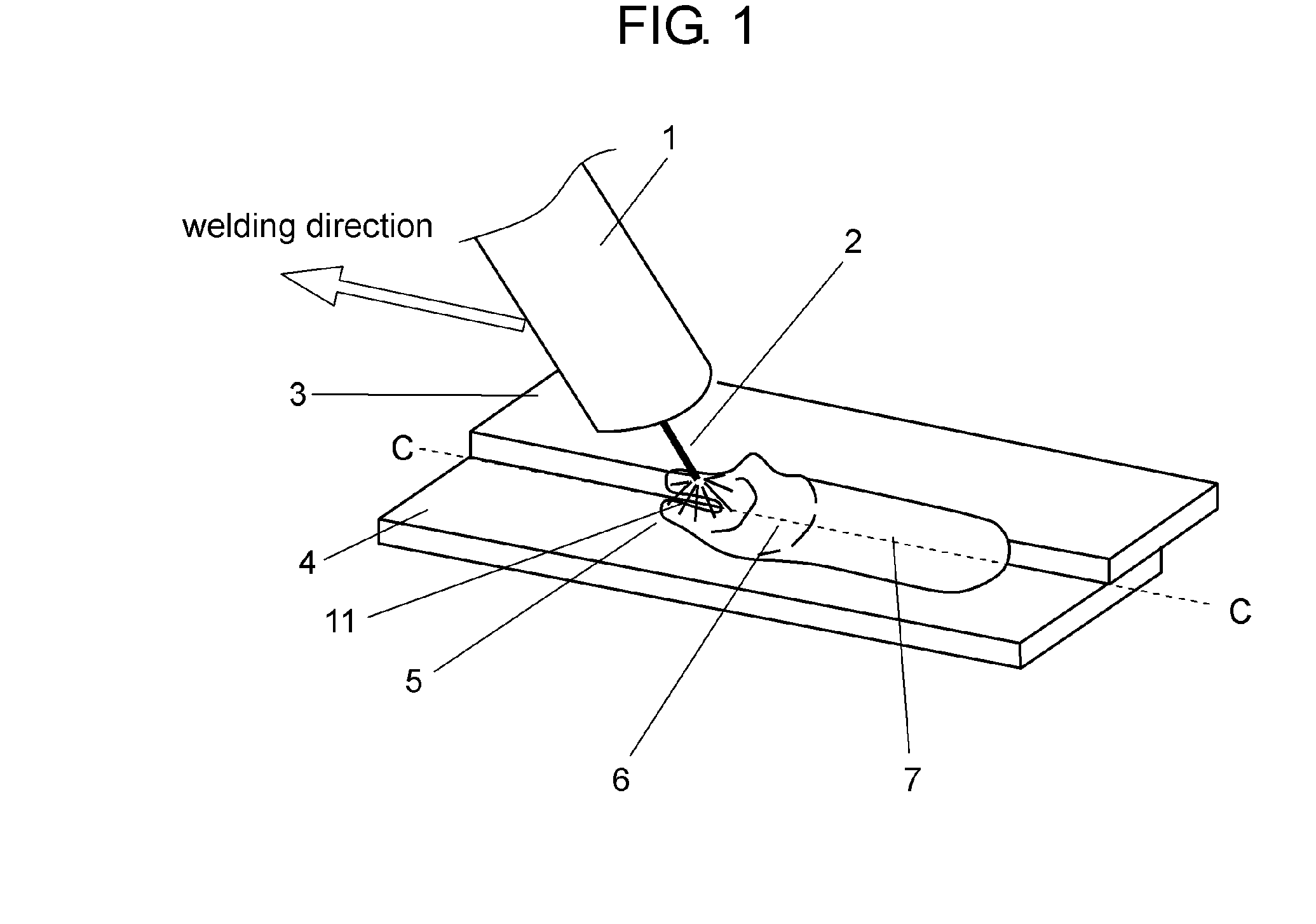

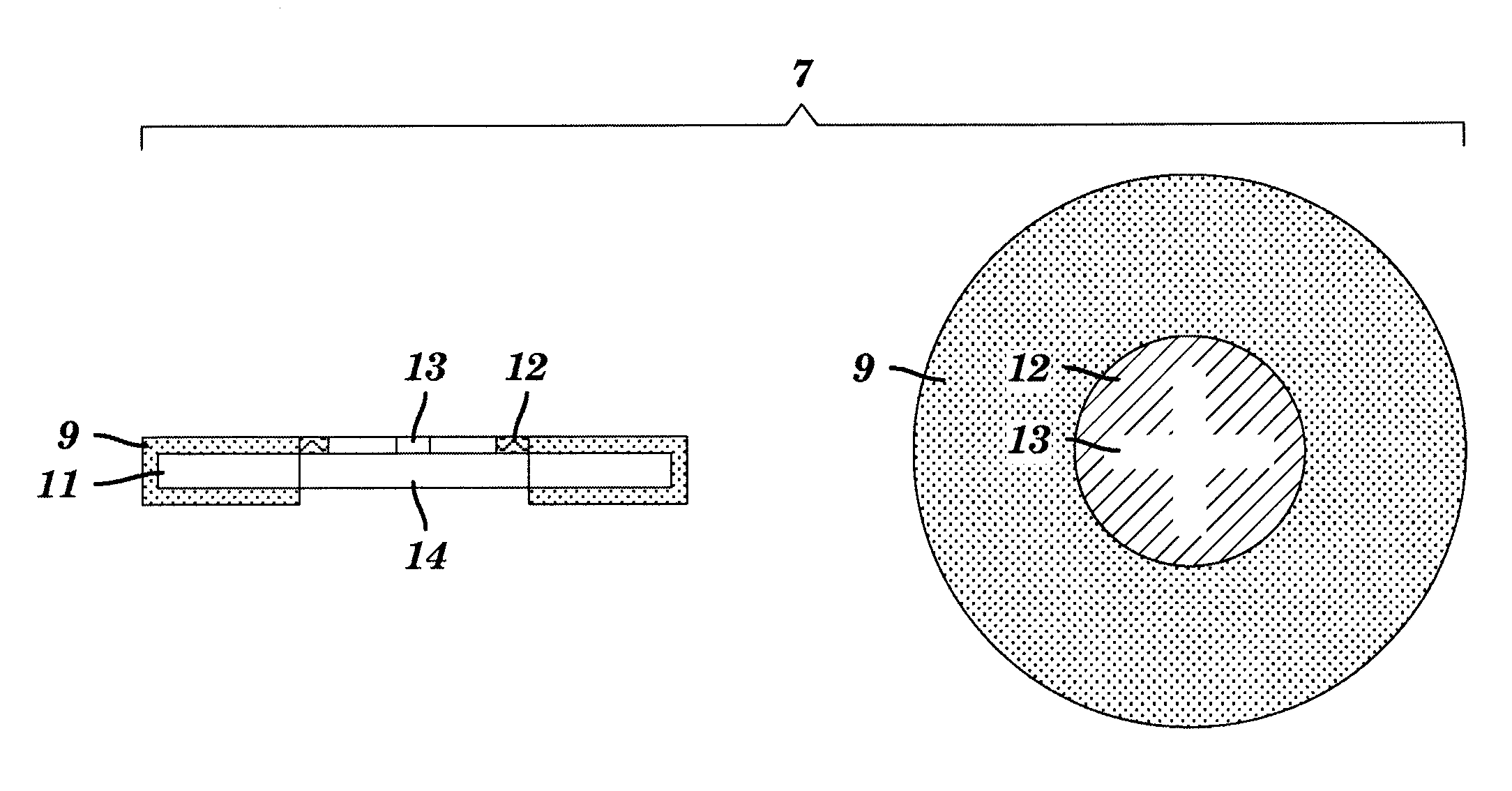

Arc welding control method

ActiveUS20150096965A1Minimize defectSuppress splashArc welding apparatusWelding/soldering/cutting articlesSteel platesElectric arc

As a conventional problem, welding on surface-treated material, such as a zinc-coated steel plate, considerably generates air holes including blowholes and also generates lots of spatters. Present invention provides a method of controlling arc welding performed in a manner that a short-circuit period, in which a short circuit is generated between a welding wire and an object to be welded, and an arc period, in which an arc is generated after release of the short circuit, are repeated alternately. According to the method, welding current is increased from an arc-regeneration-before current to a first welding current at a detection of release of the short circuit such that an increase gradient of the welding current becomes not less than 750 A / msec. This suppresses generation of air holes and spatters in welding work on a surface-treated material, such as a zinc-coated steel plate.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method to reduce mechanical wear of immersion lithography apparatus

InactiveUS20080138631A1Defect minimizationMinimize mechanical wearPhotomechanical apparatusMetallic material coating processesTitanium aluminium nitrideDiamond-like carbon

A protective coating is provided for components of an immersion lithography tool, in which at least a portion of a component exposed to the immersion fluid is protected by a thin, hard protective coating, comprising materials such as silicon carbide, diamond, diamond-like carbon, boron nitride, boron carbide, tungsten carbide, aluminum oxide, sapphire, titanium nitride, titanium carbonitride, titanium aluminum nitride and titanium carbide. The protective coating may be formed by methods such as CVD, PECVD, APCVD, LPCVD, LECVD, PVD, thin-film evaporation, sputtering, and thermal annealing in the presence of a gas. The protective coating preferably has a hardness greater than a Knoop hardness of about 1000 and more preferably greater than about 2000, or a Moh hardness greater than about 7, more preferably greater than about 9. The protective coating minimizes defects due to mechanical wear of scanner components.

Owner:IBM CORP

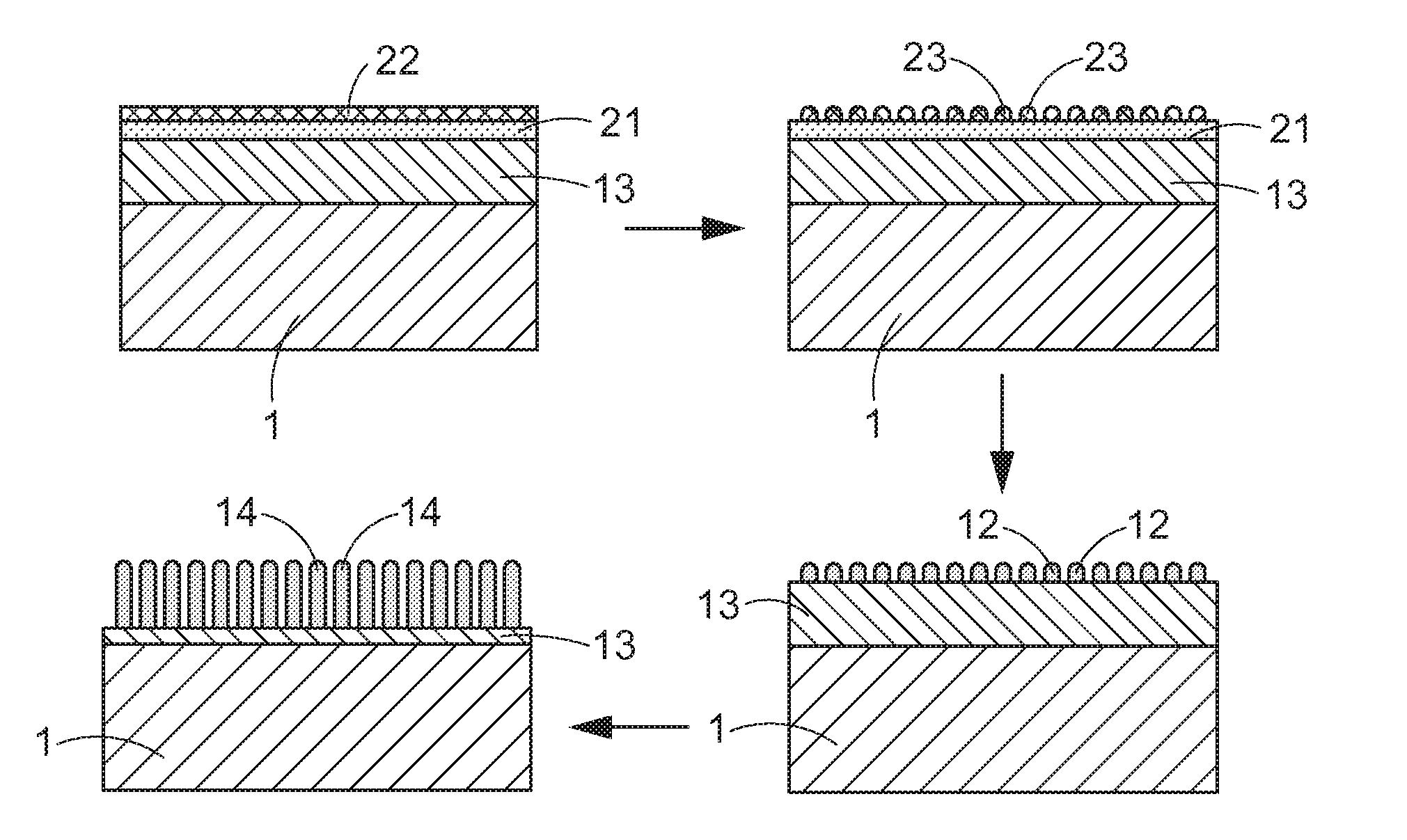

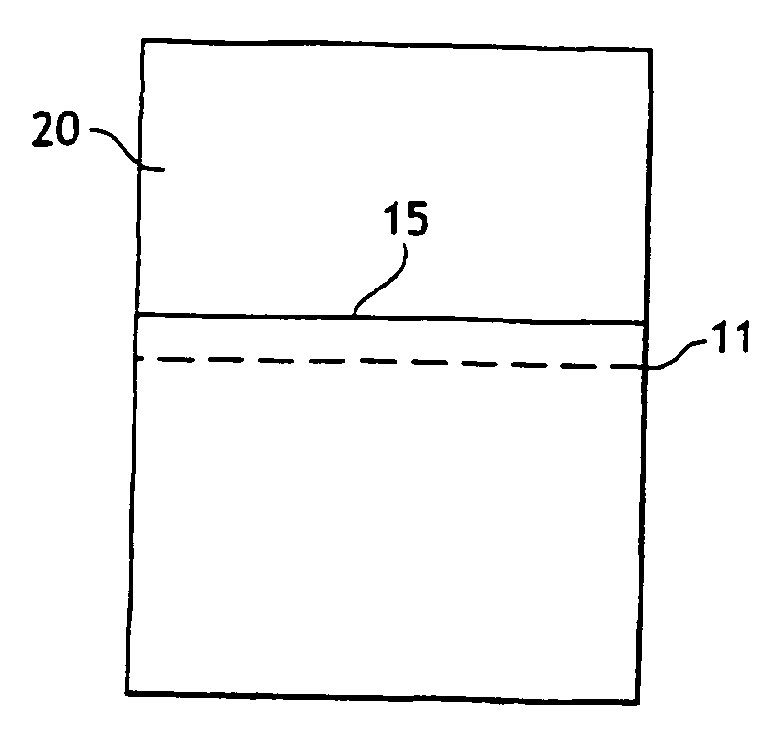

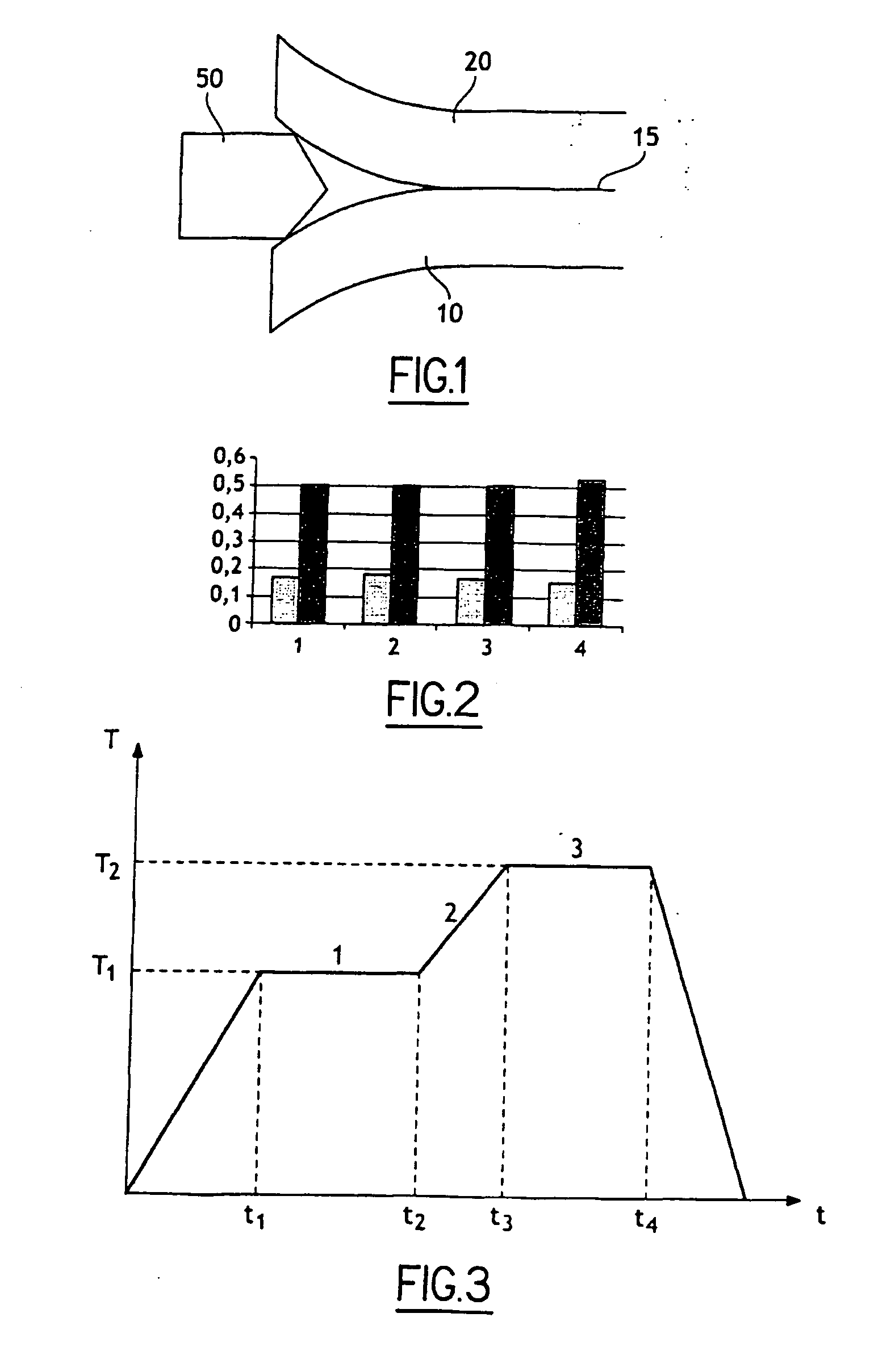

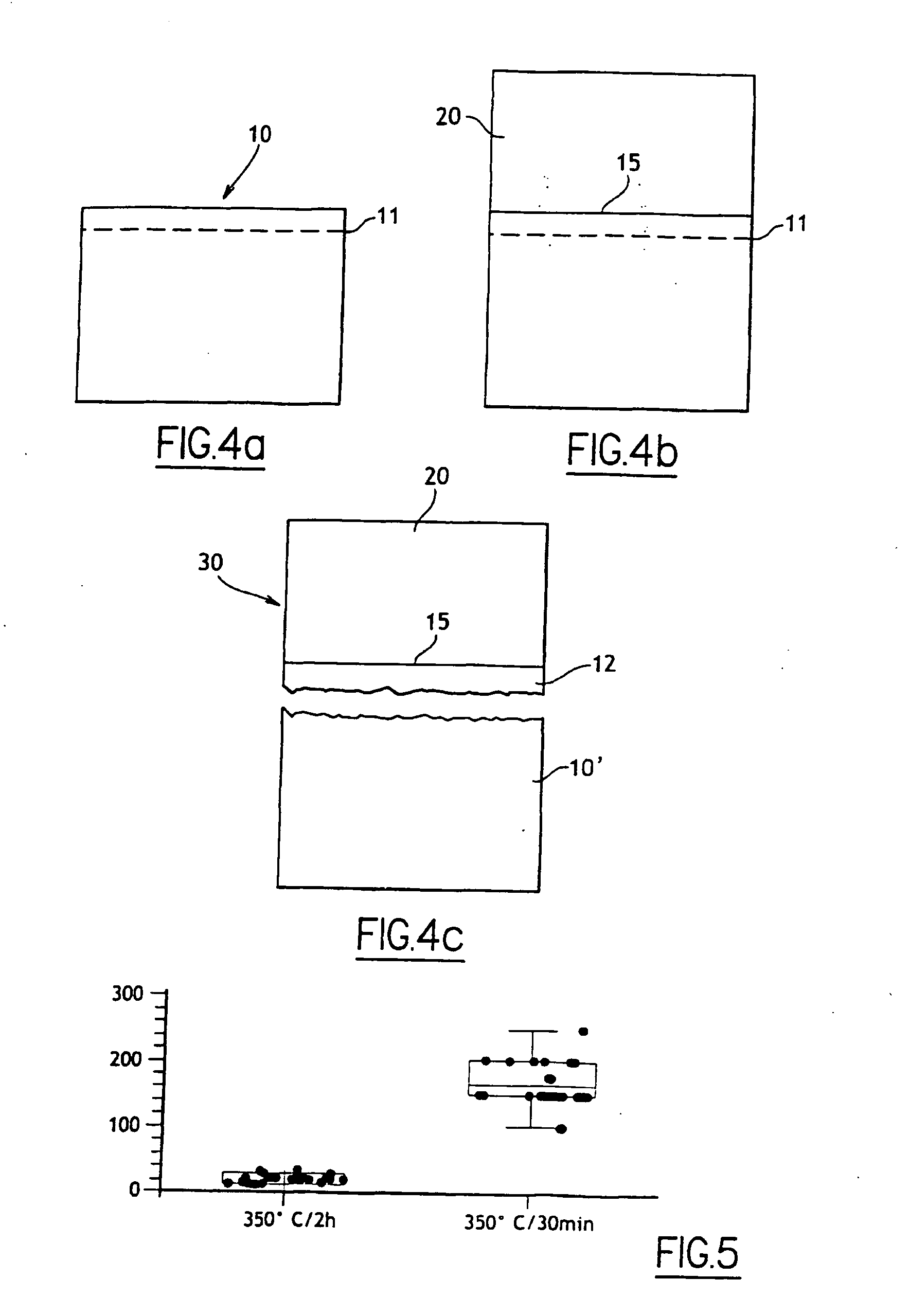

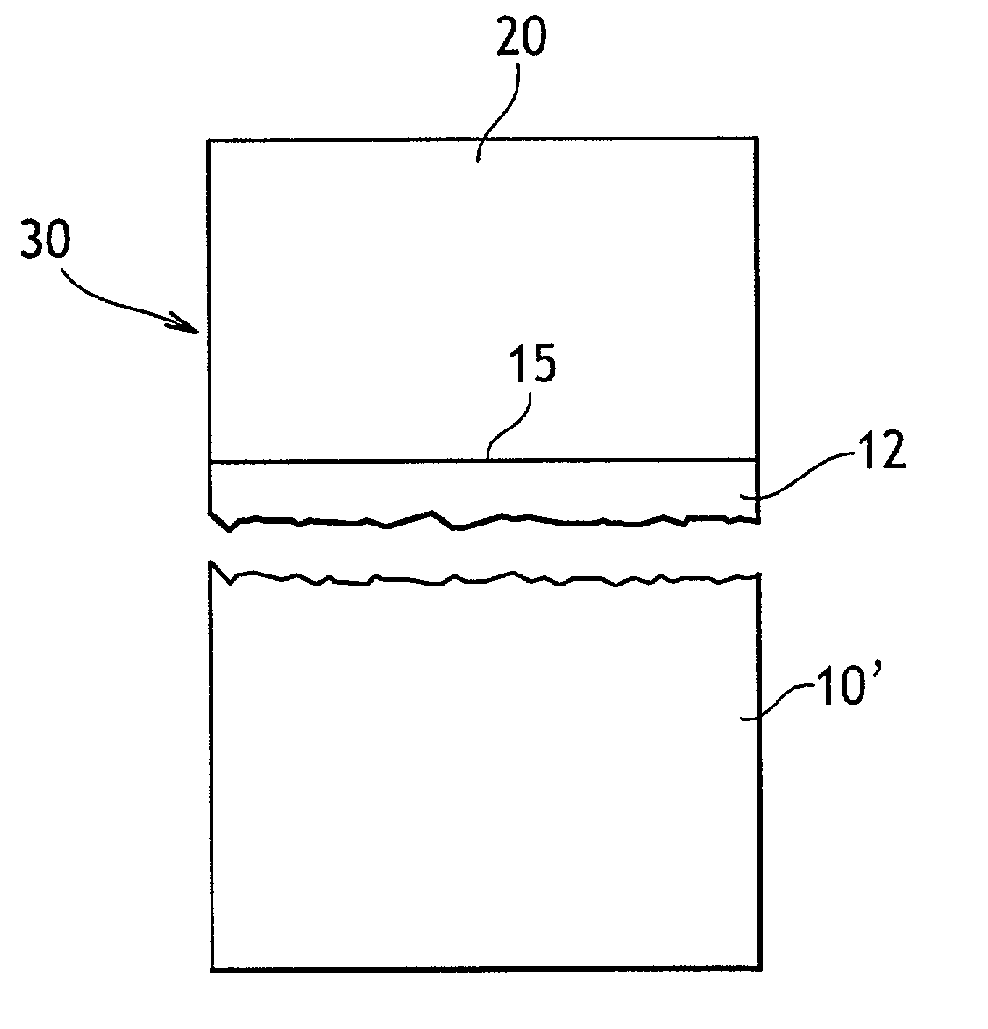

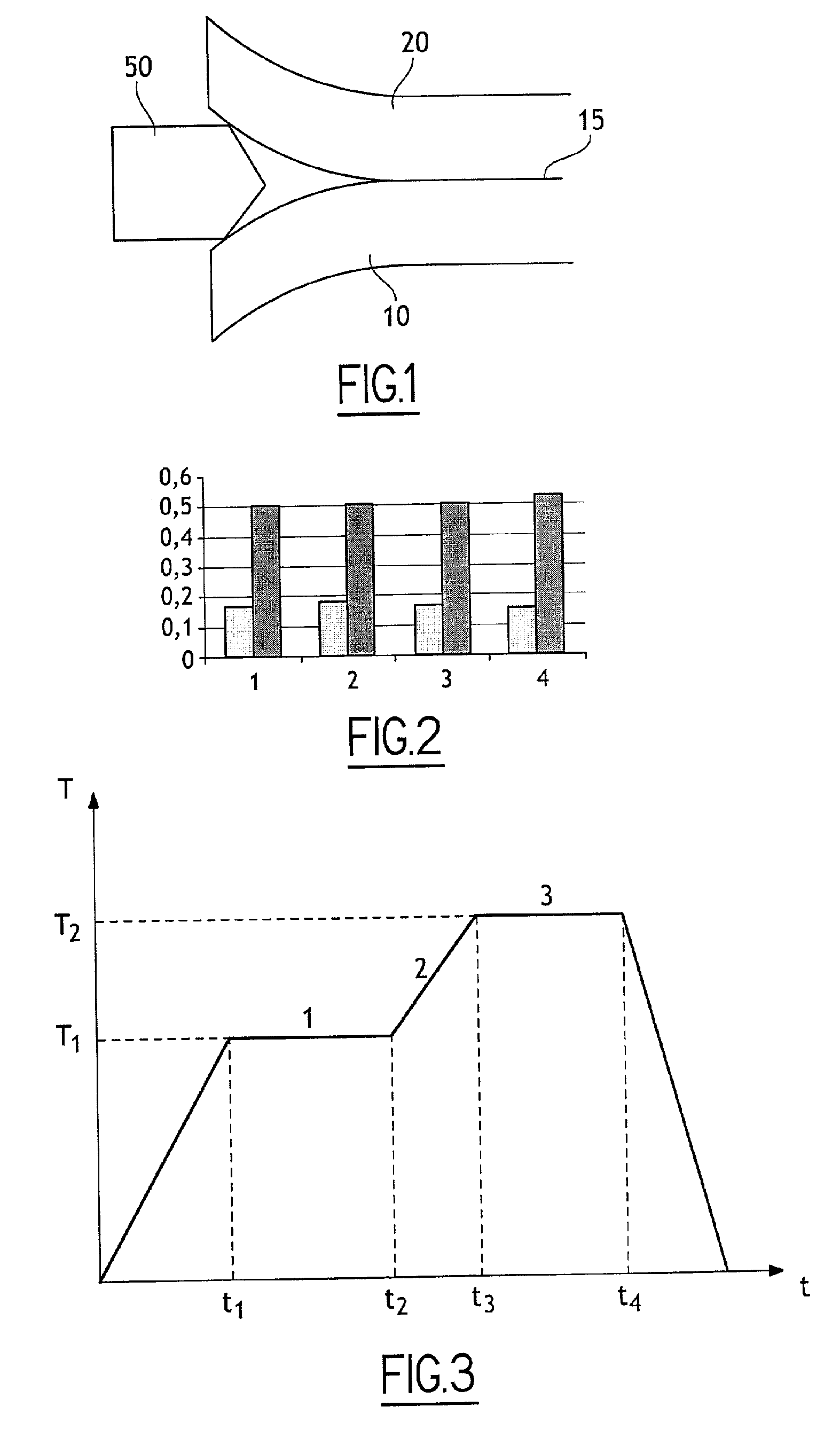

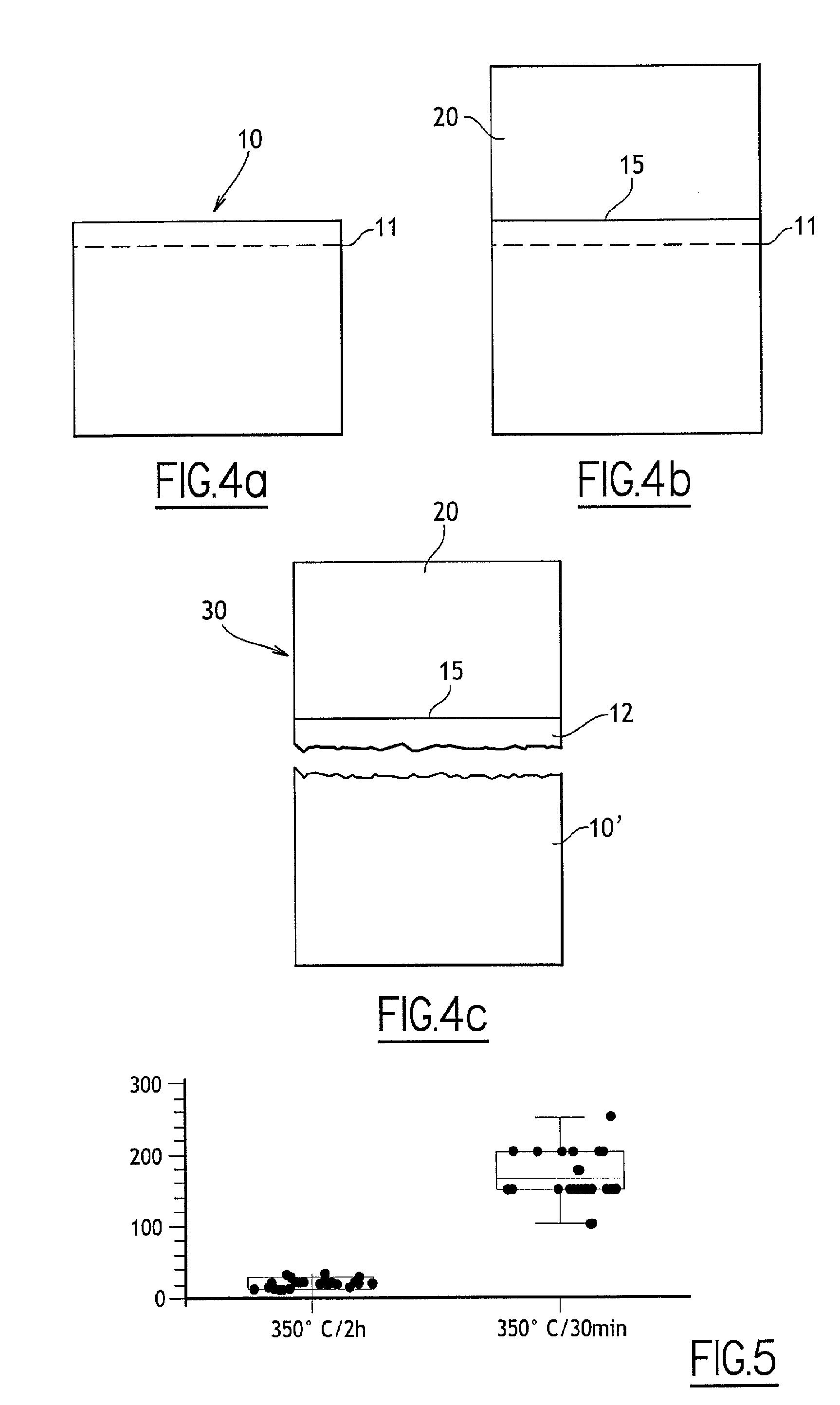

Methods for minimizing defects when transferring a semiconductor useful layer

InactiveUS20060040470A1Defect minimizationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method for minimizing defects when transferring a useful layer from a donor wafer to a receptor wafer is described. The method includes providing a donor wafer having a surface below which a zone of weakness is present to define a useful layer to be transferred, molecularly bonding at a bonding interface the surface of the useful layer of the donor wafer to a surface of the receptor wafer to form a structure, heating the structure at a first temperature that is substantially higher than ambient temperature for a first time period sufficient to liberate water molecules from the bonding interface, with the heating being insufficient to cause detachment of the useful layer at the zone of weakness, and detaching the useful layer from the donor wafer.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

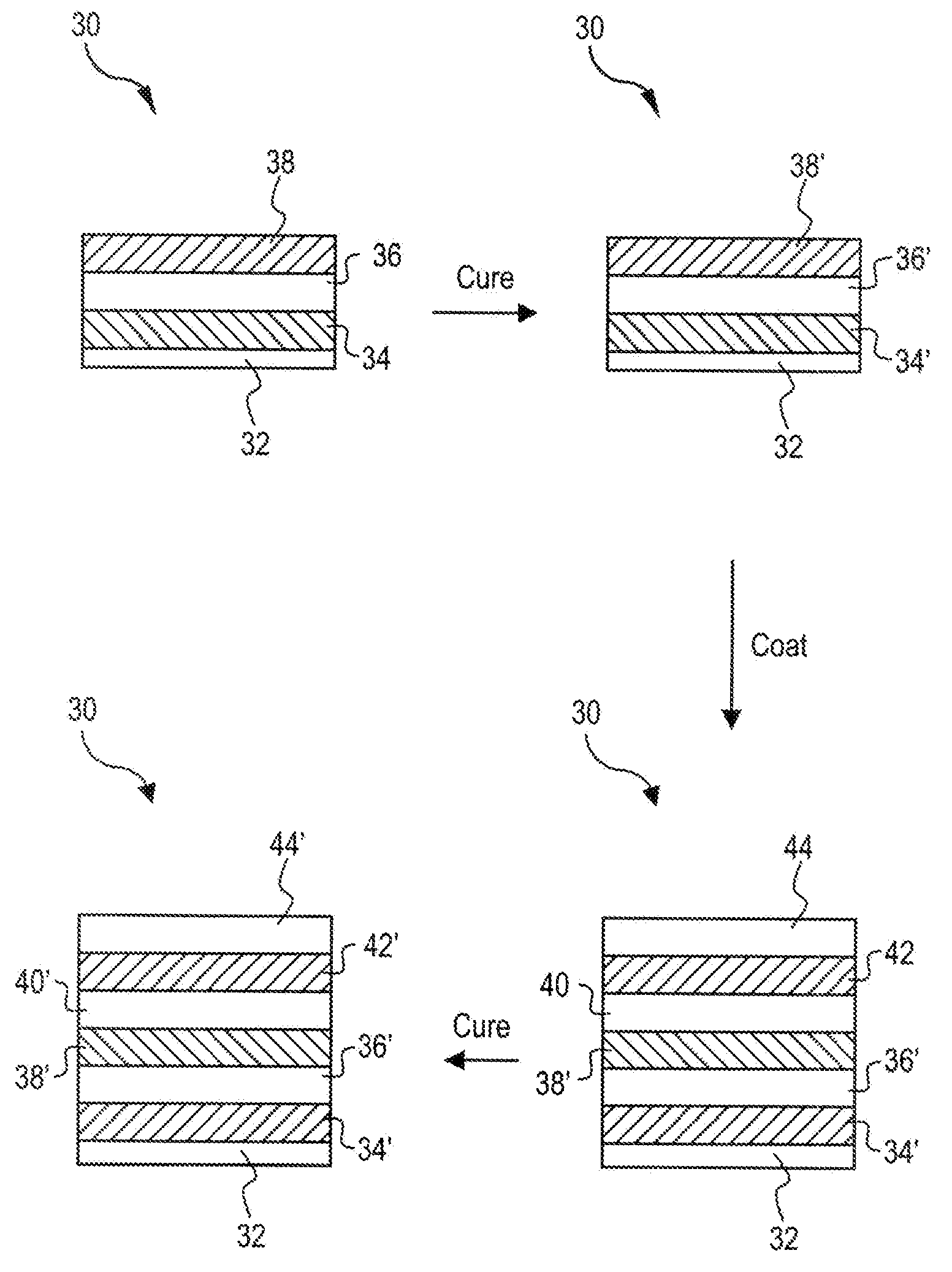

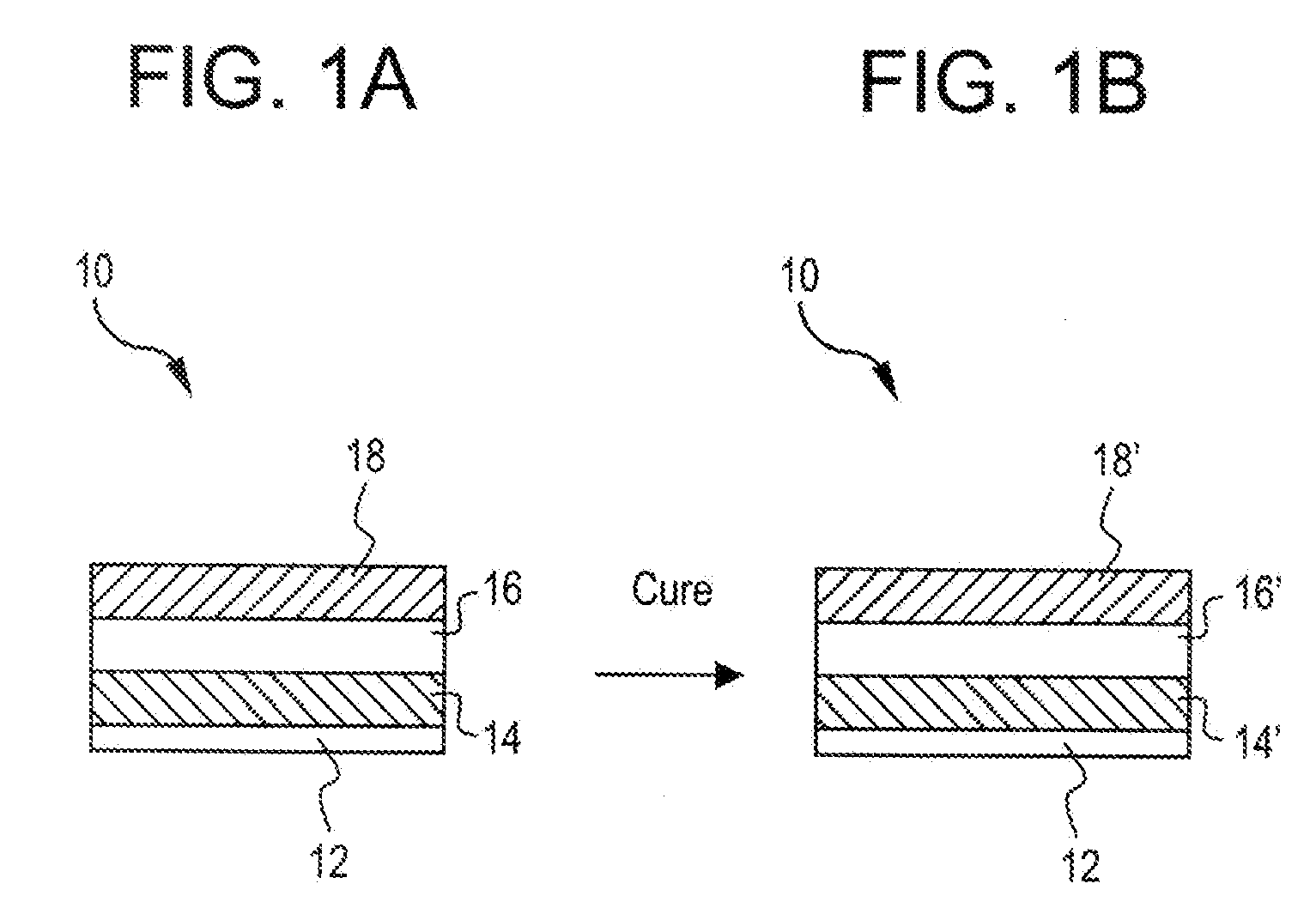

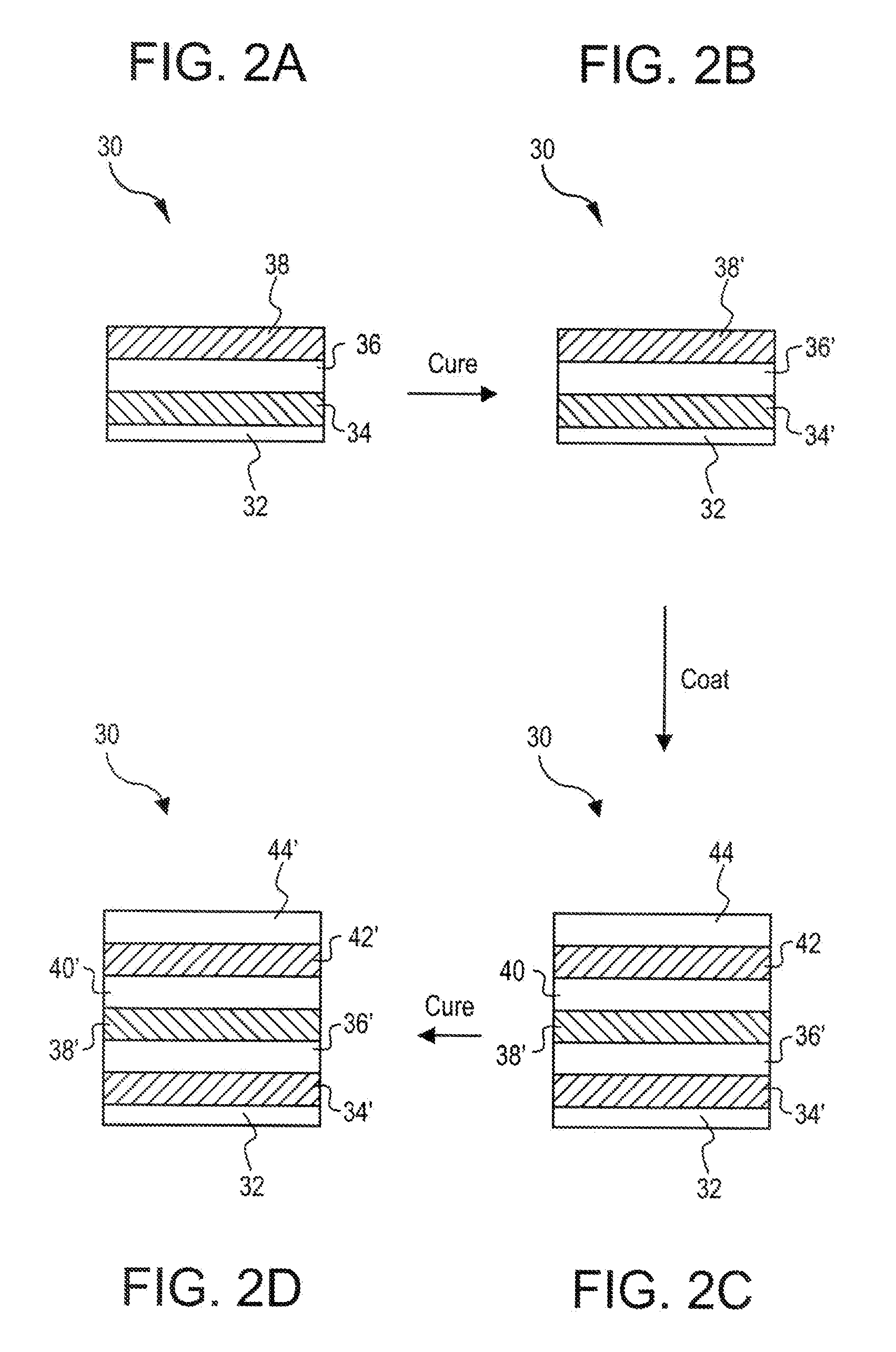

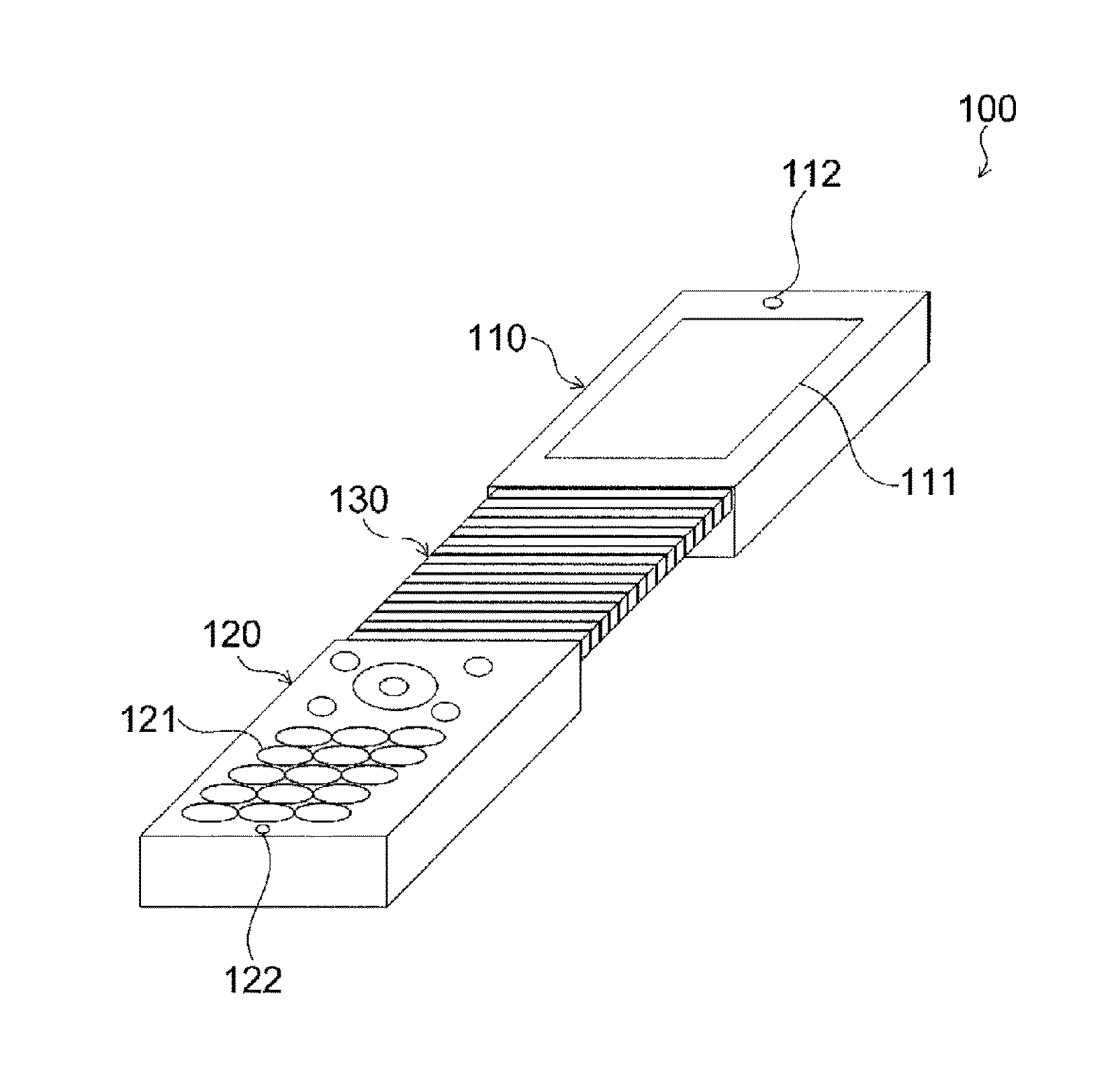

Methods of forming composite powder coatings and articles thereof

InactiveUS20090130304A1Improve manufacturing efficiencyMinimize defectLiquid surface applicatorsCoatingsAqueous corrosionFretting

A method of forming a composite powder coating comprises depositing multiple layers of a powder coating composition onto a substrate, wherein adjacent layers are formed of a different powder coating composition; and curing the multiple layers of the powder coating composition in a single thermal curing step. The layers can be used to protect power generation equipment from aqueous corrosion, particle erosion, slurry erosion, fretting, and foulig.

Owner:GENERAL ELECTRIC CO

Folding portable device and connecting mechanism

InactiveUS8855726B2Improve the immunityDefect minimizationInterconnection arrangementsDetails for portable computersEngineeringFlexible electronics

A folding portable device is provided, in which a connecting mechanism that mechanically connects a first housing and a second housing to each other includes a plurality of first members including a first plane and two engaging pieces provided on the first plane, and a plurality of second members including a second plane, an engaging groove provided on the second plane for the engaging piece to be slidably fitted, and a stopper. The first member is engaged with one of the second members by means of one of the two engaging pieces, and with another second member adjacent to the one second member by means of the other of the two engaging pieces, and the connecting mechanism includes therein a hollow portion formed along an extending direction of the engaging groove, and the hollow portion includes therein the flexible printed circuit board.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Method of manufacturing acrylic film, and acrylic film

InactiveUS20120121881A1Small thickness deviationHigh thickness accuracySynthetic resin layered productsFlat articlesUltraviolet lightsElectronic component

The present invention relates to a method for manufacturing an acrylic film and to an acrylic film manufactured by same, the method comprising: a first step of coating an acryl-based resin syrup; and a second step of hardening the acryl-based resin syrup coated in the first step by irradiating ultraviolet light. According to the present invention, an excellent film having low thickness deviation and thickness precision may be provided. In addition, defects in the film such as fish eyes and uneven distribution of physical properties in the vertical and horizontal directions may be kept to a minimum. Consequently, the film according to the present invention can be applied to various industrial sheets such as protective films for various semiconductor processes, pressure-sensitive adhesives or adhesives for optical products and pressure-sensitive adhesives or adhesives for electronic components, or to laminated products.

Owner:LG HAUSYS LTD

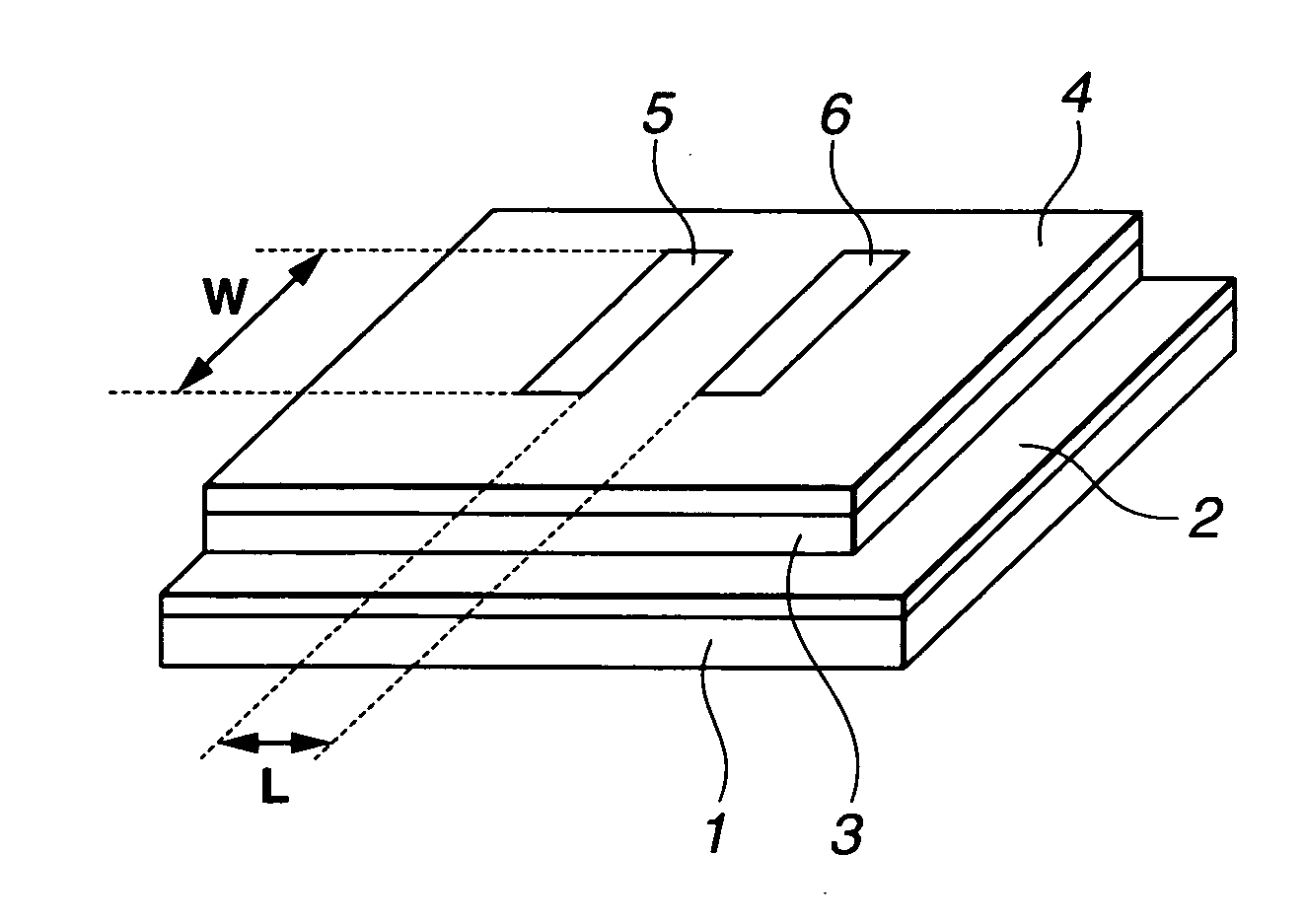

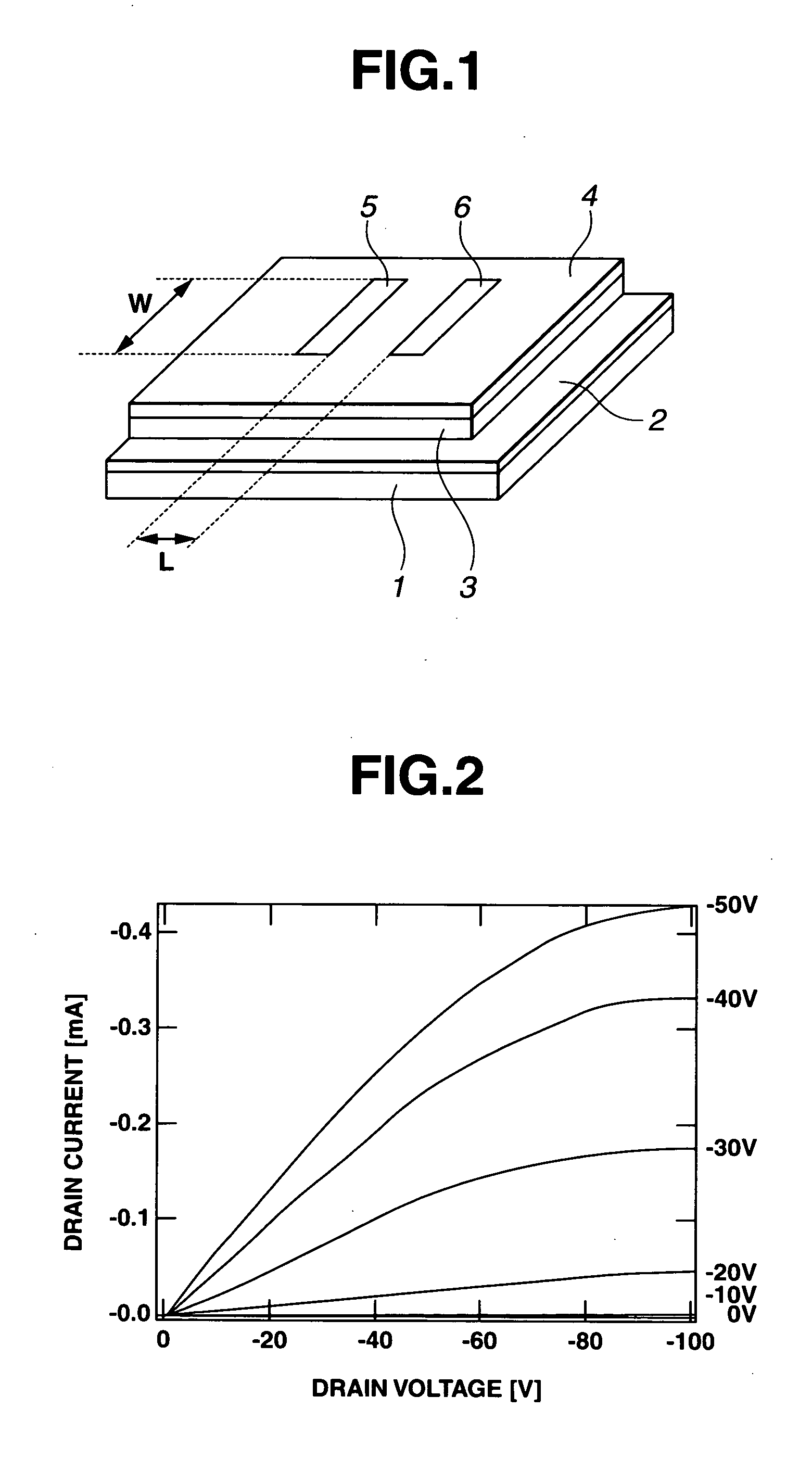

Thin-film field effect transistor and making method

InactiveUS20050045876A1High carrier mobilityDefect minimizationTransistorSolid-state devicesOrganic solventOrganic field-effect transistor

In a thin-film field effect transistor with a MIS structure, the materials of which the semiconductor and insulating layers are made are polymers which are dissolvable in organic solvents and have a weight average molecular weight of more than 2,000 to 1,000,000. Use of polymers for both the semiconductor layer and insulating layer of TFT eliminates such treatments as patterning and etching using photoresists in the prior art circuit-forming technology, reduces the probability of TFT defects and achieves a reduction of TFT manufacture cost.

Owner:SHIN ETSU CHEM IND CO LTD

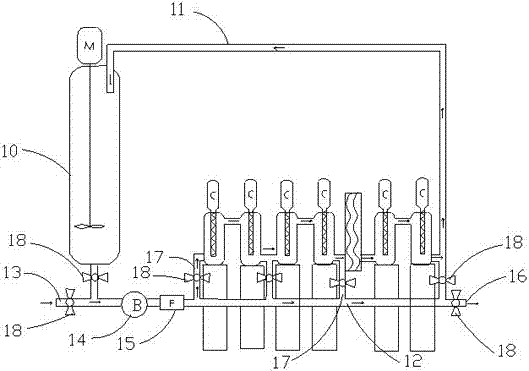

Ceramic firing furnace

InactiveUS20120037610A1Defect minimizationMinimize a defective ceramic substrateMuffle furnacesRetort furnacesInterior spaceProduct gas

A ceramic firing furnace is provided. A uniform gas atmosphere is formed in the ceramic firing furnace to thus minimize a defective ceramic substrate when the ceramic substrate is fired. The ceramic firing furnace includes: a case having an internal space in which a shaped body is disposed; a heating element disposed in the interior of the case and radiating heat; and a plurality of air supply units fastened through the case such that the plurality of air supply units are rotatable by an external force, and supplying a gas to the internal space of the case.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Nano silver loaded graphene antibacterial composite material and preparation method thereof

InactiveCN107568246AReturn to normal structureAvoid discontinuitiesBiocideDisinfectantsEscherichia coliAntibacterial activity

The invention relates to the field of graphene composite materials and discloses a nano silver loaded graphene antibacterial composite material and a preparation method thereof. A single-layer graphene oxide solution is obtained through a secondary ultrasonic dispersion technology and a discontinuous sheet layer is prevented; a carbon cake formed by mutually mixing a plurality of layers of graphene oxide sheets is innovatively subjected to secondary hydrothermal method reaction; green reduction agents including glucose and ascorbic acid and a green stabilizer soluble starch are adopted respectively and the hydrothermal method reaction is matched, so that the reduction rate is extremely improved and a sealing system with relatively high temperature and inner pressure is adopted; the recycling of dehydrated p conjugation is also promoted and the minimization of defects is facilitated; after heat treatment is carried out, the structure of graphene is easy to recover; the antibacterial activity of free Ag nanoparticles is remained in the composite material. The loading amount of silver particles in the nano silver loaded graphene antibacterial composite material reaches 58.0 percent and the antibacterial rate on escherichia coli reaches 99.9 percent.

Owner:郴州博太超细石墨股份有限公司

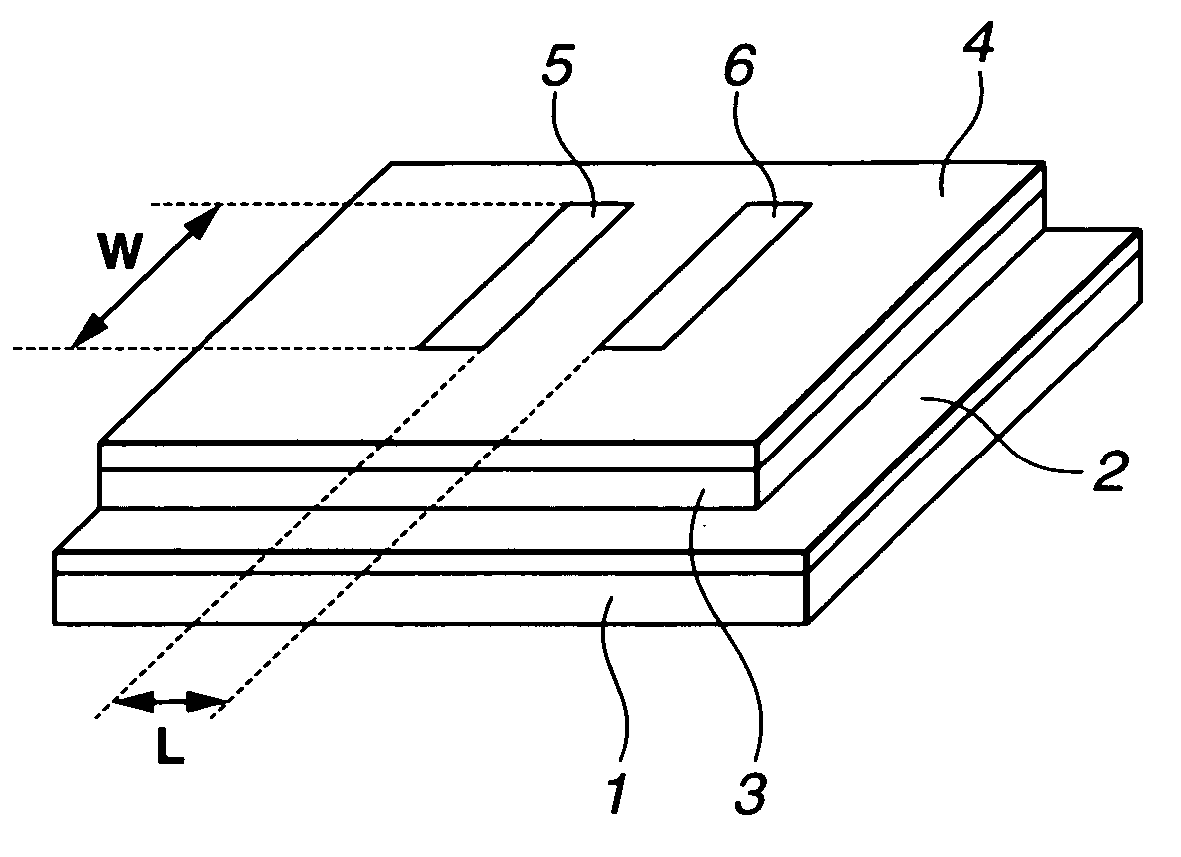

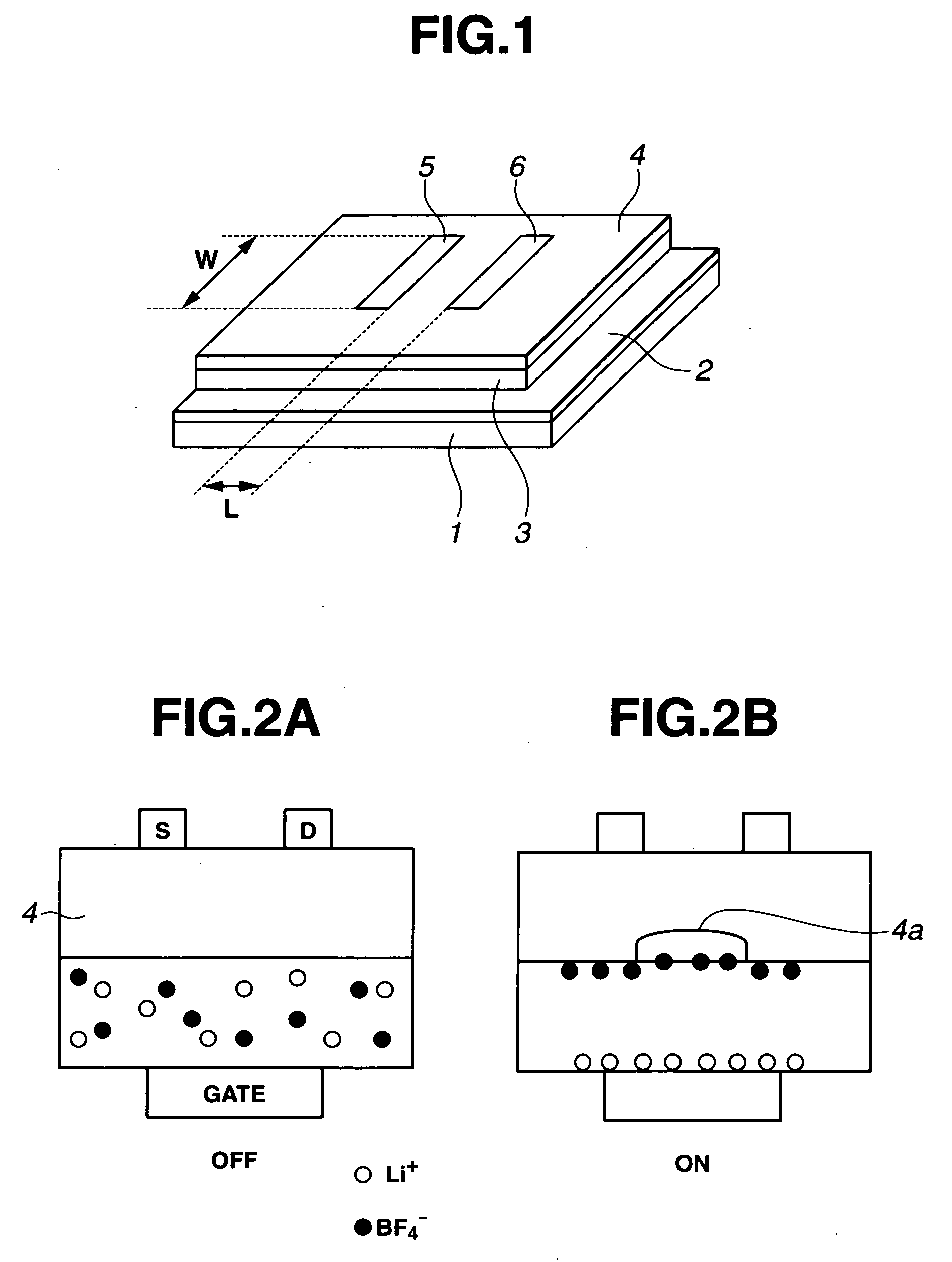

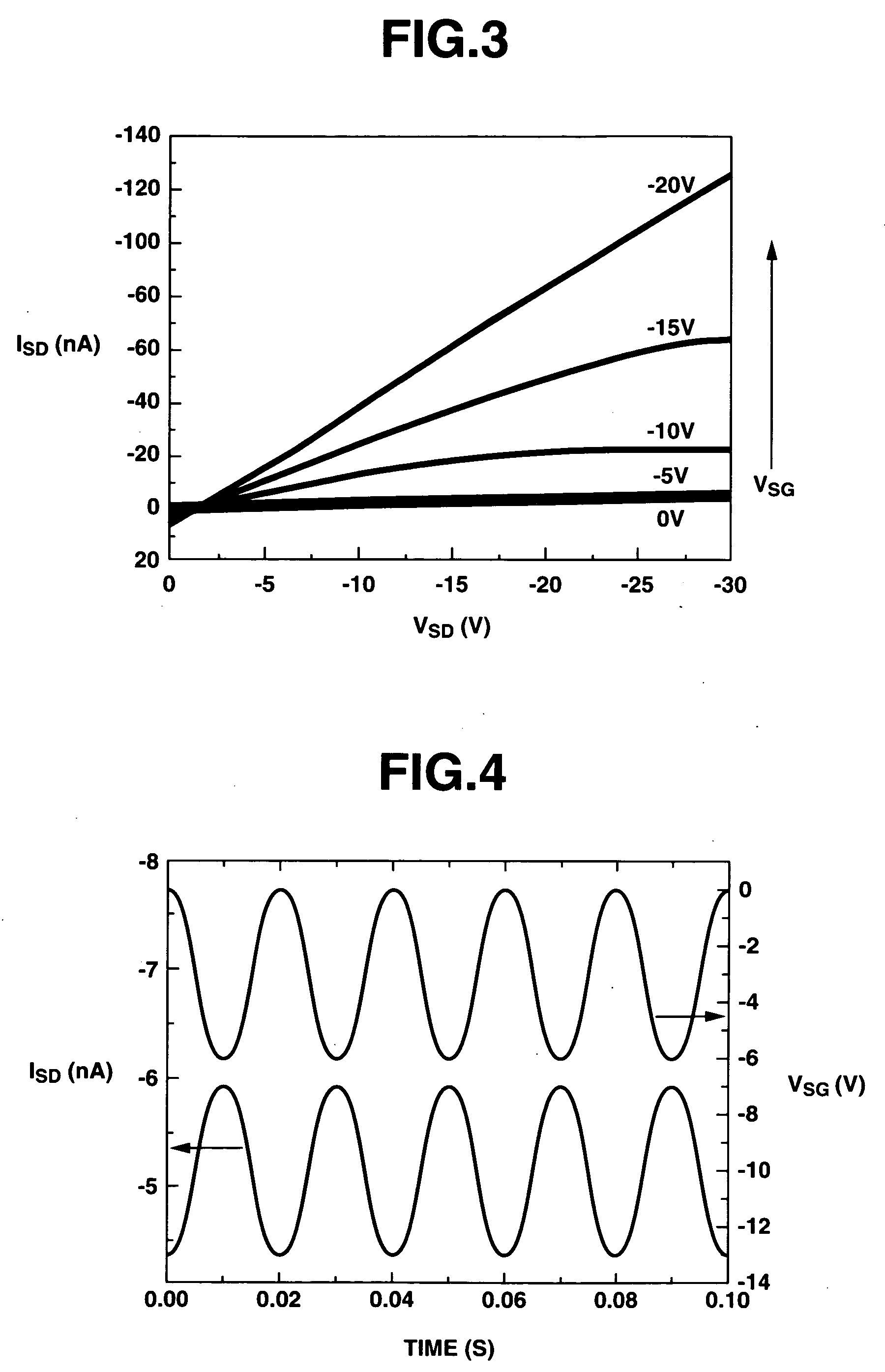

Thin-layer chemical transistor and making method

ActiveUS20060043432A1Defects can be minimizedDefect minimizationSemiconductor/solid-state device detailsSolid-state devicesOrganic solventSemiconductor structure

In a thin-layer chemical transistor having a metal / solid electrolyte / semiconductor structure, the materials of which the solid electrolyte and semiconductor layers are made comprise organic solvent-soluble compounds. The transistor can be fabricated solely by solvent processes, typically printing techniques including ink jet printing.

Owner:OSAKA UNIV +1

Methods for minimizing defects when transferring a semiconductor useful layer

InactiveUS20070117229A1Defect minimizationSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringSemiconductor

A method for minimizing defects when transferring a useful layer from a donor wafer to a receptor wafer is described. The method includes providing a donor wafer having a surface below which a zone of weakness is present to define a useful layer to be transferred, molecularly bonding at a bonding interface the surface of the useful layer of the donor wafer to a surface of the receptor wafer to form a structure, heating the structure at a first temperature that is substantially higher than ambient temperature for a first time period sufficient to liberate water molecules from the bonding interface, with the heating being insufficient to cause detachment of the useful layer at the zone of weakness, and detaching the useful layer from the donor wafer.

Owner:SOITEC SA

Washing machine having lamp device and control method of the same

InactiveUS8016444B2Long lastingImprove seismic performancePoint-like light sourceElectrical apparatusEffect lightEngineering

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com