Production process for obtaining copper alloy strip with uniform and small grains

A technology of fine grain and production process, which is applied to the production process of fine grain copper alloy sheet and strip to obtain a uniform field, can solve the problems of cumbersome process, high cost of manufacturing method, difficult scale production conditions, etc., and achieves simple process and high production efficiency. Low cost and the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples of the present invention are described with reference to specific implementations, and the examples are only used to explain the present invention, and should not be construed as limiting the present invention.

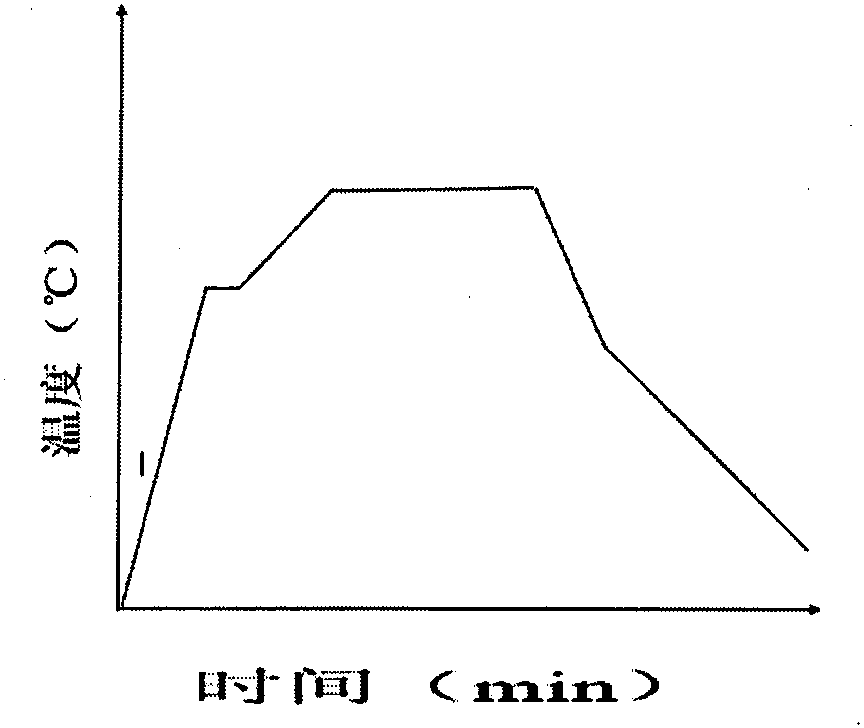

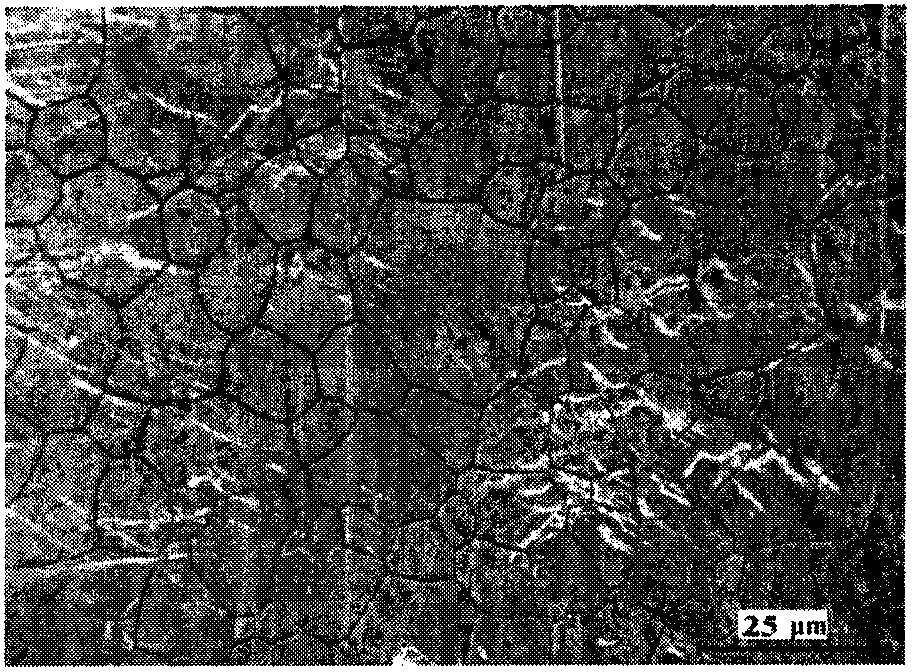

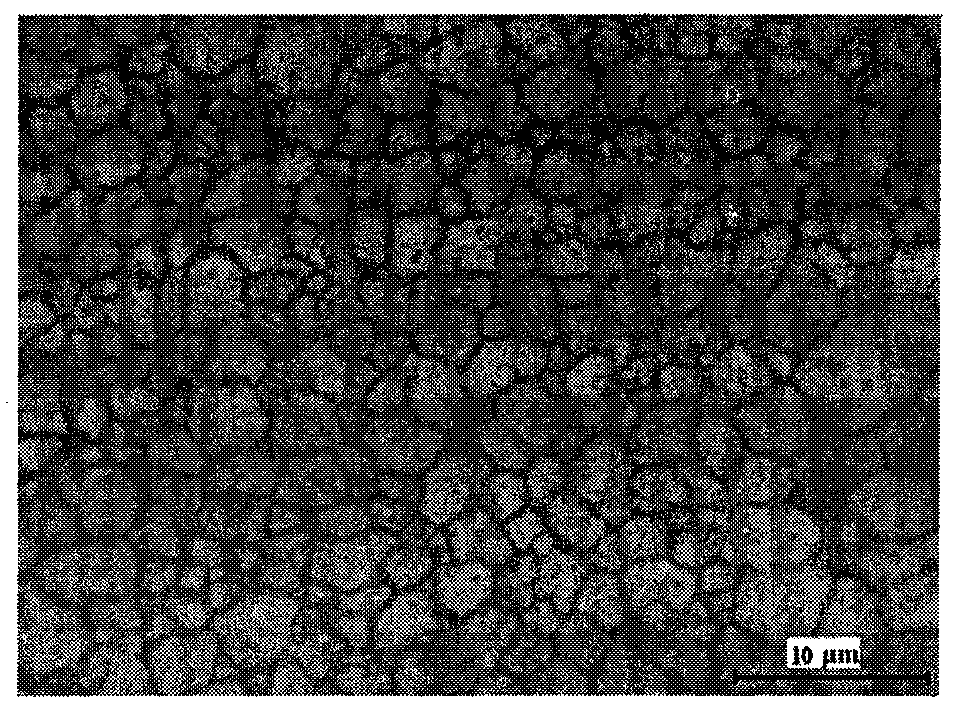

[0028] Such as figure 1 , 2 , 3, a 650 production process for obtaining uniform, fine-grained copper alloy strips, heating a brass alloy ingot containing 65% copper to 830°C, hot rolling, and then water cooling, the thickness of the ingot is 290mm and rolled Made to a thickness of 16mm, a total deformation of 94.5% was obtained. The final rolling temperature is not lower than 500°C to obtain a 16mm thick slab, and then face milling with a single side milling amount of 0.6mm, large processing rate cold rolling, cold rolling is a rolling process below the metal recrystallization temperature, billet opening control The total deformation was 86.4%, resulting in a 2.0 mm coil. Recrystallization annealing is carried out on the coil, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com