Method for synthesizing TiNi-TiN gradient material by laser-induction self-spreading under high temperature

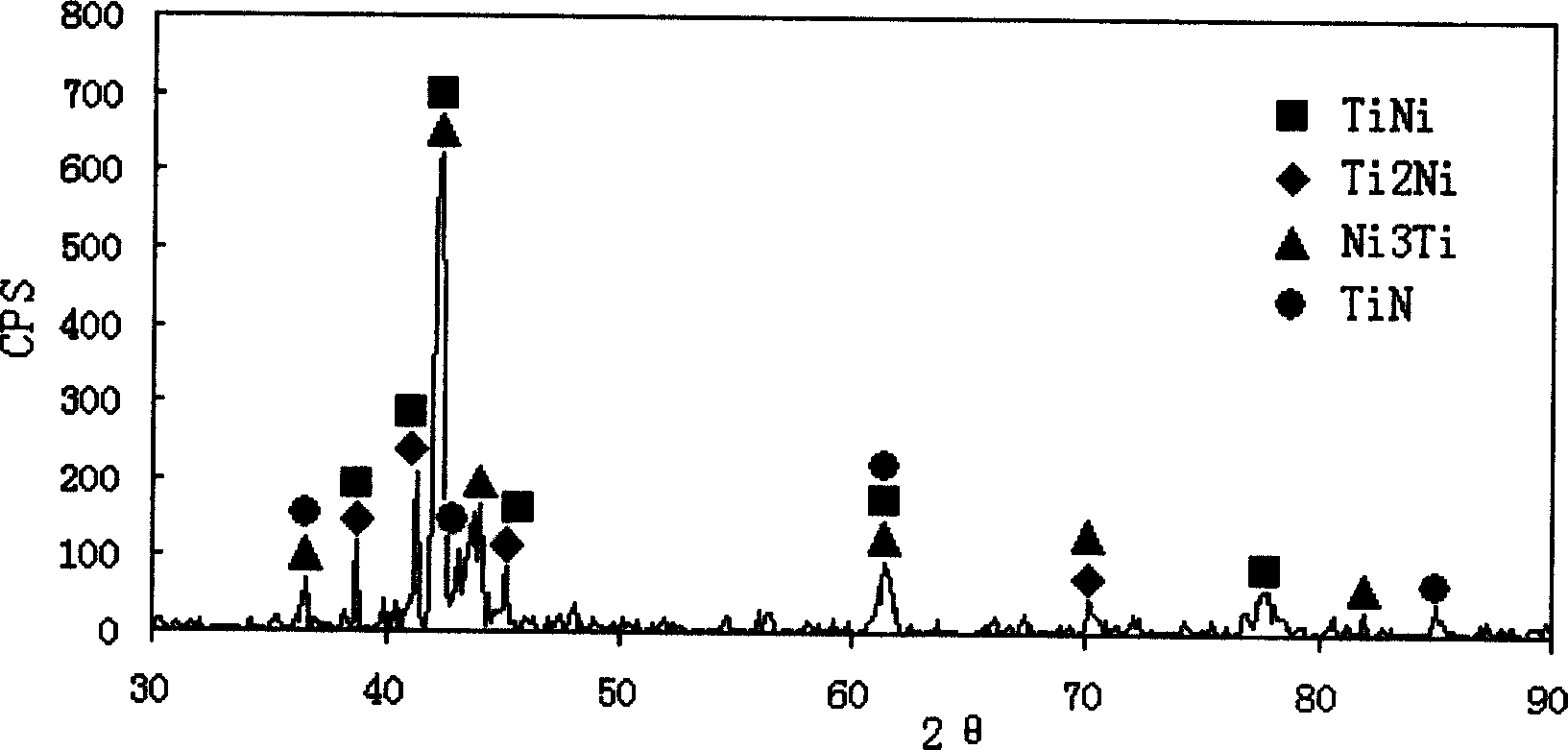

A self-propagating high temperature, laser-induced technology, applied in the field of one-time synthesis of TiNi-TiN gradient materials, can solve the problems of complex process, high cost, inability to achieve, etc., and achieve the effect of simplifying the synthesis process, easy calculation, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

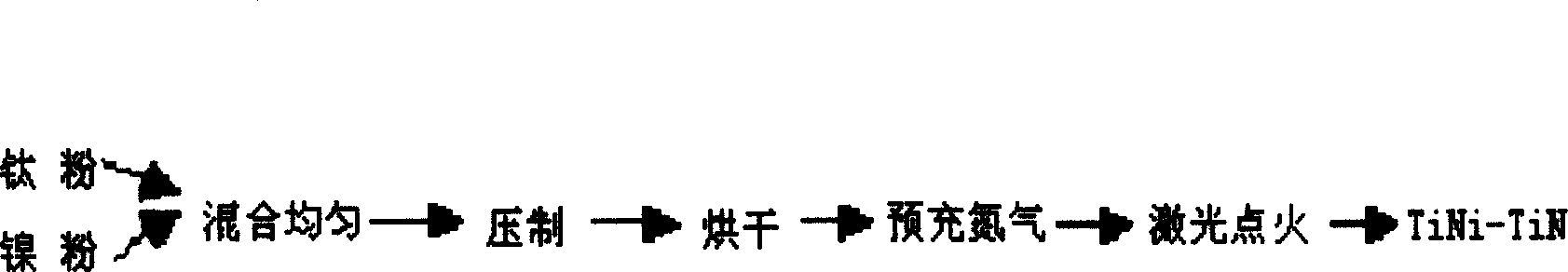

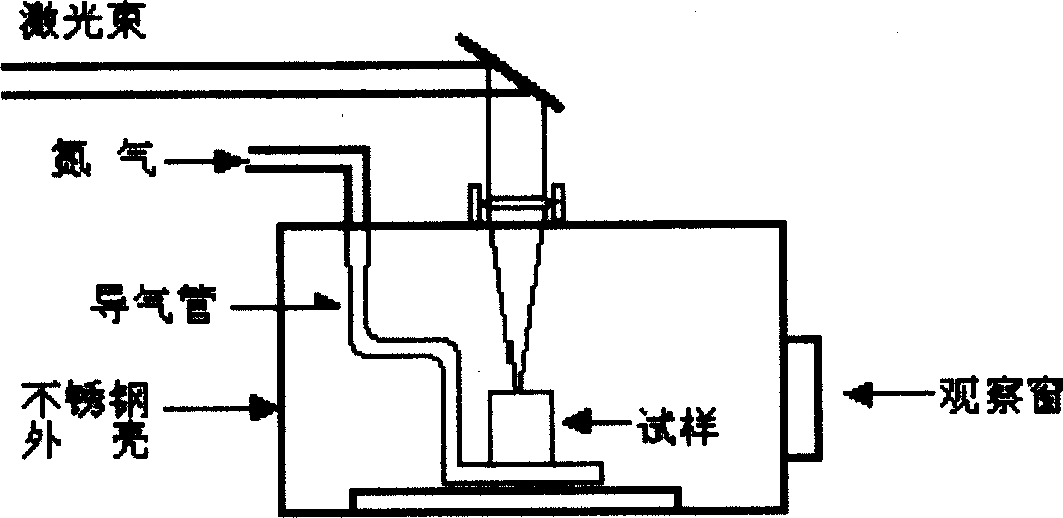

Method used

Image

Examples

Embodiment 1

[0027] The raw materials used in the present invention are Ti powder and Ni powder, and their main characteristics are shown in Table 1.

[0028] purity

atomic weight

place of origin

Titanium powder

99.0%

47.88

200 mesh

Shanghai Runjie Chemical Reagent Co., Ltd.

nickel powder

99.5%

58.71

300 mesh

Shanghai Longxin Technology Development Co., Ltd.

[0029] (2) Prepare Ti and Ni metal powders with a molar ratio of 1:1, and calculate the mass percentages of Ti and Ni in the mixed powder:

[0030] Tiwt% 1:1 = 47.88 / (47.88+58.71) × 100% = 44.92% (1)

[0031] Niwt% 1:1 = 58.71 / (47.88+58.71) × 100% = 55.08% (2)

[0032] According to the calculation results, an appropriate amount of Ti and Ni powders were weighed with an electronic balance with an accuracy of 0.01 g, and then mixed with a powder mixer (fineness: 30-300 mesh, rotational speed: 24000 r / min). Turn on the machine for one minute each t...

Embodiment 2

[0038] The raw materials used in the present invention are Ti powder and Ni powder, and their main characteristics are shown in Table 1.

[0039] purity

atomic weight

place of origin

Titanium powder

99.0%

47.88

250 mesh

Shanghai Runjie Chemical Reagent Co., Ltd.

nickel powder

99.5%

58.71

250 mesh

Shanghai Longxin Technology Development Co., Ltd.

[0040] (2) Prepare Ti and Ni metal powders with a molar ratio of 1:1, and calculate the mass percentages of Ti and Ni in the mixed powder:

[0041] Tiwt% 1:1 = 47.88 / (47.88+58.71) × 100% = 44.92% (1)

[0042] Niwt% 1:1 = 58.71 / (47.88+58.71) × 100% = 55.08% (2)

[0043] According to the calculation results, an appropriate amount of Ti and Ni powders were weighed with an electronic balance with an accuracy of 0.01 g, and then mixed with a powder mixer (fineness: 30-300 mesh, rotational speed: 24000 r / min). Turn on the machine for one minute each t...

Embodiment 3

[0049] The raw materials used in the present invention are Ti powder and Ni powder, and their main characteristics are shown in Table 1.

[0050] purity

atomic weight

place of origin

Titanium powder

99.0%

47.88

300 mesh

Shanghai Runjie Chemical Reagent Co., Ltd.

nickel powder

99.5%

58.71

200 mesh

Shanghai Longxin Technology Development Co., Ltd.

[0051] (2) Prepare Ti and Ni metal powders with a molar ratio of 1:1, and calculate the mass percentages of Ti and Ni in the mixed powder:

[0052] Tiwt% 1:1 = 47.88 / (47.88+58.71) × 100% = 44.92% (1)

[0053] Niwt% 1:1 = 58.71 / (47.88+58.71) × 100% = 55.08% (2)

[0054]According to the calculation results, an appropriate amount of Ti and Ni powders were weighed with an electronic balance with an accuracy of 0.01 g, and then mixed with a powder mixer (fineness: 30-300 mesh, rotational speed: 24000 r / min). Turn on the machine for one minute each ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com