Protective steel and production method thereof

A production method and technology of steel coils, applied in the field of metallurgy, can solve problems such as fatigue cracking of weld seams, decline in welding performance, poor cold forming performance and low-temperature impact toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The embodiment of the present invention provides a protective steel, please refer to figure 1 , the composition mass percentage of the protective steel is C: 0.10%-0.20wt%; Si: 0.10%-0.60wt%; Mn: 0.8%-1.65wt%; Nb: 0.02%-0.05wt%; Mo: 0.3 %~0.8wt%; V: 0.05%~0.15wt%; Ti: 0.01%~0.05wt%; Al: 0.01%~0.06wt%; Cr: 0.4%~1.0wt%; B: 0.0015%~0.0025wt% ; P: ≤0.02wt%; S: ≤0.01wt%; N: ≤0.008wt%, the rest is Fe and unavoidable impurities.

[0025]Further, the mass percentage of a part of the protective steel is C: 0.13-0.20wt%, Mn: 1.0-1.5wt%, Nb: 0.03-0.04wt%, Ti: 0.01-0.03wt%, Mo: 0.3- 0.5wt%, V: 0.06-0.10wt%, Cr: 0.5-1.0wt%, B: 0.0015-0.0020wt%.

[0026] Further, the mass percentage of a part of the protective steel is C: 0.15-0.18wt%, Mn: 1.2-1.6wt%, Nb: 0.02-0.03wt%, Ti: 0.02-0.04wt%, Mo: 0.35- 0.65wt%, V: 0.05-0.13wt%, Cr: 0.55-0.08wt%, B: 0.0016-0.0022wt%.

[0027] Specifically, C in the protective steel plays an important role in the heat treatment of high-strength steel. On...

Embodiment 2

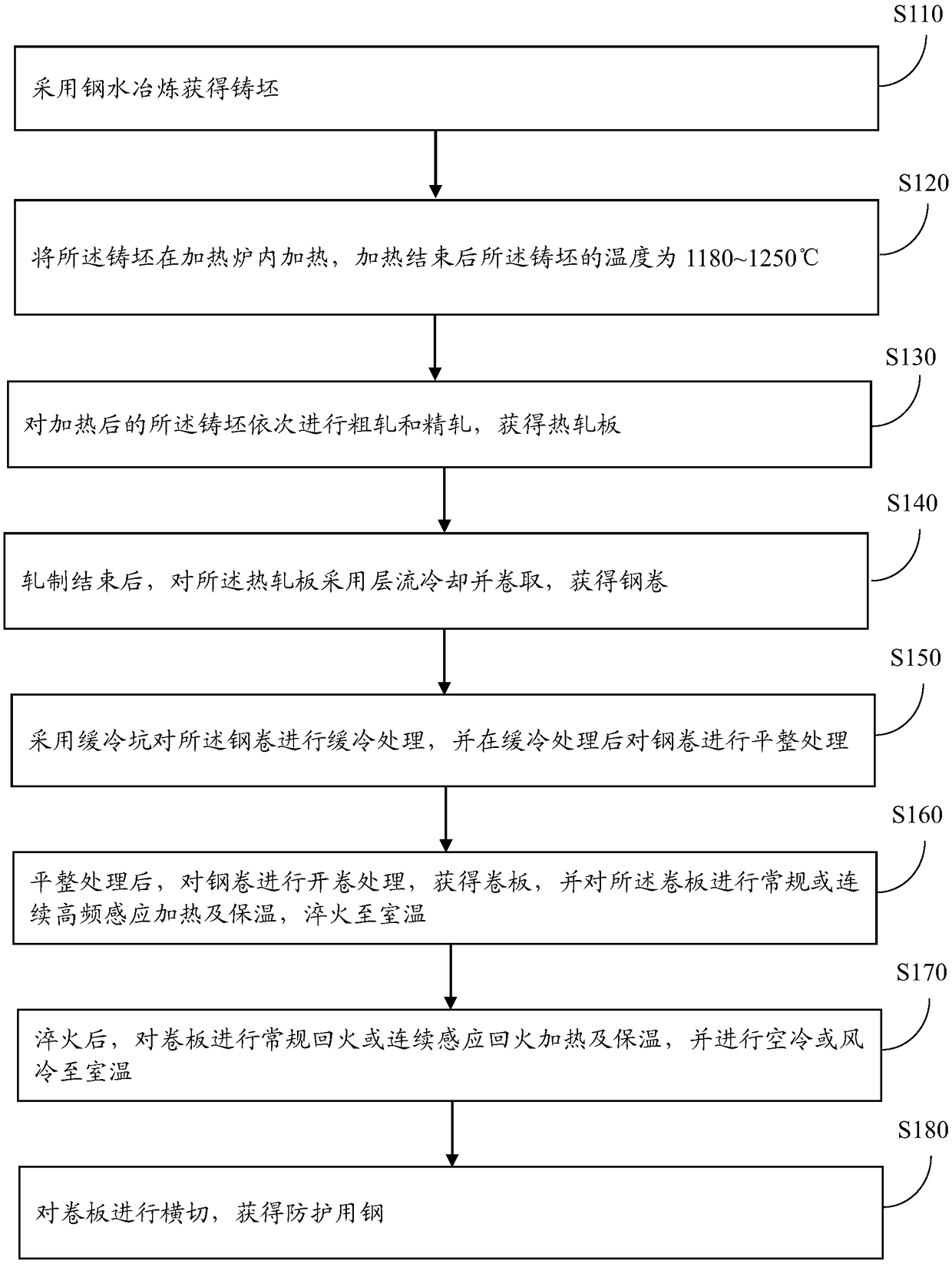

[0031] This embodiment provides a production method of protective steel, please refer to figure 2 , the method includes:

[0032] Step 110: Obtain a cast slab by smelting molten steel.

[0033] Step 120: heating the cast slab in a heating furnace, and the temperature of the cast slab is 1180-1250° C. after heating.

[0034] Further, the holding time of the slab is set to control the effective thickness of the slab within the range of 1-1.5 min / mm.

[0035] Specifically, in the embodiment of the present application, molten steel is smelted by a converter to obtain a slab, and the slab is heated in a heating furnace. After the heating, the temperature of the slab is 1180-1250°C. The holding time of the slab is set according to controlling the effective thickness of the slab within the range of 1 to 1.5 min / mm. The purpose of using a higher heating temperature is to ensure the homogenization of austenite and the formation of alloy elements such as the slab. Compounds of Ti an...

Embodiment 3

[0055] This embodiment provides a production method of steel for protection. The method is smelted in a 220-ton converter and rolled on a 1580 or 2250 hot rolling production line. The target width of the finished steel for protection is 1500 mm, and the thickness is 2-12 mm. The specific steps of this embodiment are as follows:

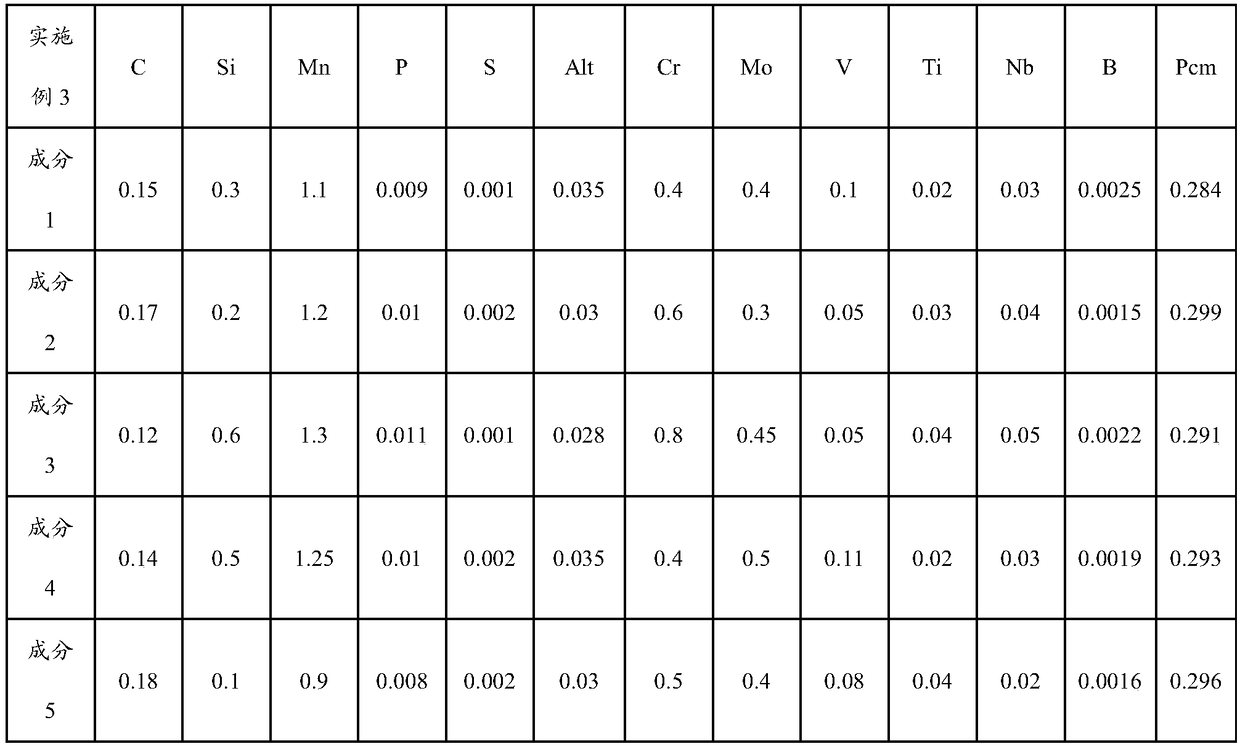

[0056] The molten steel is smelted in a converter to obtain a slab; the smelting process strictly controls the content of P and S to ensure the quality of the slab. The chemical composition of steel for smelting protection is shown in Table 1. Table 1 lists the chemical composition of the protective steel used in the examples of the present application.

[0057] Table 1 Chemical composition of protective steel

[0058]

[0059]

[0060] The cast slab is put into a heating furnace for heating, and the heated cast slab is put into a rolling mill for rolling to obtain a hot-rolled plate. Cool the hot-rolled sheet, adopt the front cooling mode to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com