High-speed rotary atomization and absorption device for desulfurizing and removing smoke dust

A technology of high-speed rotation and absorption device, applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of low absorption and treatment efficiency of harmful substances, low efficiency of harmful waste gas treatment, and high equipment investment cost, and achieve a one-time The effect of low input cost, significant use effect, low manufacturing and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

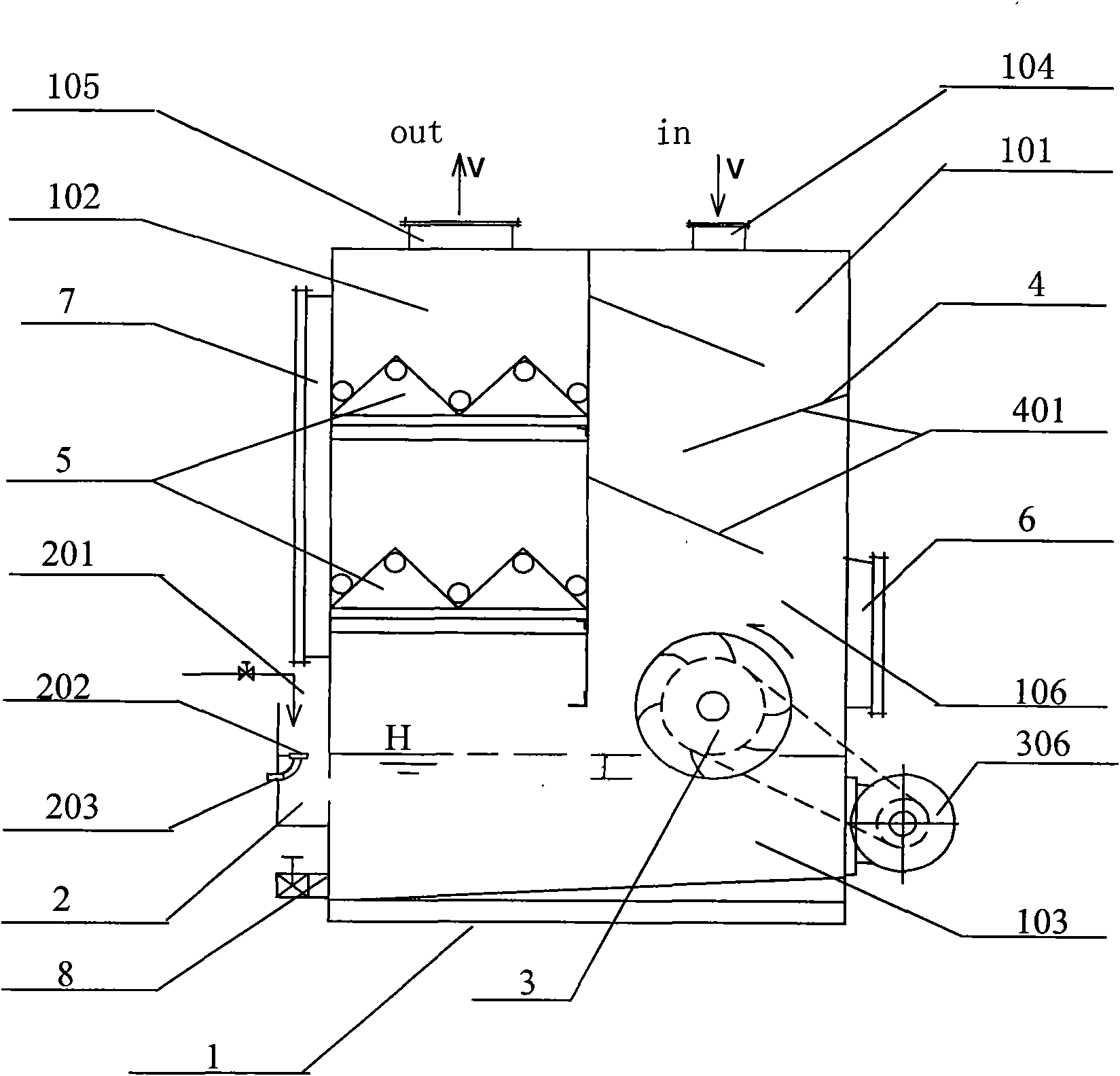

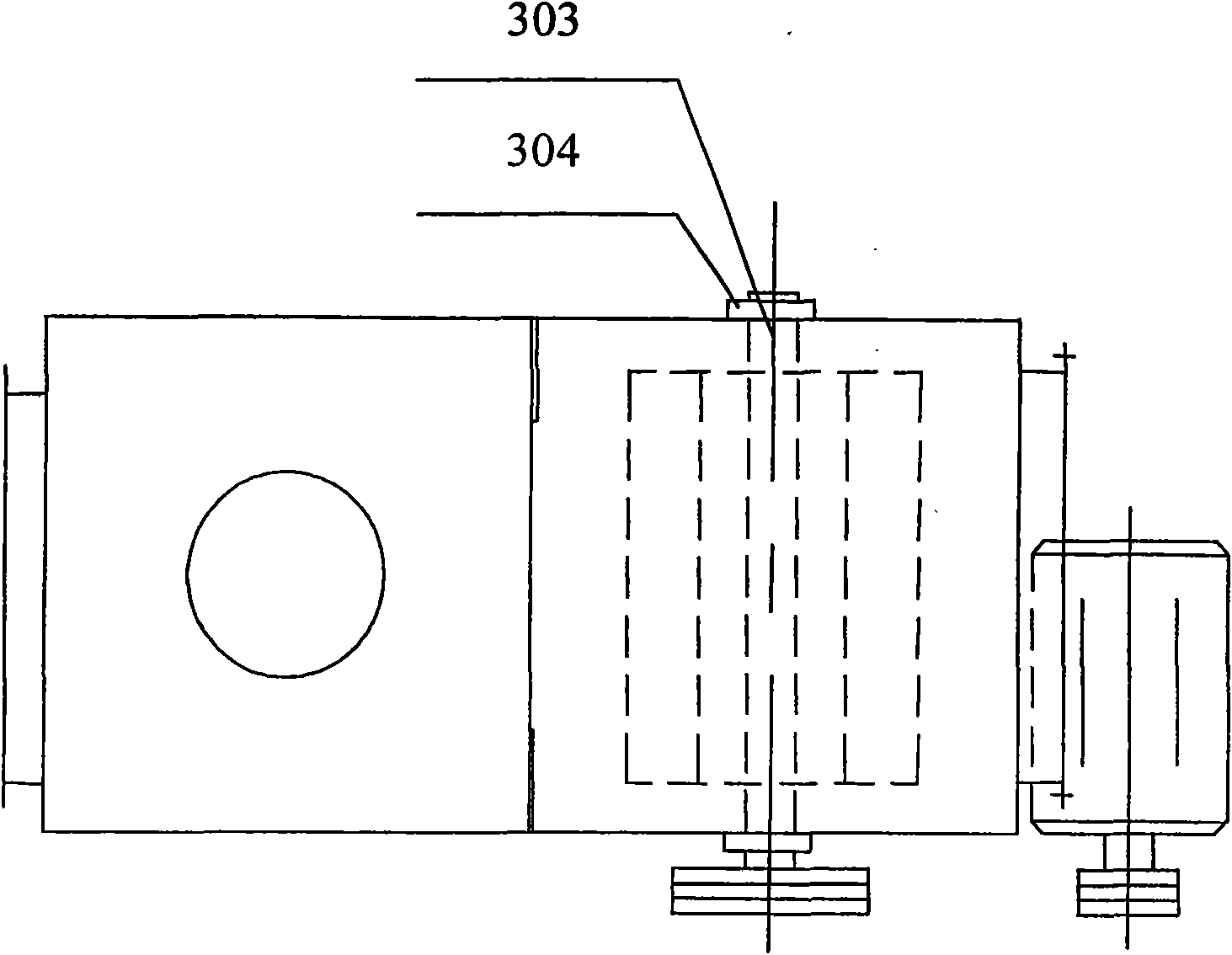

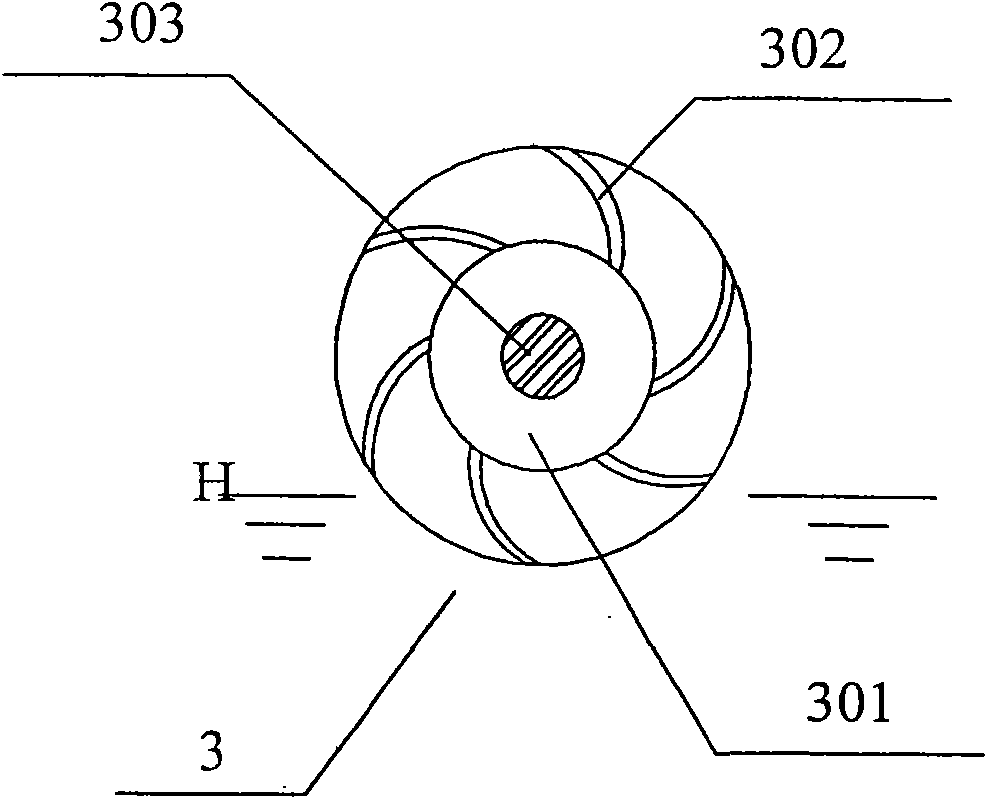

[0026] Referring to the accompanying drawings, the high-speed rotary atomization absorption device for desulfurization and dust removal of the present invention includes a cavity 1, and a solvent tank 103 is arranged at the bottom of the cavity 1, and the cavity above the solvent tank 103 is divided into two air inlet ends whose bottoms communicate with each other. The chamber 101 and the exhaust end chamber 102, the intake port 104 and the exhaust port 105 are respectively arranged on the intake end chamber 101 and the exhaust end chamber 102, and a flow guiding device is arranged in the intake end chamber 101 4. The guide device includes several guide plates 401 to form a labyrinth design and installation. The secondary microfiltration device 5 is installed in the exhaust end chamber 102, and the rotary aeration device 3 is installed in the intake end chamber 101. At the bottom, in this embodiment, the rotary aeration device 3 includes a runner 301 and a transmission shaft 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com