Gas circuit axial grading type dual-fuel nozzle

A staged, dual-fuel technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problem of deteriorating working environment of gas turbine blades, lower uniformity of temperature field at the outlet of combustion chamber, poor mixing of pyrolysis gas and air, etc. problem, to achieve the effect of increasing the radial size, shortening the flame, and strengthening the combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

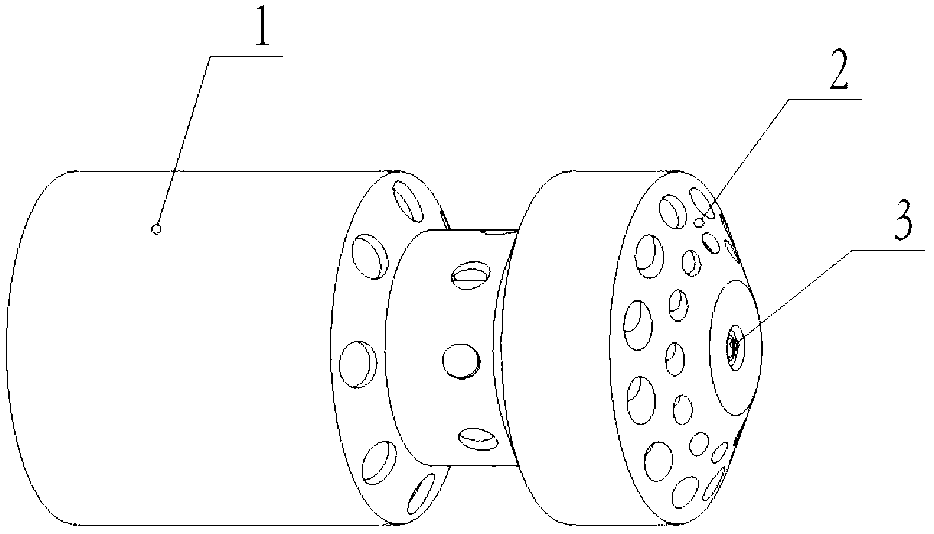

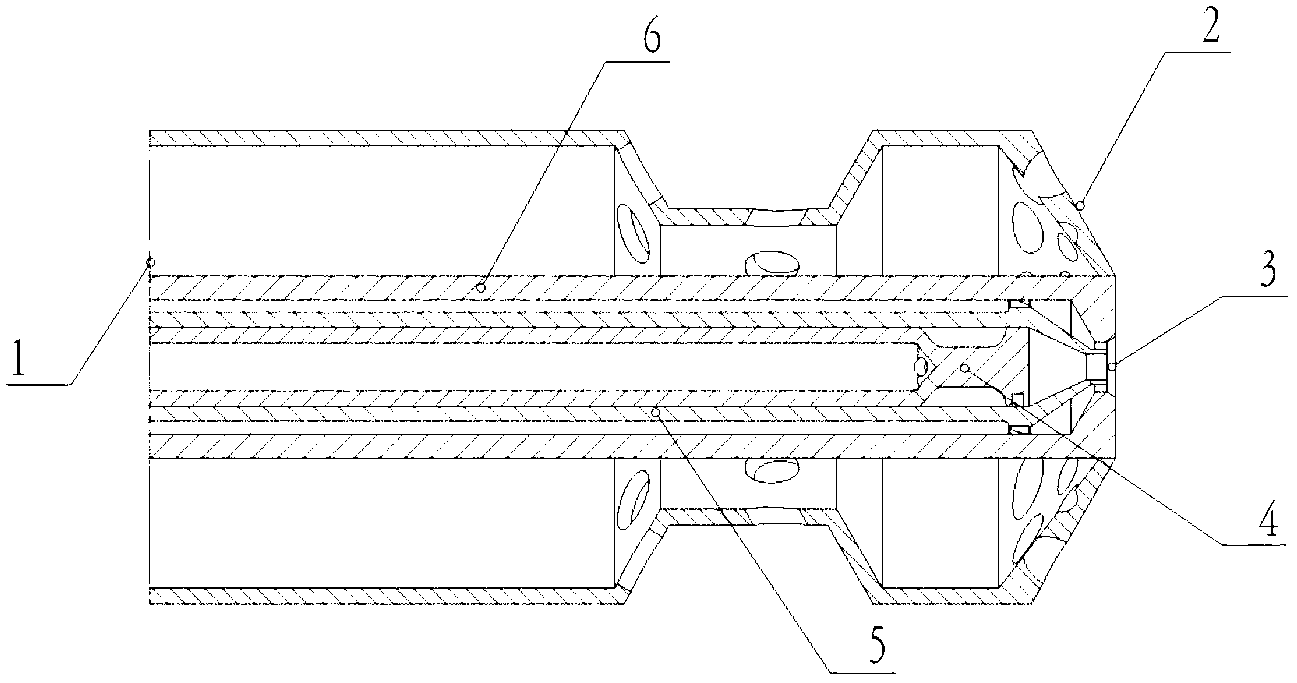

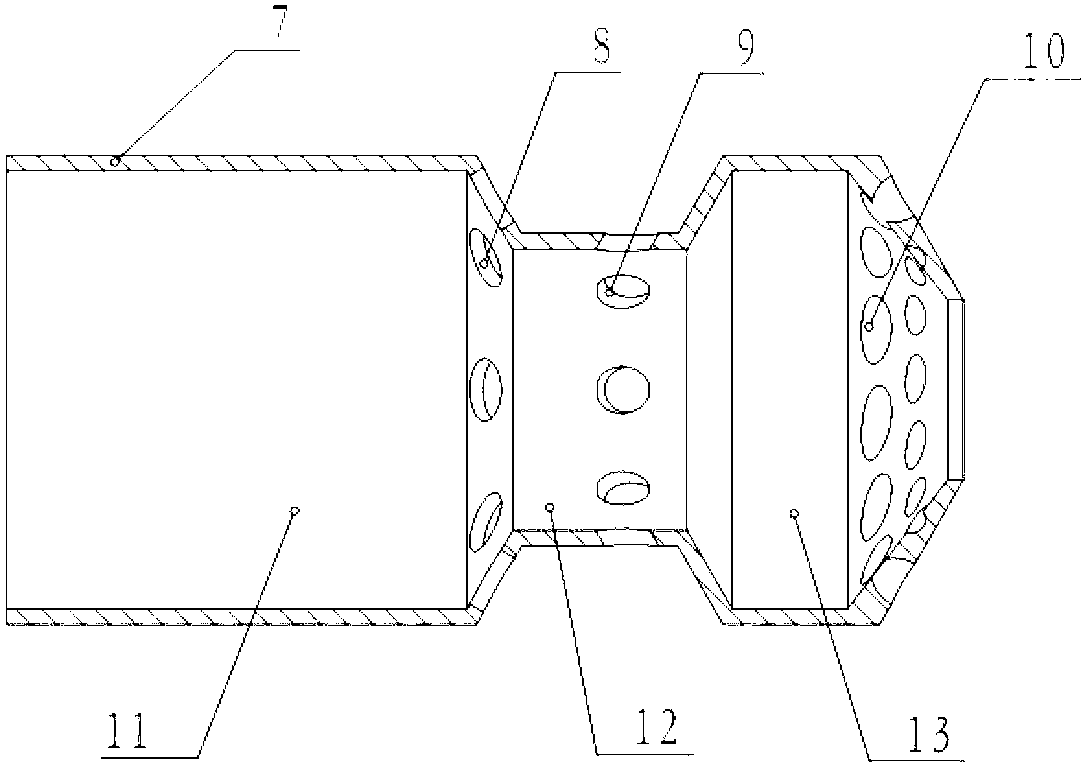

[0017] combine Figure 1~3 , an air path axially graded dual fuel nozzle 1 of the present invention includes an outer wall of the gas path 7, a main oil path pipeline 6, an auxiliary oil path pipeline 5, and an auxiliary oil path swirler 4, and the gas path 2 adopts an axially graded arrangement , the oil circuit 3 pipeline is installed in the middle of the gas circuit 2 and forms a gas circuit cavity between the outer wall of the gas circuit 7, and the gas circuit 2 is divided into a gas circuit front cavity 11 and a gas circuit rear cavity 13 through the gas circuit throat part 12, and the gas fuel It is ejected through the jet holes 8, 9, 10 of the primary, throat and secondary air passages, and the liquid fuel is injected into the combustion chamber through the main and auxiliary oil passages 6, 5, and water can be injected back through the air passage during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com