Functional ceramic low voltage discharge compression forming method

A technology for press forming and functional ceramics, applied in ceramic forming machines, manufacturing tools, etc., which can solve the problems of difficult to increase compaction density, high price, and complex production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

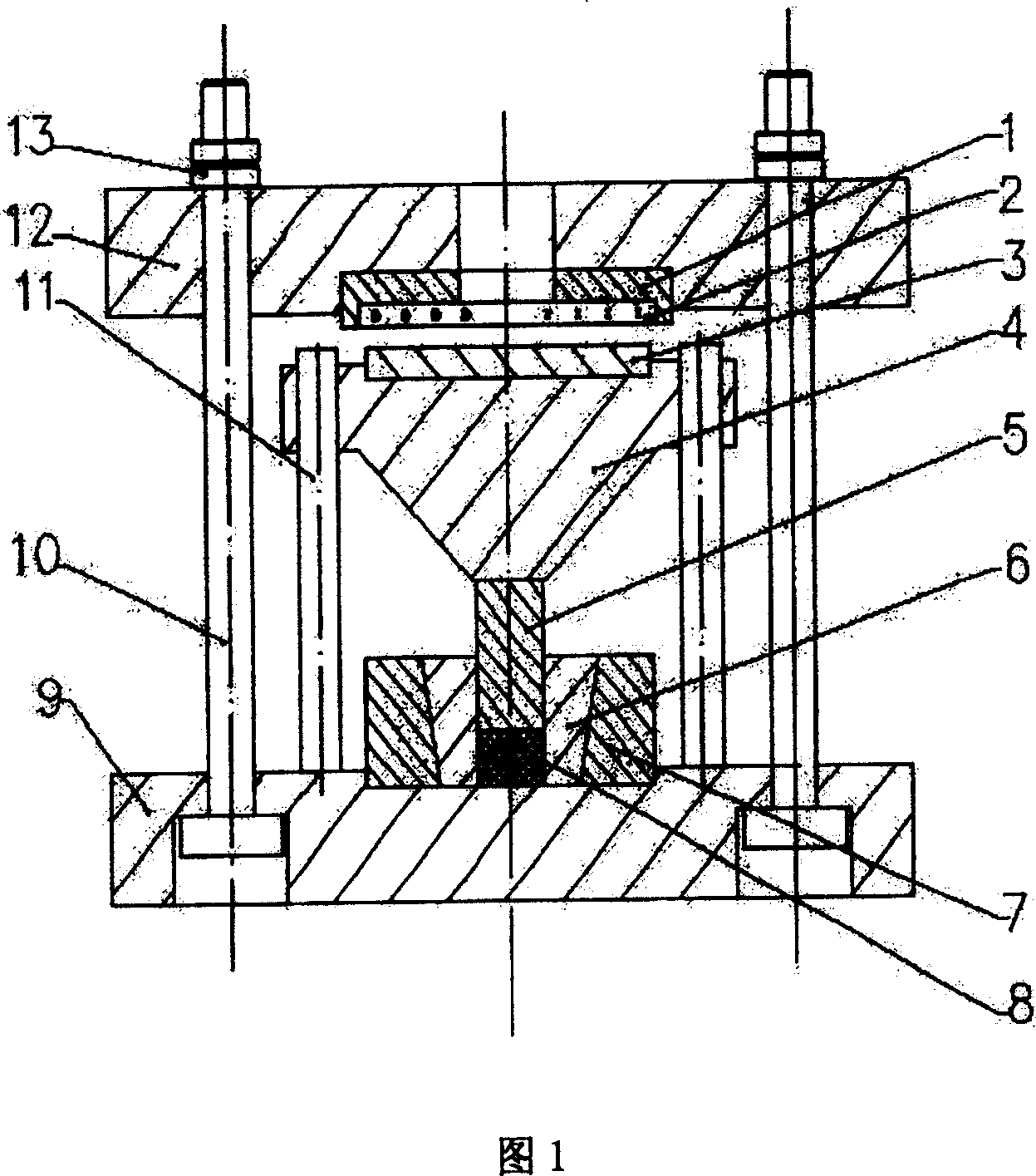

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 uses TiO 2 Powder for experiment

[0022] 1. Experimental process:

[0023] 1. Powder preparation

[0024] TiO 2 The powder is pre-fired at 1150° and kept for 4 hours to convert it into a rutile phase, then placed in a ball mill, wet-milled with absolute ethanol in a high-speed ball mill for 4 hours, dried, hand-ground, and set aside.

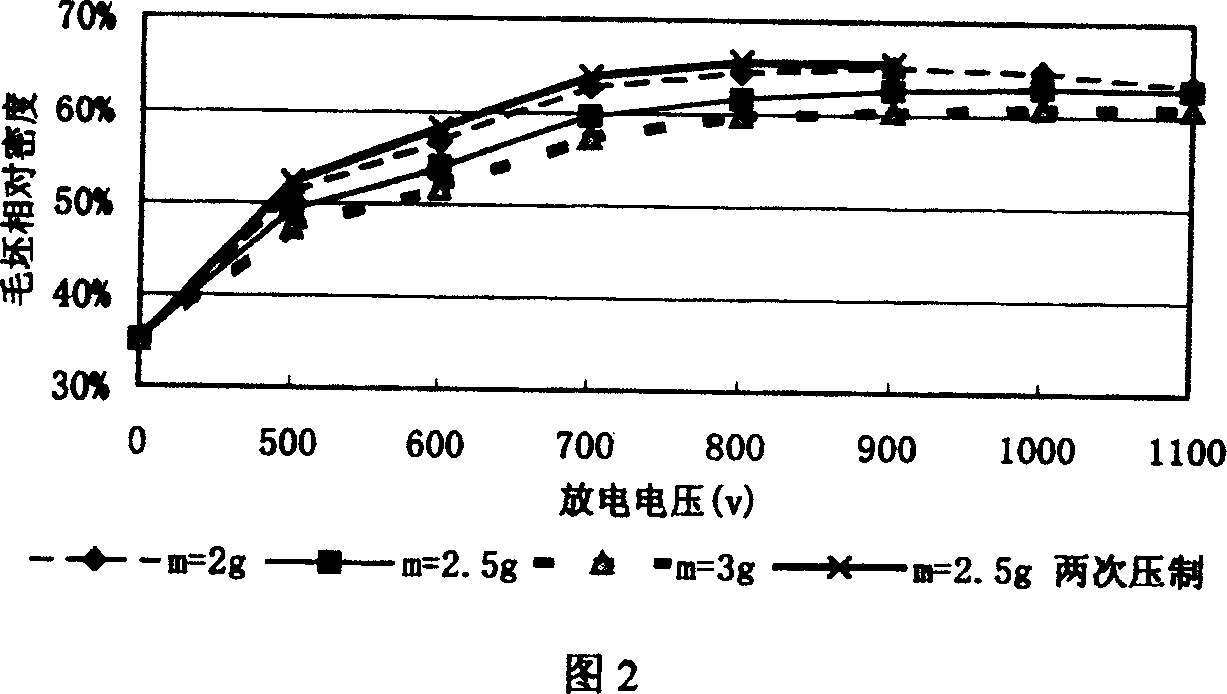

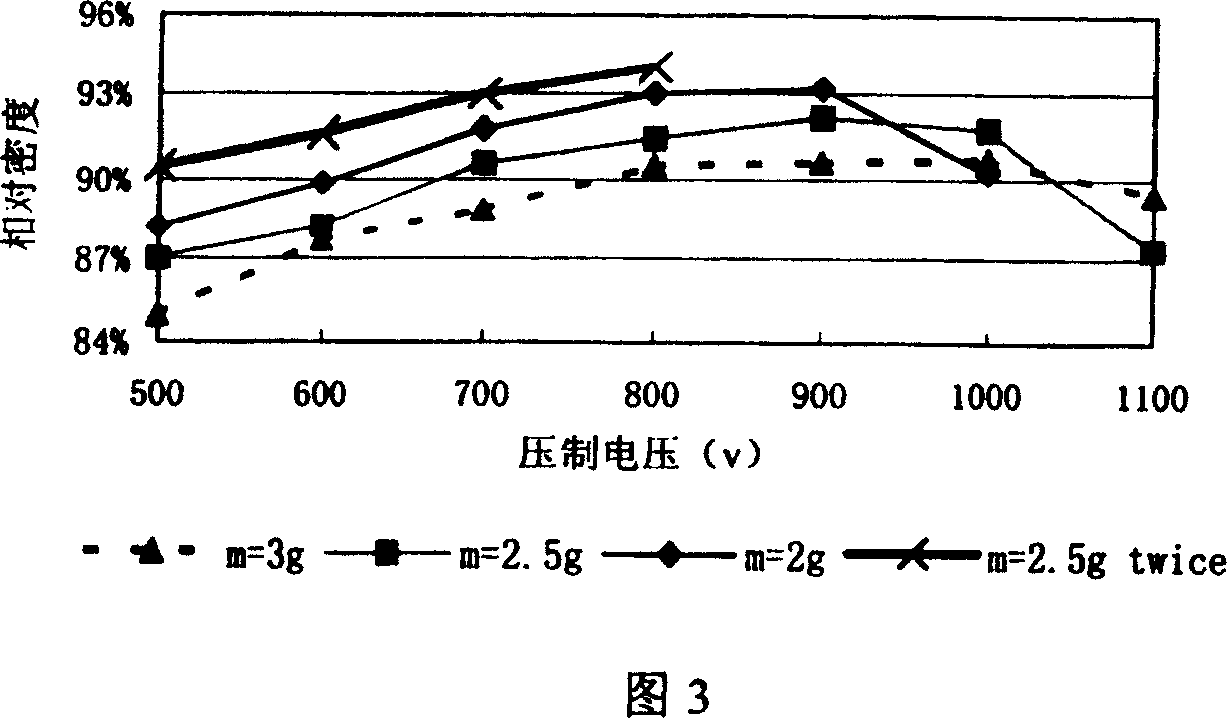

[0025] 2. Compression process

[0026] TiO 2 4wt% polyvinyl alcohol solution is added to the powder as a binding agent in an amount of 2% of the weight of the powder, then fully ground in a mortar and passed through a 40-mesh sieve. In the pressing experiment, firstly, the quality of the pressed powder is fixed each time, and the parameters of the discharge voltage are changed, and 10--15 samples are pressed every 100v between 400-1100v. Secondly, change the quality of the pressed powder, and change the voltage to press the sample as before to analyze the influence of the shape factor (height-to-diameter ratio) on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com