Soil leaching remediation reduction system and construction method thereof

A technology of soil leaching and high-pressure jet, which is applied in the field of soil remediation, can solve the problems of large remediation amount, complex equipment structure, and low cost performance, and achieve the effect of reducing the number of stages and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

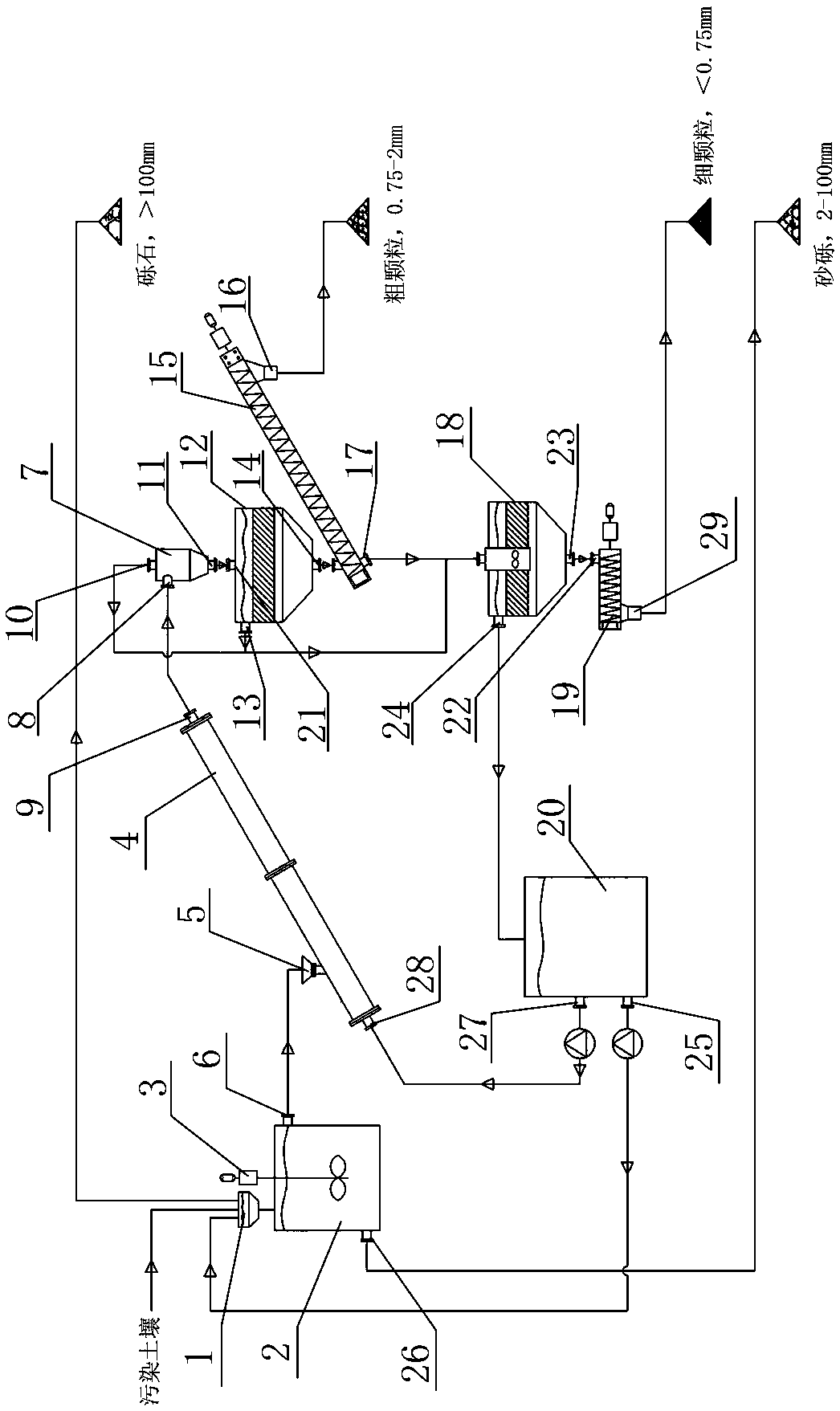

[0053] Such as figure 1 with 2 As shown, a soil washing repair reduction system includes a primary feed classification unit, a high-pressure jet separation unit, a secondary classification unit, a mud settlement concentration unit, a filter press unit, a sewage treatment unit, a dust tail gas treatment unit and Instrument electrical control unit.

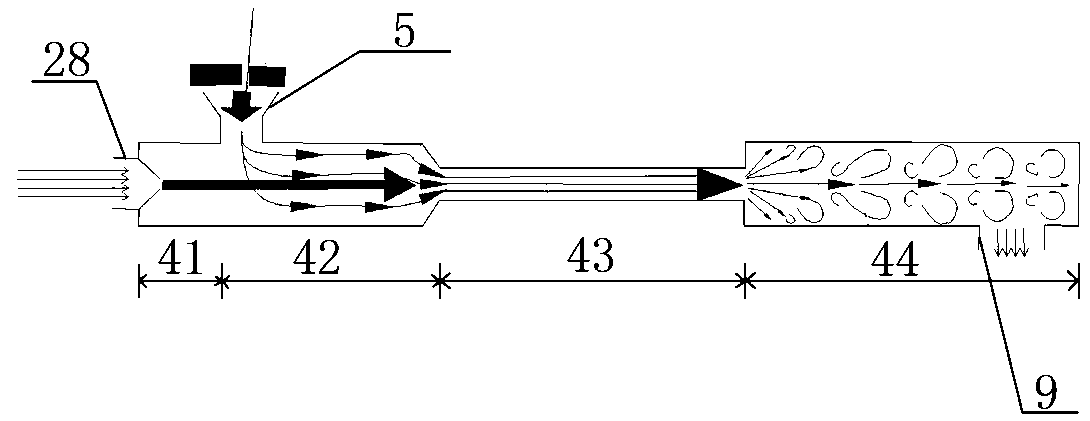

[0054] The feed primary classification unit includes a silo 1, a mud tank 2 arranged at the bottom of the silo 1 and a mud mixer 3 arranged in the mud tank 2, and the upper part of the side wall of the mud tank 2 is provided with an upper discharge port of the mud tank 6. The high-pressure jet separation unit includes a high-pressure jet separation device 4, the high-pressure jet separation feed port 5 of the high-pressure jet separation device 4 communicates with the upper discharge port 6 of the mud tank, and the sewage treatment unit includes sewage treatment reaction equipment 18. Sludge dehydration equipment 19 and circulatin...

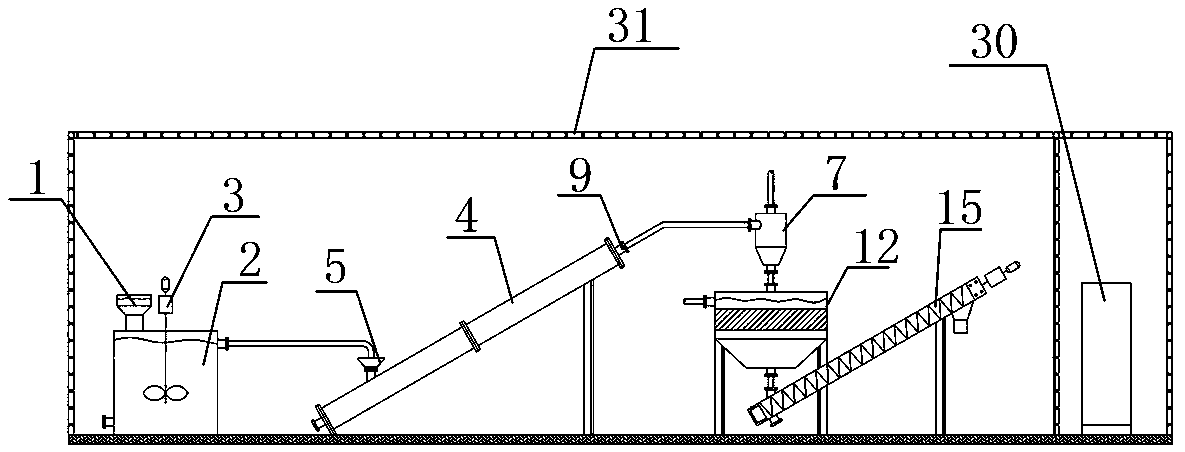

Embodiment 2

[0084] The difference from Example 1 is that the soil washing repair and reduction system in this embodiment is a container-type soil washing repair reduction system, and the soil washing repair reduction system is installed in one or more containers 31, which is convenient Fast moving and processing, in general, the hourly processing capacity ranges from 0.5t / h soil to 2t / h soil. This equipment is designed to run and operate 24 / 7. In this embodiment, the electric control cabinet 30 is installed on one side of the soil washing restoration and weight reduction system, and the electric control cabinet 30 is separated from the soil washing restoration weight reduction system with a baffle.

Embodiment 3

[0086] The difference from Example 1 is that the soil washing restoration reduction system in this embodiment is a skid-mounted soil washing restoration reduction system, and the soil washing restoration reduction system is installed on one or more skid-mounted steel foundations 34, which is convenient for fast movement and processing. Under normal circumstances, the hourly processing capacity ranges from 0.5t to 2t of soil. In this embodiment, the electric control cabinet 30 is installed on one side of the soil washing restoration reduction system, and a steel canopy 32 is installed on the top of the soil washing restoration reduction system and the electric control cabinet 30 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com