Method for preparing p-xylene from benzene and methanol through alkylation

A p-xylene and alkylation technology, applied in chemical instruments and methods, isomerization hydrocarbon production, organic chemistry, etc., can solve the problems of low production efficiency of reactors, underutilization of catalysts, high energy consumption of separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

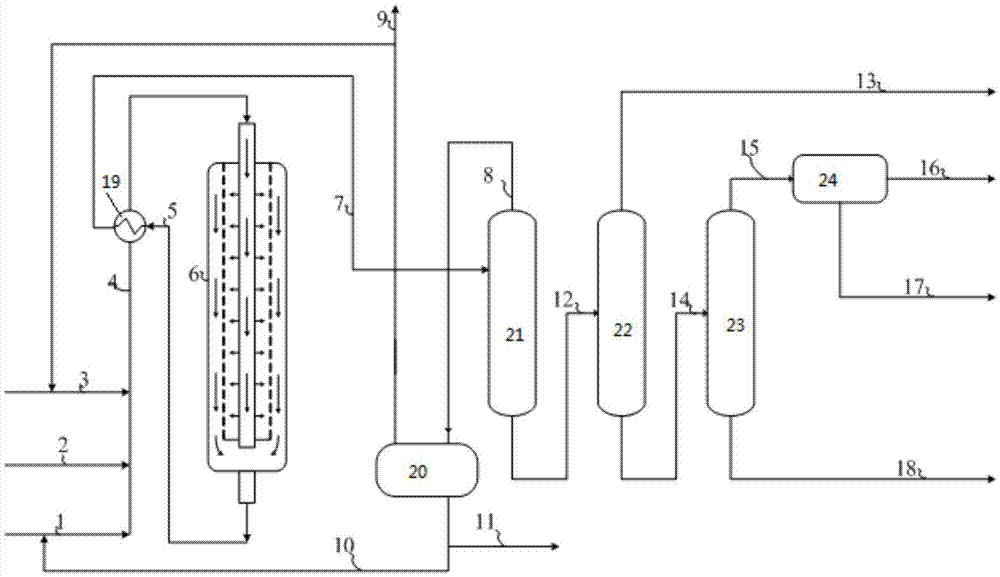

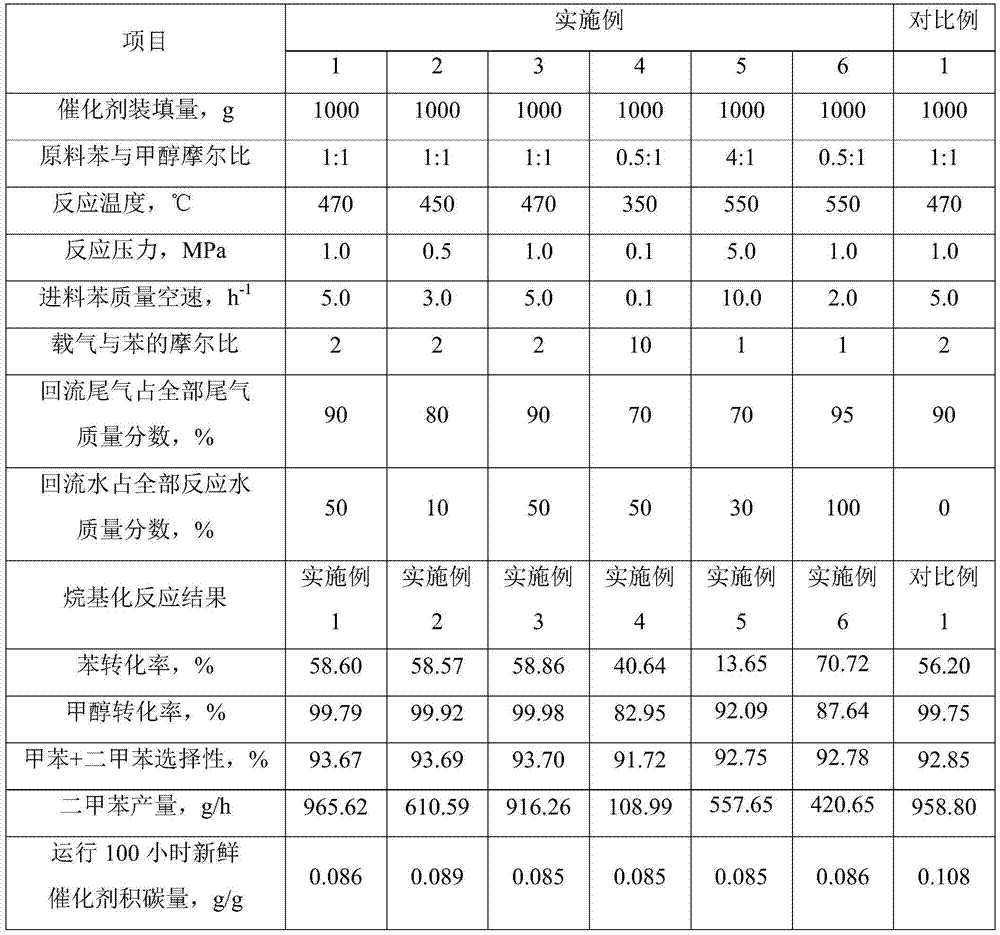

[0065] as attached figure 1 , the fixed bed radial reactor technology was selected for the alkylation reaction experiment, the catalyst loading was 1000 grams, the molar ratio of benzene and methanol as the reaction raw material was 1:1, and the reaction process conditions were: reaction temperature 470°C, reaction pressure 1.0MPa, Material benzene mass space velocity 5.0h -1 , the molar ratio of hydrogen to feed benzene is 2; the reflux tail gas accounts for 90% of the total tail gas volume fraction; the reflux water accounts for 50% of the total reaction water mass fraction.

Embodiment 2

[0067] as attached figure 1 , choose the fixed bed radial reactor technology to carry out the alkylation reaction experiment, the catalyst load is 1000 grams, the molar ratio of reaction raw material benzene and methanol is 1:1, reaction process conditions: reaction temperature 450 ℃, reaction pressure 0.5MPa, carry out Material benzene mass space velocity 3.0h -1 , the molar ratio of nitrogen to feed benzene is 2; the reflux tail gas accounts for 80% of the total tail gas volume fraction; the reflux water accounts for 10% of the total reaction water mass fraction.

Embodiment 3

[0069] as attached figure 1 , choose the fixed bed radial reactor technology to carry out the alkylation reaction experiment, the catalyst load is 1000 grams, the molar ratio of reaction raw material benzene and methanol is 4:1, reaction process conditions: reaction temperature 470 ℃, reaction pressure 1.0MPa, carry out Material benzene mass space velocity 5.0h -1 , the molar ratio of hydrogen to feed benzene is 2; the reflux tail gas accounts for 90% of the total tail gas volume fraction; the reflux water accounts for 50% of the total reaction water mass fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com