Three-phase separator and device for biological sewage purification

A three-phase separator, a pair of technology, applied in biochemical instruments, biochemical equipment and methods, gas production bioreactors, etc., can solve problems such as large number of parts and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

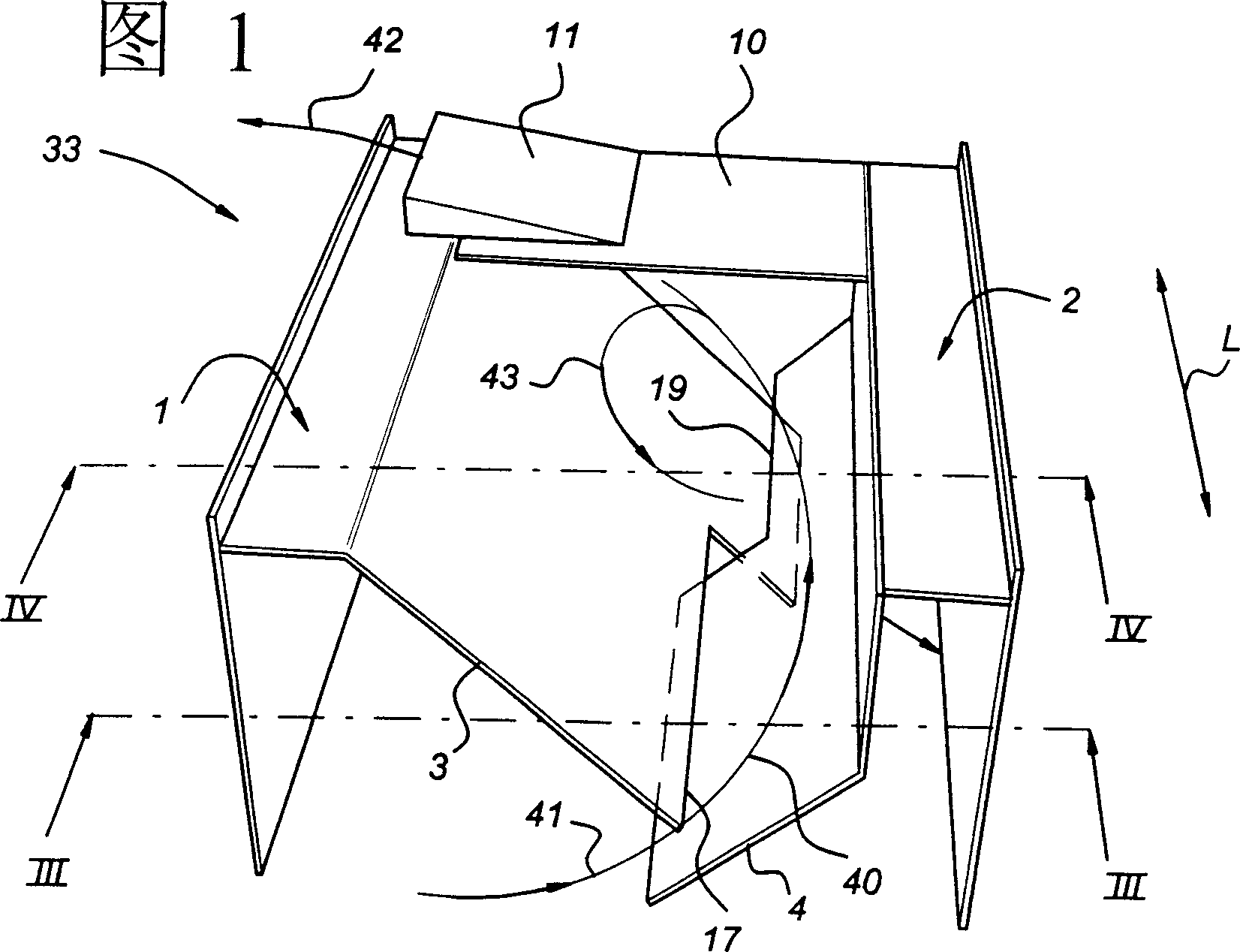

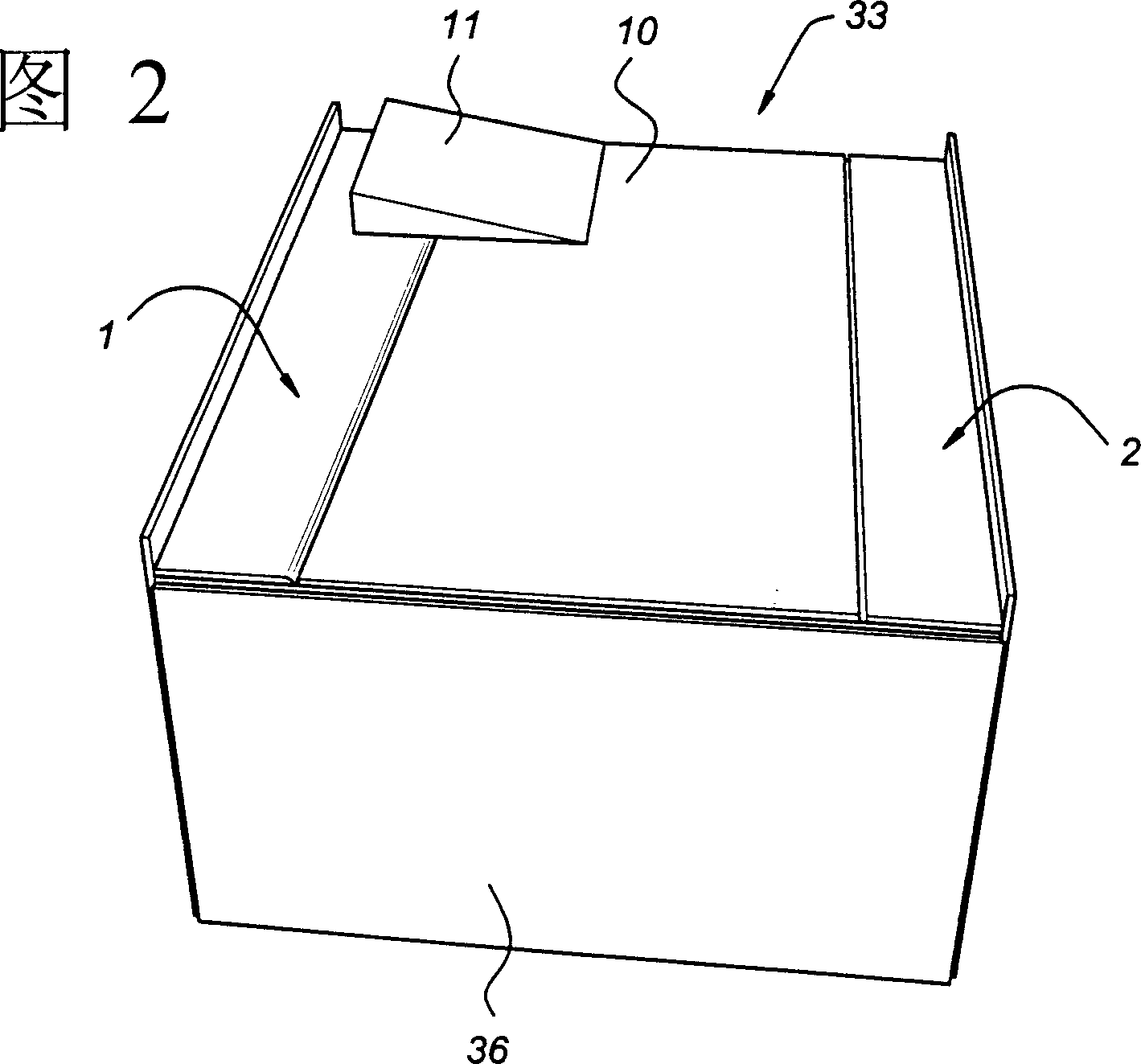

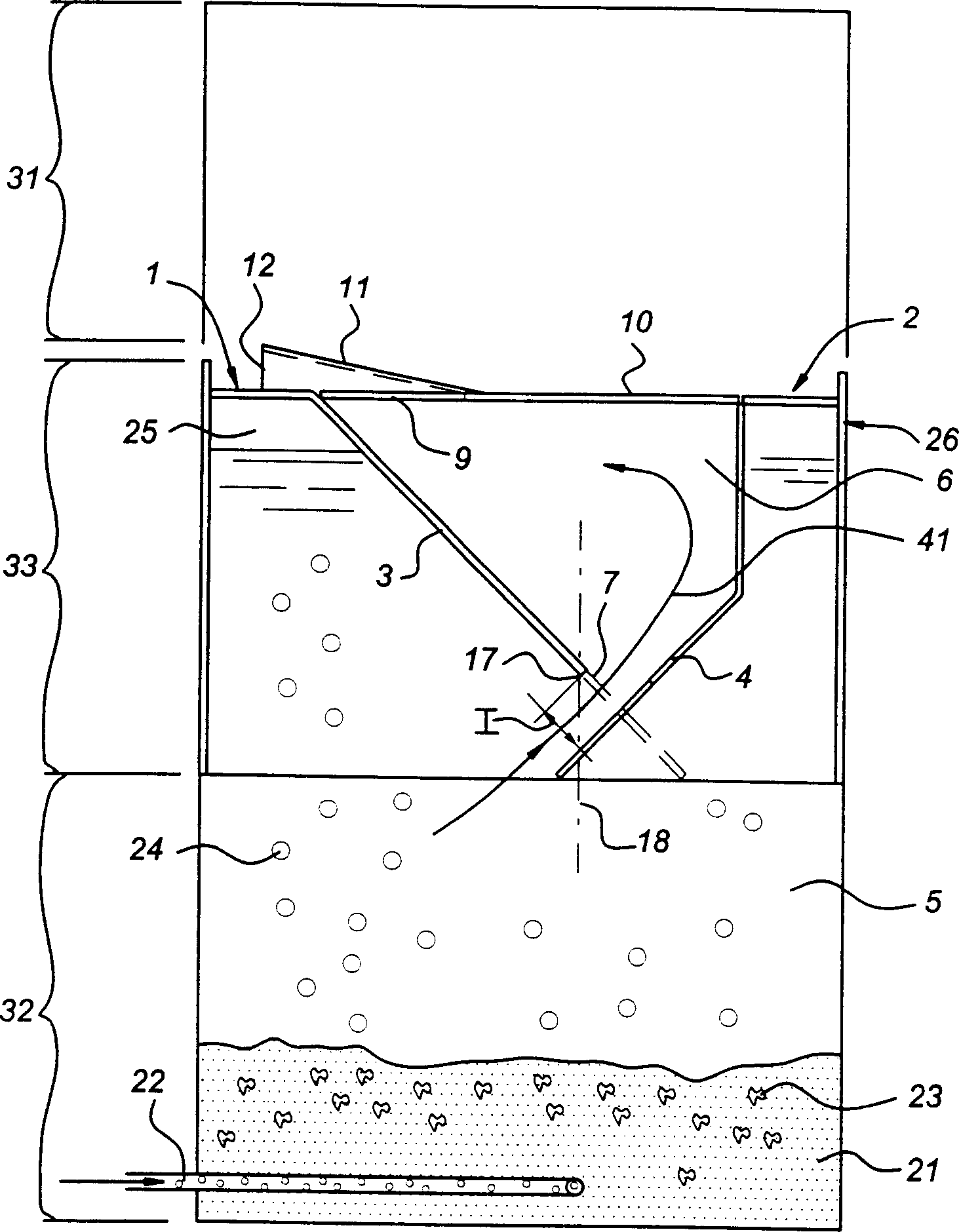

[0024] Accompanying drawing shows a three-phase separator 33, then Figure 5 A pair of three phase separators 33 are shown. The three-phase separator according to the invention comprises a pair of two gas collecting covers 1 and 2 each having a plate section 3 and 4 respectively. These plate parts 3 and 4 converge downwards and leave two elongated channels 7, 8 at their bottom ends. One of the elongated channels is the inlet channel 7 and the other channel is the outlet channel 8 . Viewed in the longitudinal direction L, the inlet channel 7 and the outlet channel 8 lie in extension of each other. Viewed perpendicularly to the longitudinal direction L, the width I of the inlet channel 7 is greater than the width E of the outlet channel 8 . The width I of the inlet channel 7 is, for example, 90 mm and the width E of the outlet channel 8 is 70 mm. More particularly, the width of the two channels ranges from 40 to 120 mm.

[0025] A reaction chamber 5 is located below the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com