Preparation method for improving performance of 4Cr5MoSiV1 hot work die steel

A high-performance technology for hot-working die steel, applied in heating/cooling equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of low mechanical performance index of materials, affecting the service life of molds with comprehensive performance of materials, and unqualified production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

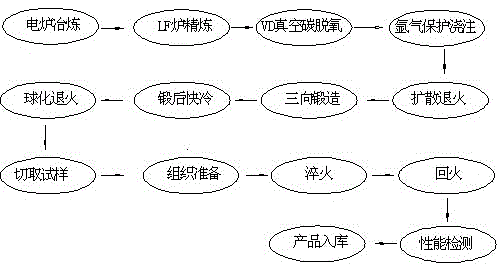

[0024] 1) The molten steel is smelted in an electric furnace, refined in an LF furnace, and subjected to vacuum carbon deoxidation and slag surface full-diffusion deoxidation refining, so that the free oxygen is ≤ 6ppm, and then a mixture of La and Ce with an oxygen content of 60ppm is added. The weight ratio of La and Ce is 3:7, at the same time, rare earth La and Ce account for 0.02% of the total molten steel, realizing the three functions of purifying molten steel, metamorphic inclusions and microalloying, and pouring through atmosphere protection to prevent secondary oxidation of molten steel. ;

[0025] 2) The steel ingot in step 1) is demolded and sent to the forging workshop, heated to 1250-1260°C, and subjected to 25-27 hours of heat preservation, diffusion, and homogenization annealing to reduce the segregation of C, Cr, Mo, and V components in the steel through diffusion. Reduce the level of zonation to lay the foundation for increased strength and isotropy;

[0026...

Embodiment 2

[0034] 1) The molten steel is smelted in an electric furnace, refined in an LF furnace, and subjected to vacuum carbon deoxidation and slag surface full-diffusion deoxidation refining, so that the free oxygen is ≤ 6ppm, and then a mixture of La and Ce with an oxygen content of 50ppm is added. The weight ratio of La and Ce is 3:7, at the same time, rare earth La and Ce account for 0.02% of the total molten steel, realizing the three functions of purifying molten steel, metamorphic inclusions and microalloying, and pouring through atmosphere protection to prevent secondary oxidation of molten steel. ;

[0035] 2) The steel ingot in step 1) is demolded and then hot sent to the forging workshop. After heating to 1260-1280°C, 26-28 hours of heat preservation, diffusion, and homogenization annealing, the segregation of C, Cr, Mo, and V components in the steel can be reduced by diffusion. Reduce the level of zonation to lay the foundation for increased strength and isotropy;

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com