Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166results about "Coal charges mechanical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

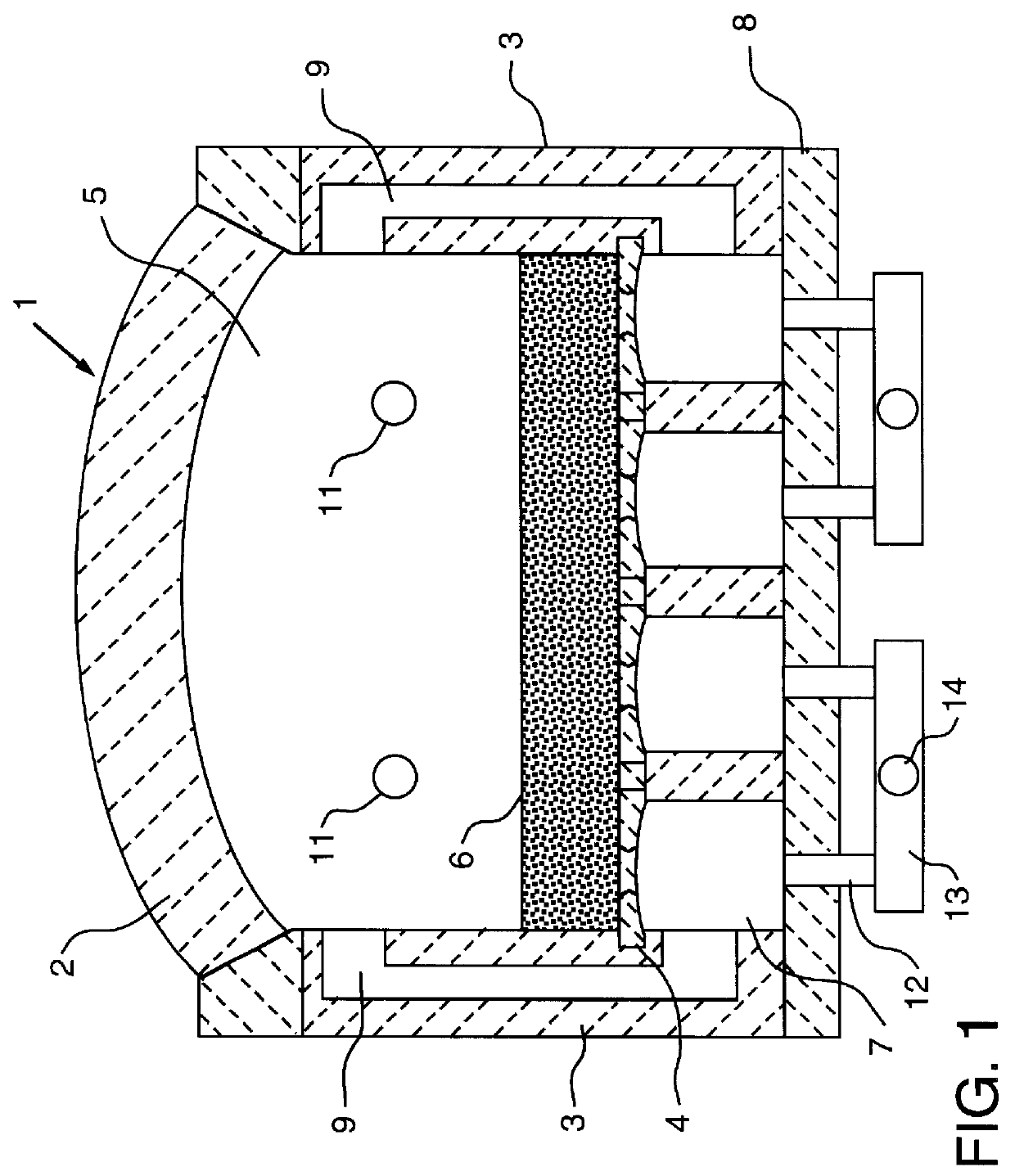

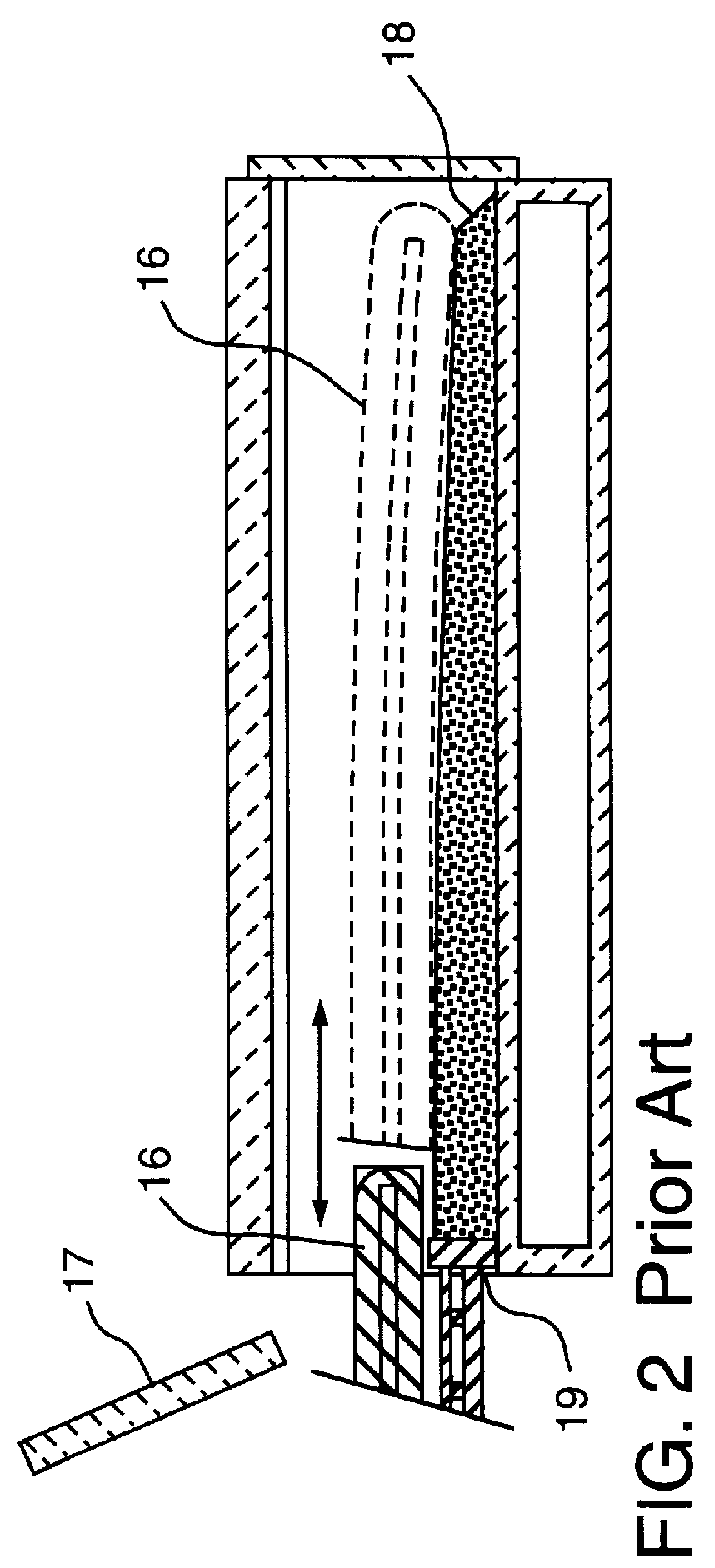

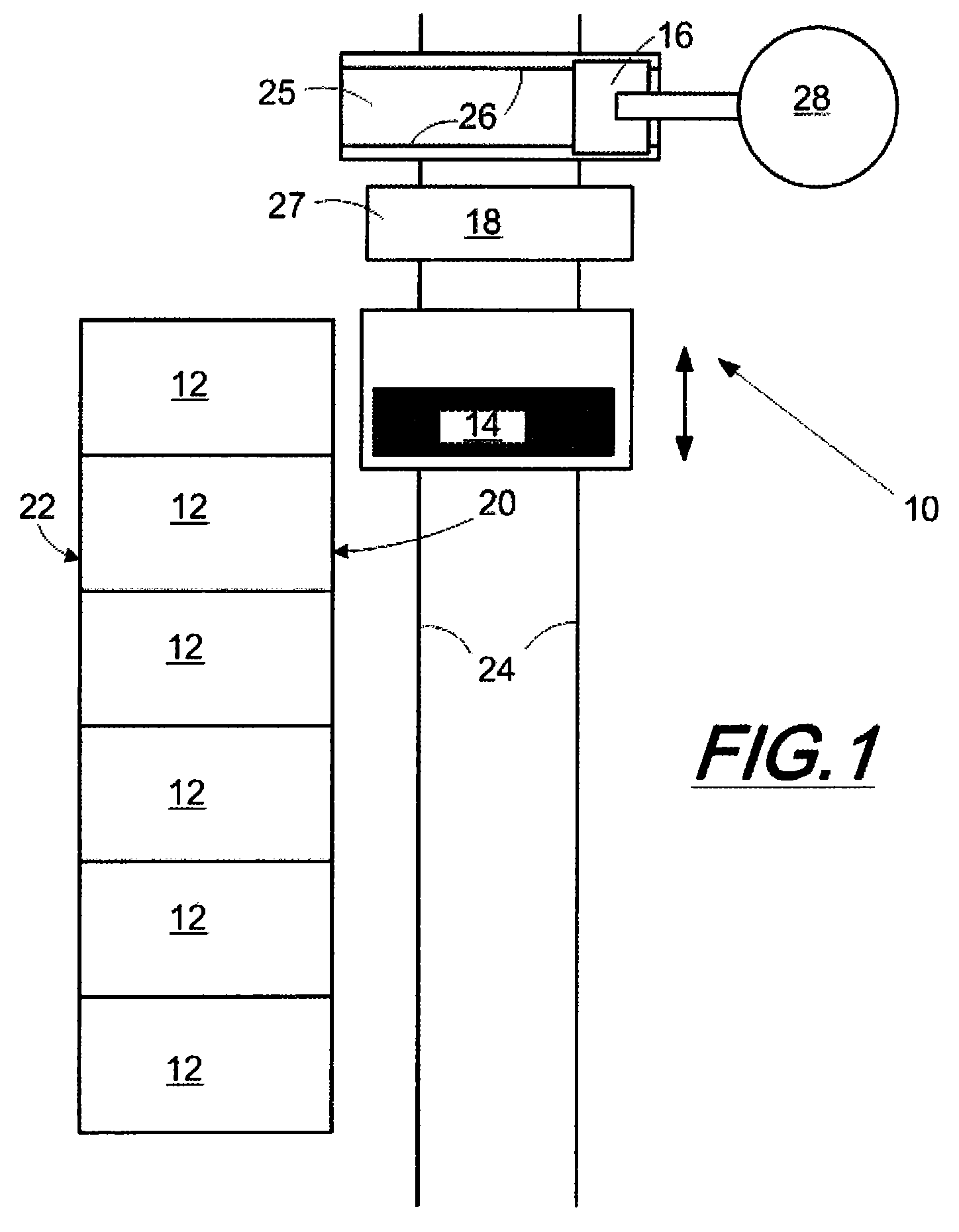

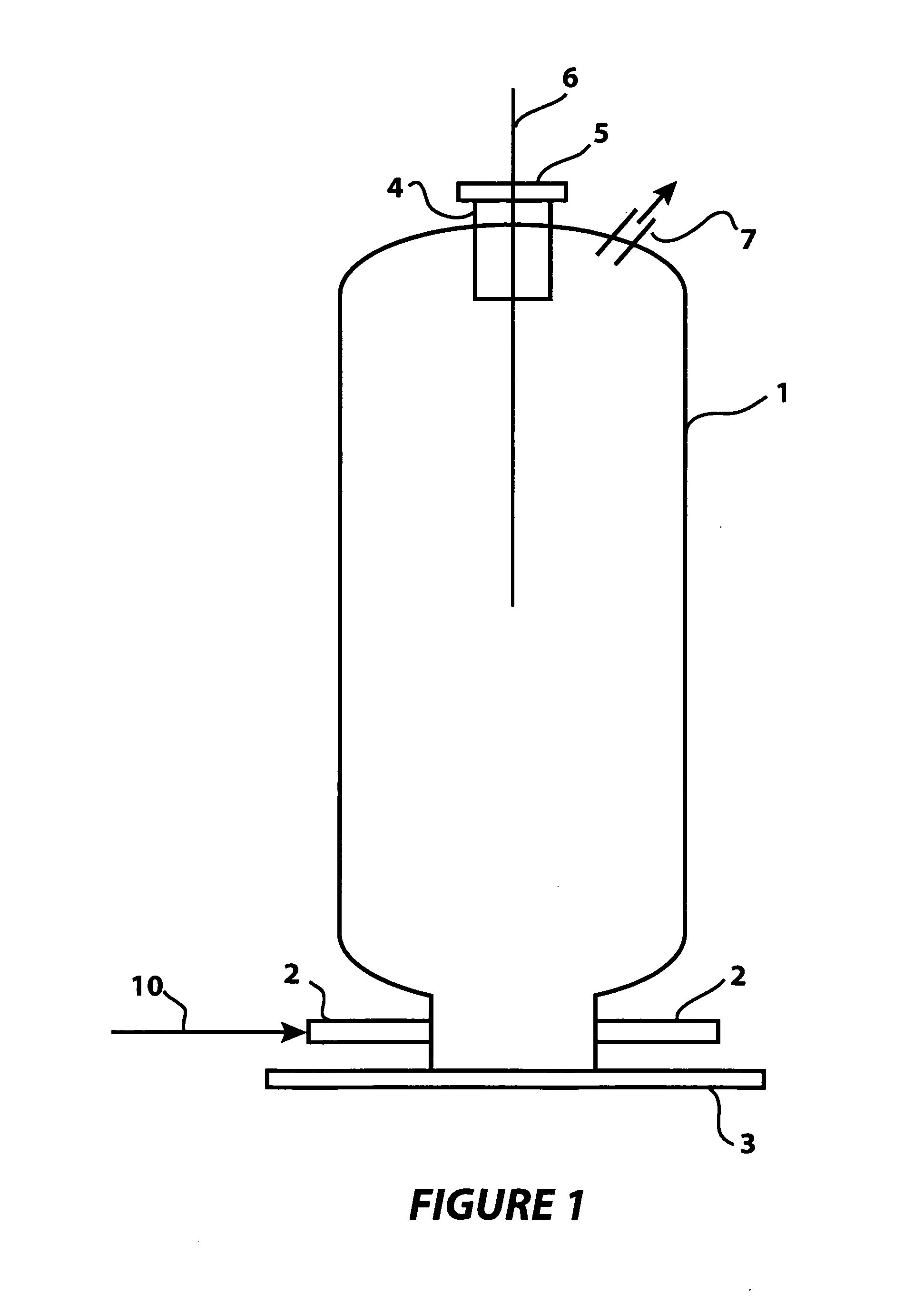

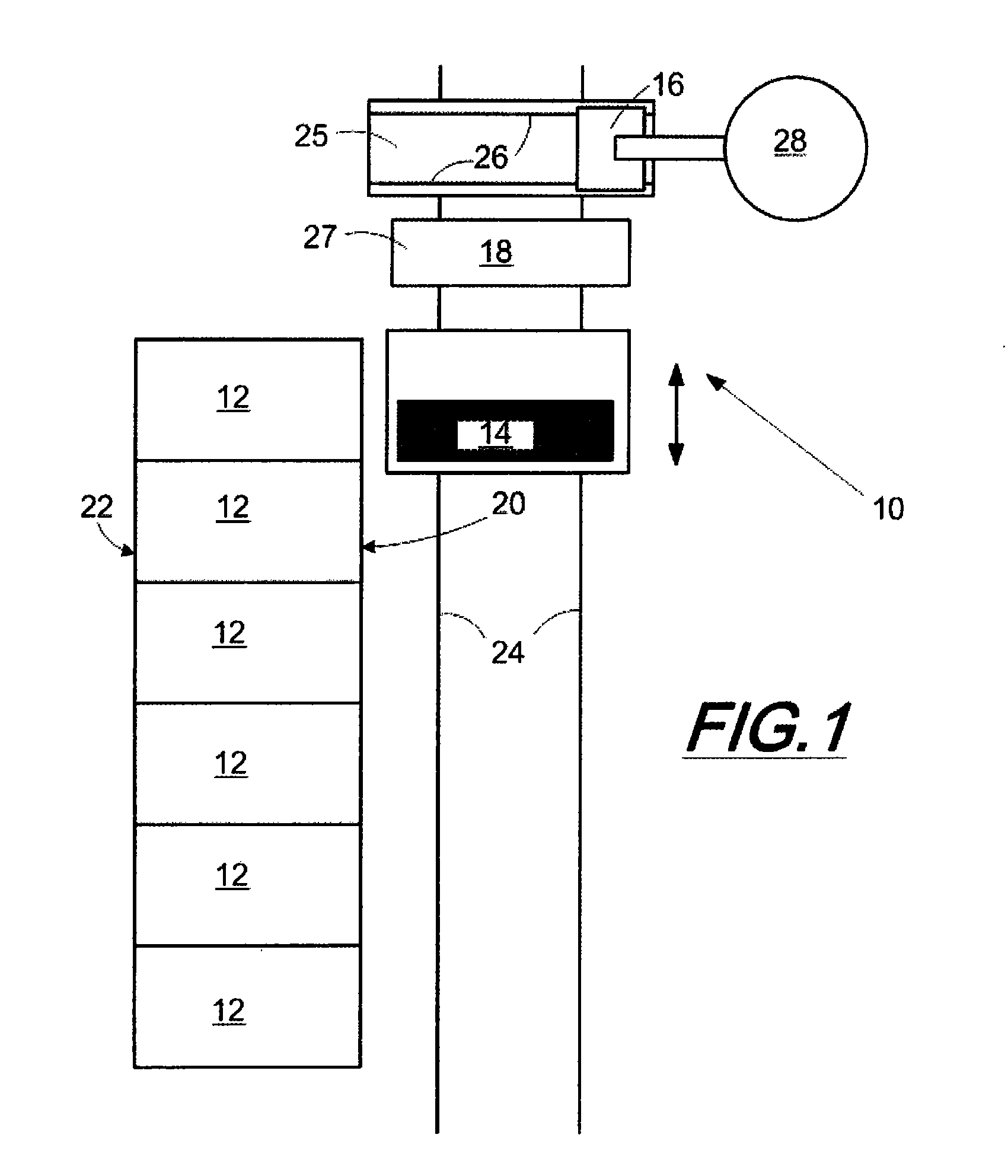

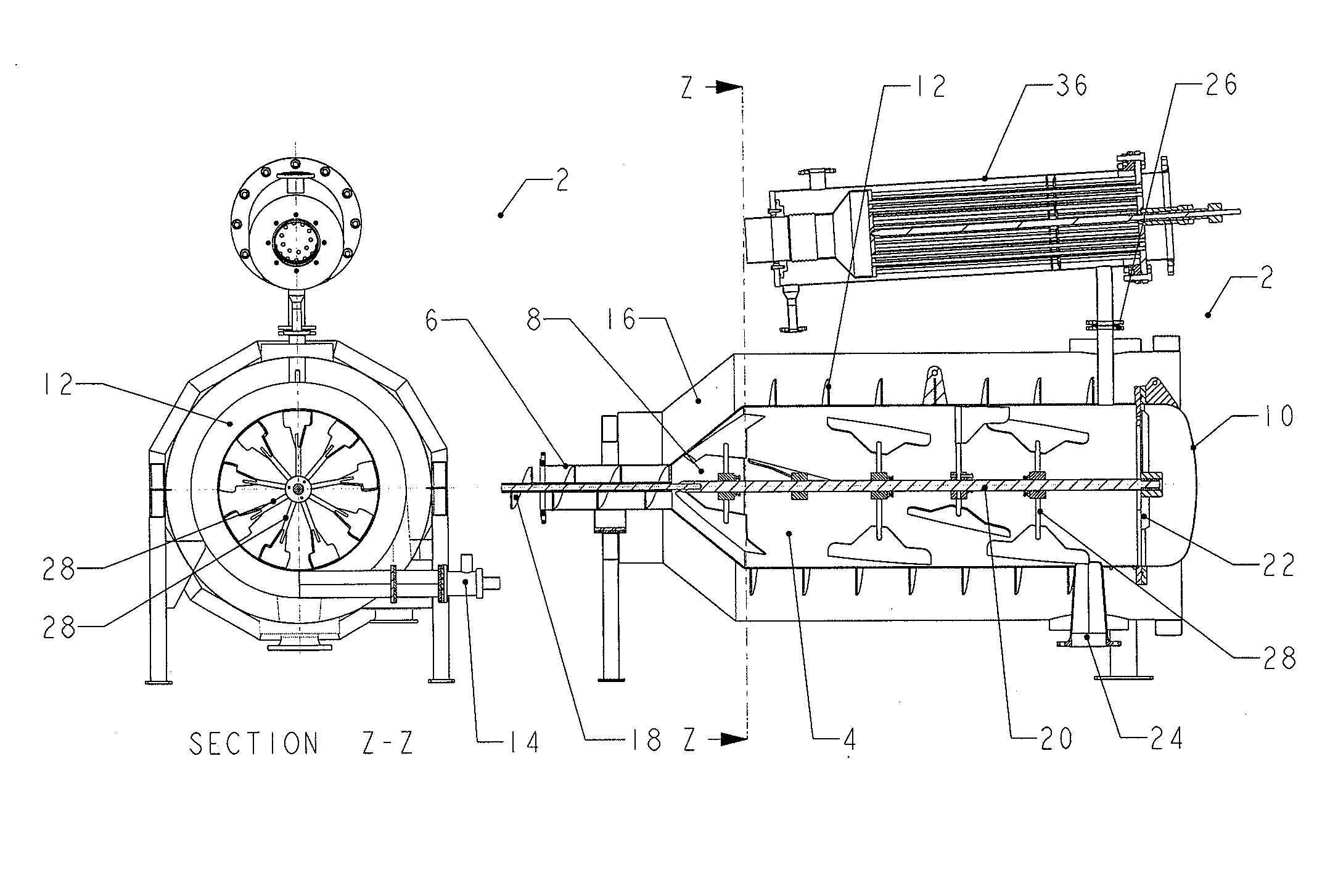

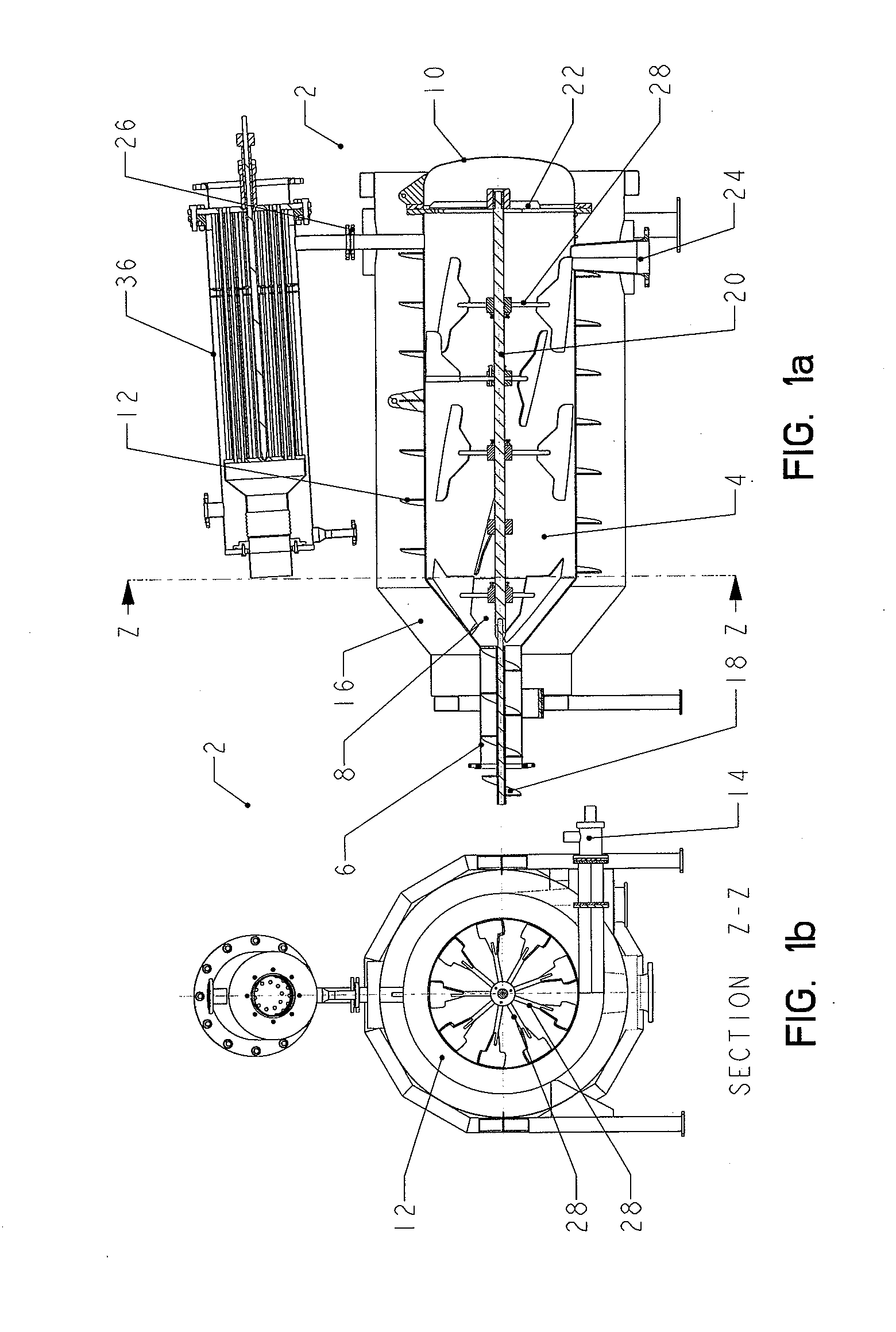

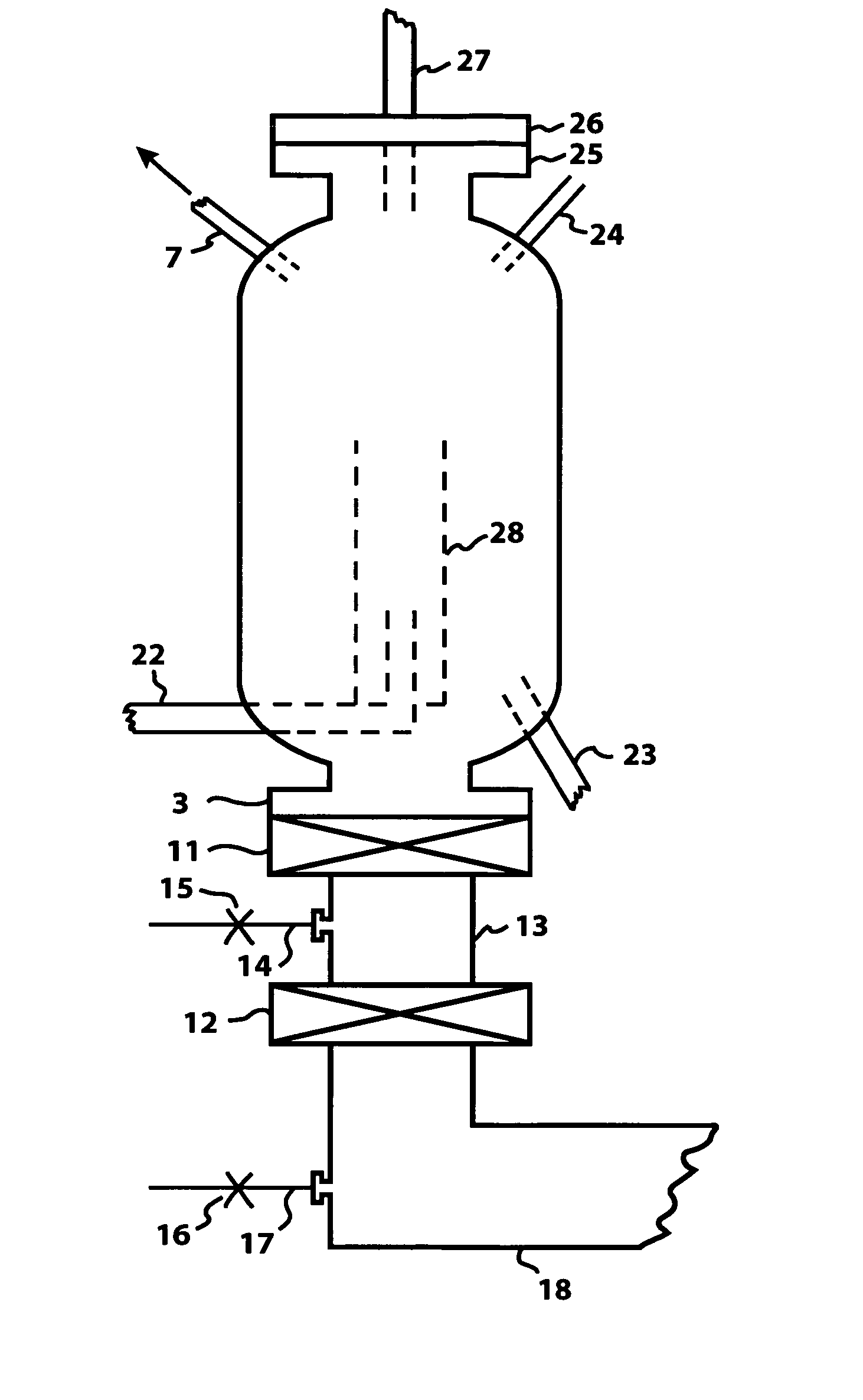

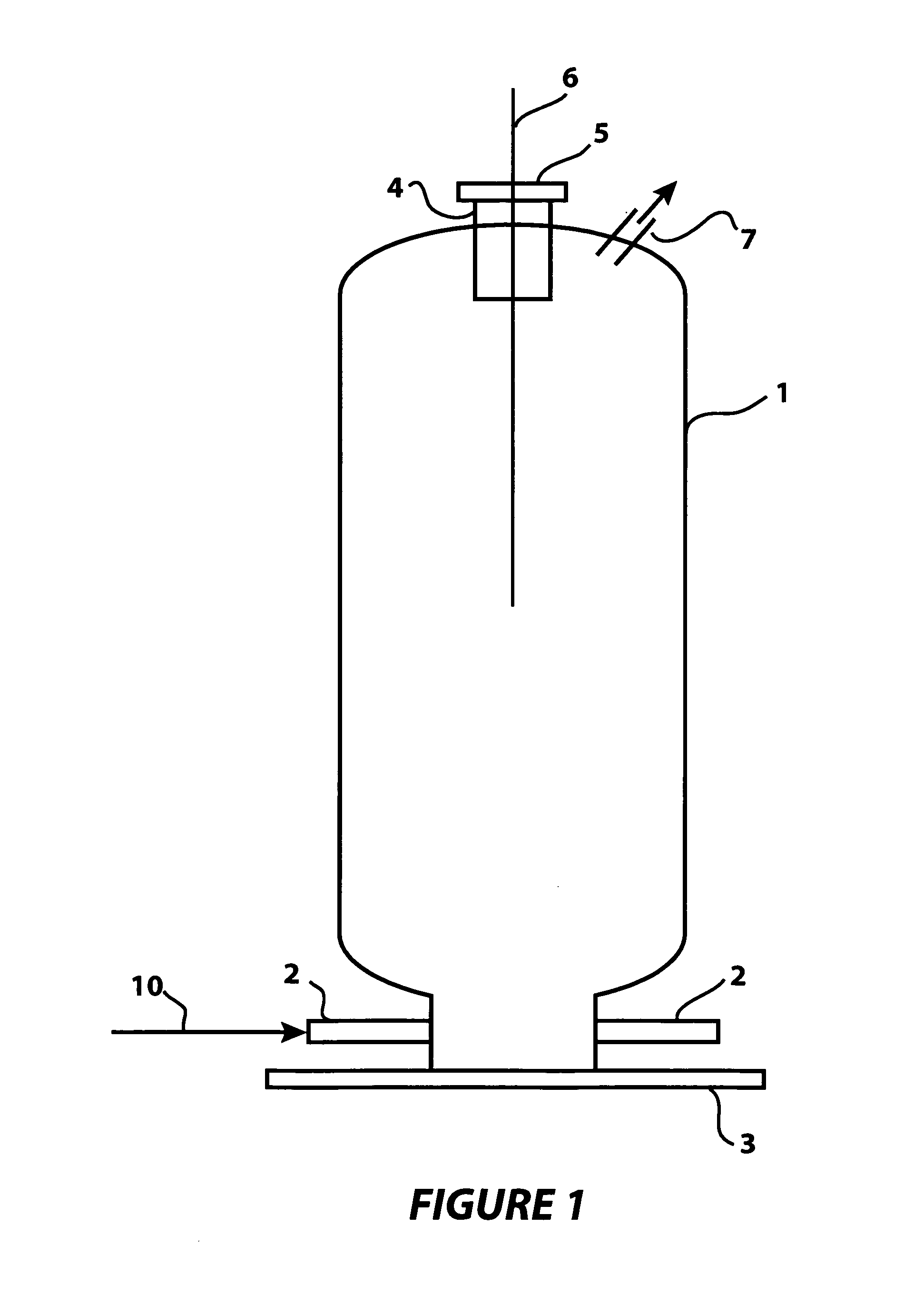

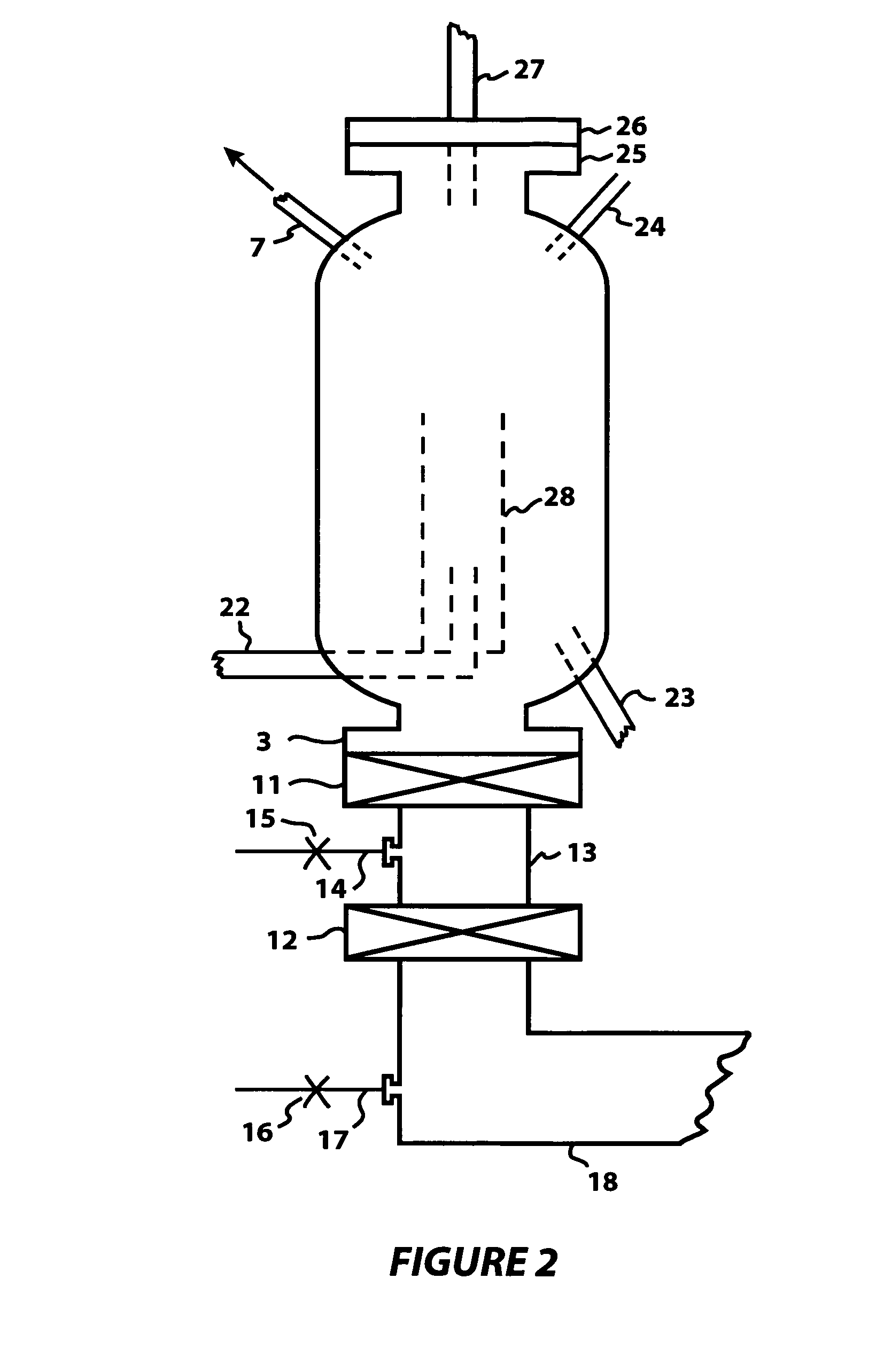

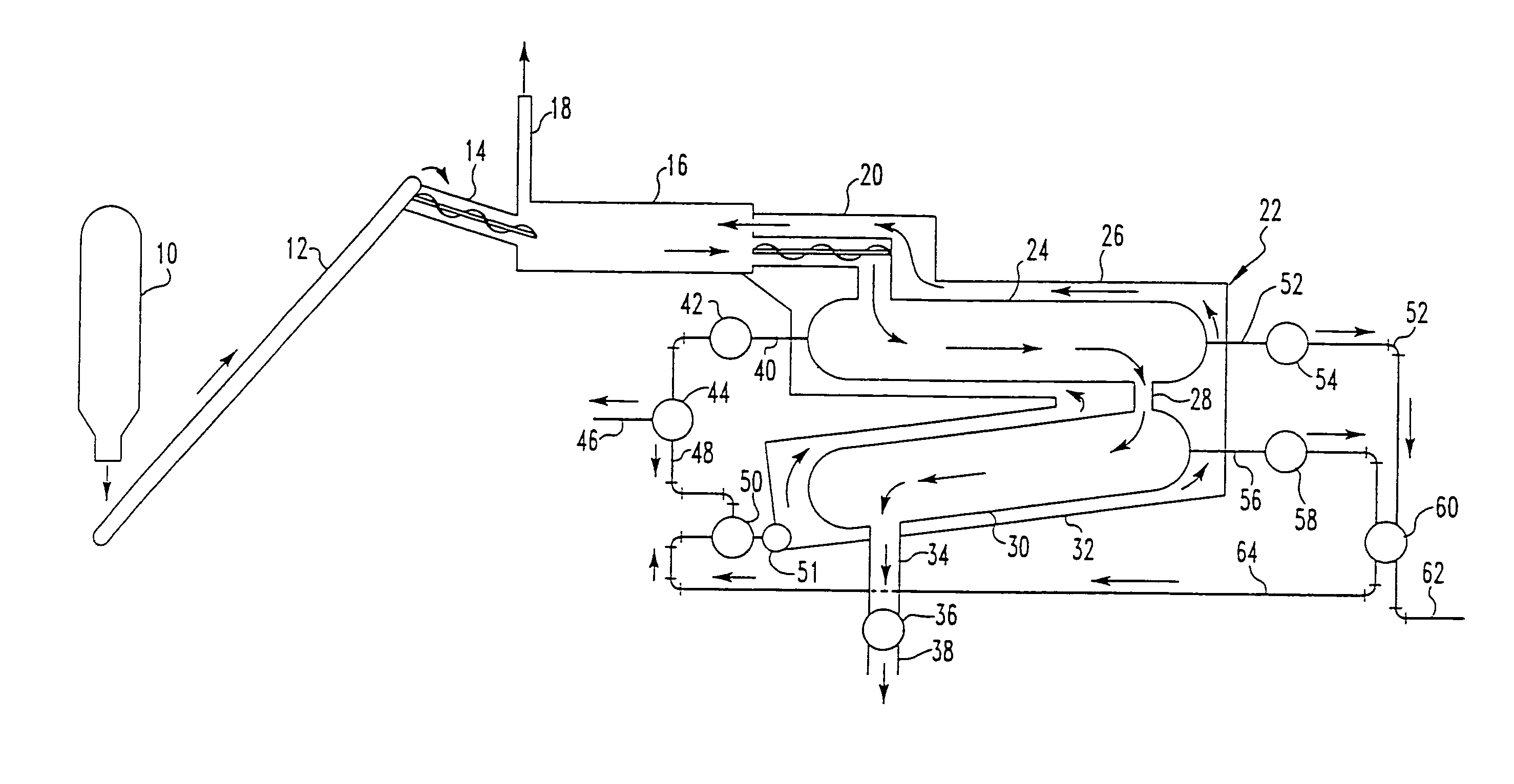

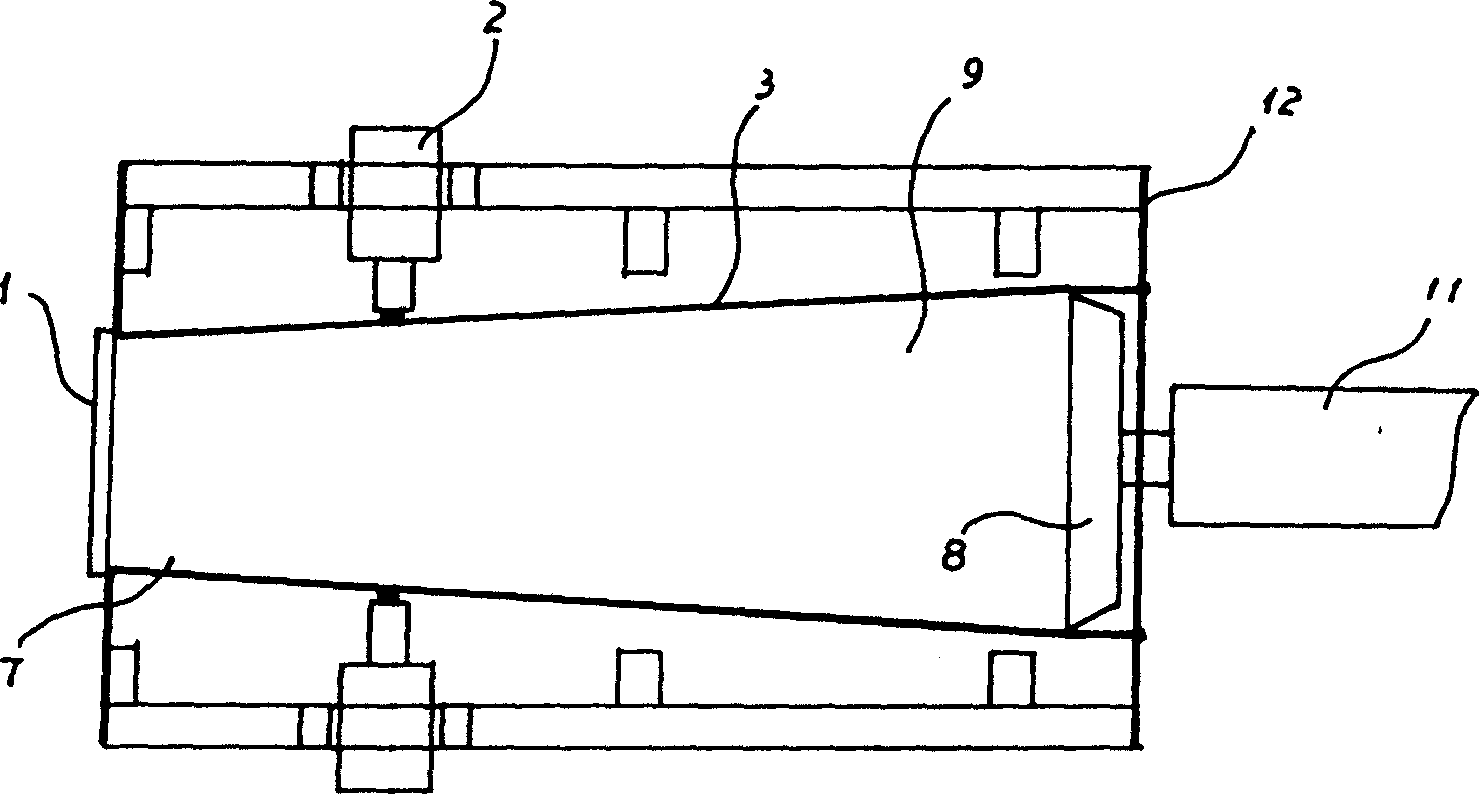

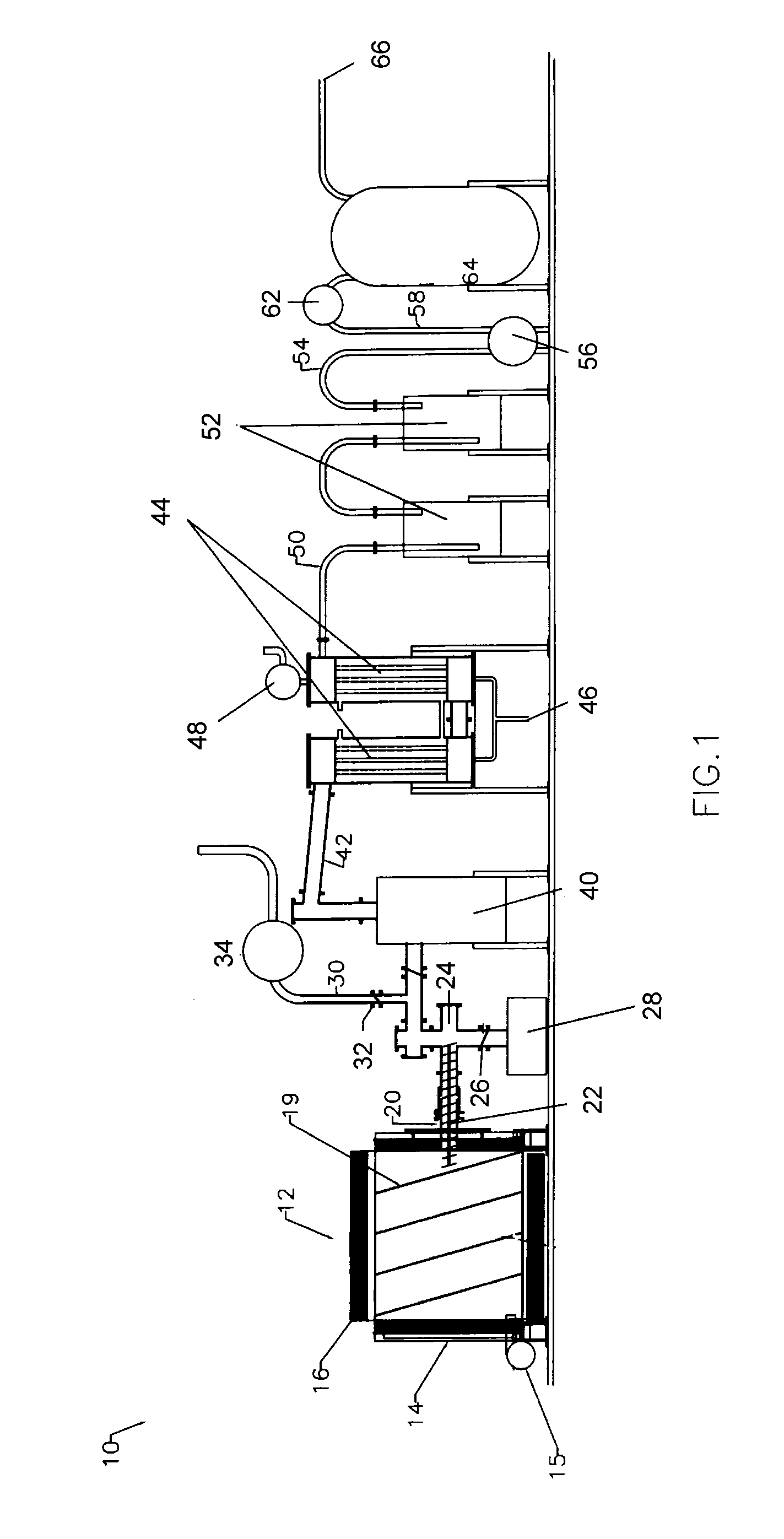

Coal bed vibration compactor for non-recovery coke oven

InactiveUS6059932AMechanical conveying coke ovensCharging-discharging device combinationsEngineeringCoke oven

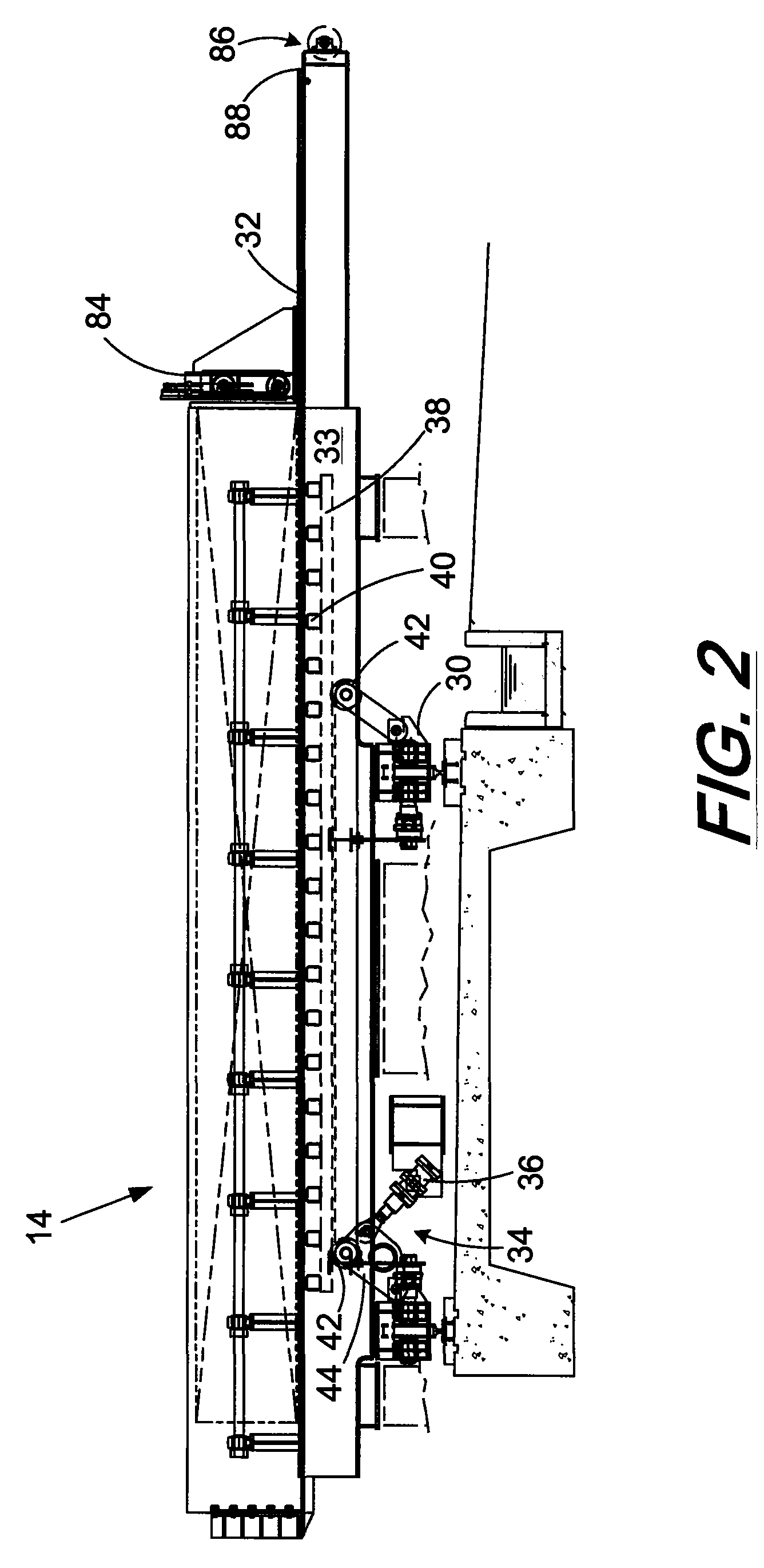

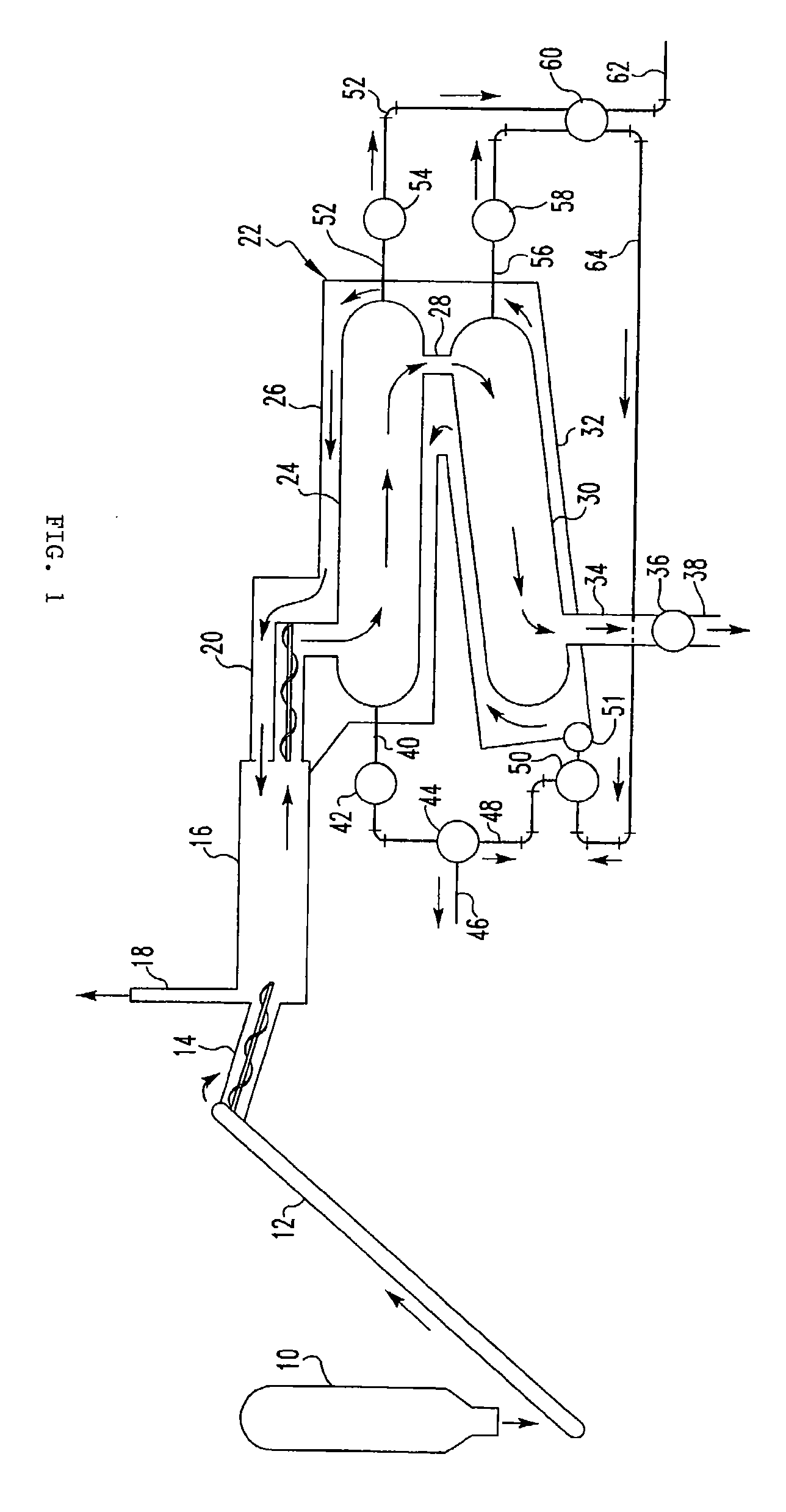

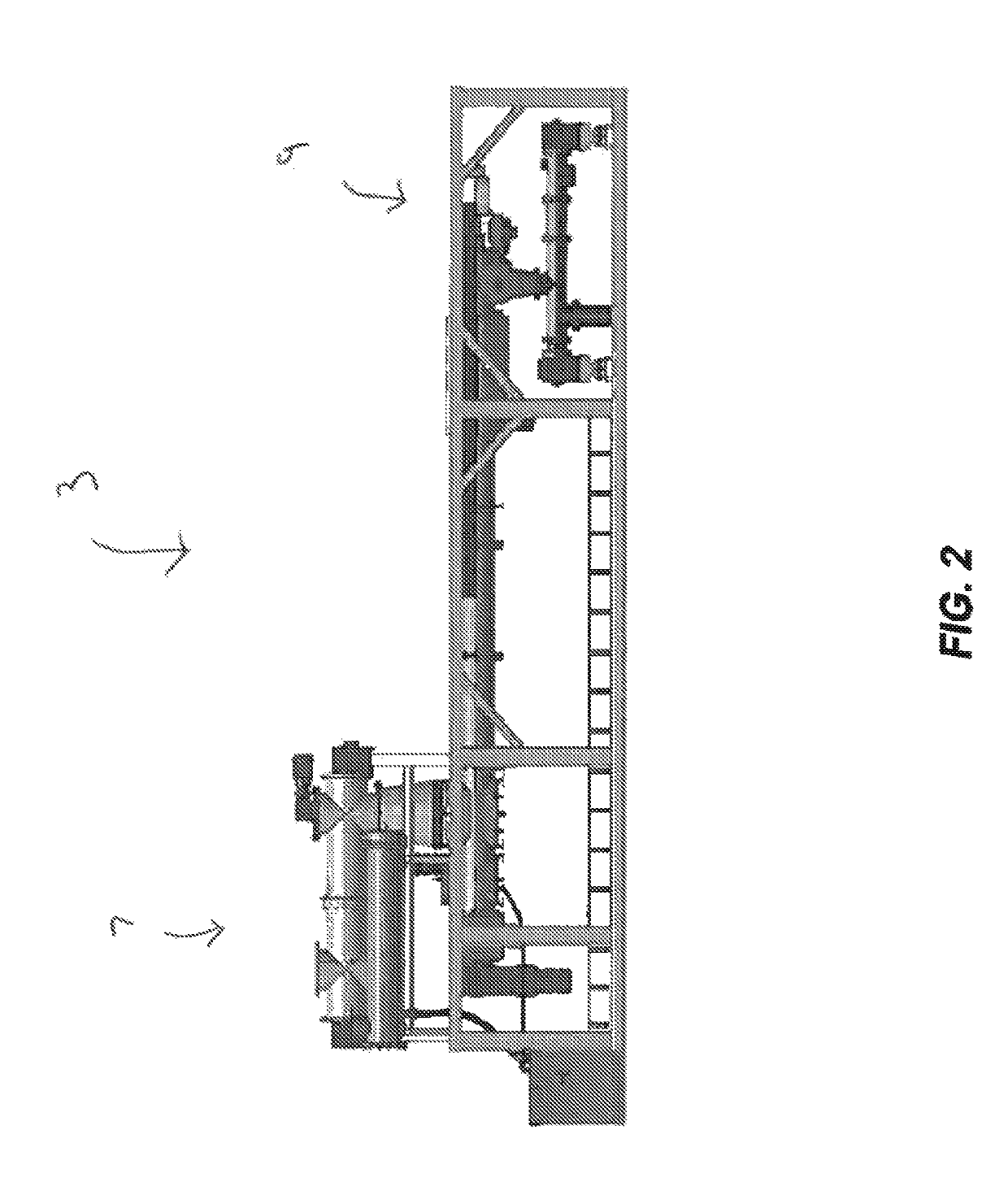

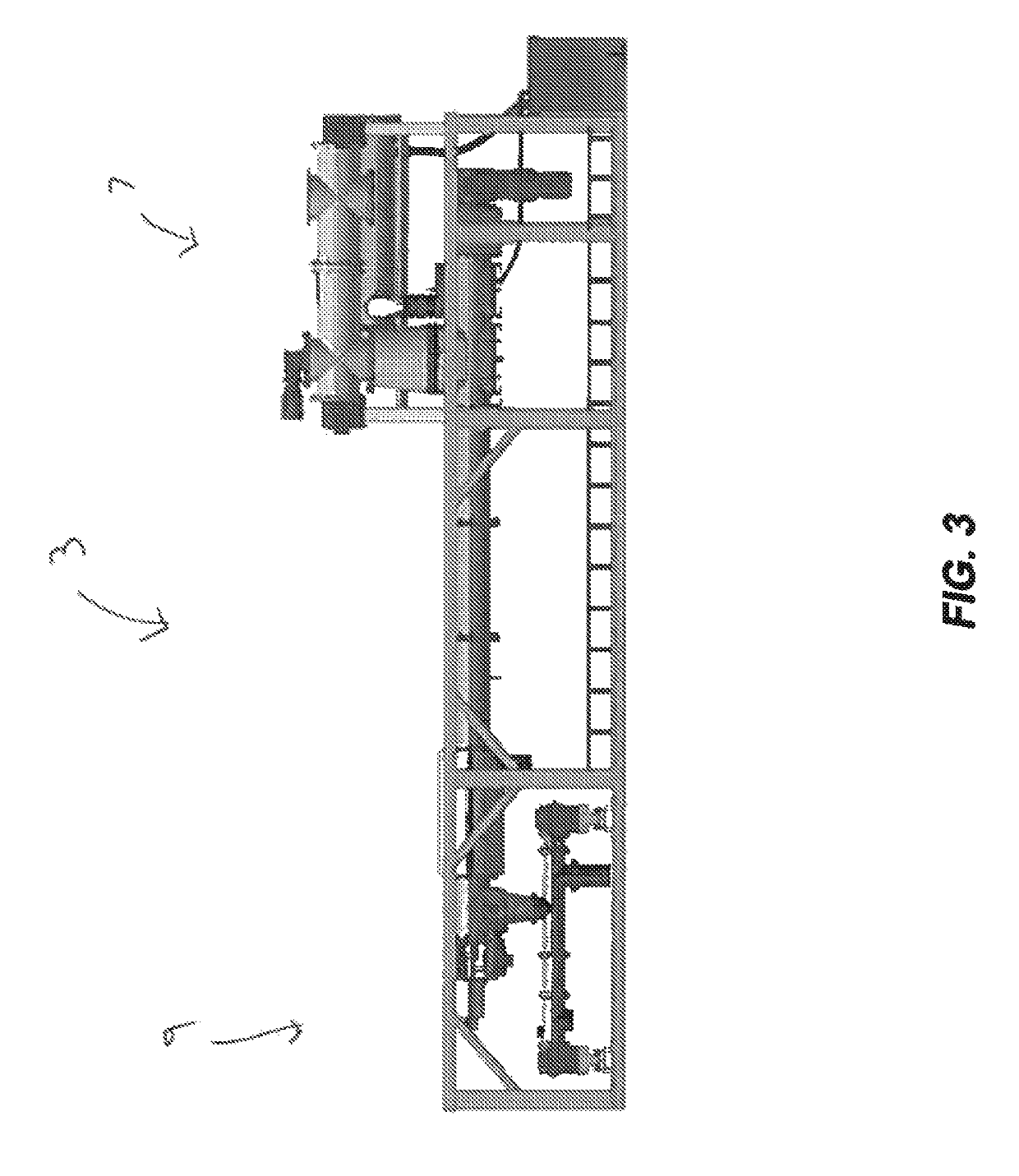

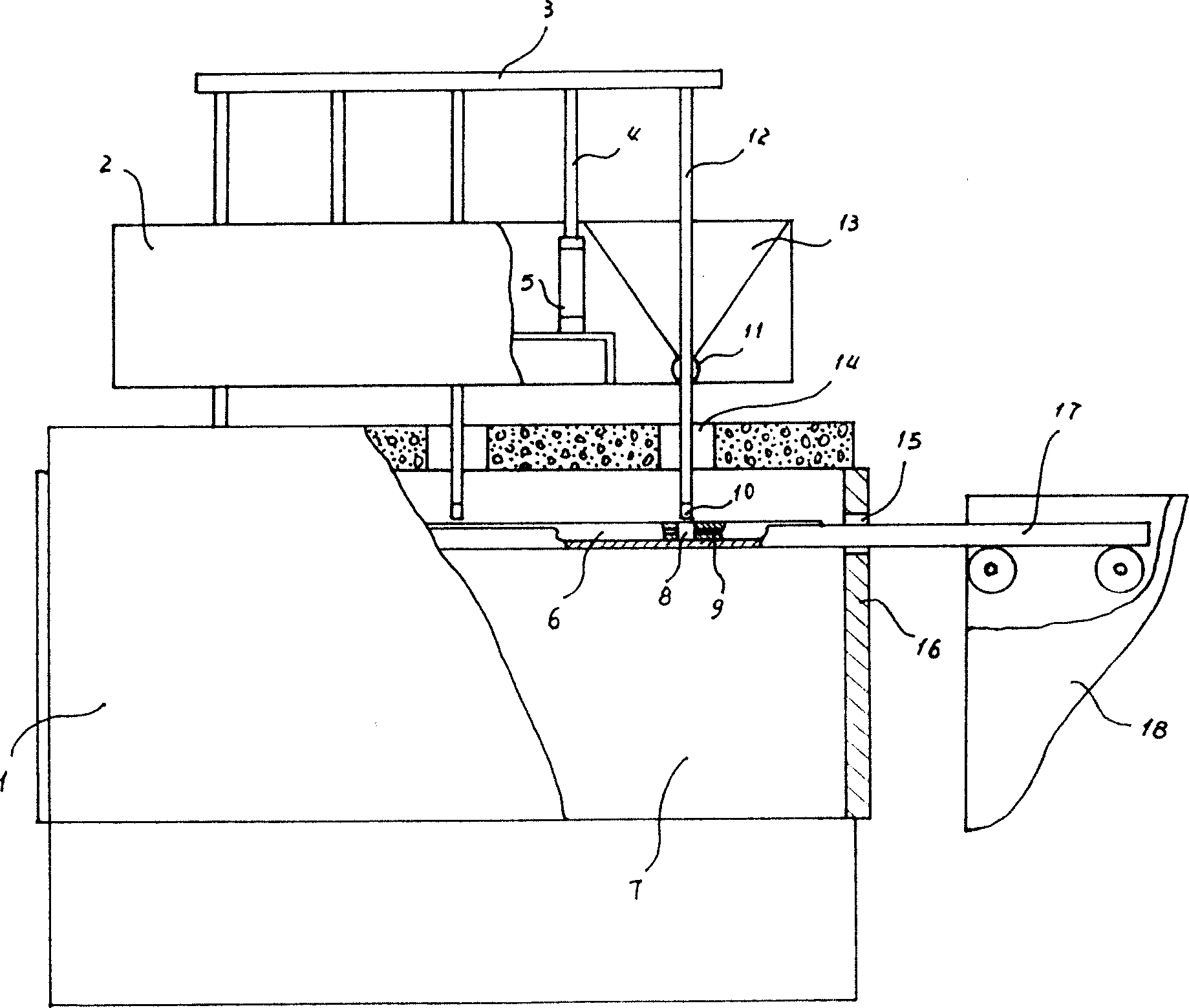

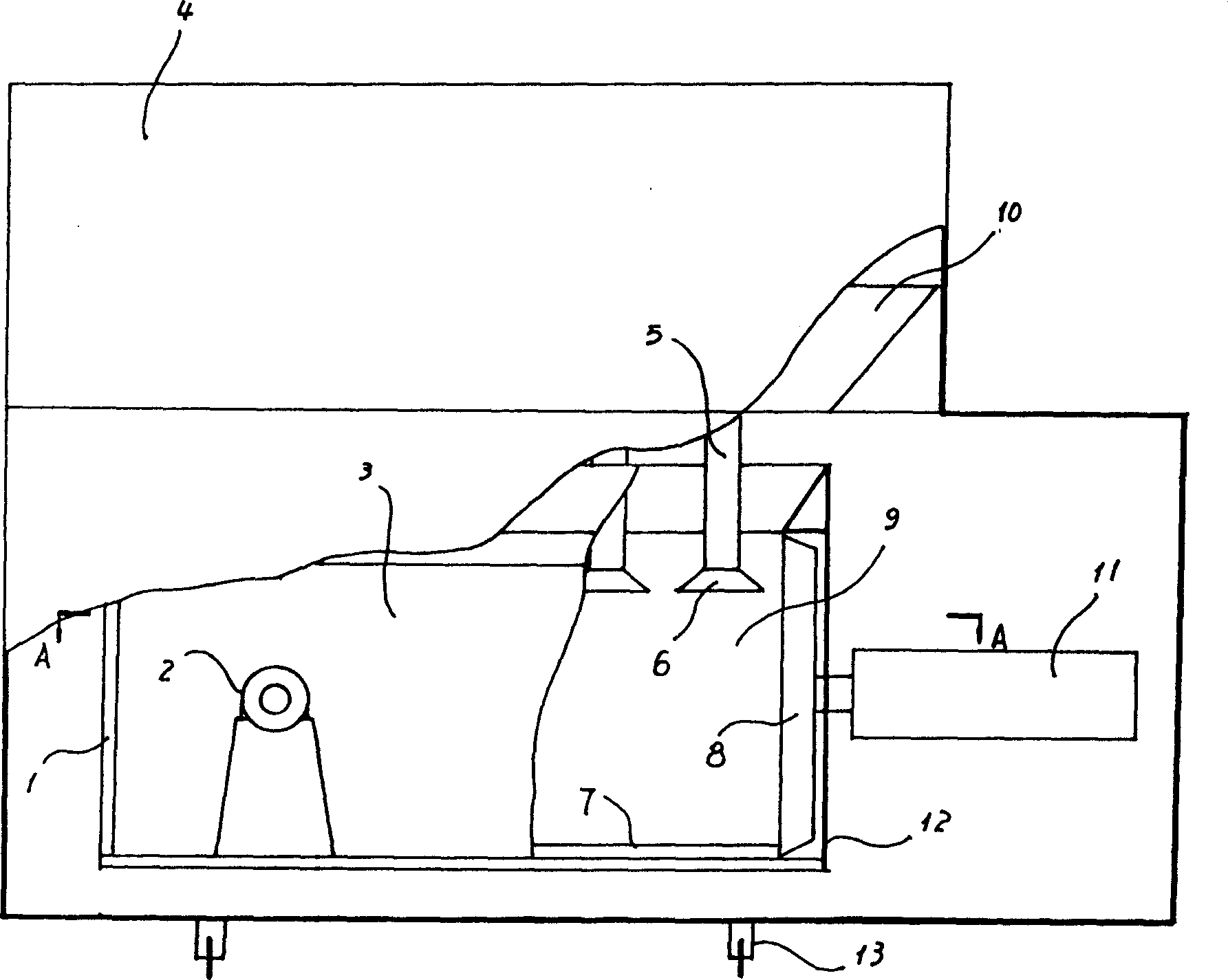

A coal compaction system and method for a non-recovery coke oven having refractory roof, floor, side walls and end doors for coal charging and coke discharge provides an improved coal charging machine carrying a coal conveyor supported intermediate the ends of the conveyor to avoid conveyor sagging and non-uniform depth of a deposited coal bed, a number of pressurized fluid-driven vibratory compactors mounted on an end of the charging machine and spaced-apart across the width of the coal bed and serving to compact the coal bed on a retraction stroke of the charging machine, a pivoted lifting frame mounted on the charging machine above the compactors and from which the compactors individually are suspended and are provided with individual supply of pressurized fluid, and a coke pusher head mounted on the charging machine behind the compactors and serving, when the lifting frame and associated compactors are raised, to push finished coke from the coke oven.

Owner:PENNSYLVANIA COKE TECH

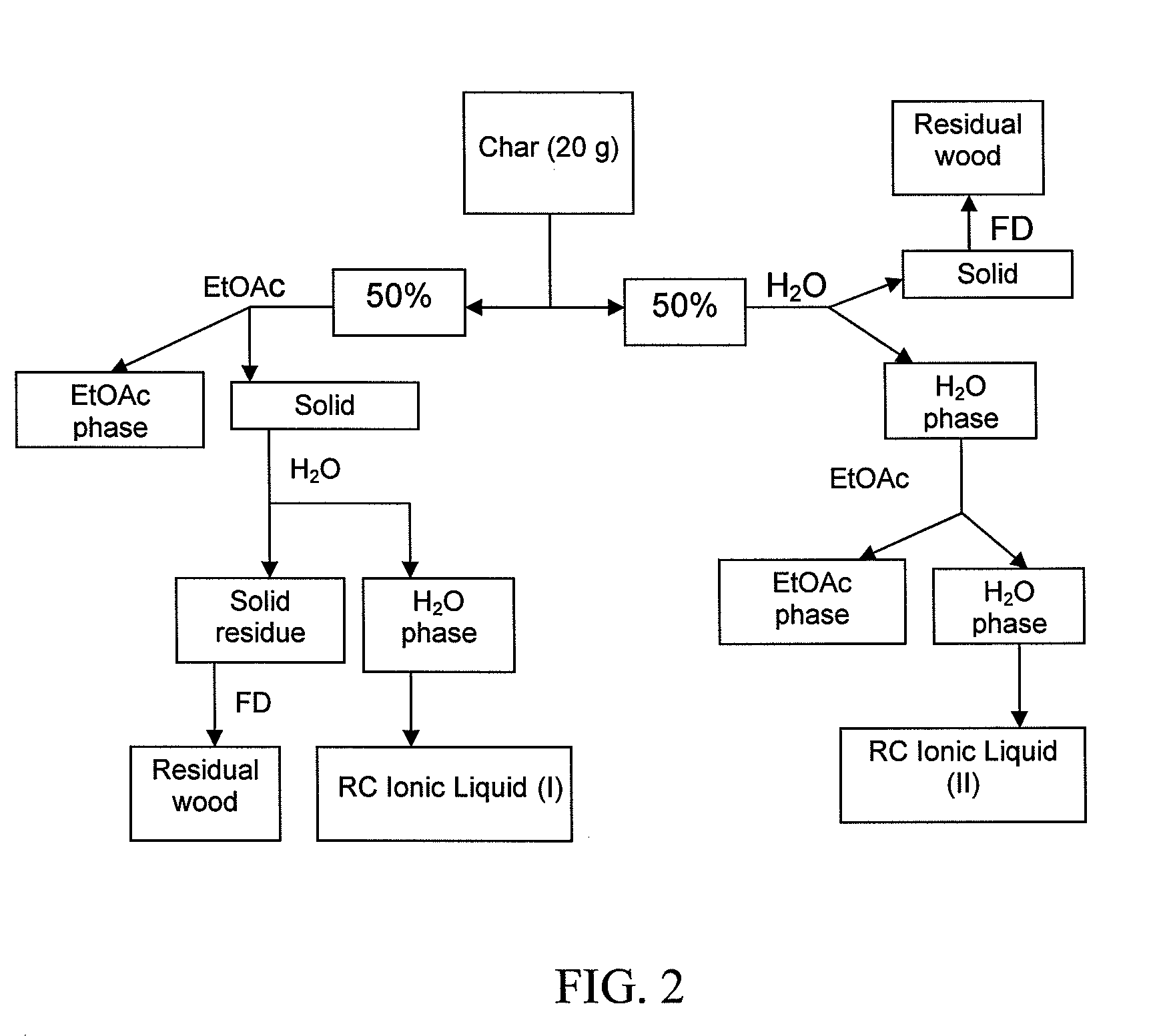

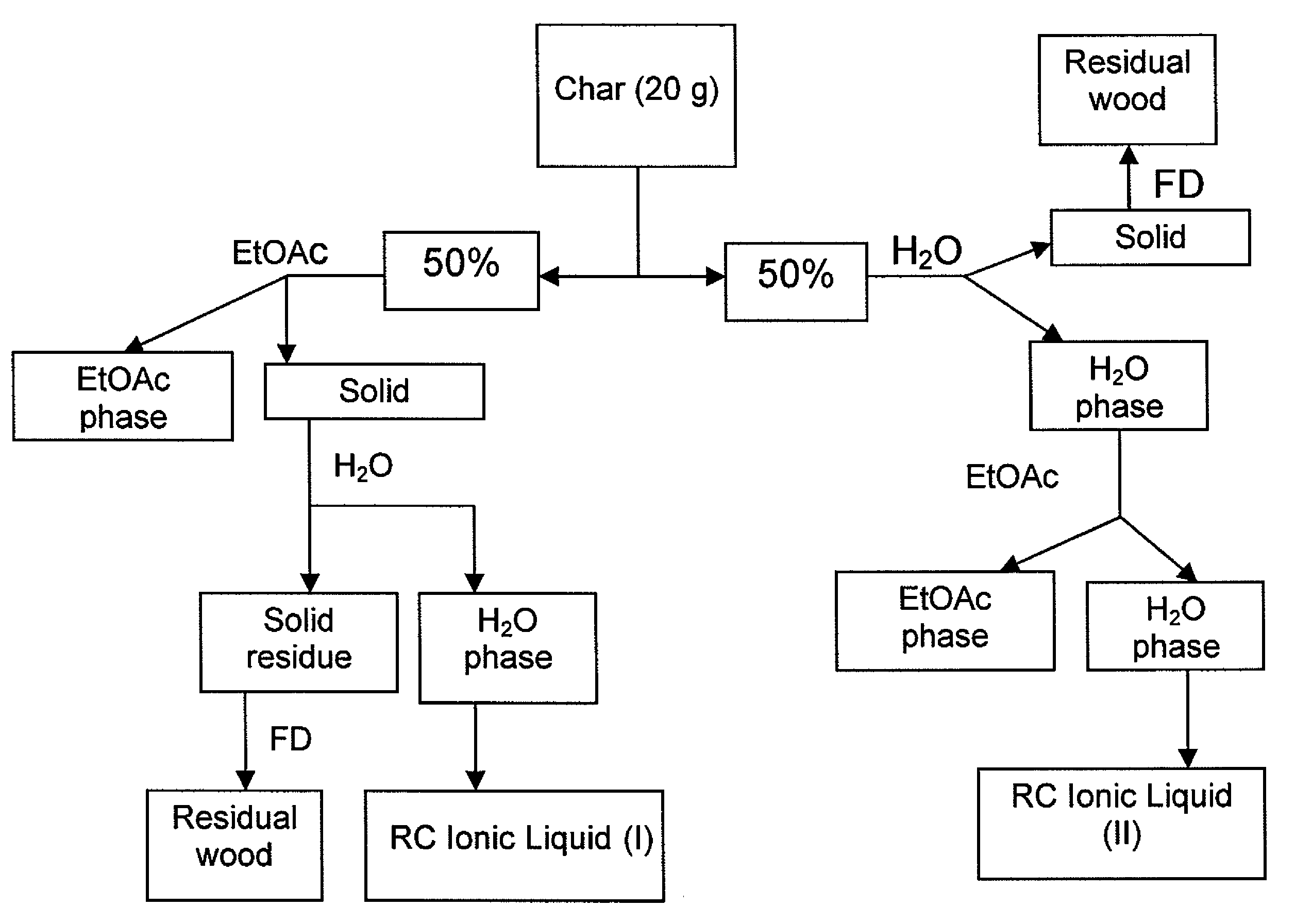

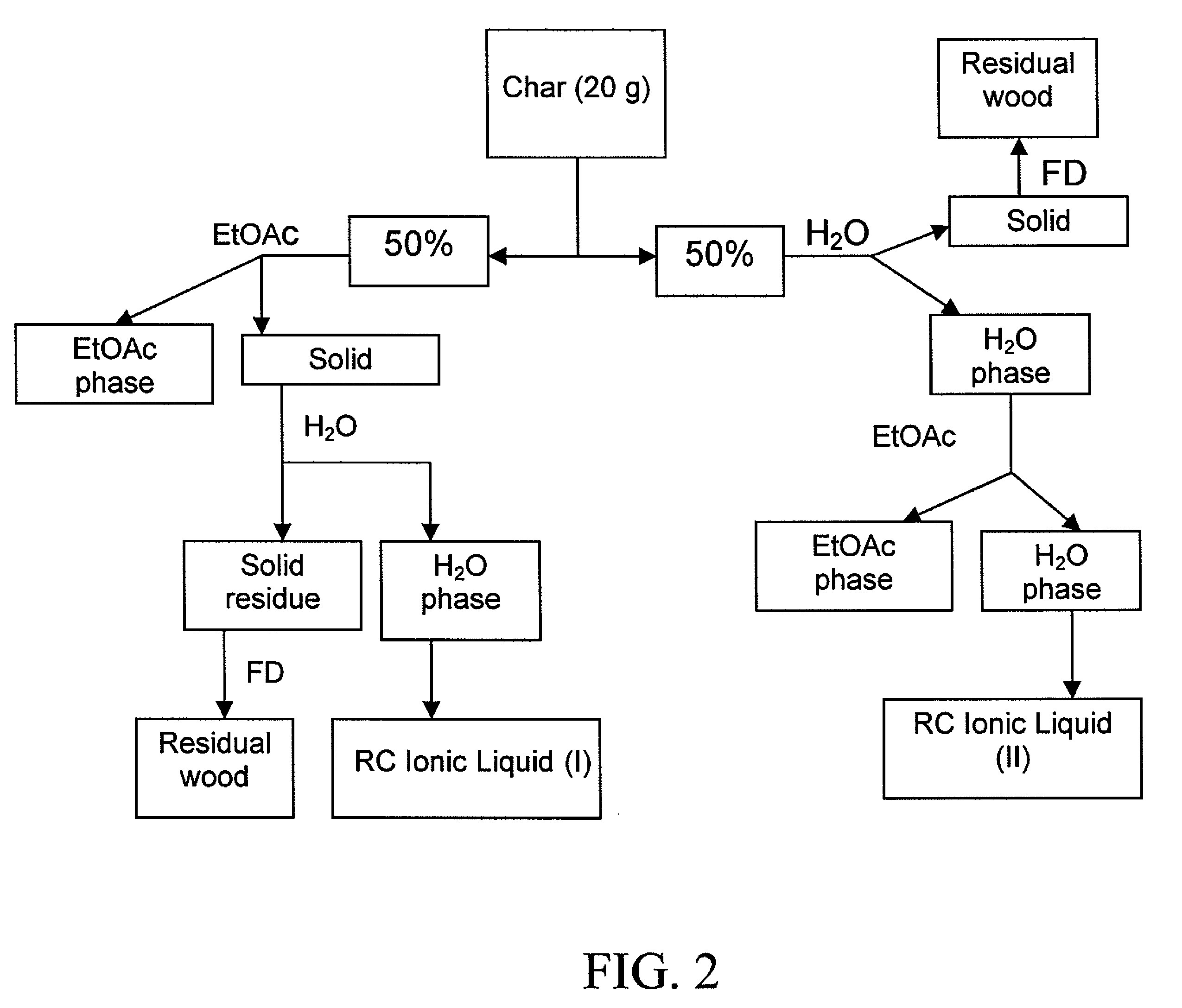

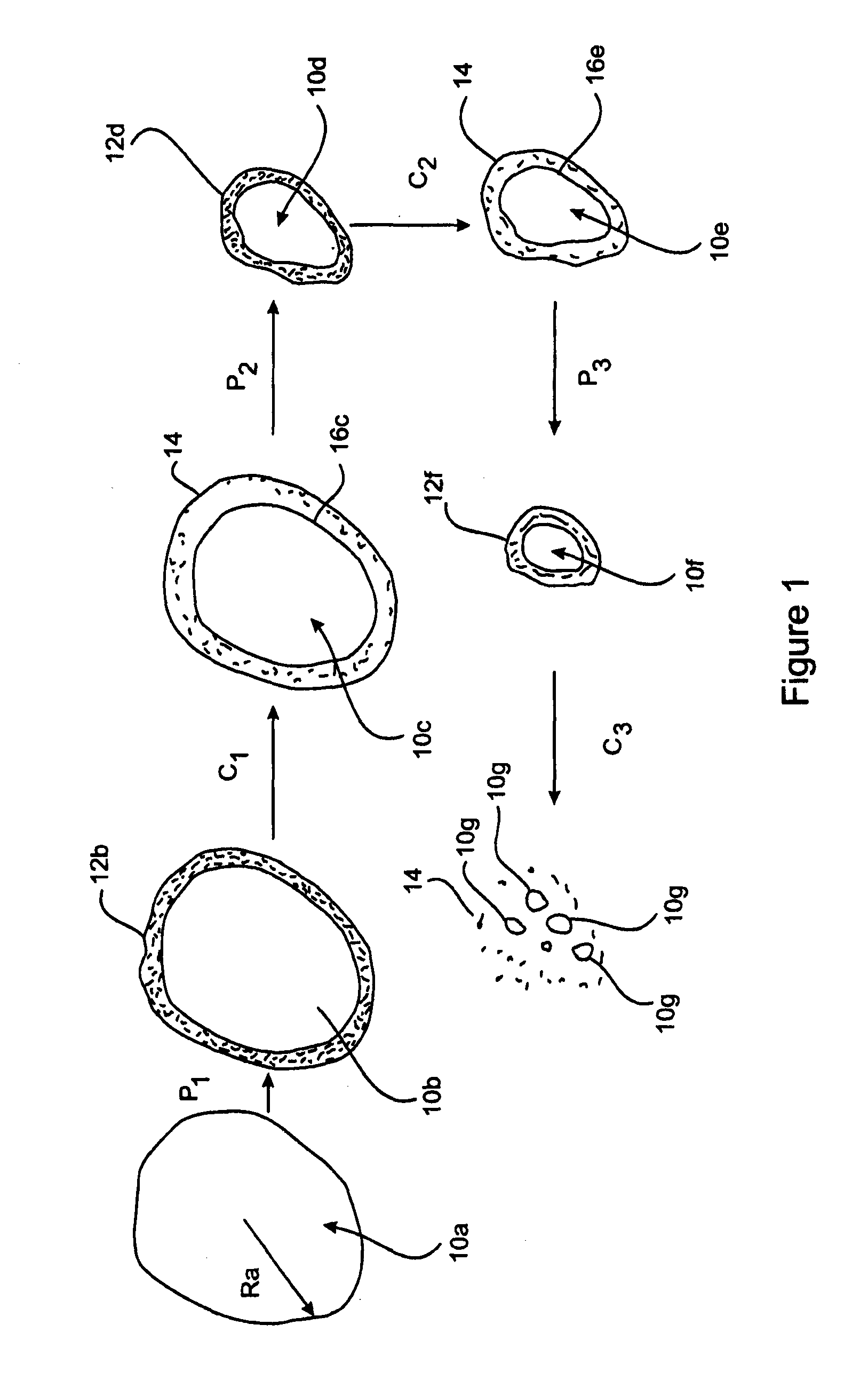

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS20080185112A1Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

The present invention provides methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose. In specific embodiments, the methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to pyrolytic conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

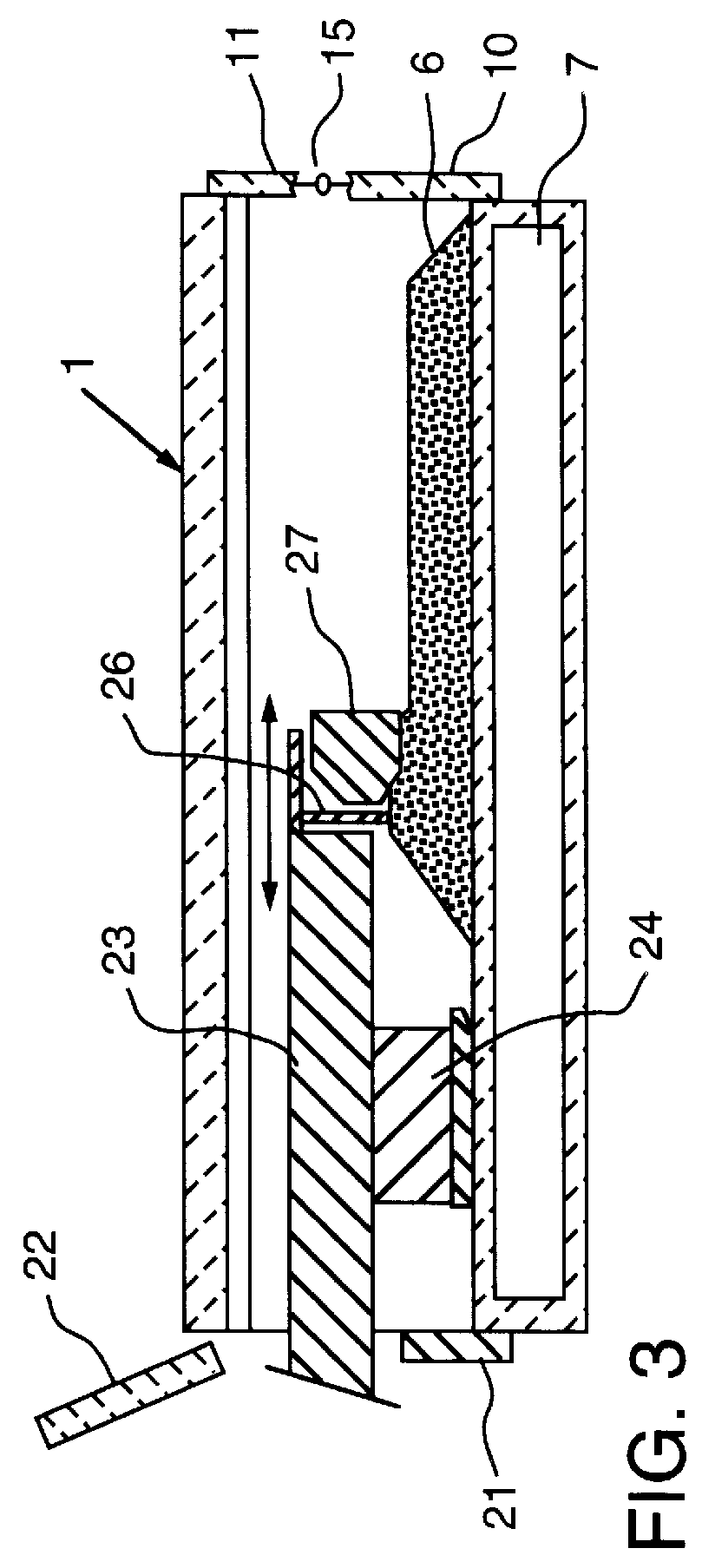

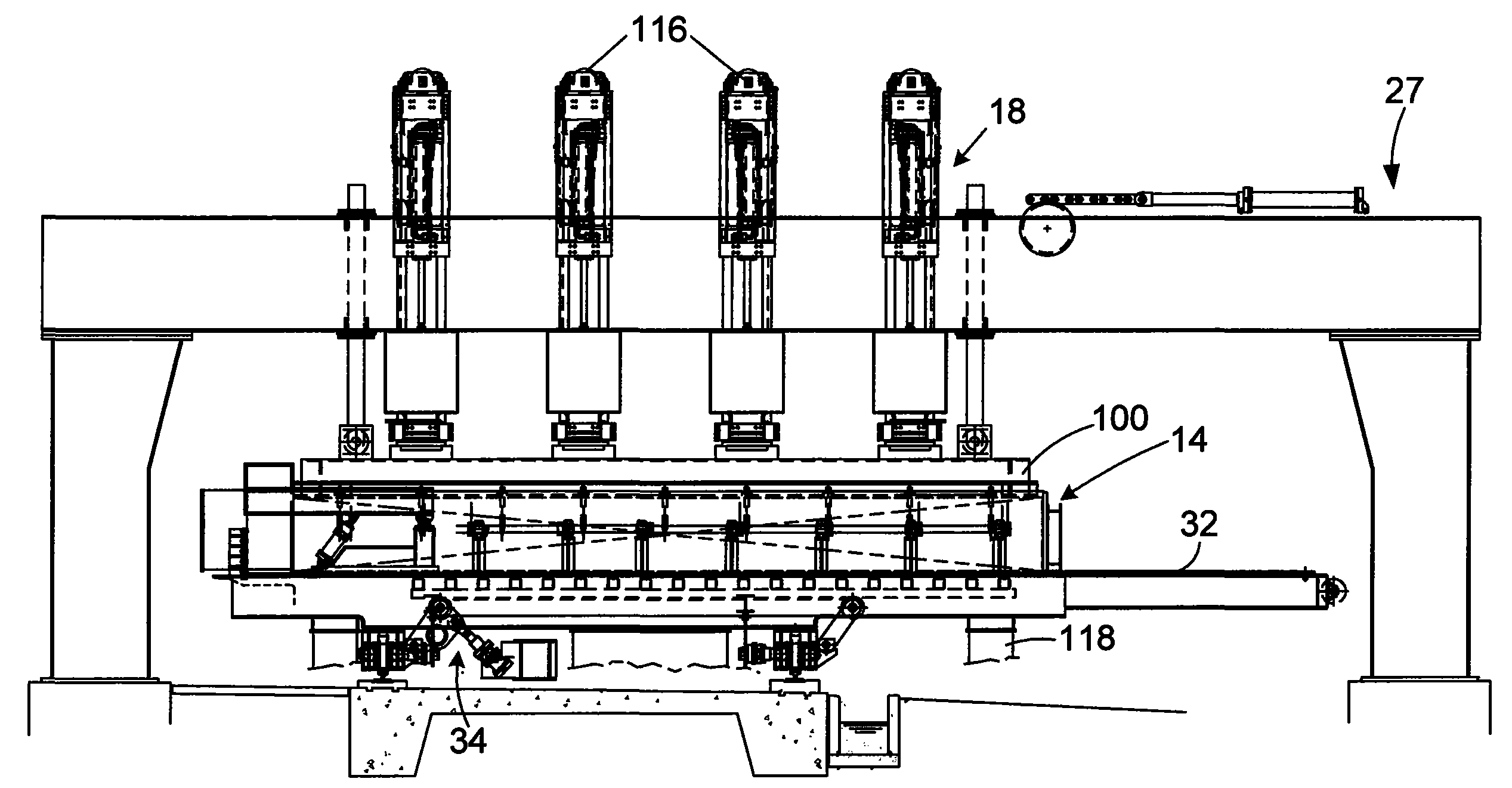

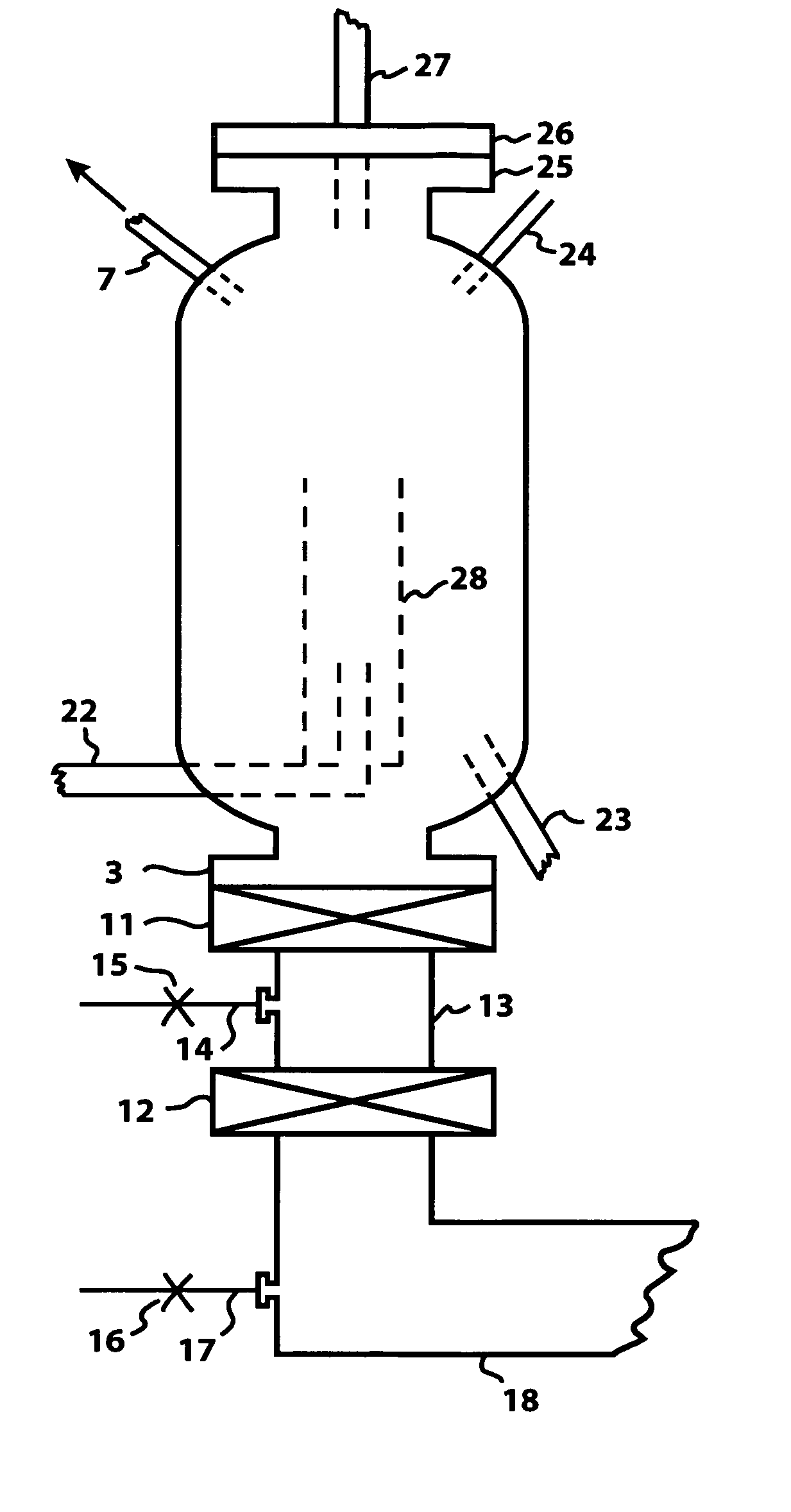

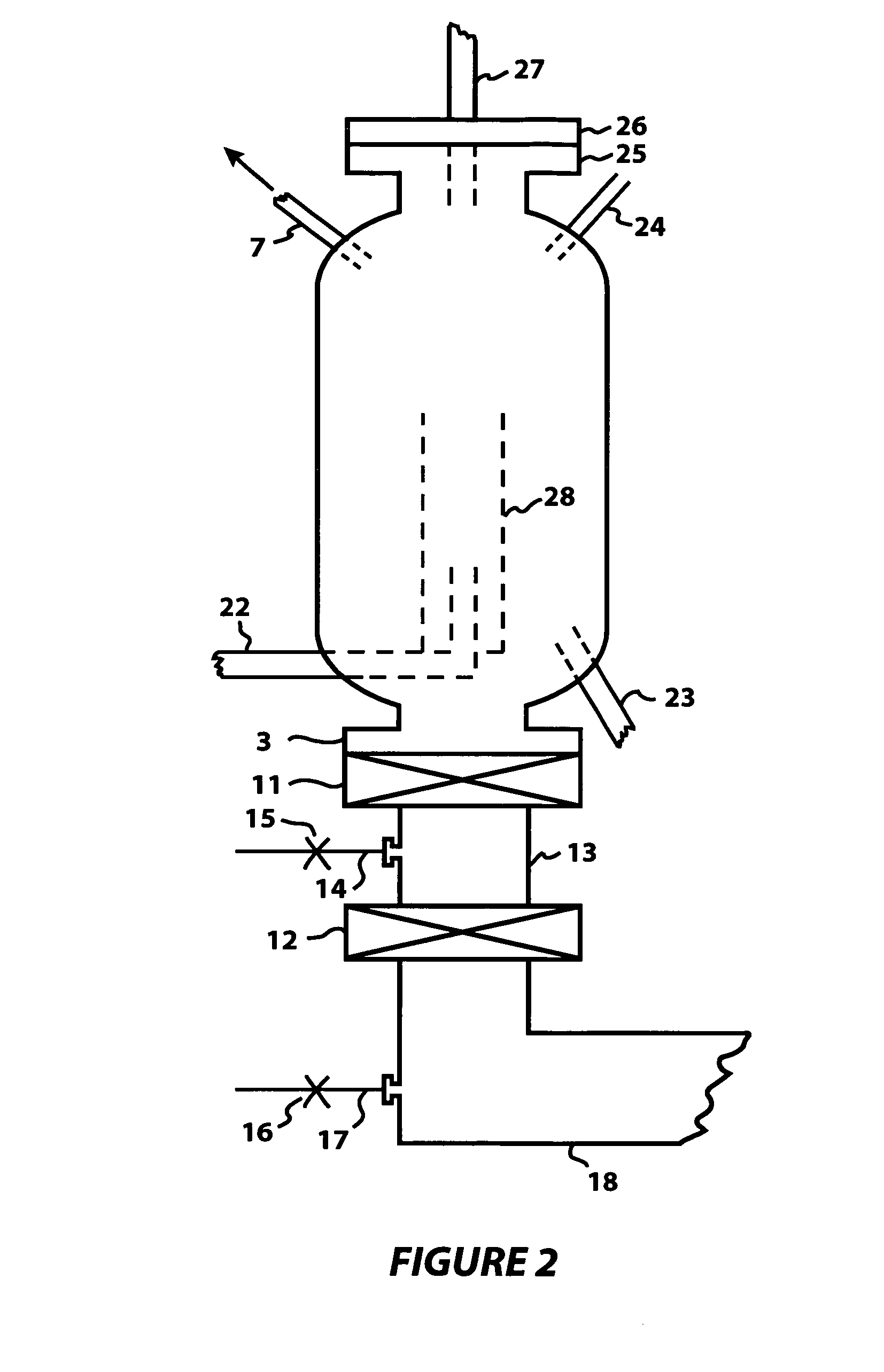

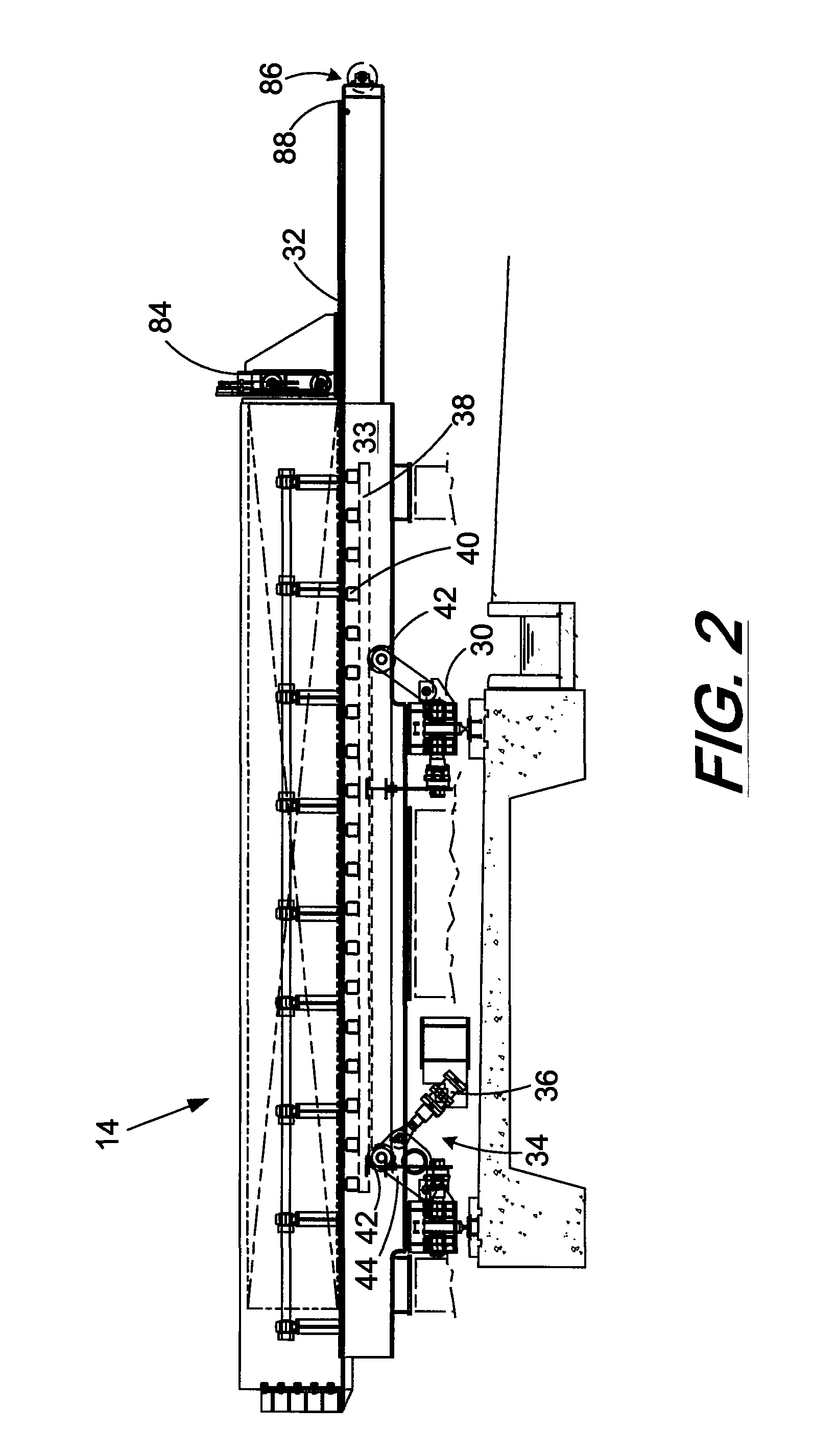

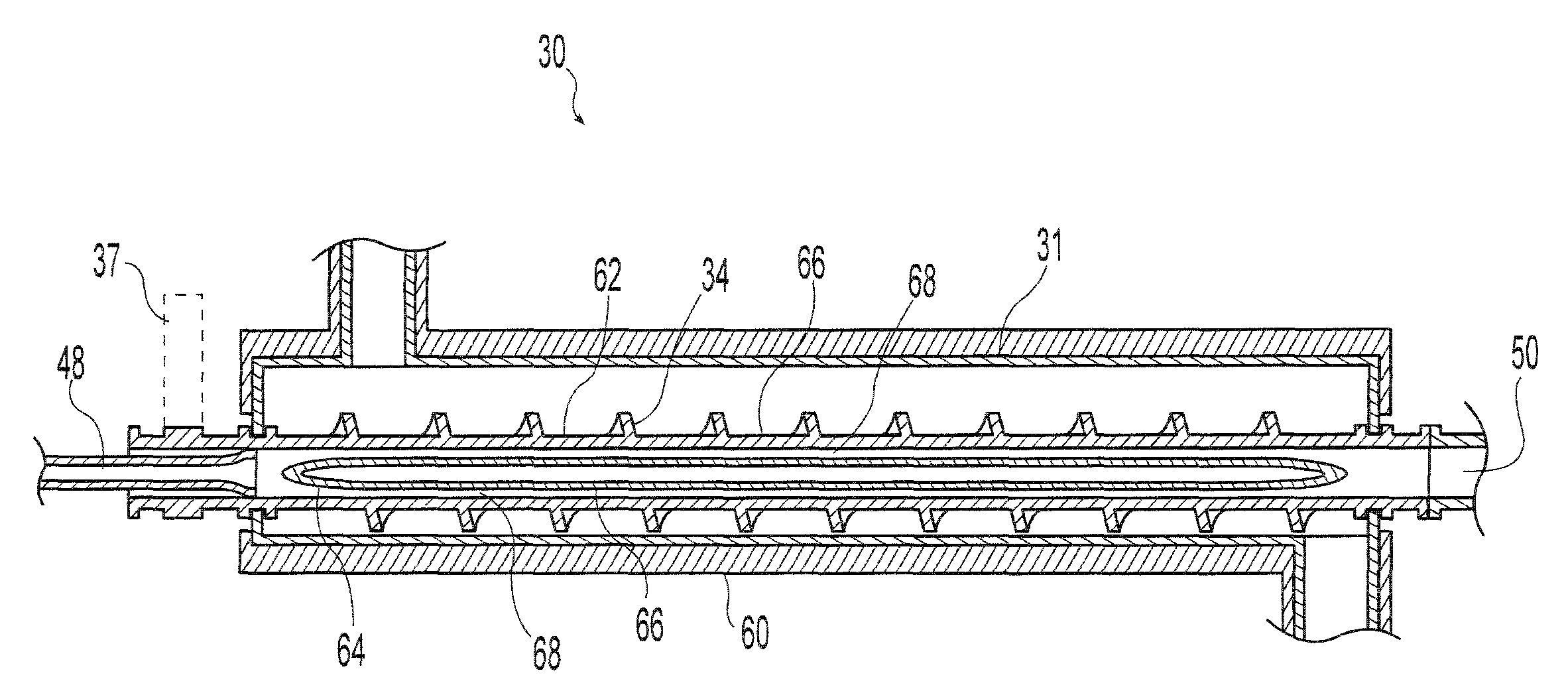

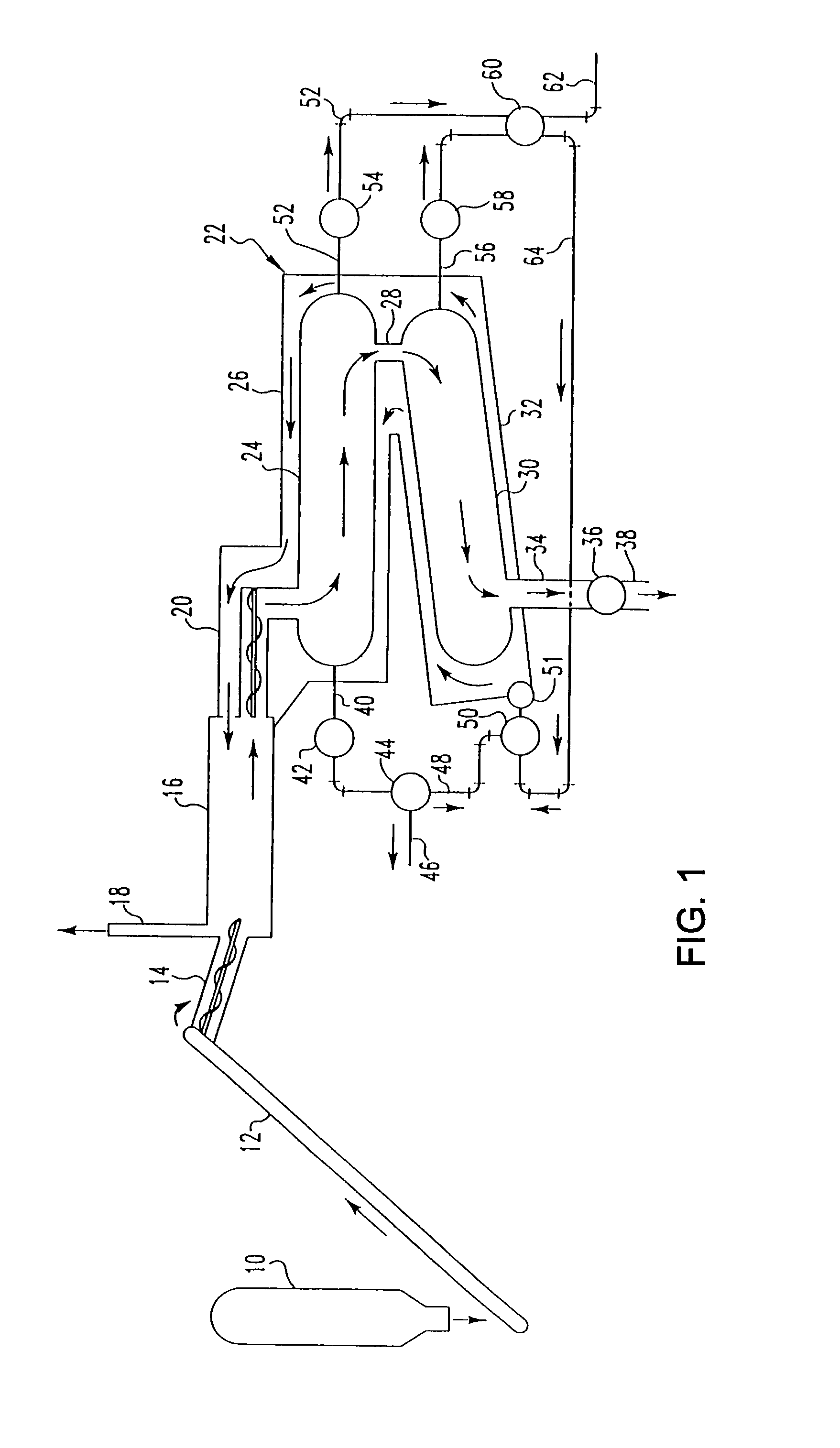

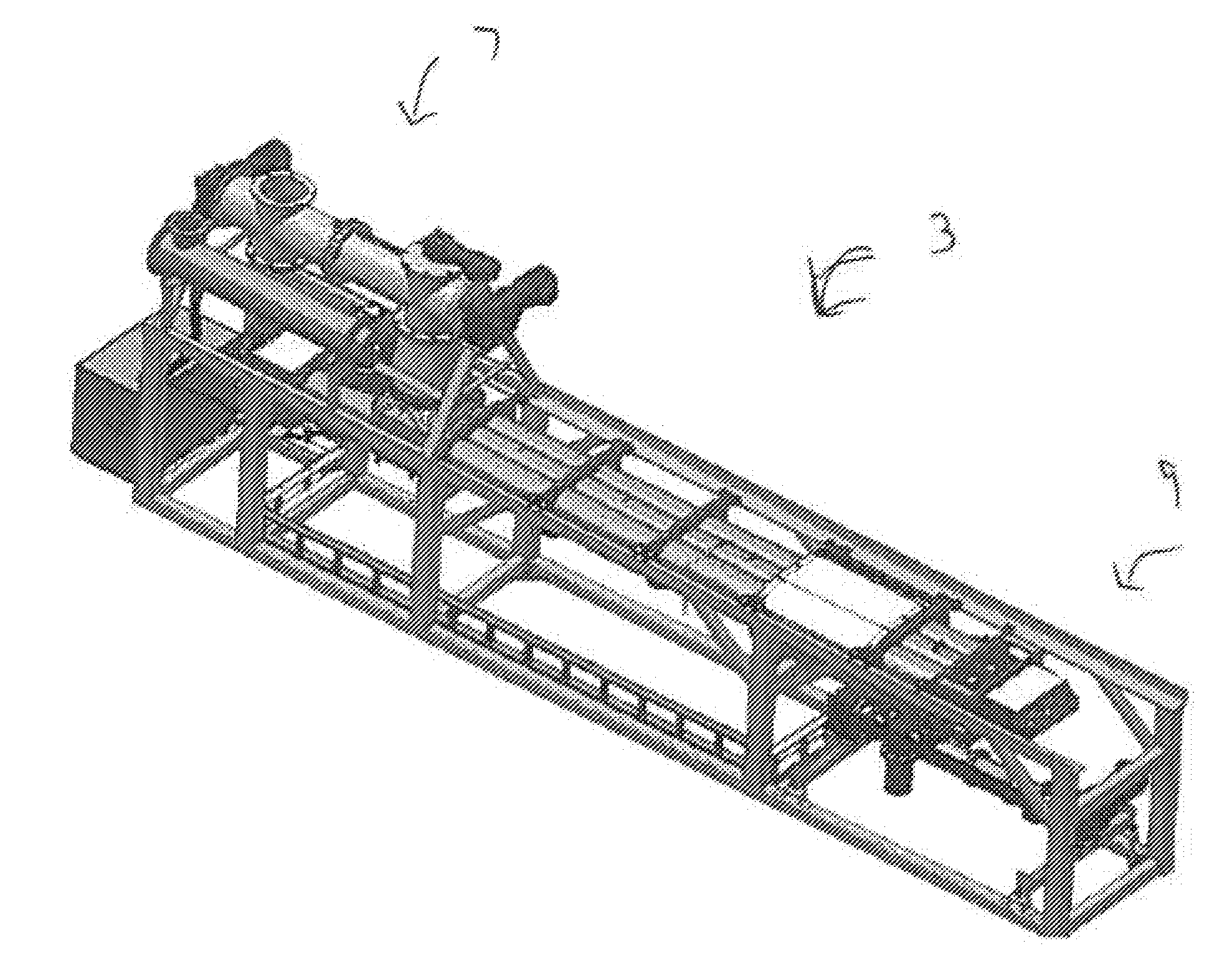

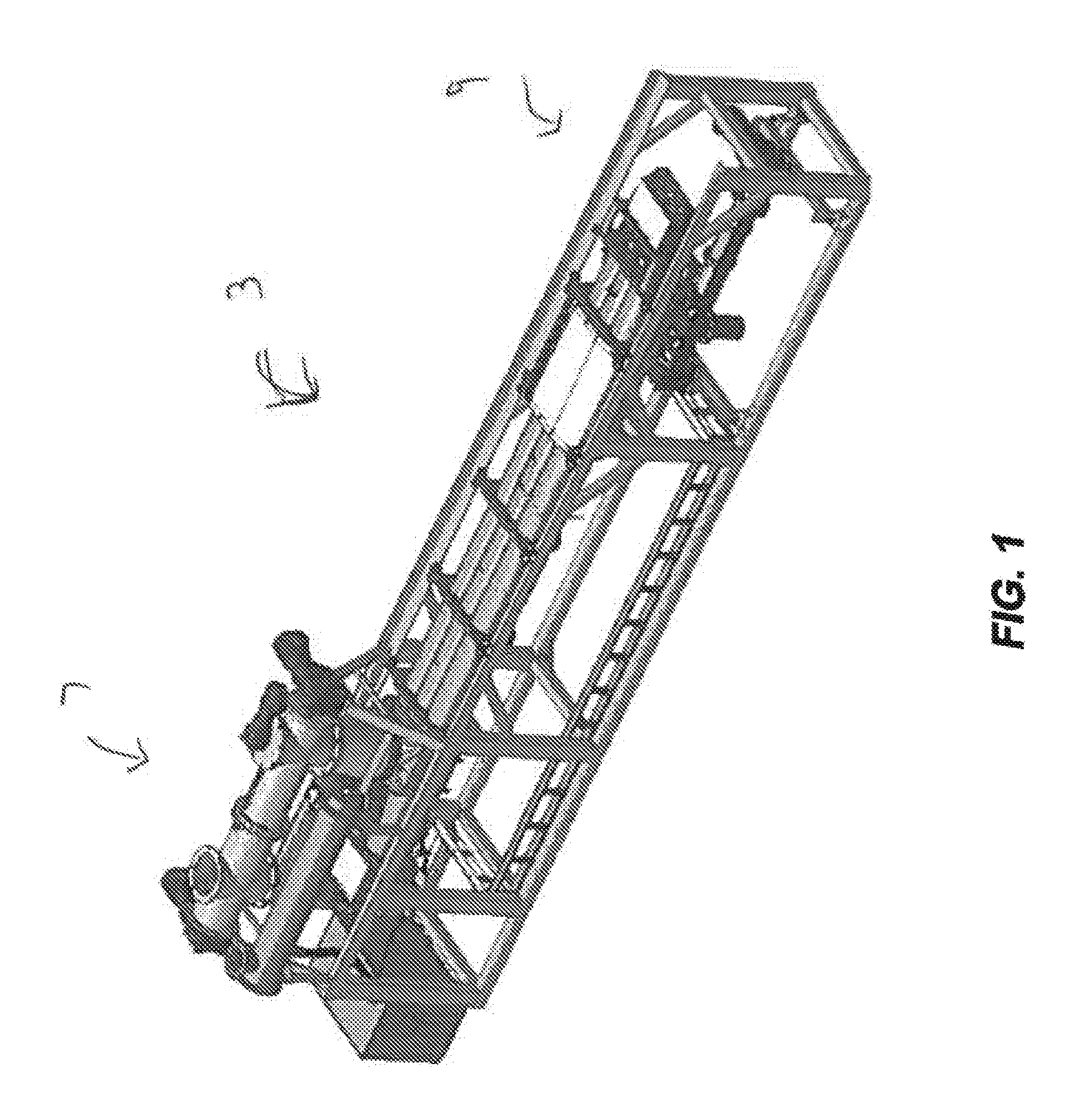

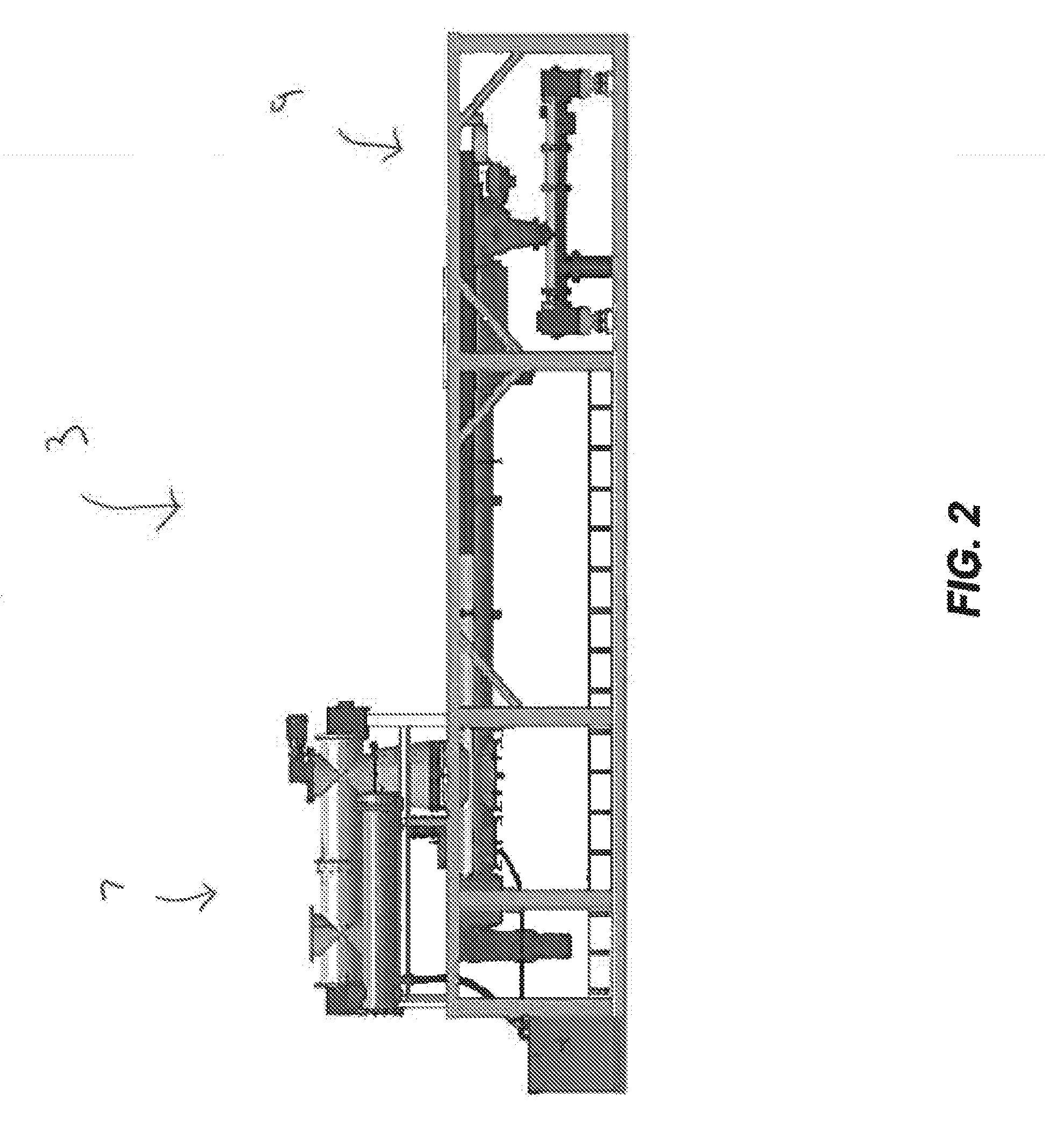

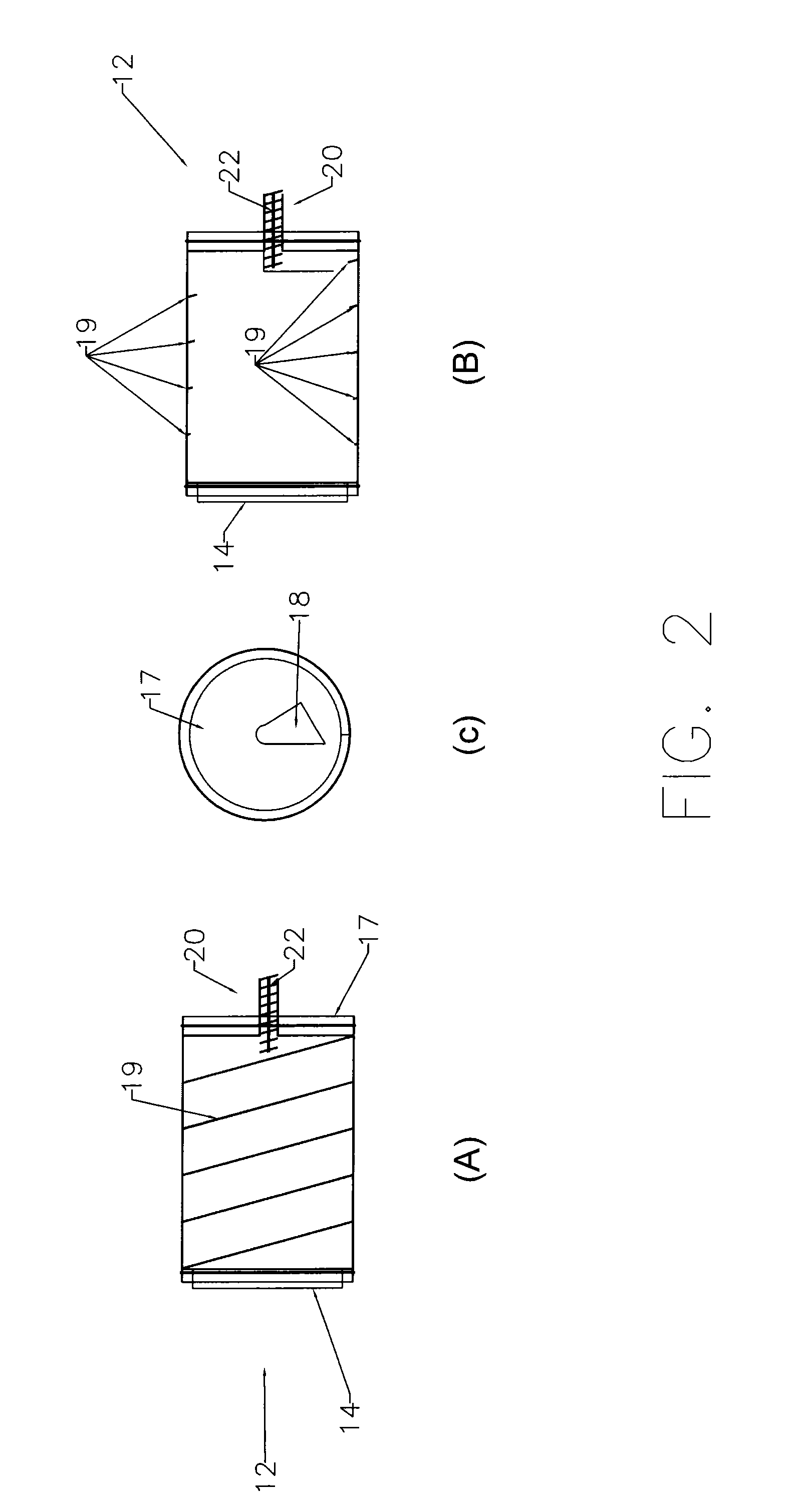

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

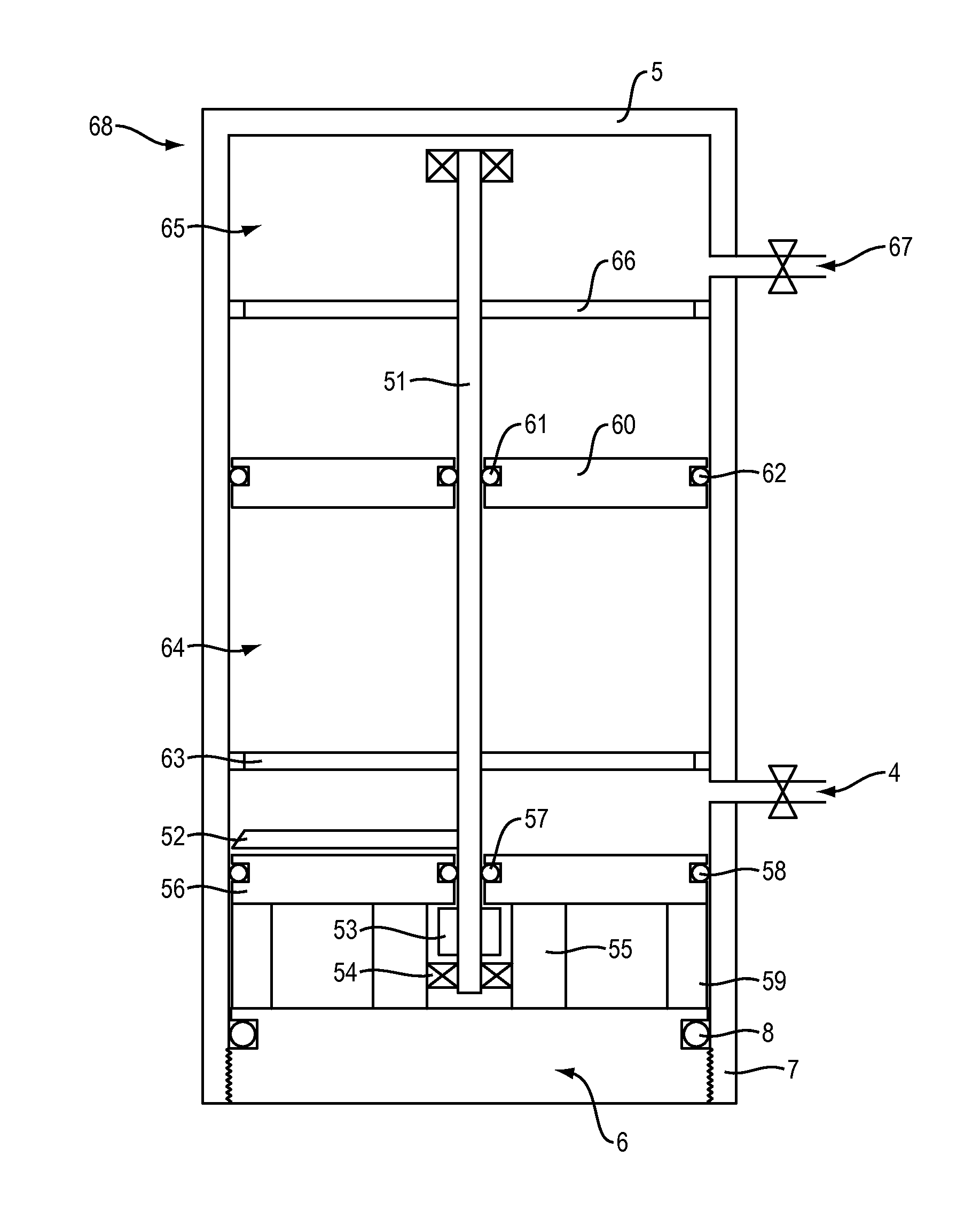

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

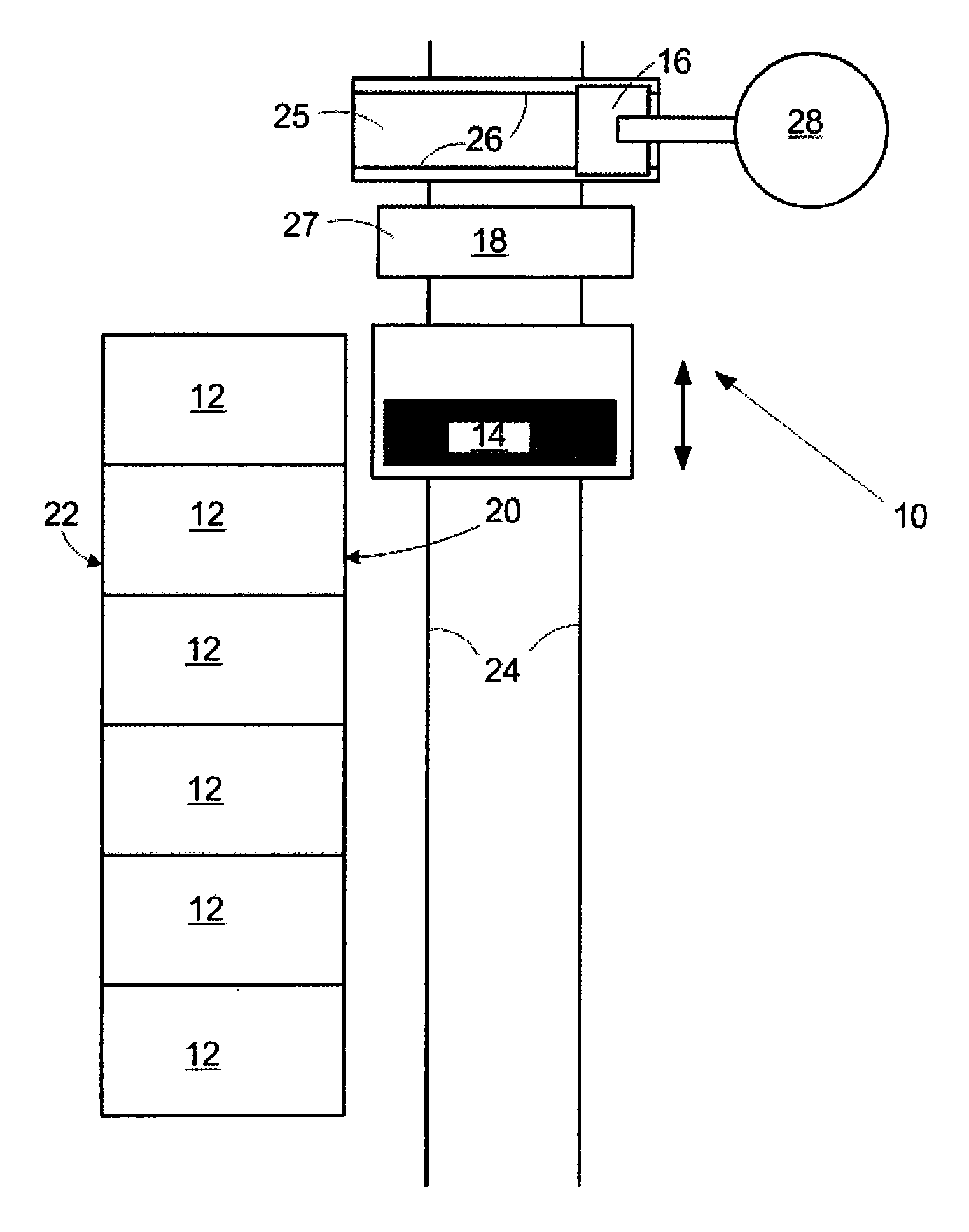

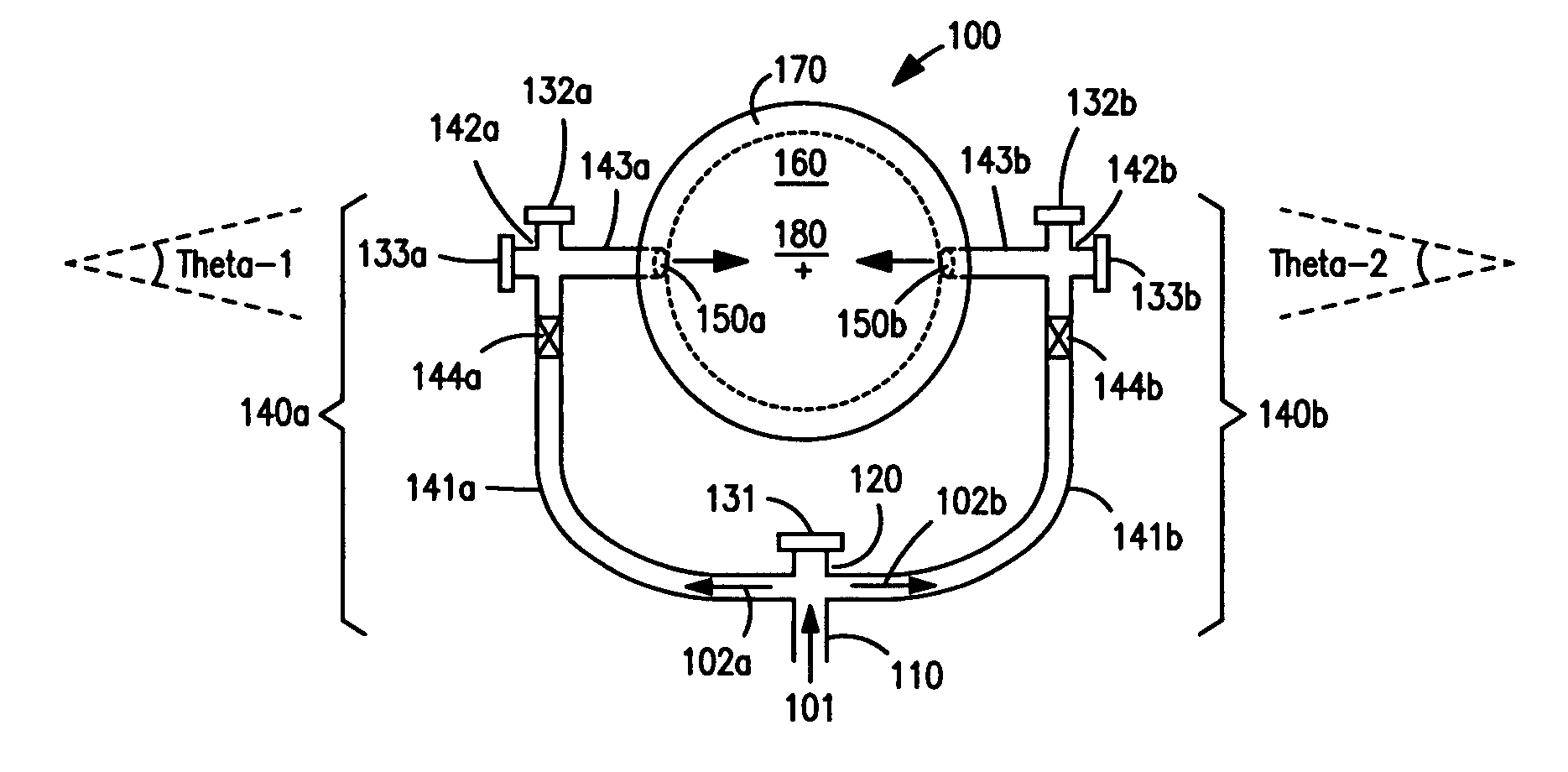

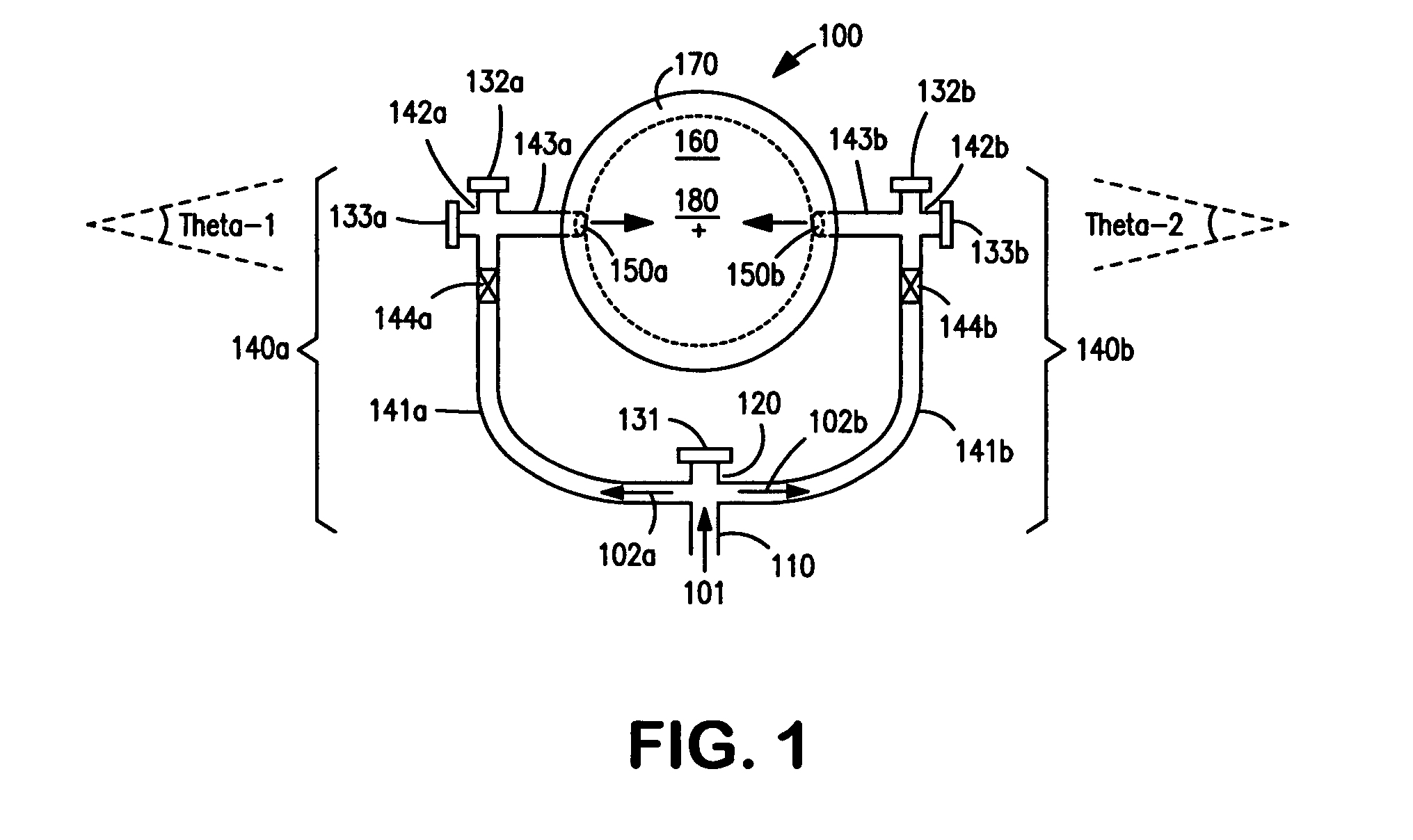

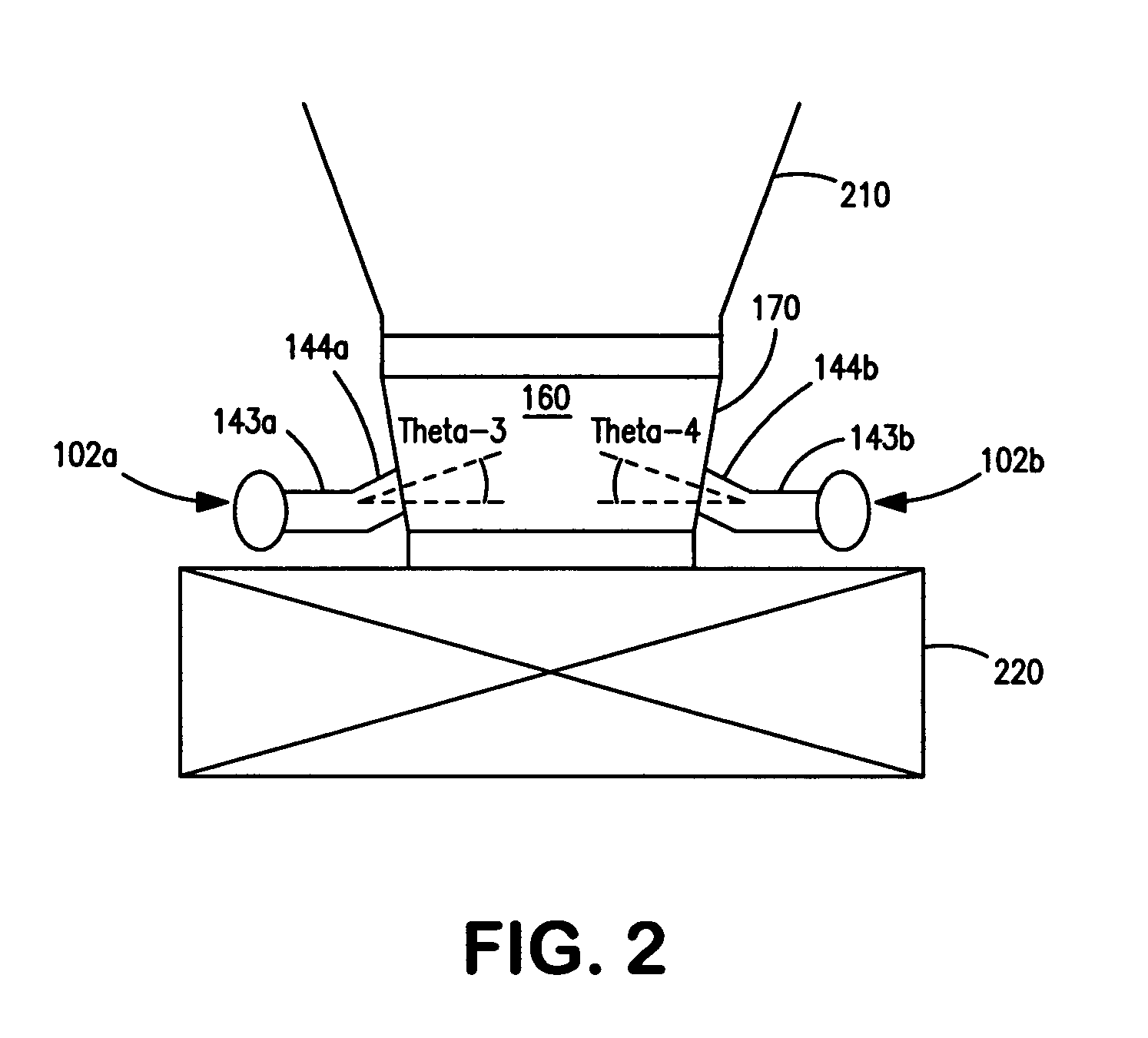

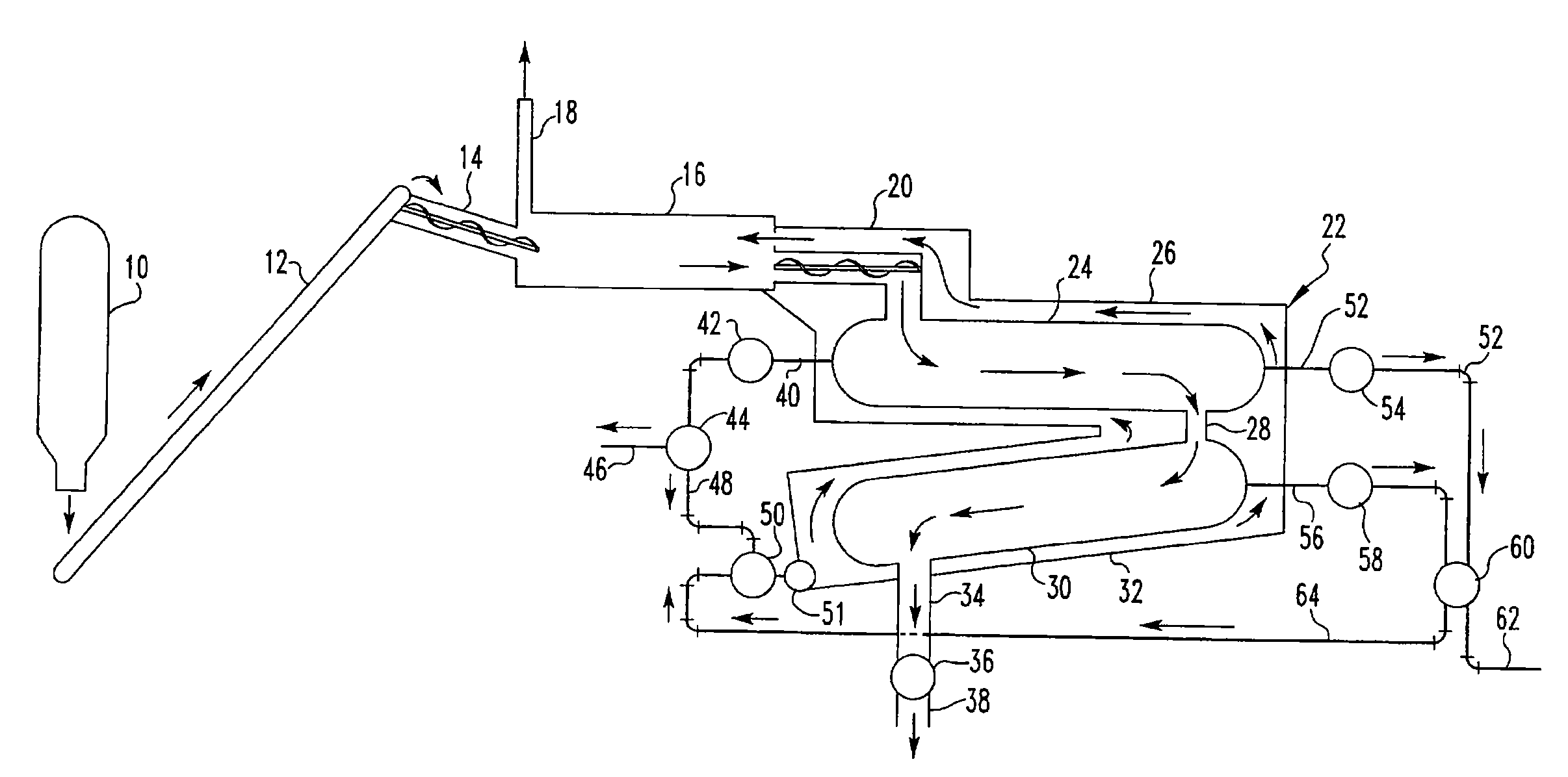

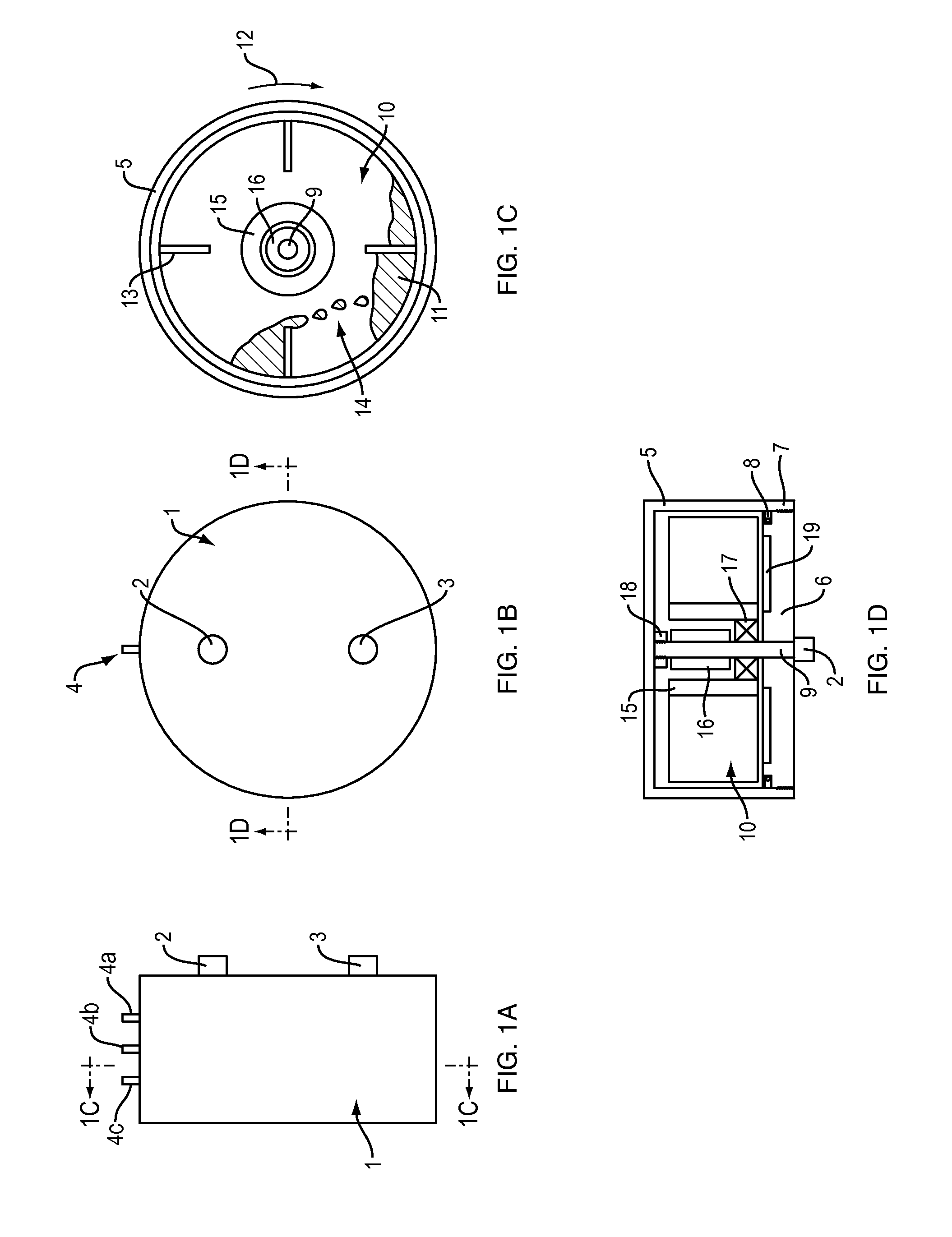

Coker feed method and apparatus

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

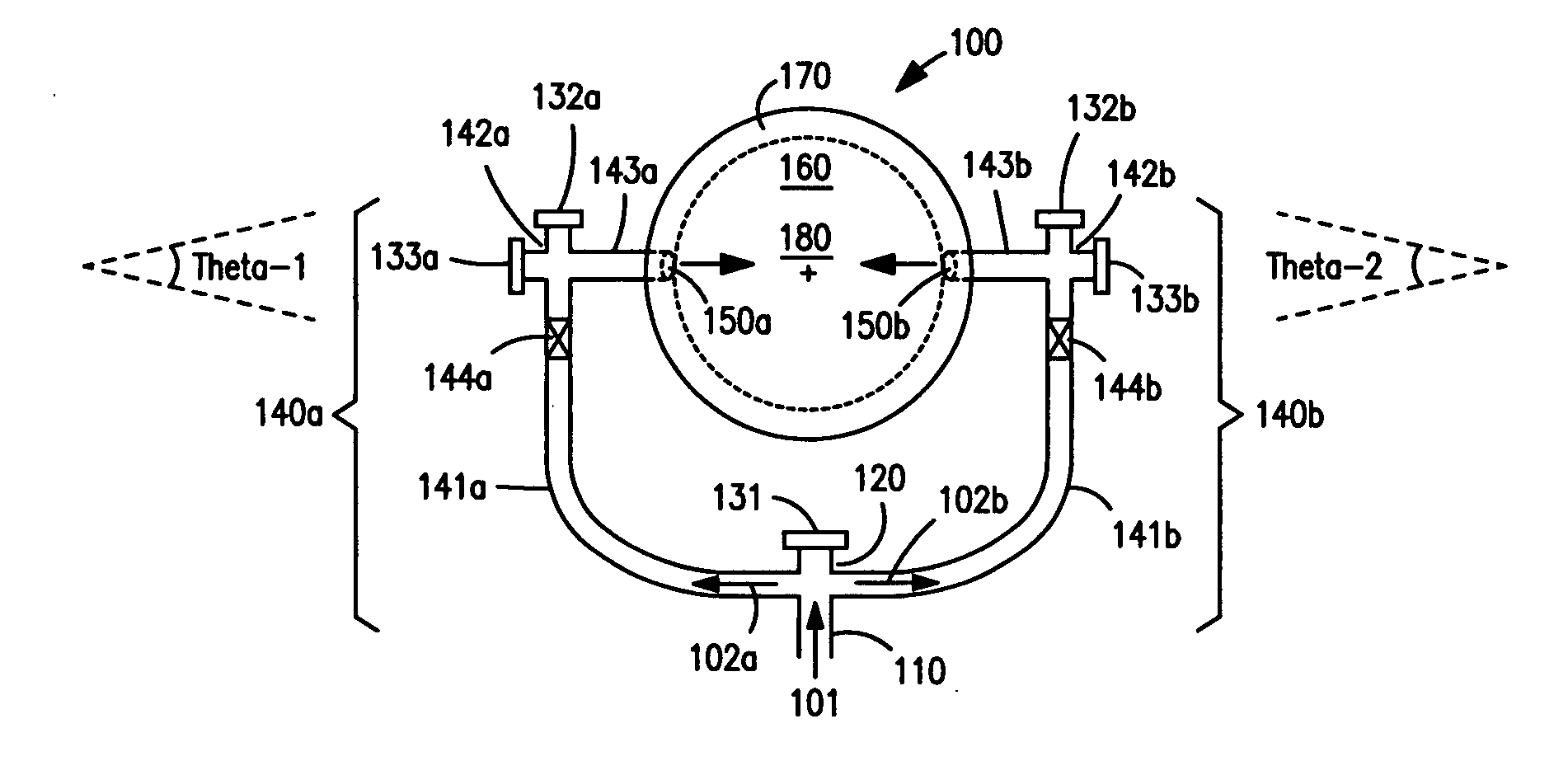

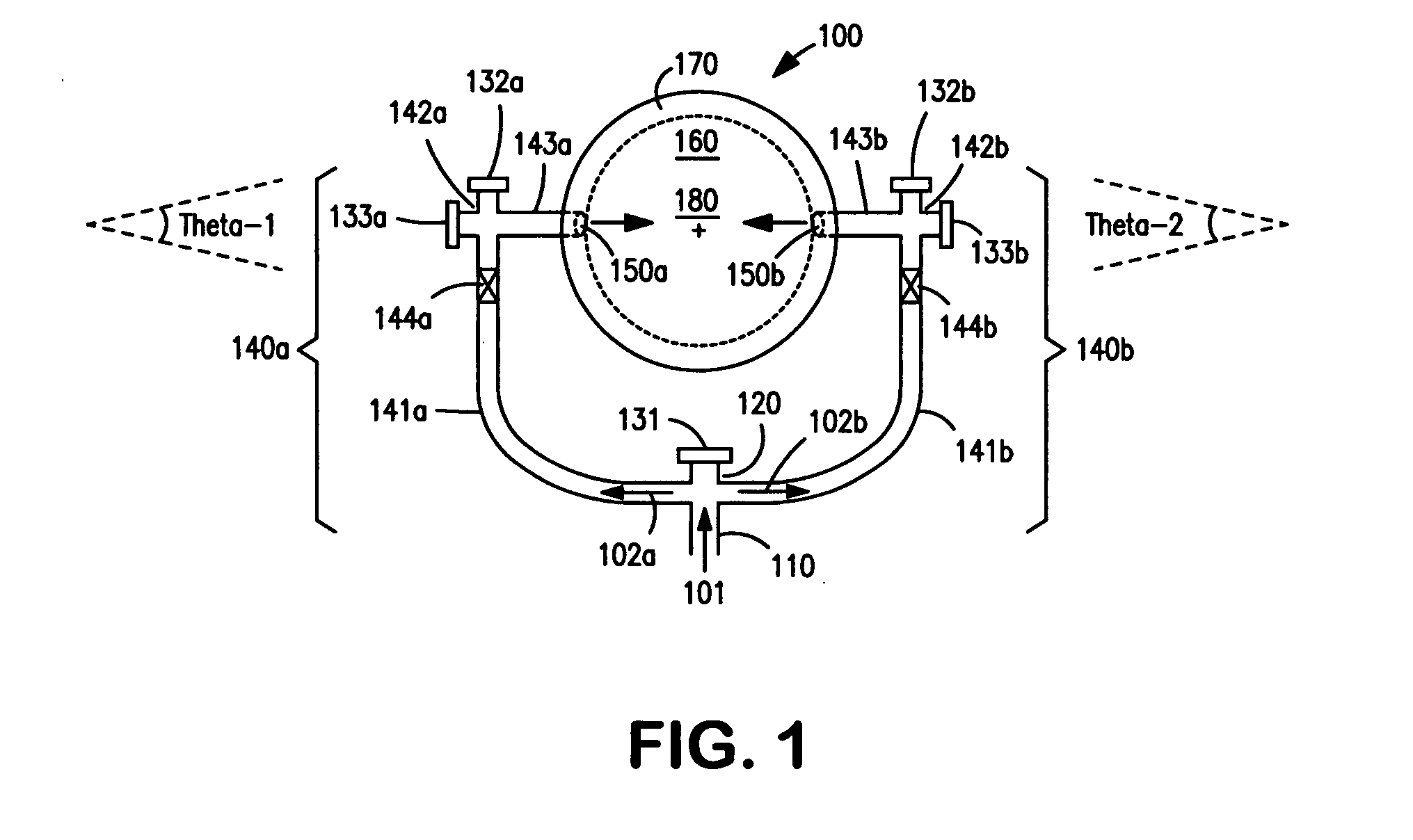

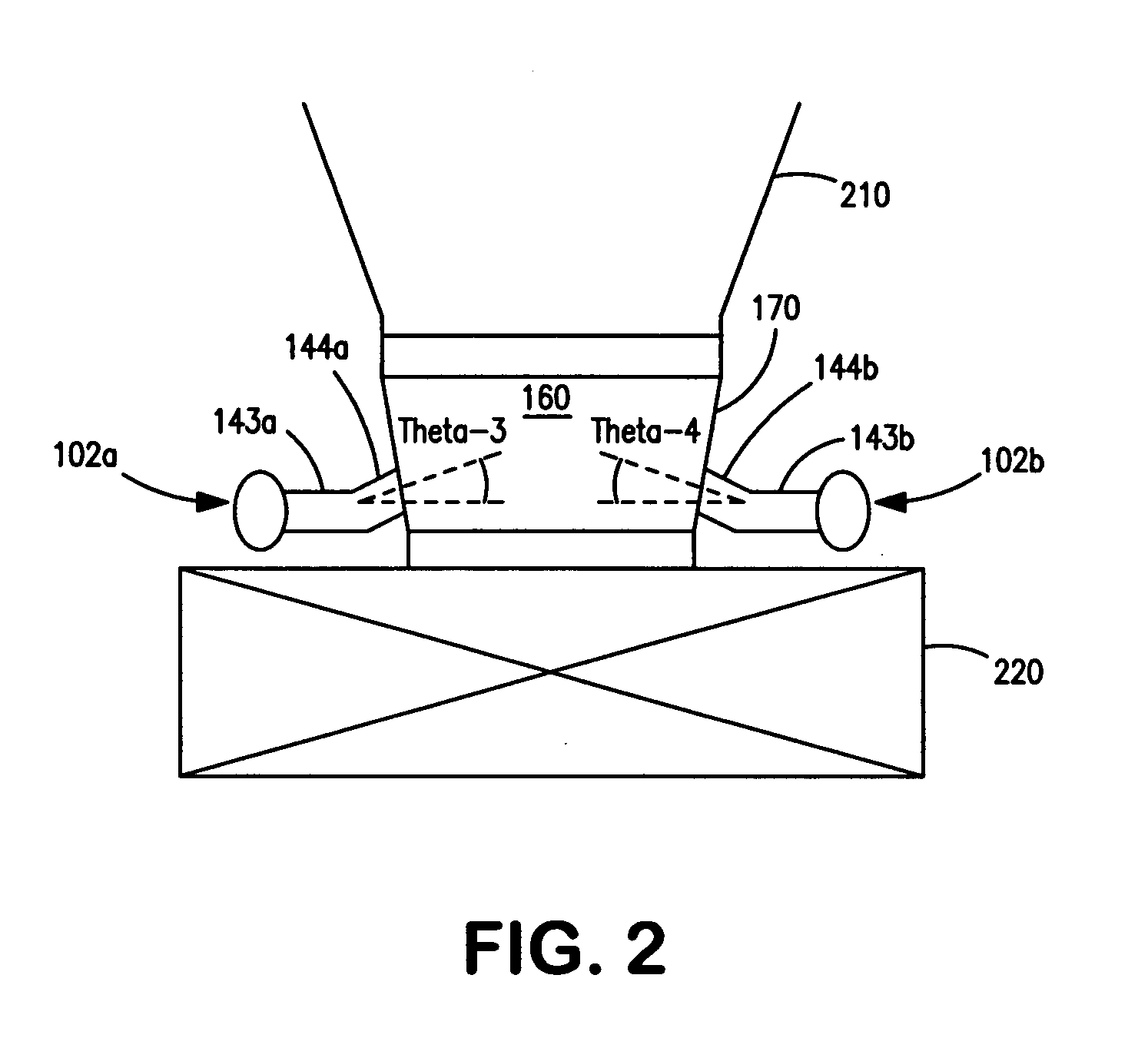

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

Continuous coking process

InactiveUS20070108036A1Thermal non-catalytic crackingCombustible gas coke oven heatingThermodynamicsCoke

The invention relates to a thermal conversion process for continuously producing hydrocarbon vapor and continuously removing a free-flowing coke. The coke, such as a shot coke, can be withdrawn continuously via, e.g., a staged lock hopper system.

Owner:EXXON RES & ENG CO

Method and apparatus for compacting coal for a coal coking process

InactiveUS20070289861A1Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsCoke ovenEngineering

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS7959765B2Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

Methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose are provided. Some methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to thermolysis conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

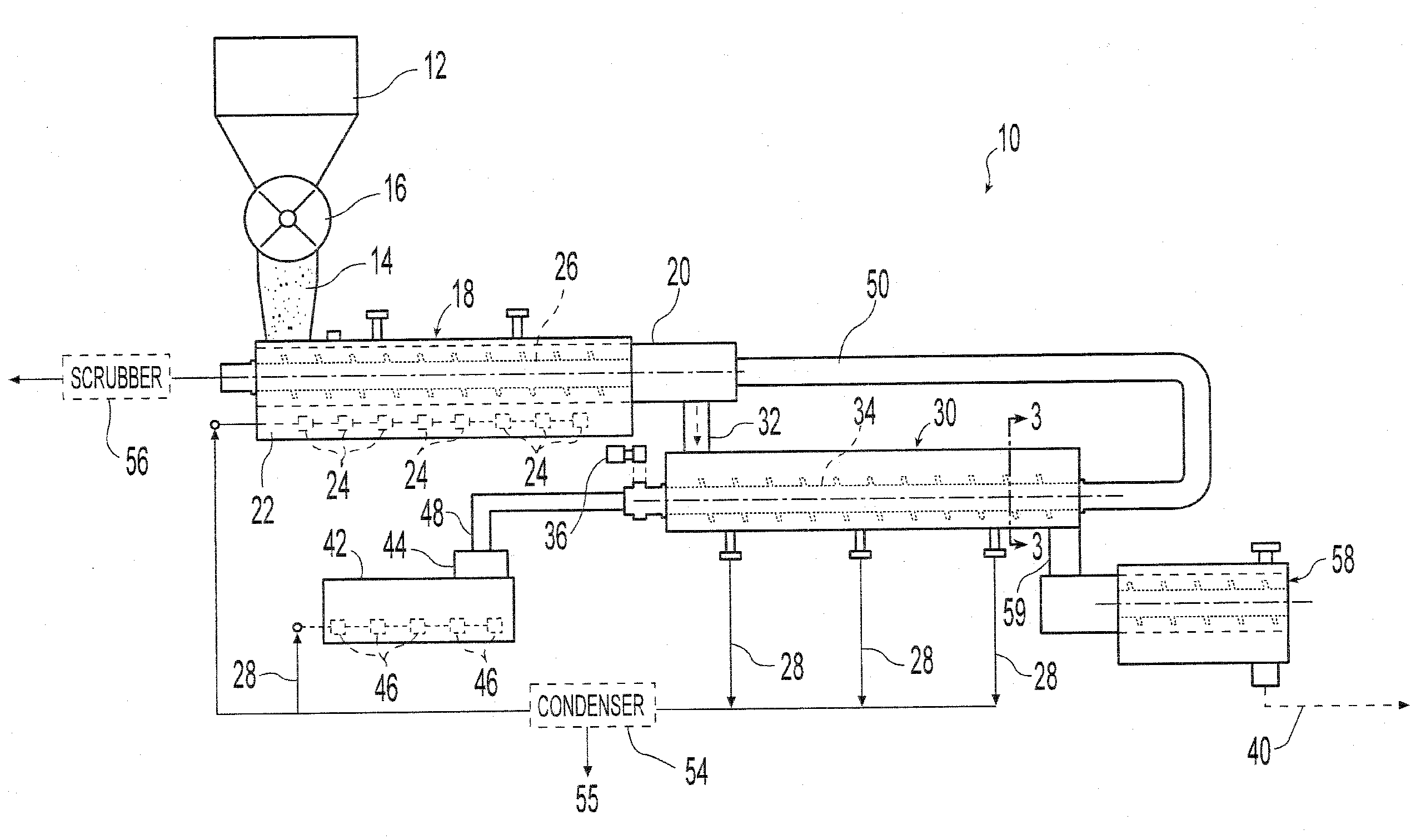

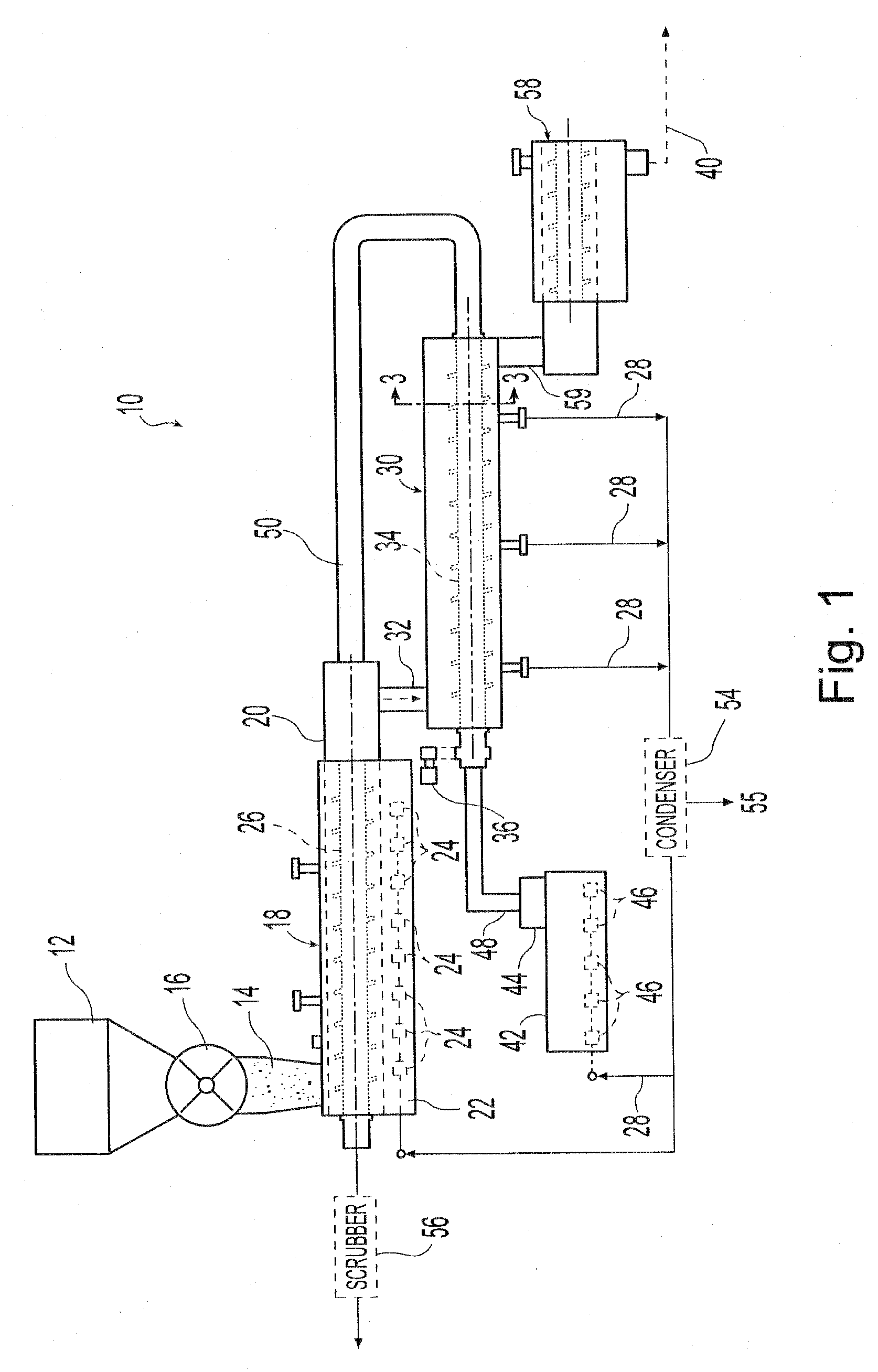

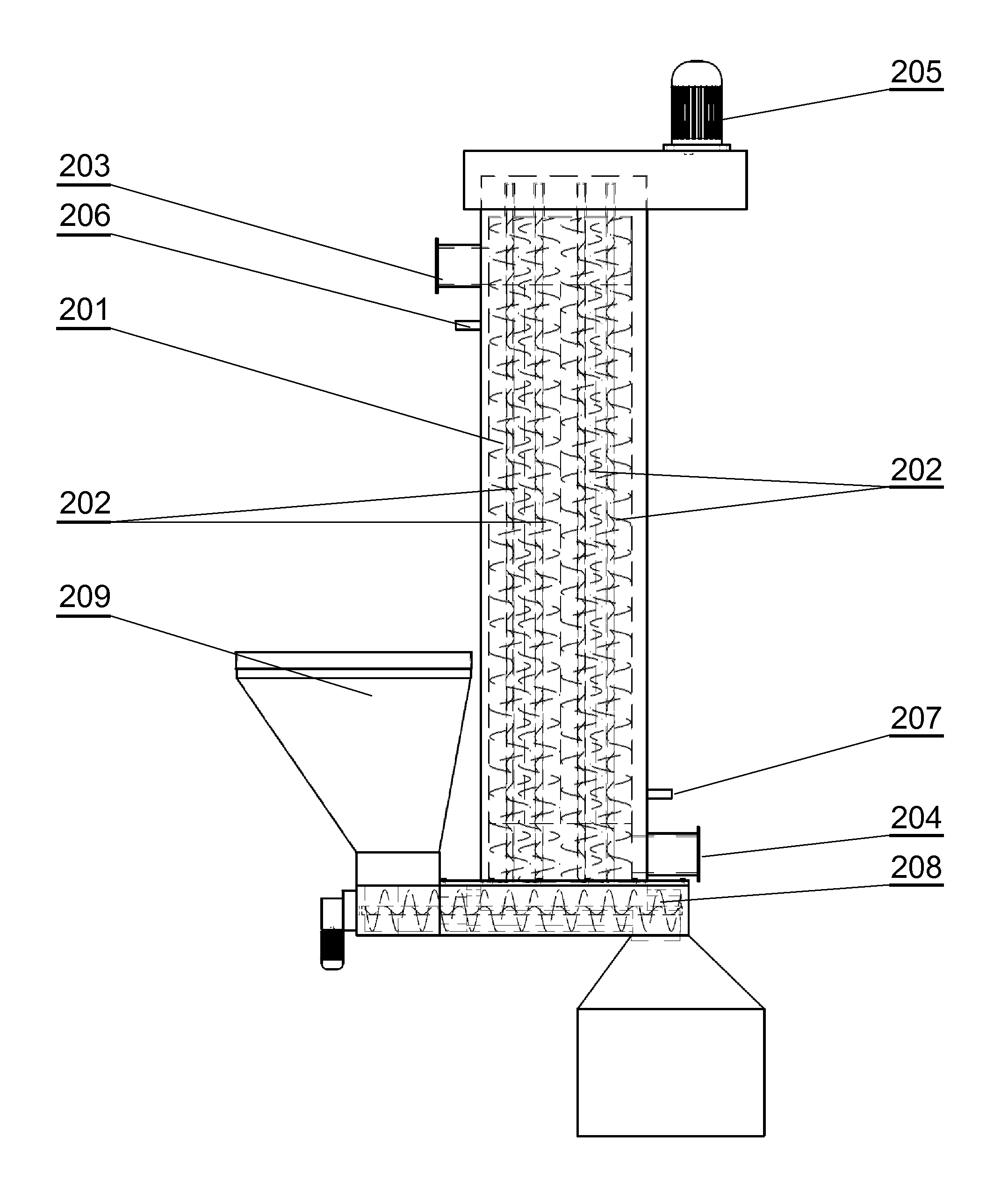

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS20130240343A1Reduce the cross-sectional areaWeaken energyCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberMechanical engineering

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS9045693B2Weaken energyLower Level RequirementsCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberDrive shaft

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

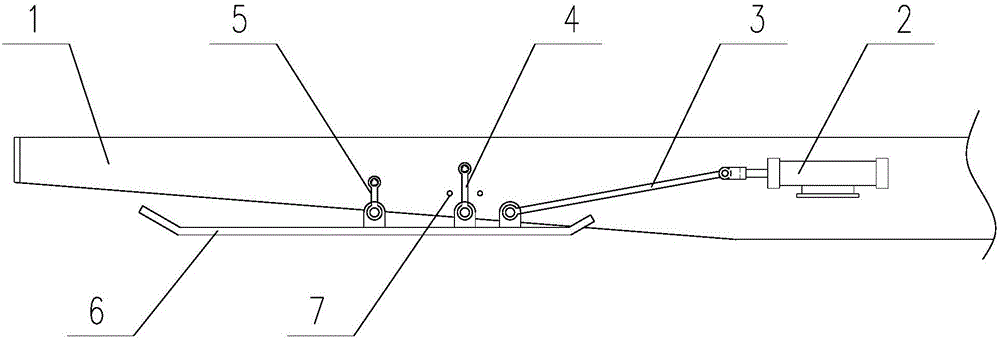

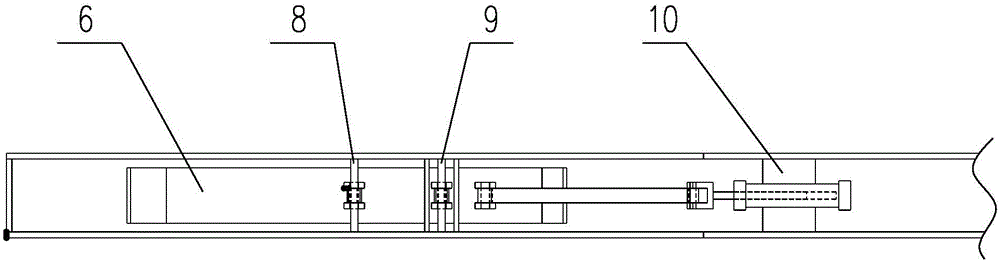

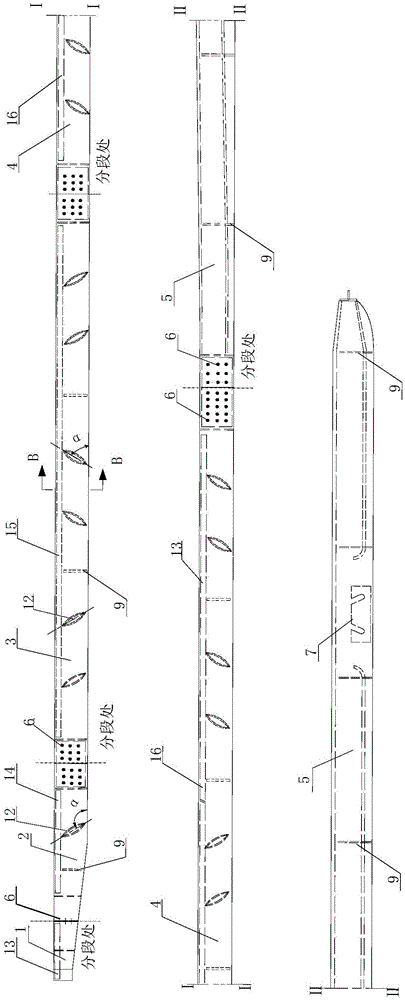

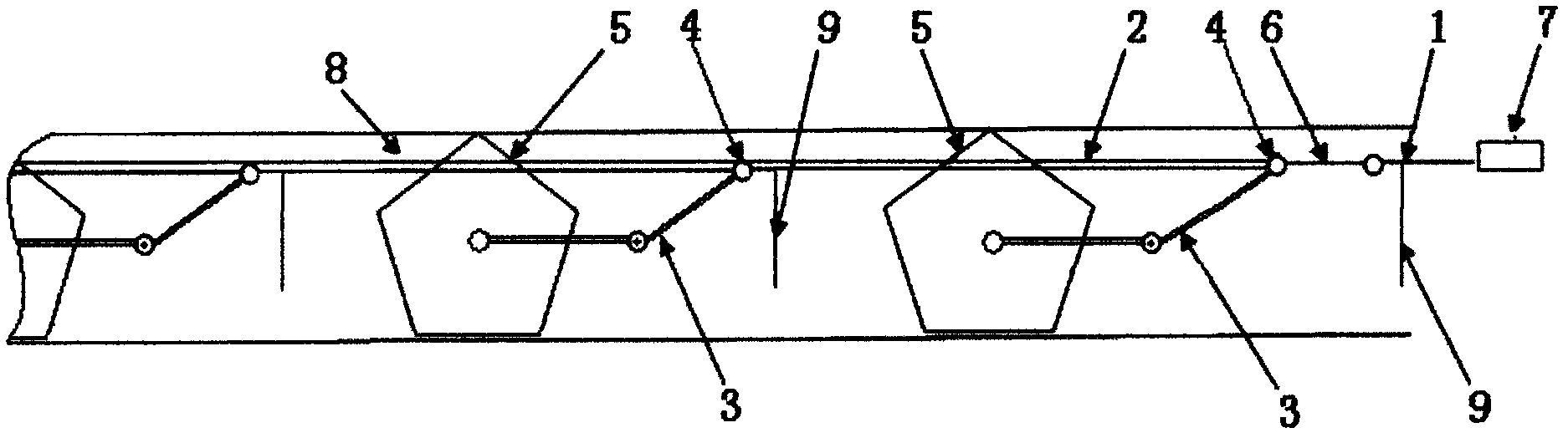

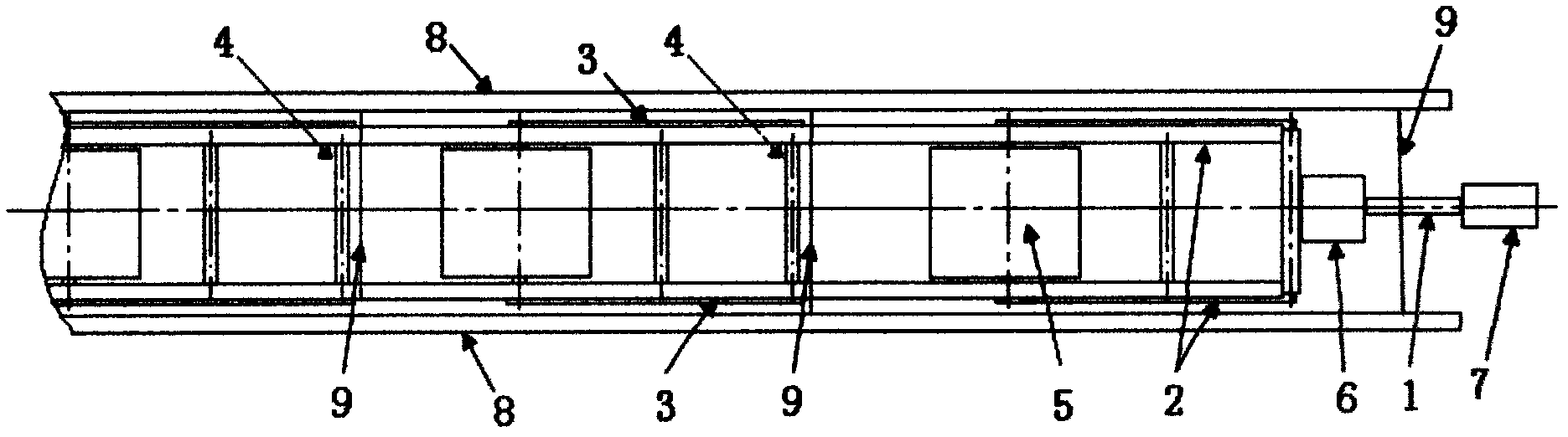

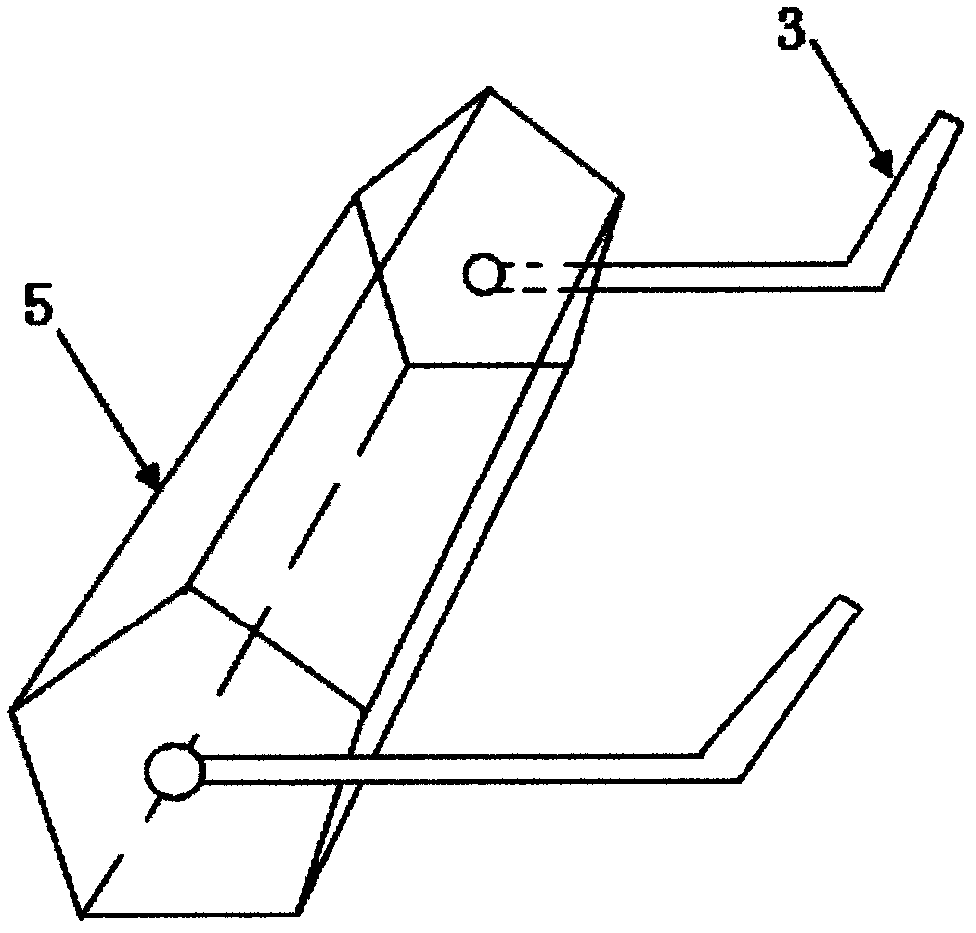

Coal leveling bar with vibrating compacting function

ActiveCN105885878ATo achieve the purpose of compactionImprove compactionCoal charges mechanical treatmentEngineeringPiston rod

The invention relates to a coal leveling bar with a vibrating compacting function. At least one group of vibrating compacting devices are mounted on the coal leveling bar in the longitudinal direction; each vibrating compacting device comprises a pneumatic vibrator and a compacting plate, and the compacting plate and the coal leveling bar are mounted in the same direction; three hinged supports are longitudinally arranged on each compacting plate, one hinged support is hinged with one end of a connecting rod I, the other end of the connecting rod I is hinged with a piston rod of the corresponding pneumatic vibrator, the other two hinged supports are hinged with one end of a connecting rod II and one end of a connecting rod III respectively, and the other end of the connecting rod II and the other end of the connecting rod III are hinged with the coal leveling bar. The vibrating compacting devices are arranged on the coal leveling bar, the pneumatic vibrators promote the compacting plates to vibrate, a four-bar mechanism promotes the compacting plates to perform vertical patting motions, the purpose of compacting of a coal cake at the top of a top-mounted coking furnace is achieved, the practical use effect is good, the yield of coke of a single furnace is increased, and the coke quality is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

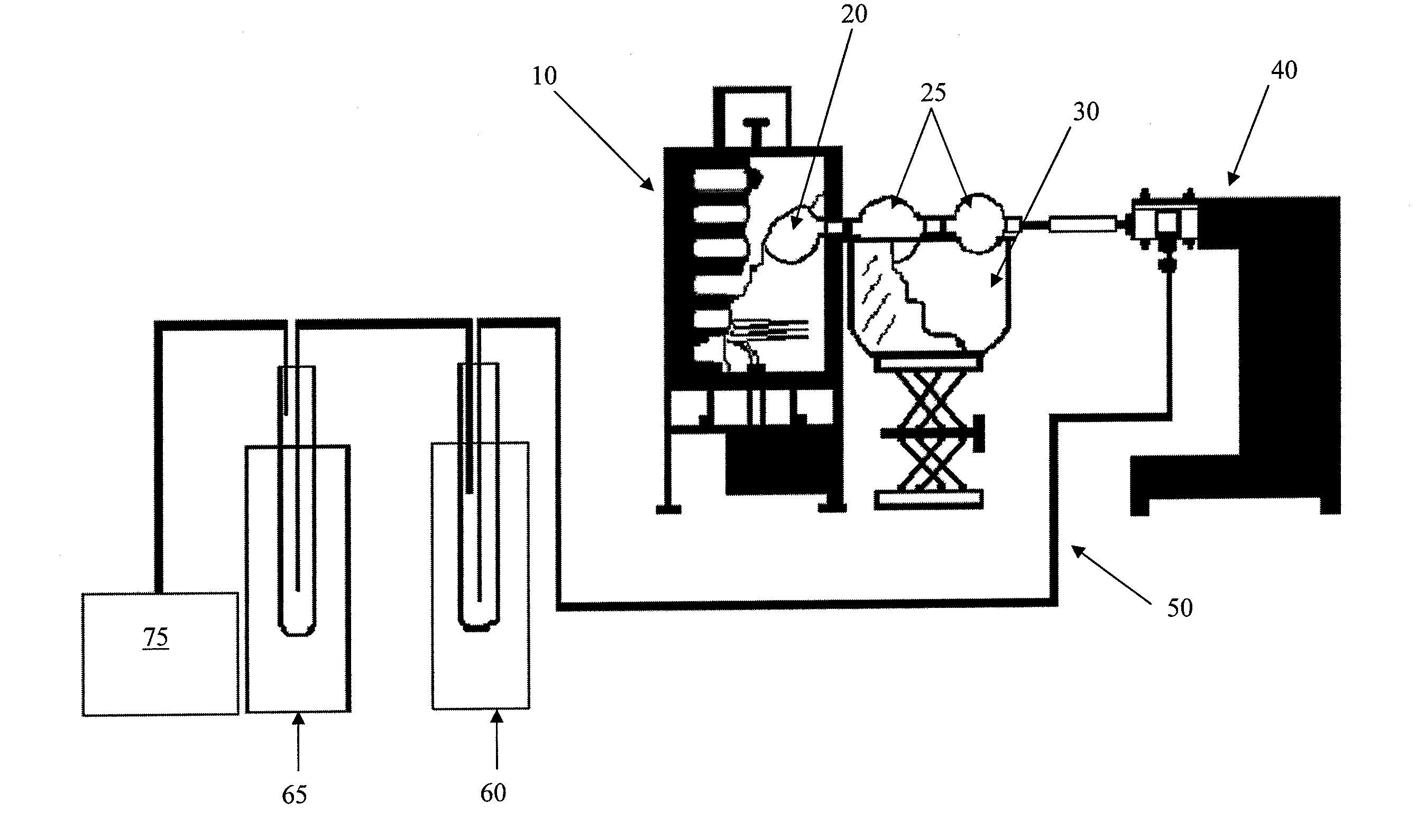

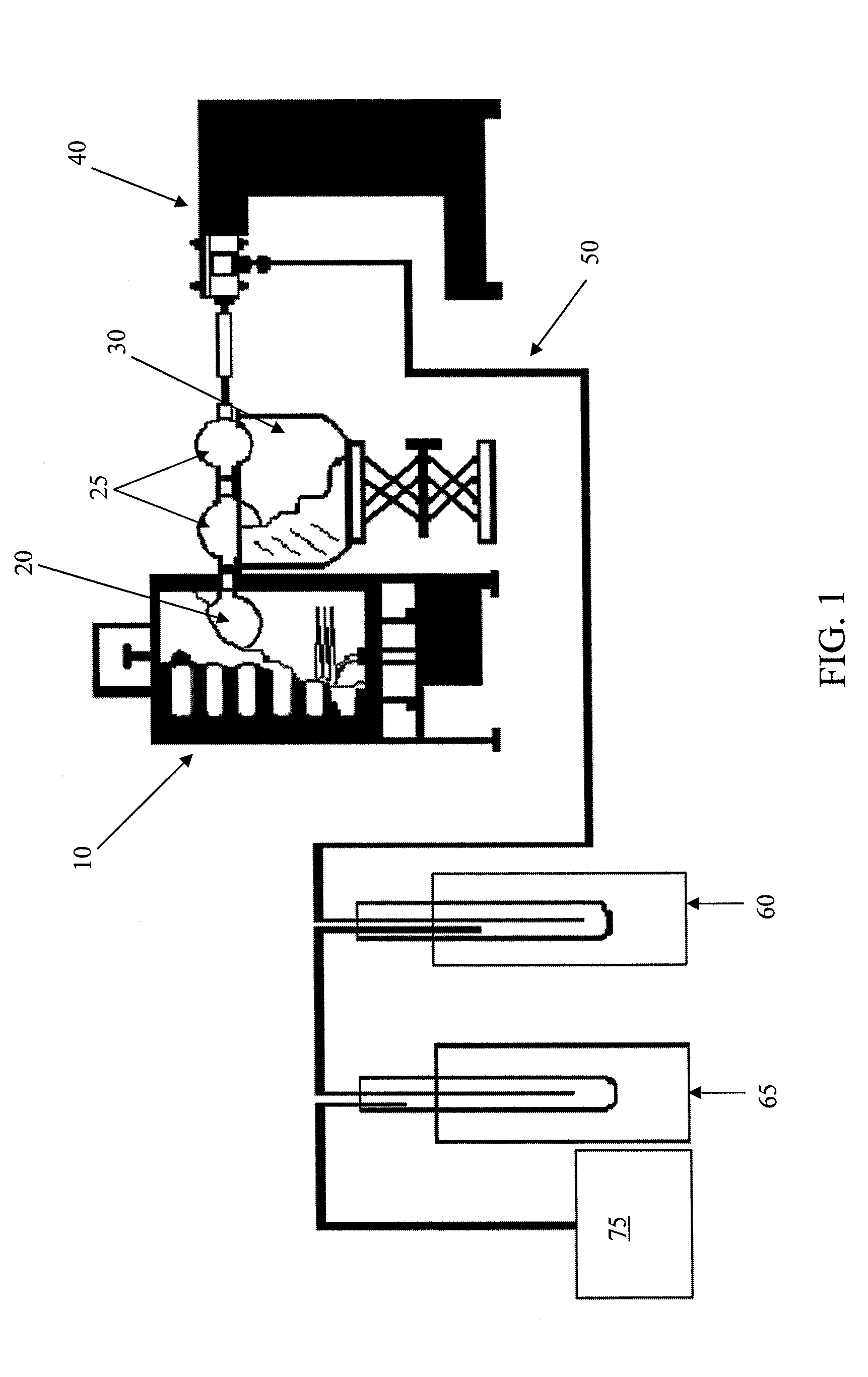

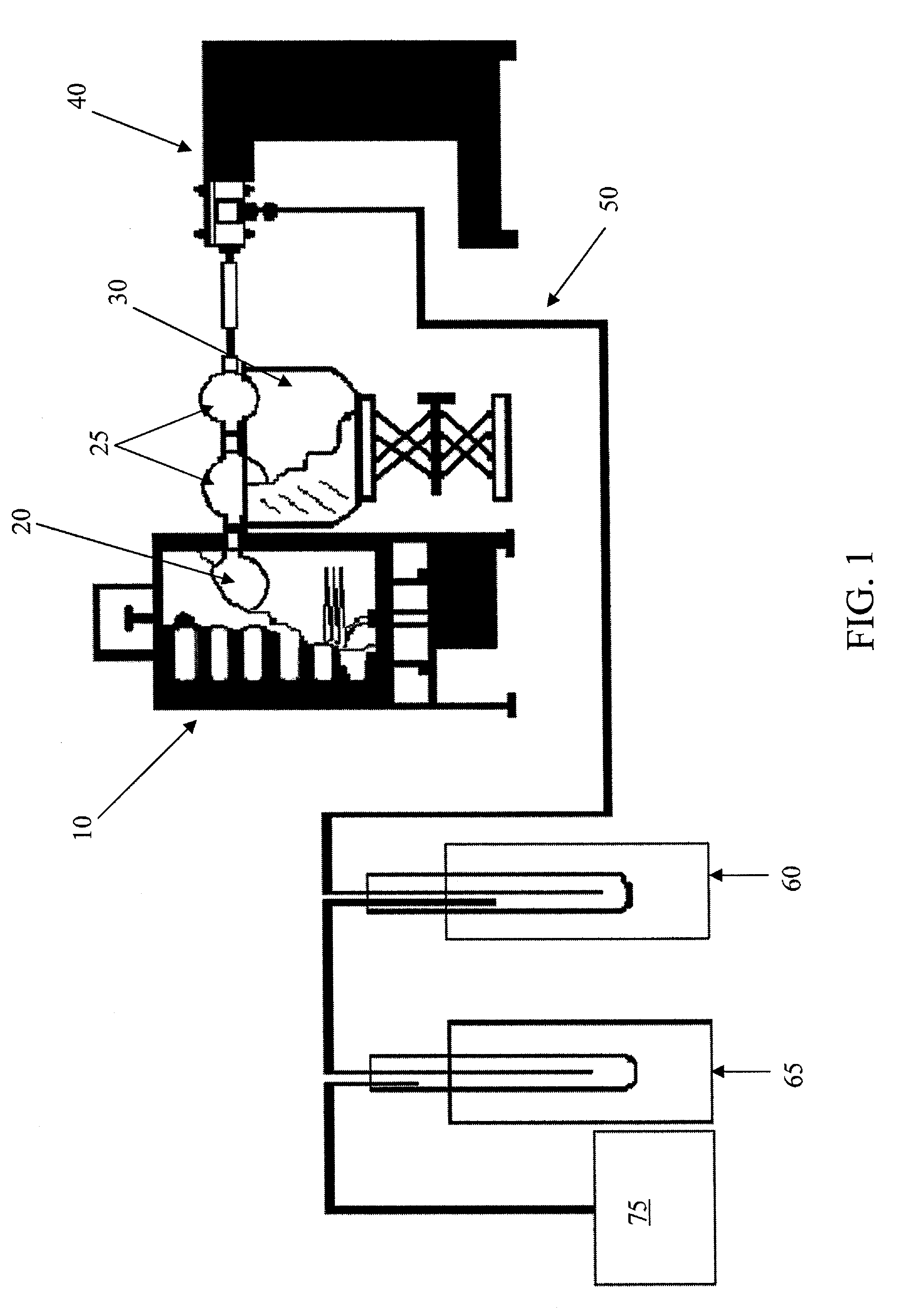

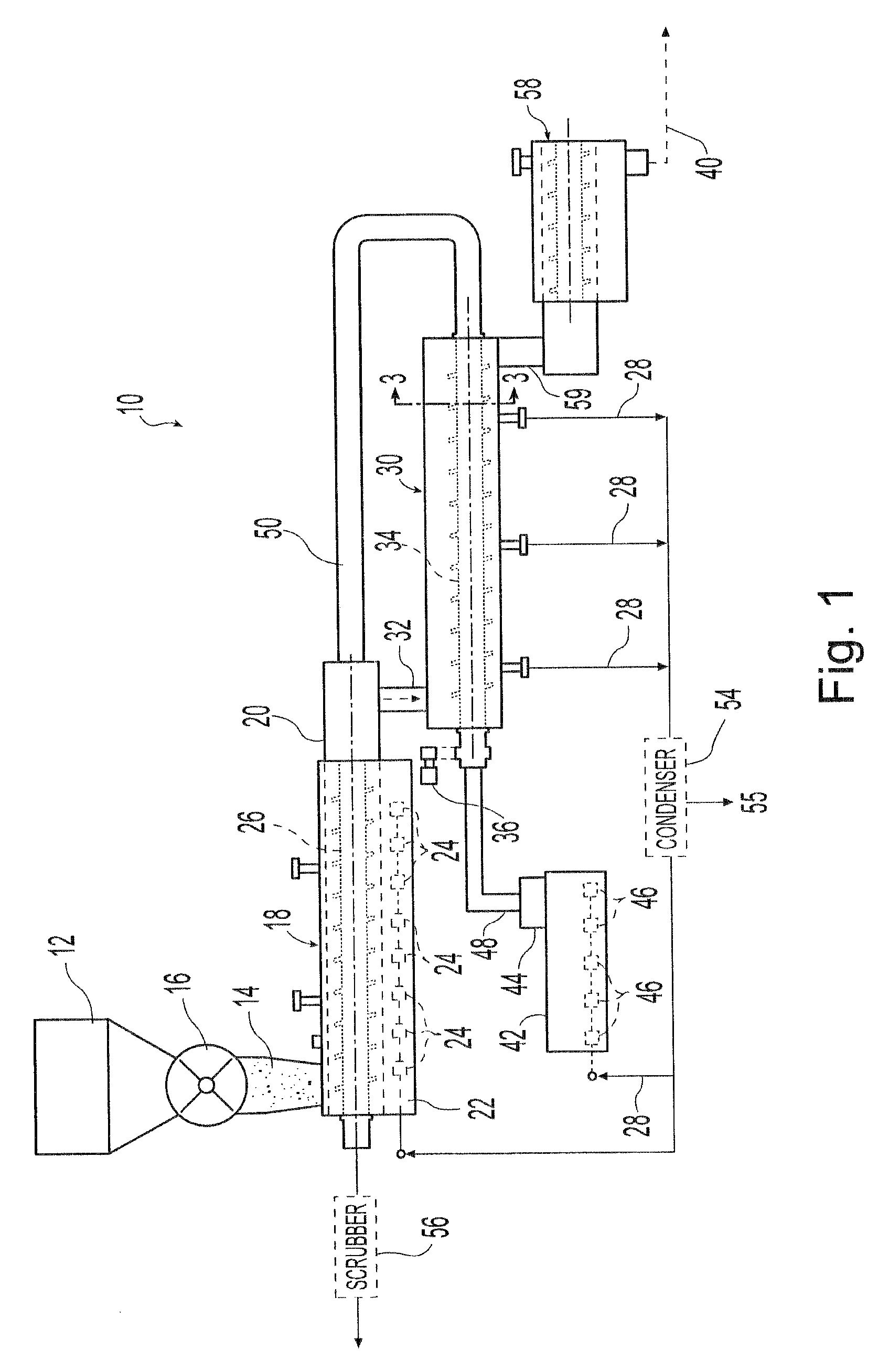

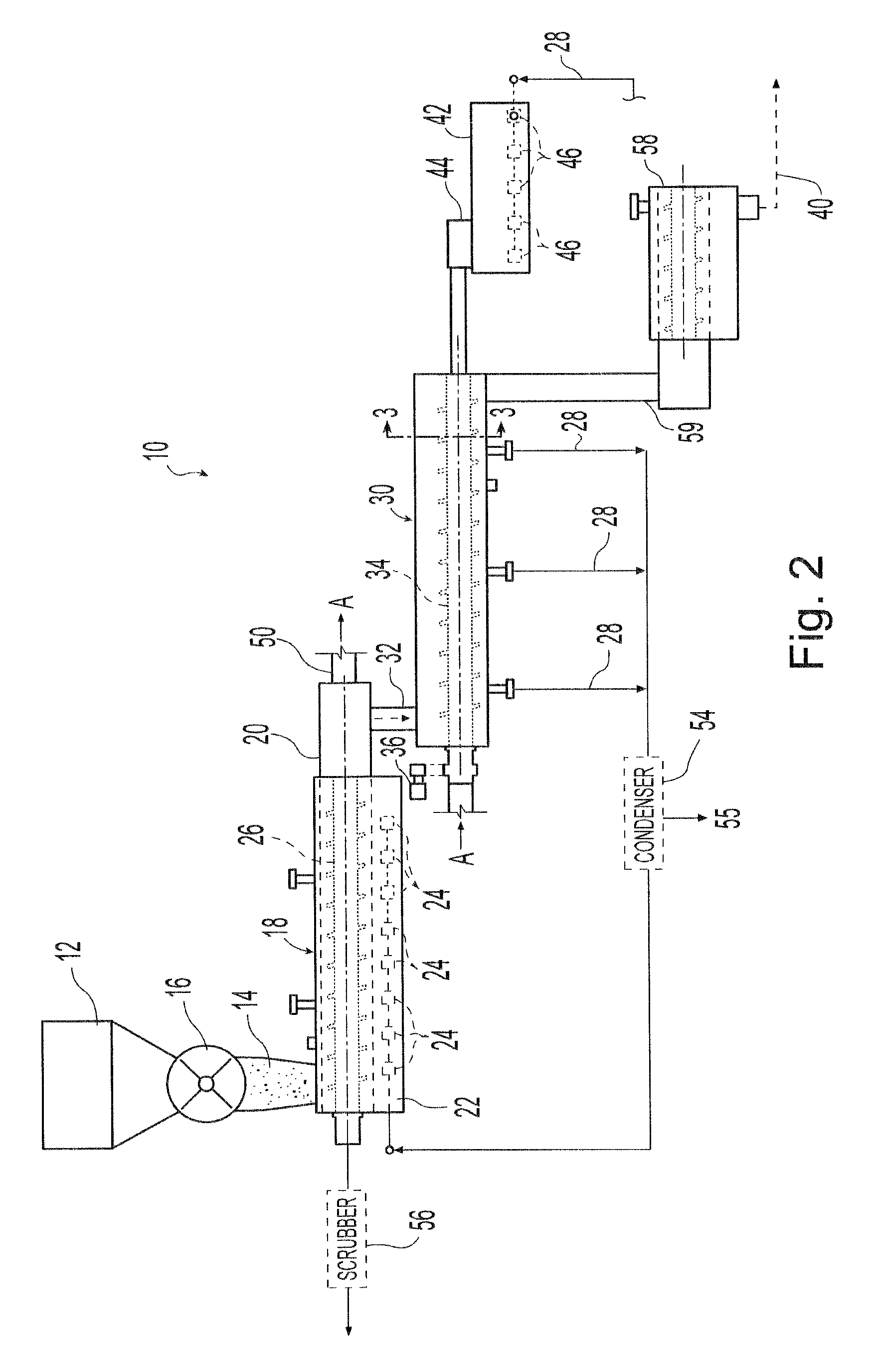

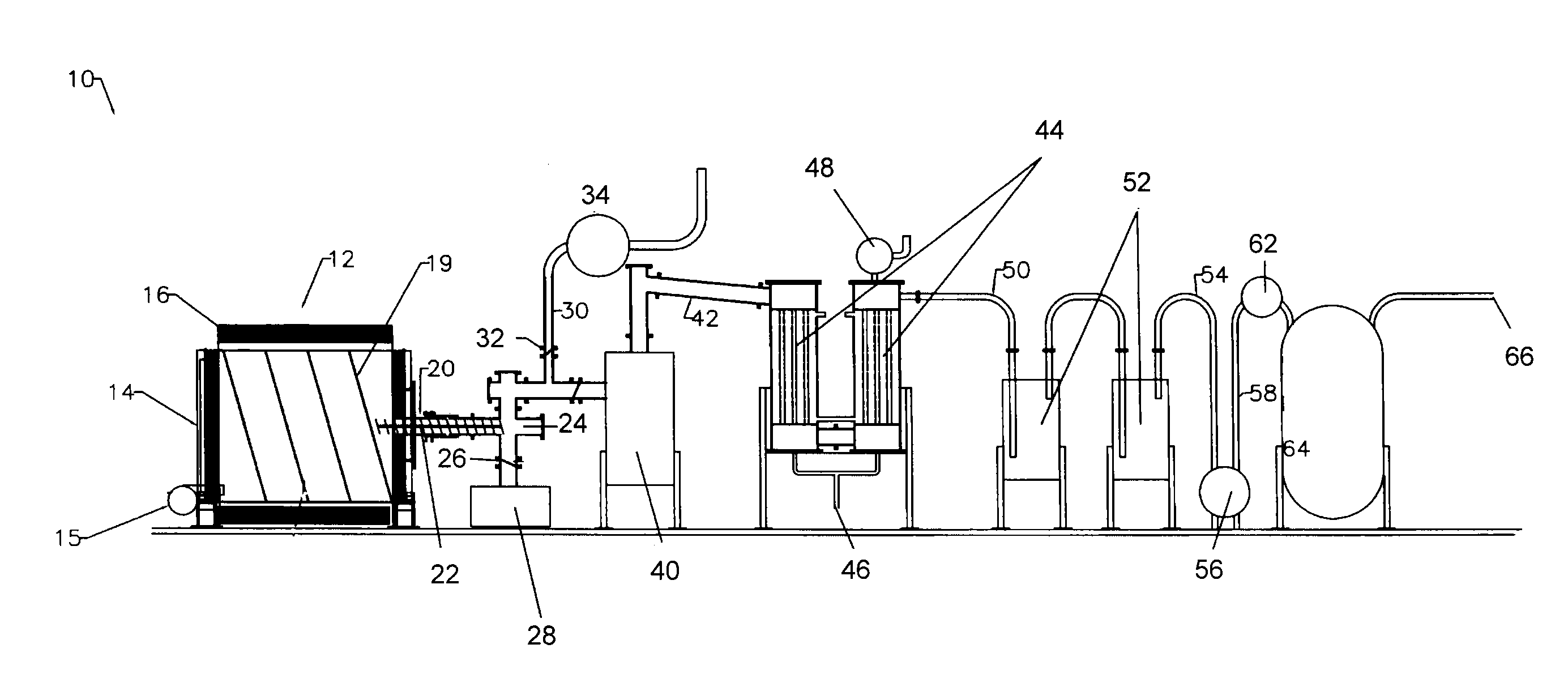

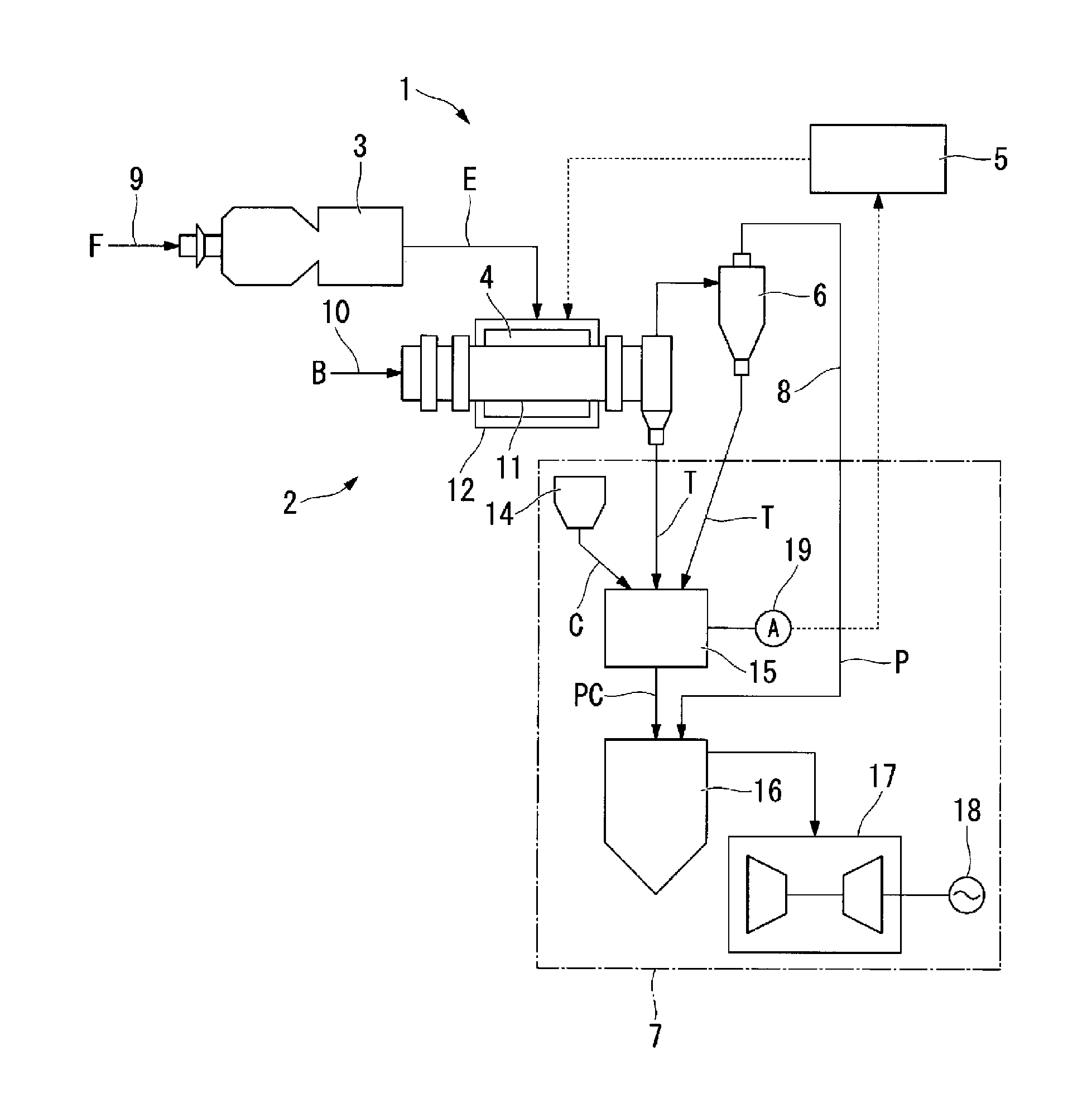

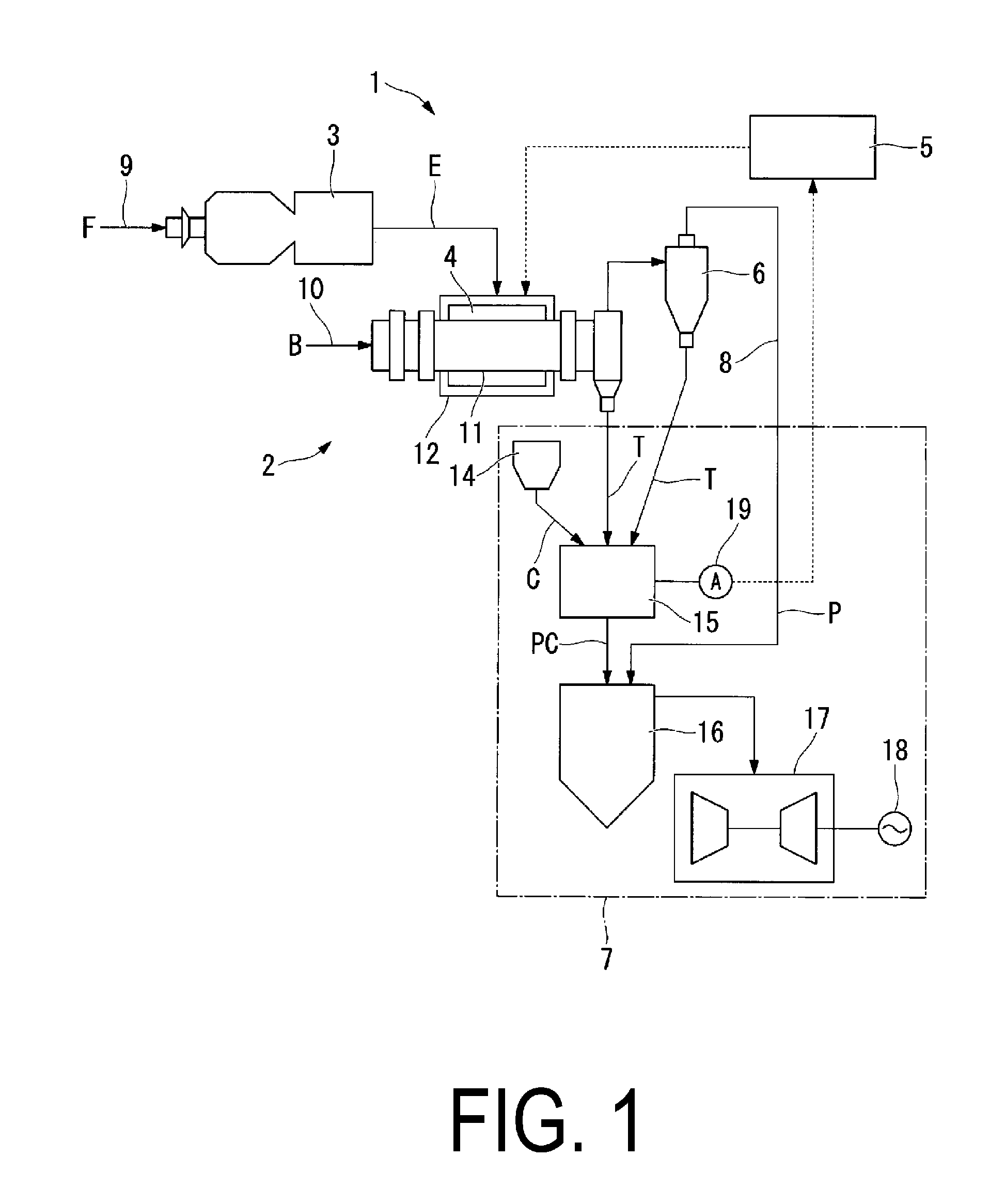

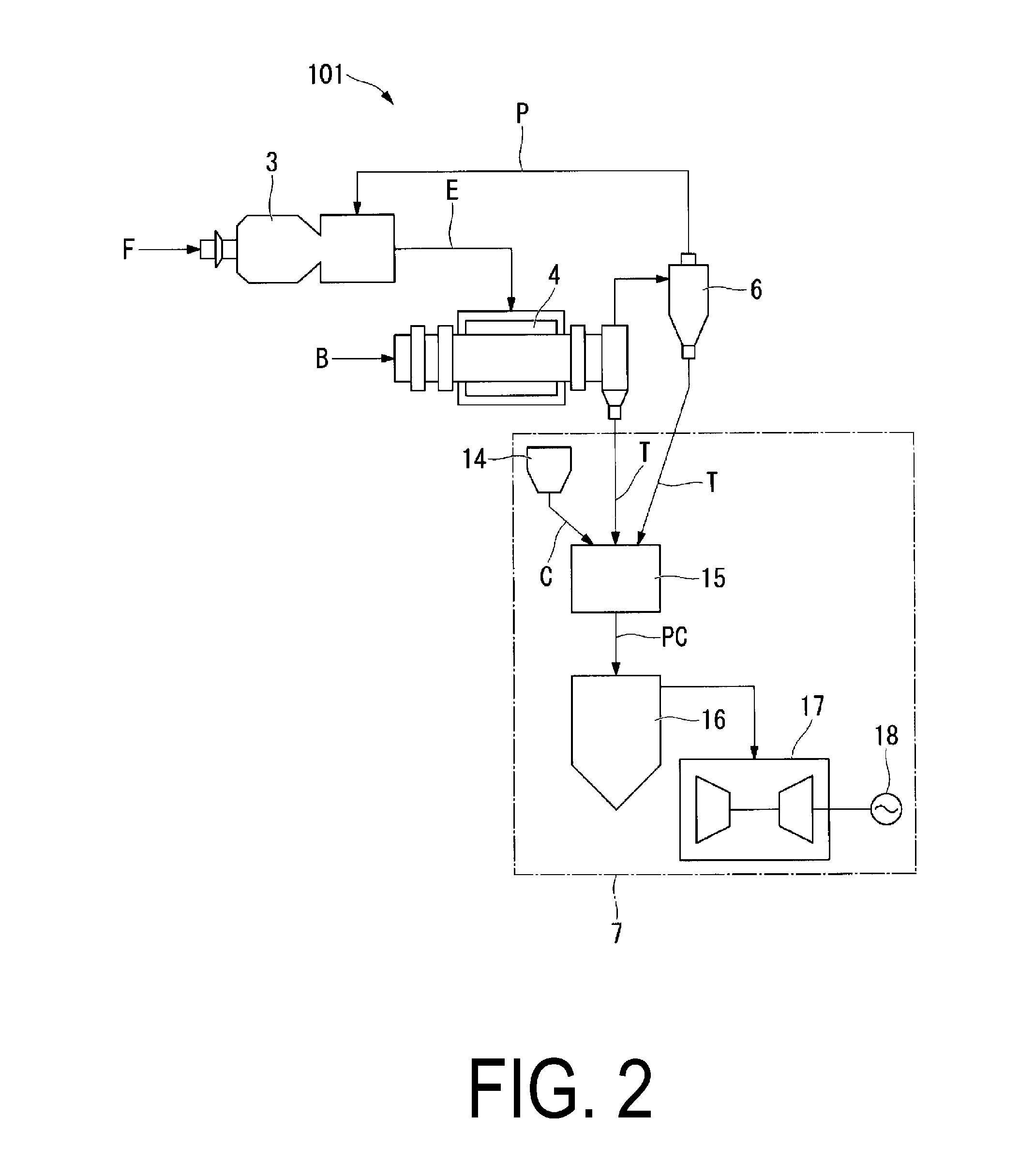

Method of and system for grinding pyrolysis of particulate carbonaceous feedstock

ActiveUS20130199919A1Small particle sizeThermal quenching of pyrolysis vapours is simplifiedCombustible gas coke oven heatingCoal charges mechanical treatmentParticulatesProcess engineering

A pyrolysis plant 20 comprises a grinding pyrolyser 22, being a machine or apparatus in which both particle size reduction and pyrolysis occur simultaneously. Plant 20 also comprises a bin (hopper) 30 for holding wet particulate biomass feedstock. Chute 32 leads from the bin 30 to a biomass dryer 34 which reduces moisture content of the feedstock as low as possible, e.g., to below about 10. Dried feedstock is conveyed from dryer 34 via line 36 to a dried biomass feedstock hopper 38. Dried feedstock is fed from hopper 38 into a chute 40 which leads to an inlet trunnion 42 of grinding pyrolyser 22. A discharge trunnion 44 of grinding pyrolyser 22 leads to a char holder 60 for collecting char particles and a condensation train 62 for condensing vapour generated by the pyrolysis to produce oil.

Owner:RENERGI PTY LTD

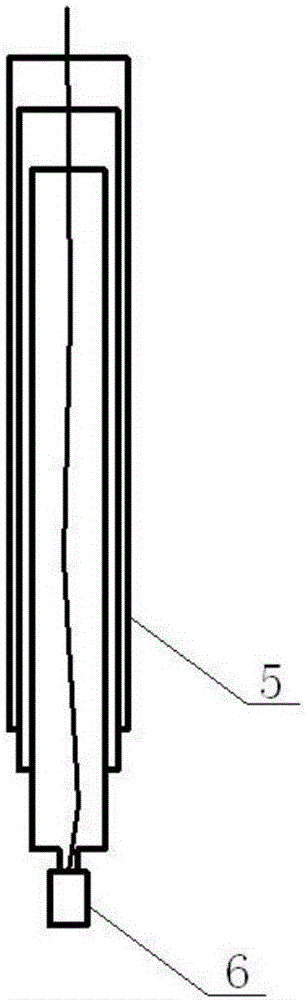

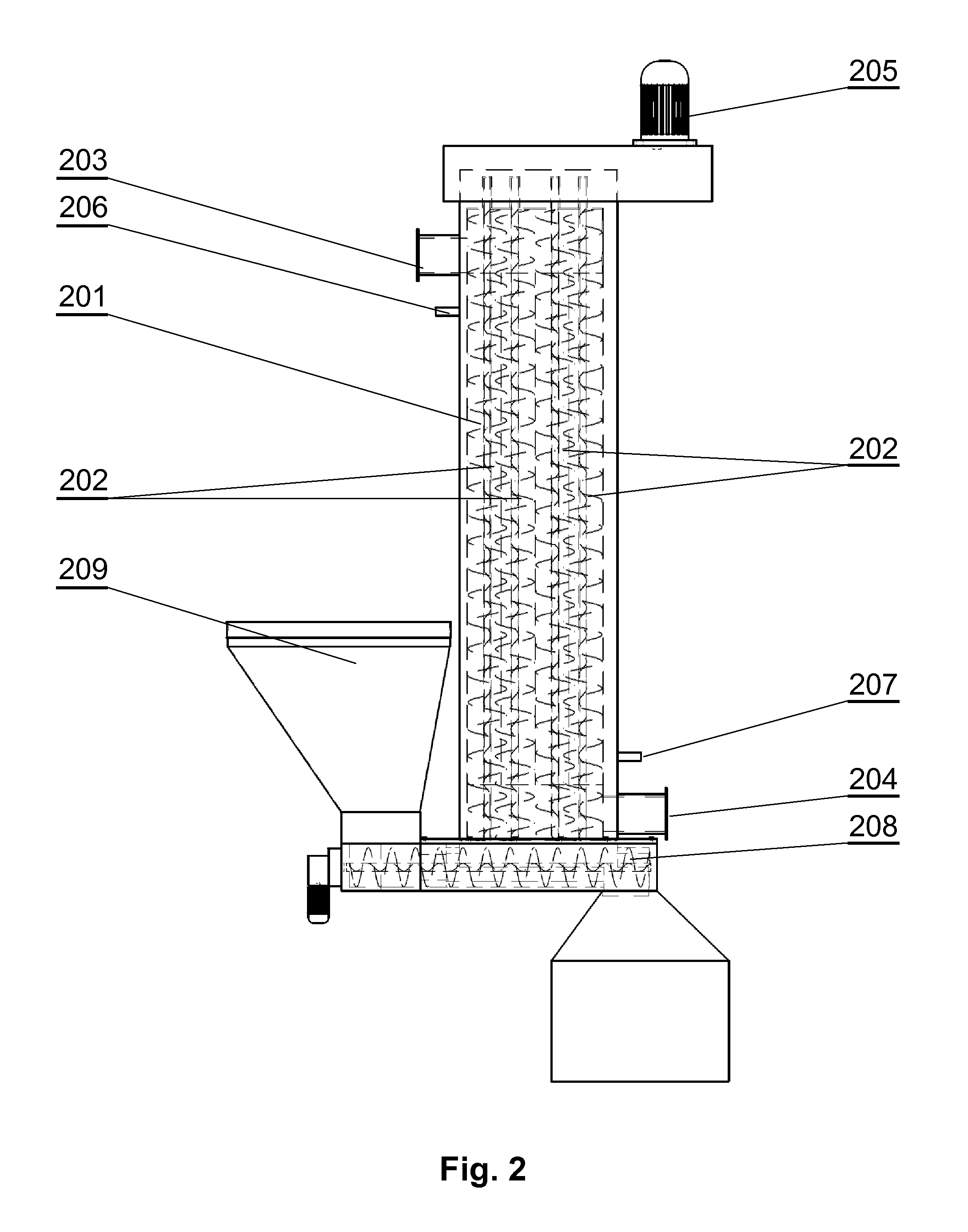

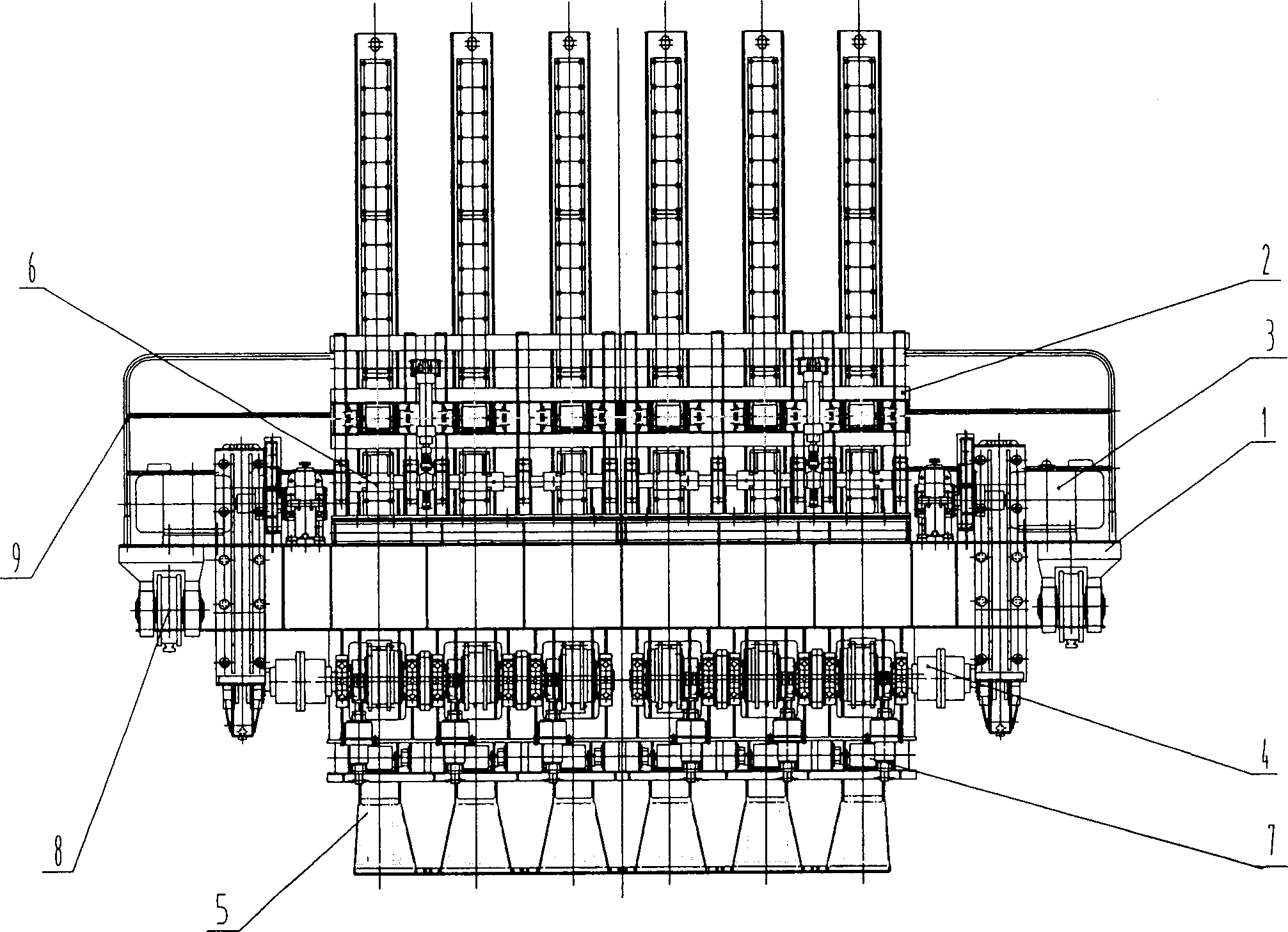

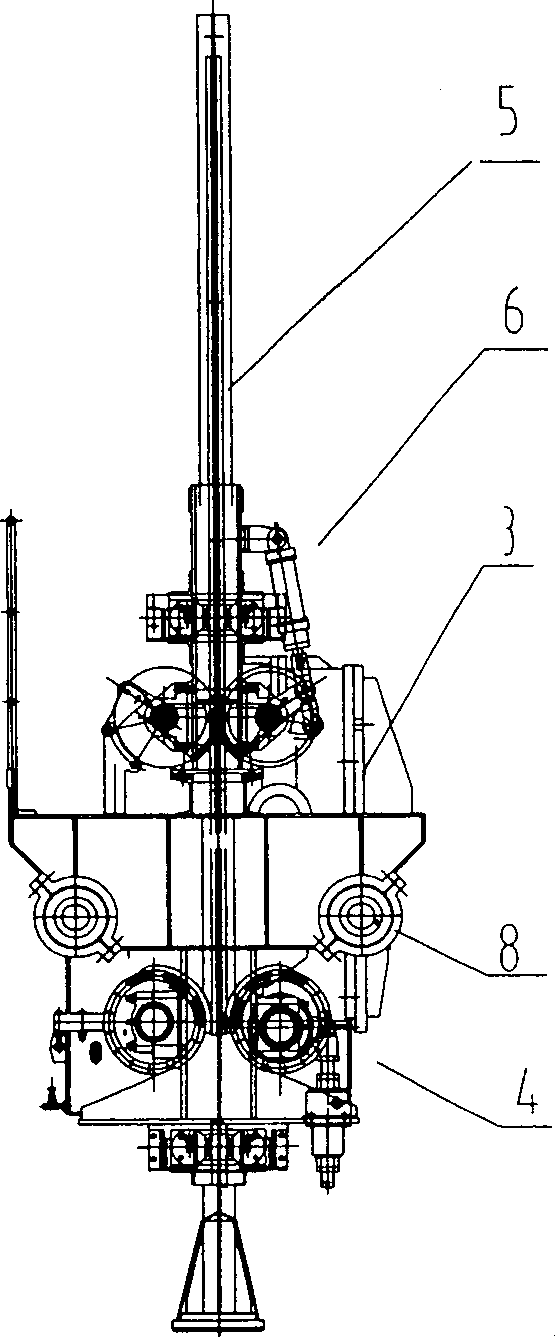

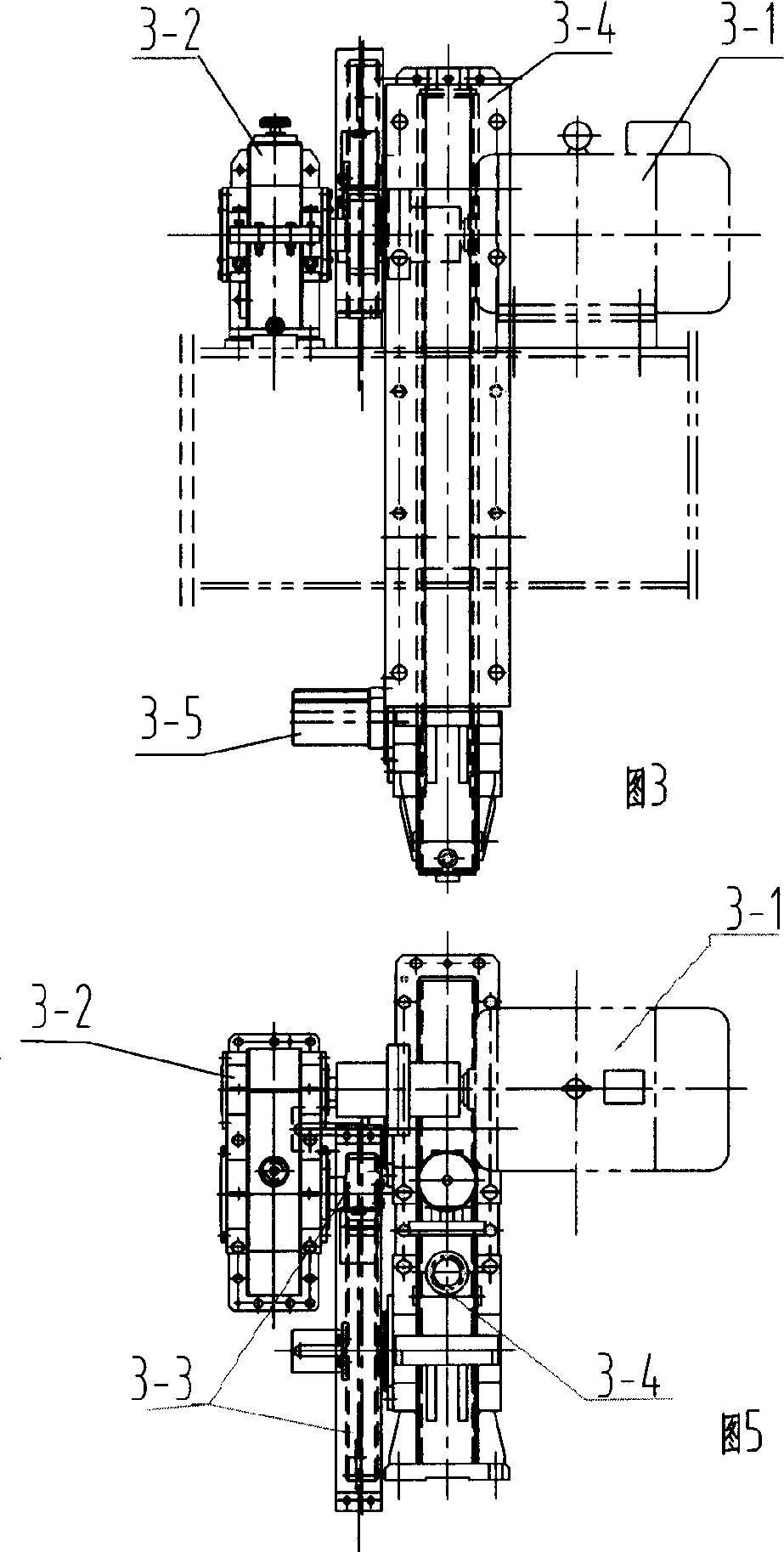

Method and device for increasing bulk density of coal charged into top-charging coke oven

InactiveCN105713623AIncrease the amount of coal loaded in a single holeHigh densityCoal charges mechanical treatmentCoke ovenHigh frequency vibration

The invention relates to a method and a device for increasing the coal charging bulk density of a top-loading coke oven. A plurality of coal charging ports are arranged on the top of the top-loading coke oven, and a coal charging car is used to simultaneously charge coal at the multiple coal charging ports; the coal charging car The coal lowering device is equipped with a telescopic vibration compacting device. When coal is loaded, the vibrating head at the bottom of the telescopic vibration compacting device extends into the position of 1 / 3~2 / 3 of the coal charging height of the coke oven carbonization chamber. Vibration compacts the surrounding coal material; while coal is being loaded, the vibrating head is lifted synchronously with the rise of the coal loading height. After the coal loading is completed, the vibrating head of the telescopic vibration compacting device continues to lift while vibrating, and reaches the top of the coal material Stop the vibration and retract until the stretchable vibrating compact device is withdrawn from the carbonization chamber as a whole. The invention can vibrate and compact the coal charged into the coking chamber of the coke oven, increase the bulk density of the coal charged into the furnace, increase the coal loading and coke output of the single-hole coke oven, and improve the quality of the coke.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Apparatus and method for pyrolysis of organic waste

ActiveUS20100282587A1Photosensitive materialsCoal charges mechanical treatmentProcess engineeringPyrolysis

A gasification reactor includes a wiper system including at least one wiper blade operable to wipe an interior surface of the reactor. A condenser unit of the gasification reactor includes a scraper system including at least one scraper segment operable to scrape an interior surface of the condenser unit.

Owner:ITERO DEV LTD

Coal blending method for coking chamber coke oven with width of 7.63 meters

InactiveCN101619224ASave resourcesReduce coal blending costsCoal charges mechanical treatmentCoke ovenProcess engineering

The invention relates to a coal blending method for a coking chamber coke oven with the width of 7.63 meters, which comprises the following steps: 1. selecting each single-species coking coal for participating in coal blending; 2. blending all the single-species coking coal comprising the following components in percentage by weight: 30-45 percent of coking coal, 5-10 percent of gas-fat coal, 30-45 percent of 1 / 3 coking coal and 8-15 percent of meager lean coal. Compared with the prior art, the invention breaks through a current high-cost coal blending structure mainly using high-quality coking coal with moderate degree of metamorphism, partial gas-fat coal and 1 / 3 coking coal with low degree of metamorphism are used for replacing fat-free coal, the meager lean coal is used for replacing lean coal, the coal blending cost is greatly reduced, and high-quality coking coal resources are saved. By the coal blending method, the acquired coke of the coke oven with the width of 7.63 meters comprises the following components in percentage by weight: 85-90 percent of M40 and 5.0-7.5 percent of M10, and the intensity after reaction is 63-70 percent, thereby satisfying the need of a blast furnace in more than 3,000 m<3>.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Coker feed method and apparatus

InactiveUS7736470B2Reduce thermal stressMore controllableThermal non-catalytic crackingCombustible gas coke oven heatingLine tubingCoke

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

Continuous coking process

InactiveUS7914668B2Thermal non-catalytic crackingCombustible gas coke oven heatingThermodynamicsCoke

Owner:EXXON RES & ENG CO

Pyrolytic process and apparatus for producing enhanced amounts of aromatc compounds

InactiveUS20080200738A1Thermal non-catalytic crackingCoal charges mechanical treatmentCompound aProcess engineering

Owner:RES POLYFLOW LLC

System and Method for Renewable Fuel Using Sealed Reaction Chambers

InactiveUS20160160124A1Improve productivityImprove uniformityCombustible gas coke oven heatingCoal charges mechanical treatmentFluid intakeFractionation

The system and method described herein provide for the higher production rate fractionation of biomass for the purpose of selectively separating specific volatile components, which may subsequently be used in the production of a renewable liquid fuel, such as gasoline. Increased production rates of processing of biomass or other feedstock is achieved through the use of sealed reaction chambers, which may be transferred in a sealed configuration between stations in a multi-station processing system. Also, the present invention considers the use of piston assemblies for the dual functions of controlling fluid intake and exhaust (in combination with valves) and for providing a more robust and more cost effective sealing mechanism. The present invention may also achieve improved uniformity of biomass processing through the introduction of a mechanical agitator designed to mix the biomass during processing.

Owner:STRIMLING JON

Coal leveling method for coke oven

ActiveCN105001884AHigh bulk densityQuality improvementCoal charges mechanical treatmentCarbonizationCoke oven

The invention discloses a coal leveling method for a coke oven. The method comprises steps as follows: coking coal is loaded in a carbonization chamber of the coke oven through a coal charging car; when the coking coal in the carbonization chamber reaches two thirds of the capacity of the carbonization chamber, the coking coal in the carbonization chamber is leveled by a coal leveling bar, a coal peak formed at a coal loading port of the carbonization chamber is pushed to be flat by the coal leveling bar, and a coal valley in the position where no coal is loaded is replenished to be full, so that the coking coal is flatly and uniformly loaded in the carbonization chamber. The coking coal in the coke oven can be really pressed and compacted, the stacking density of the coking coal is increased, and the quality of coke is improved.

Owner:王煊

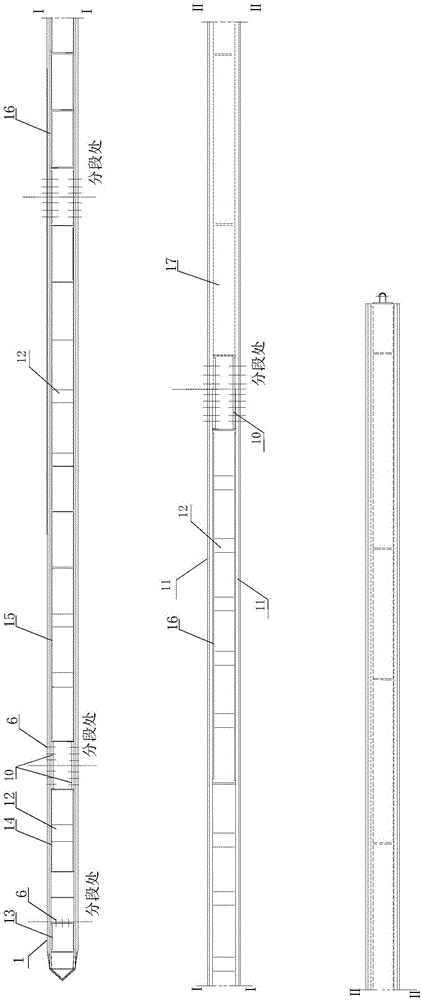

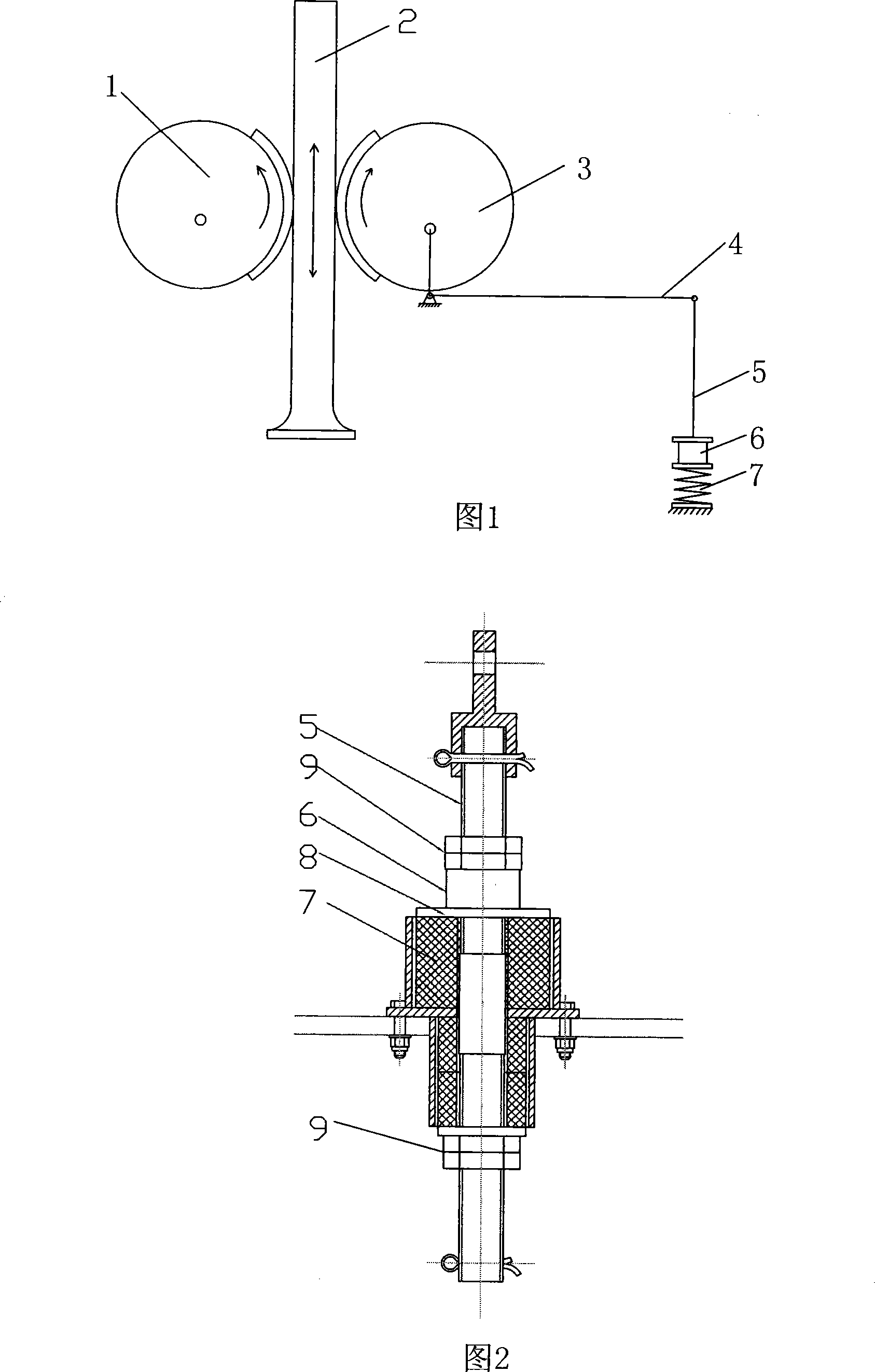

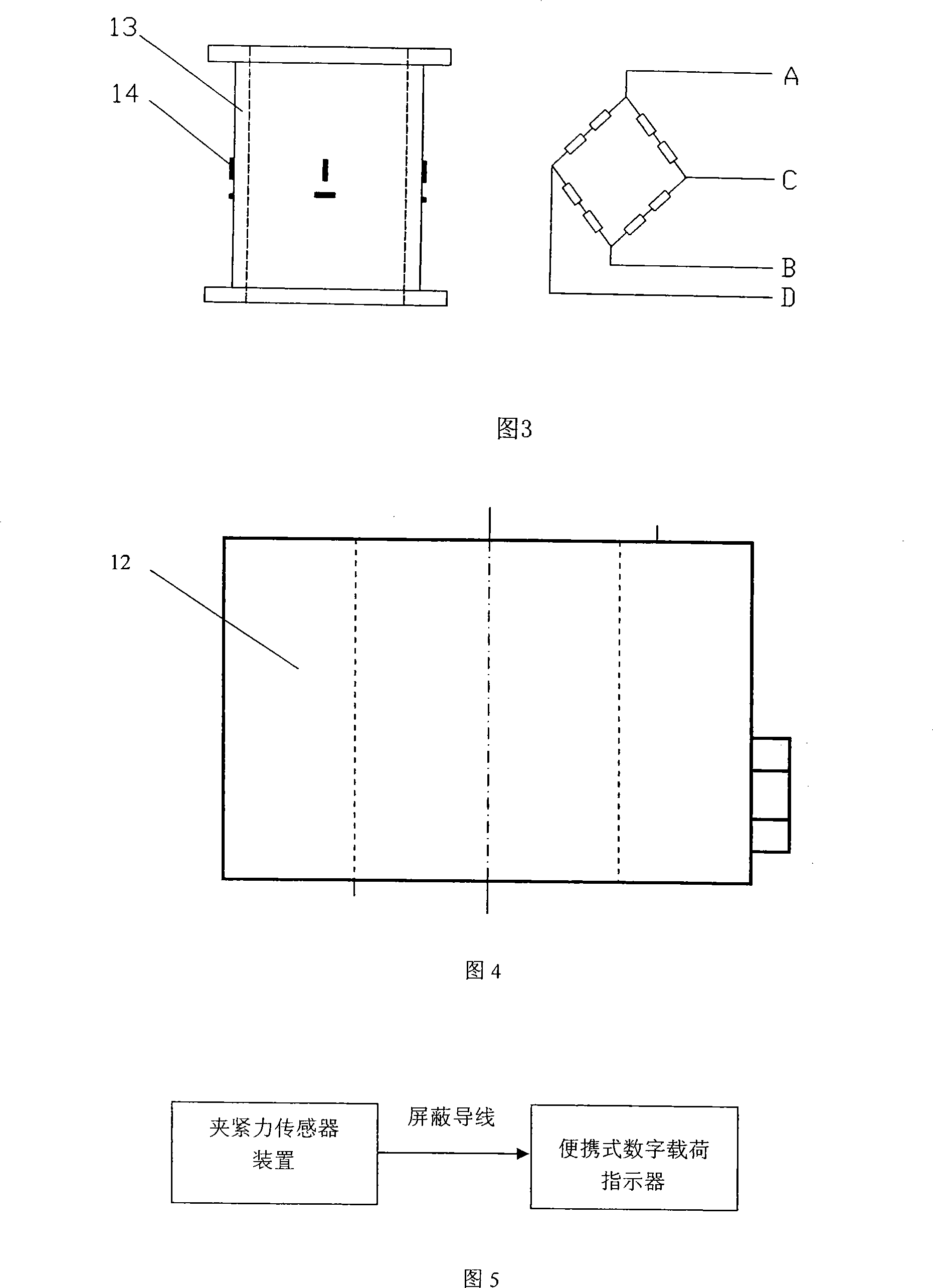

Method for measuring and regulating clamping force of coke oven tamping tool hammer rod and measuring system

InactiveCN101206151AOutstanding FeaturesHighlight significant effectMeasurement of torque/twisting force while tighteningCoal charges mechanical treatmentEngineeringCoke oven

The invention relates to a measuring adjusting method and measuring system of coke oven tamping machine hammer stem clamping force. The invention which uses a force sensor and a portable digital load indicator is characterized in that: the sensor is arranged on a bolt of a cam mechanism compressing device of a coke oven tamping machine clamping mechanism, the force sensor can measure the pressure of a rubber spring on the regulation bolt of the cam mechanism, the hammer stem clamping force corresponds to the rubber spring pressure and is amplified by leverage, the hammer stem clamping force is the measured clamping force multiplied by the amplification factor of the leverage of the clamping mechanism and is displayed by the portable digital load indicator, and the clamping force of the cam clamping the hammer stem can be adjusted through adjustment of the rubber spring pressure via adjusting the cam mechanism regulation bolt. The invention which has the advantages of high measuring accuracy and reliability, convenient assembly and use, and visual display can realize static and real-time dynamic measurement of the clamping force.

Owner:TAIYUAN HEAVY IND

Pyrolytic process for producing enhanced amounts of aromatic compounds

InactiveUS7883605B2Coal charges mechanical treatmentDirect heating destructive distillationLiquid productChemical compound

Various embodiments of a process for pyrolyzing hydrocarbonaceous material are provided. In one embodiment the process for pyrolyzing hydrocarbonaceous material includes charging a reactor with a feed material comprising hydrocarbonaceous material, heating the feed material, and collecting liquid product from the reactor which is anaerobic in operation. At least 5% of the organic carbon atoms which are not present in an aromatic ring of a compound of the feed material are present in an aromatic ring of a compound in a liquid portion of the product.

Owner:RES POLYFLOW LLC

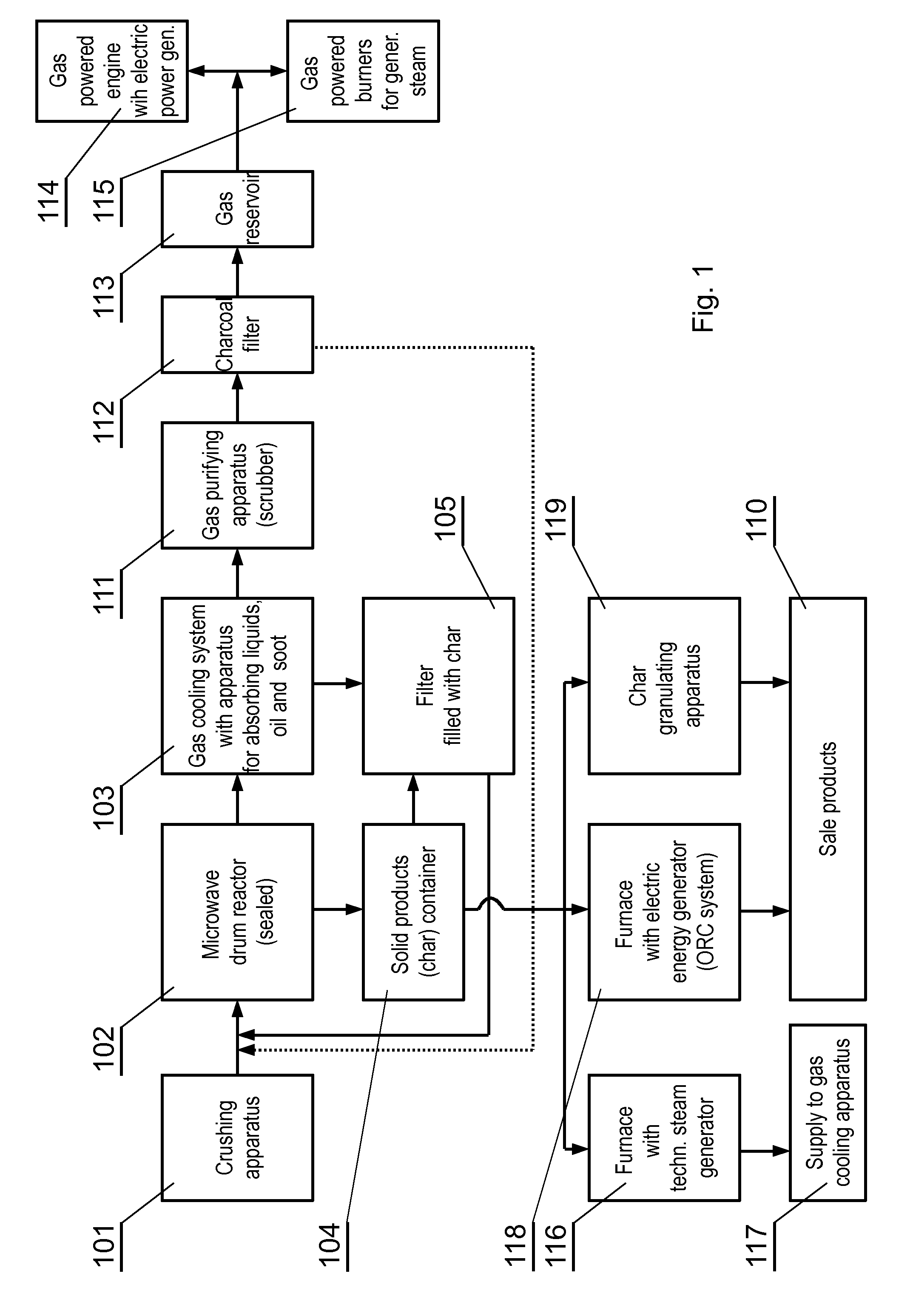

A method and a system for processing plastic waste

ActiveUS20160122654A1Electrical coke oven heatingPigmenting treatmentMetallic materialsPlastic waste

A method for processing of plastic and / or rubber waste to generate energetic gas comprising aliphatic hydrocarbons C1-C4, carbon oxide and hydrogen, wherein the waste may comprise halogens, sulphur, nitrogen and oxygen and may be contaminated by substances of inorganic origin comprising ceramic and metallic materials, the method comprising processing the waste in a pyrolysis process, wherein a powdered waste material is fed to a microwave drum reactor (102), where it is heated by microwaves while being moved through the reactor (102), the method comprising: conducting the pyrolysis reaction inside the reactor (102) at a temperature of 800-950° C. to obtain end products comprising gases, dust and a porous char of a large surface area having absorptive properties; separating the char from the other pyrolysis products by deposition; directing a portion, preferably a quarter, of the obtained char to a filter (105); directing the dust and gases to a gas cooling apparatus (103) comprising at least two synchronized screw conveyors, wherein the gases are cooled to a temperature of 120-160° C. and wherein the dust and the condensate are directed to the filter (105) filled with the char; and feeding back the mixture of char, condensate and dust from the filter (105) to the microwave reactor (102).

Owner:MTT TECH GES MBH GMBH

Coke oven coal leveling bar with pressing device

InactiveCN102585852ADoes not affect structural strengthIncreased downforceCoal charges mechanical treatmentEngineeringCoke oven

The invention discloses a coke oven coal leveling bar with a pressing device. A plurality of clapboards are fixedly arranged between two side plates; a rolling piece is arranged between two clapboards; the two end shafts of the rolling piece are connected with crank arms and connected with a connecting bar through the crank arms; and a transmission bar is connected with the connecting bar through a rotating shaft and connected with an actuator through a hydraulic bar. The coke oven coal leveling bar has the obvious advantages that the density of a coal cake can be increased, the coke yield of a single oven is increased, and pressing force and pressing depth can be adjusted.

Owner:谢铮一

Converter for organic materials

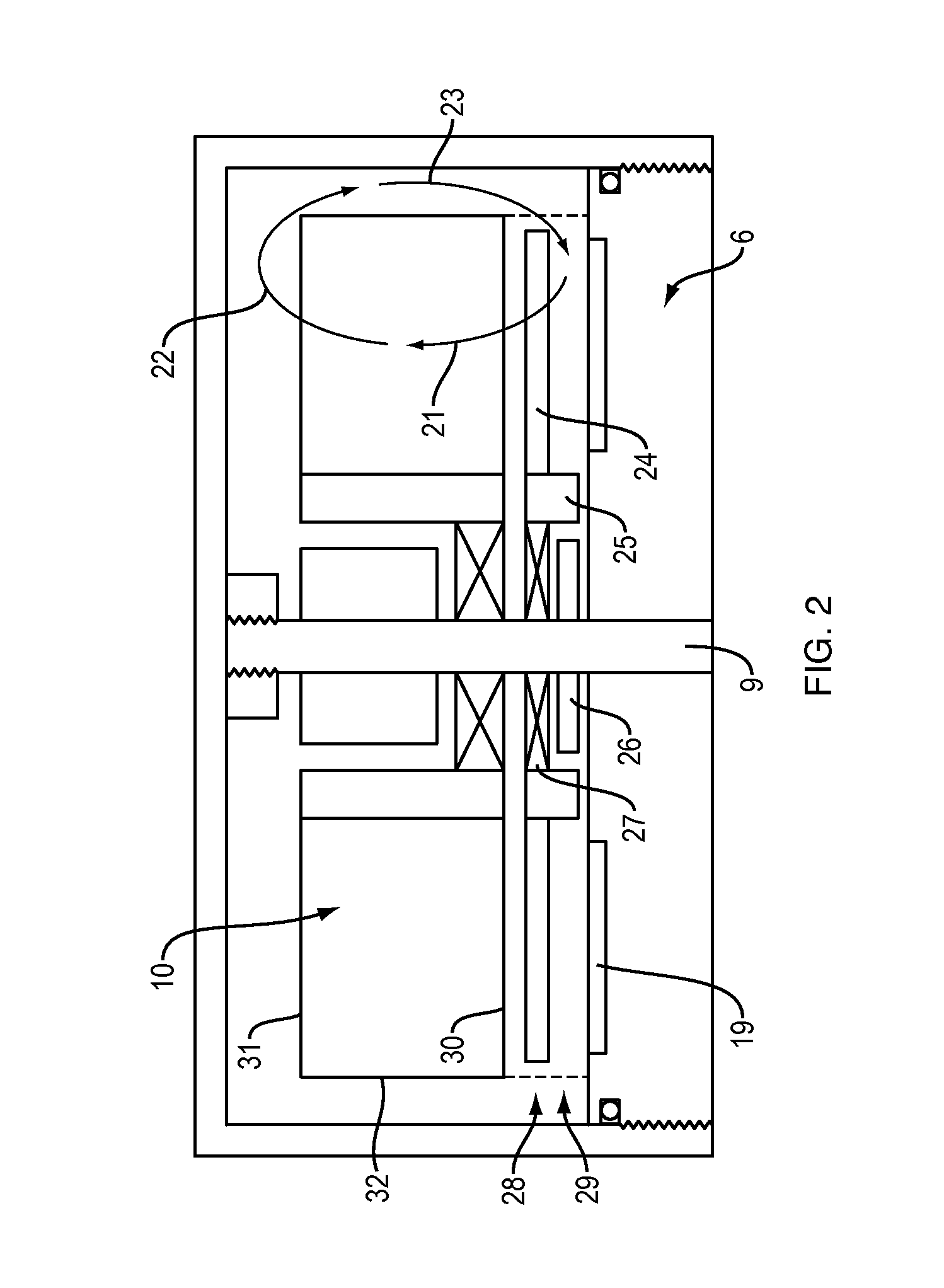

ActiveUS10364394B2Minimize escapePrevent escapeCoal charges mechanical treatmentDirect heating destructive distillationSolid carbonLiquid water

A continuous converter for pyrolyzing or otherwise processing biomass or other solid organic feed materials includes a reaction chamber (5) for producing a solid carbon-containing product and a gas product and optionally a liquid water product via pyrolysis or other reaction mechanisms from a solid organic feed material. The chamber has an inlet (41) for supplying a solid organic feed material to the chamber and separate outlets (15, 35) for the solid carbon-containing product and the gas product produced in the reaction chamber. The inlet and the solid carbon-containing product outlet are configured so that the solid materials in the inlet and in the outlet form respective gas seals in the inlet and the outlet.

Owner:THE CRUCIBLE GROUP

Coke stamping method and apparatus for top coal loading coke oven

InactiveCN1706913AHigh specific gravityIncrease productionCoal charges mechanical treatmentCoke ovenEngineering

The present invention is one kind of technological scheme of stamping method and apparatus in top coal loading coke oven, and the technological scheme has coal stamping inside the carbonizing chamber. By means of the coal leveling rods capable of being stretched into the carbonizing chamber, bar pressure heads may set on the coal leveling rods and loaded into the carbonizing chamber, and pressure rods connected to the bar pressure head are stretched into the carbonizing chamber through the coal loading ports. The coal leveling rods are first unloaded from the carbonizing chamber, and while loading coal, the bar pressure heads driven by the pressure rods and the lifting mechanism stamp the coking coal. The coal leveling rods are then stretched into the carbonizing chamber to support the bar pressure heads for separating with pressure rods and withdrawing from the carbonizing chamber before entering the coking step.

Owner:SHANDONG IRON & STEEL CO LTD

Coking coal stamping method and apparatus for top coal loading coke oven

InactiveCN1706914AHigh specific gravityImprove production efficiencyCoal charges mechanical treatmentCoal briquetteCoke oven

The present invention is one kind of technological scheme of coking coal stamping method and apparatus in top coal loading coke oven, and the technological scheme features coking coal stamping apparatus in the coke discharging end of the top coal loading coke oven. The coking coal stamping apparatus forms stamped coal cake in the shape corresponding to the carbonizing chamber and the coal cake is fed into the carbonizing chamber via the coke discharging door before coking. The coking coal stamping apparatus is one stamping machine, which has stamping bin in the shape corresponding to that of carbonizing chamber and with side walls capable of being opened by means of the bin wall moving mechanism.

Owner:SHANDONG IRON & STEEL CO LTD

Internal gear type tamping tool for horizontal coke oven

InactiveCN1803980AReasonable structureReduce wearCoal charges mechanical treatmentVehicle frameGear wheel

The disclosed internal-gear tamping tool for horizontal coke oven comprises: a vehicle frame, a gearing with symmetrical two sets mechanisms, a clamp-hammer device, a stop-hammer device, a guiding device, an actuator, and tamping hamper. Wherein, using a motor to drive a small speed reducer; driving an L-shaped gear in drive box by engaging of a couple of external gears; and driving the cam friction gear group and frictional wheel group by the double output axis of L-shaped gear box. This invention overcomes the defects in prior art, realizes single-hammer regulation conveniently, and needs low cost.

Owner:TAIYUAN HEAVY IND

Converter for organic materials

ActiveUS20160244674A1Minimize escapePrevent escapeCoal charges mechanical treatmentDirect heating destructive distillationSolid carbonLiquid water

A continuous converter for pyrolysing or otherwise processing biomass or other solid organic feed materials includes a reaction chamber (5) for producing a solid carbon-containing product and a gas product and optionally a liquid water product via pyrolysis or other reaction mechanisms from a solid organic feed material. The chamber has an inlet (41) for supplying a solid organic feed material to the chamber and separate outlets (15, 35) for the solid carbon-containing product and the gas product produced in the reaction chamber. The inlet and the solid carbon-containing product outlet are configured so that the solid materials in the inlet and in the outlet form respective gas seals in the inlet and the outlet.

Owner:THE CRUCIBLE GROUP

Hybrid system and process for converting whole tires and other solid carbon materials into reclaimable and reusable components

ActiveUS20120132733A1Saving all energy neededUseful sizePigmenting treatmentCoal charges mechanical treatmentSolid carbonHybrid system

A system and method of converting tires or other solid carbon based material is disclosed, including providing a chamber, feeding solid carbon based material into the chamber, rotating the chamber while heating and reducing the material in the chamber, collecting solid residue from the chamber, collecting vapor from the chamber, and converting vapor collected from the chamber to a liquid. The chamber has an interior surface and can include one or more ribs on the interior surface for rotating and tumbling the material in the chamber while heating the material. In an embodiment, the system and method includes rotating and heating tires in the chamber to a temperature from about 500° F. to about 1000° F. at least in part under vacuum causing the tires to collapse and liquefy, collecting solid carbon black, and collecting and re-pressurizing hot gasses from the chamber and using the re-pressurized hot gasses to heat the chamber.

Owner:GREEN CARBON INC

Biomass pyrolysis apparatus, and power generation system

ActiveUS20160024389A1Effective quantityCoke oven safety devicesCoal charges mechanical treatmentCombustionEngineering

Provided is a biomass pyrolysis apparatus comprising: a combustion furnace that produces a heat quantity by causing a stable property fuel to combust; a pyrolysis gasification furnace that produces a torrefied material, and a pyrolysis gas by pyrolyzing woody biomass by a heat quantity produced by the combustion furnace; and a pyrolysis gas introduction passage that introduces the pyrolysis gas from the pyrolysis gasification furnace into a boiler, into which the torrefied material is introduced.

Owner:MITSUBISHI HEAVY IND ENVIRONMENTAL & CHEM ENG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com