Coal leveling bar with vibrating compacting function

A technology of vibratory compaction and flat coal, which is applied to the mechanical treatment of coal loaded into the furnace, the petroleum industry, and coke ovens, etc. It can solve the problems of poor coke quality, low bulk density, and looseness at the top, and achieve increased Coke production, improve coke quality, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

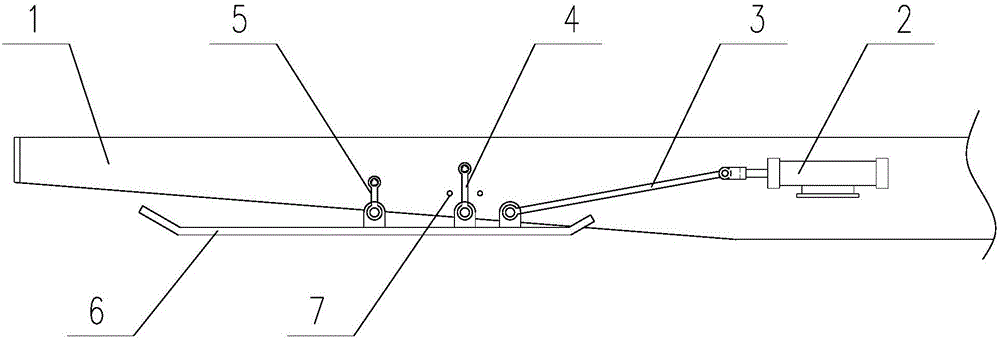

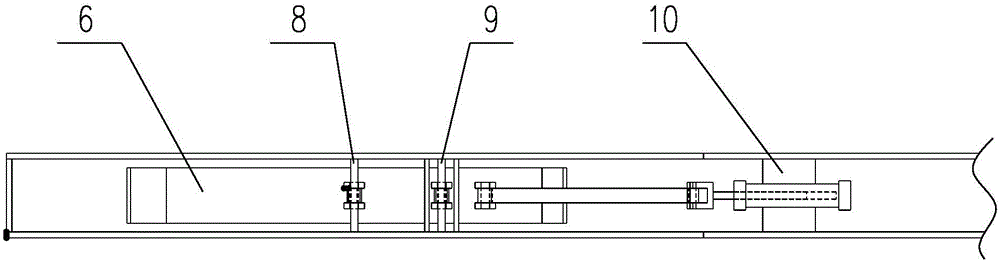

[0018] Such as Figure 1-Figure 2 As shown, a flat coal rod with vibration compaction function described in the present invention includes a flat coal rod 1, and at least one group of vibration compaction devices are installed on the flat coal rod 1 along the longitudinal direction; the vibration compaction devices include The pneumatic vibrator 2 and the compacting plate 6 are installed in the same direction as the flat coal rod 1; the compacting plate 6 is longitudinally provided with 3 hinge supports, one of which is connected to the connecting rod-3 One end is hinged, and the other end of connecting rod one 3 is hinged with the piston rod of pneumatic vibrator 2; the other two hinge supports are respectively hinged with one end of connecting rod two 4 and one end of connecting rod three 5, and the other end of connecting rod two 4 and The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com