Grey water treatment technology for graded gasification furnace

A treatment process and technology for a gasifier, which is applied in the field of coal gasification ash water gasification ash water by coal-water slurry gasification, can solve the problems of cumbersome process operation, complicated structure, energy waste and the like, and achieves simplified process flow, process simplification, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

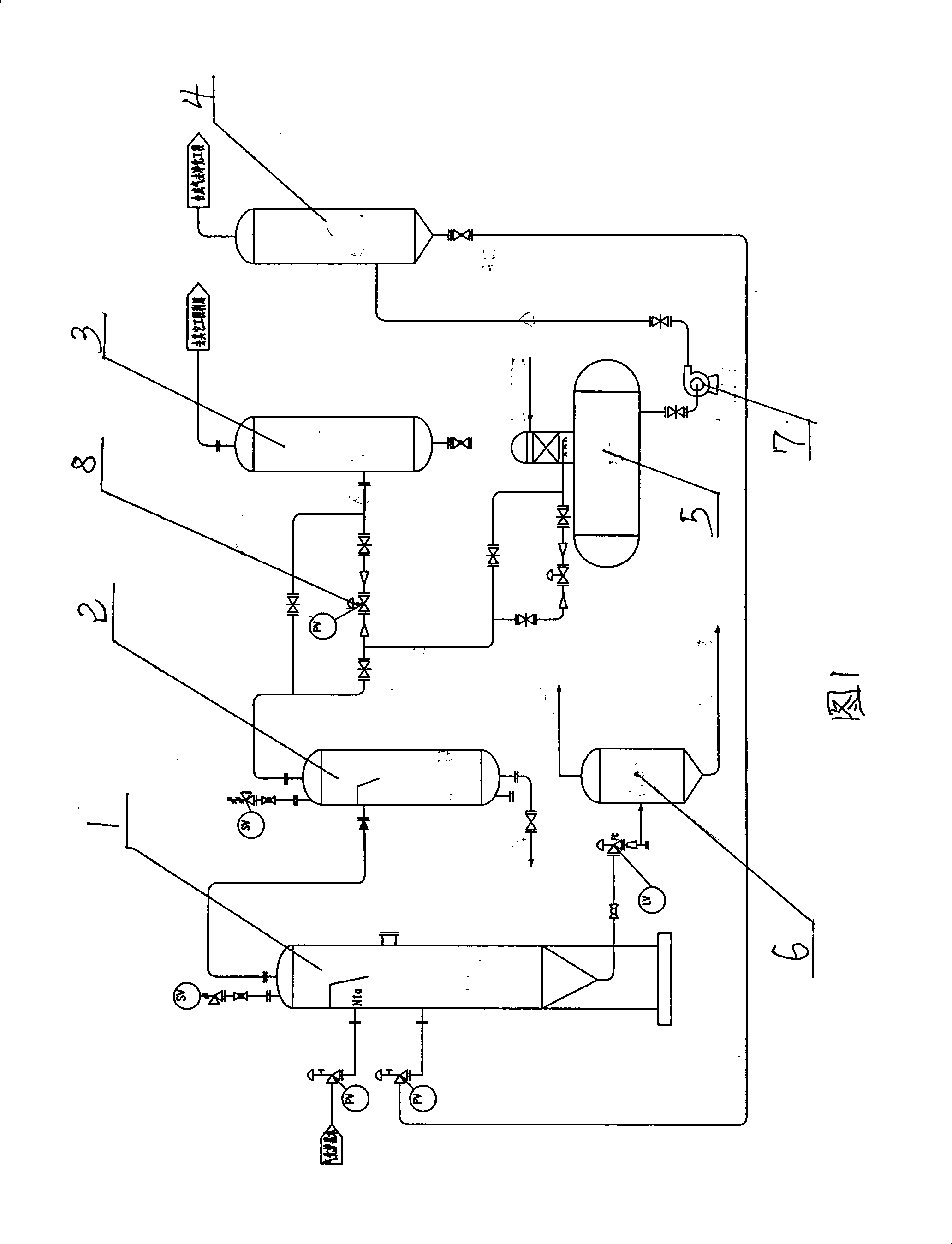

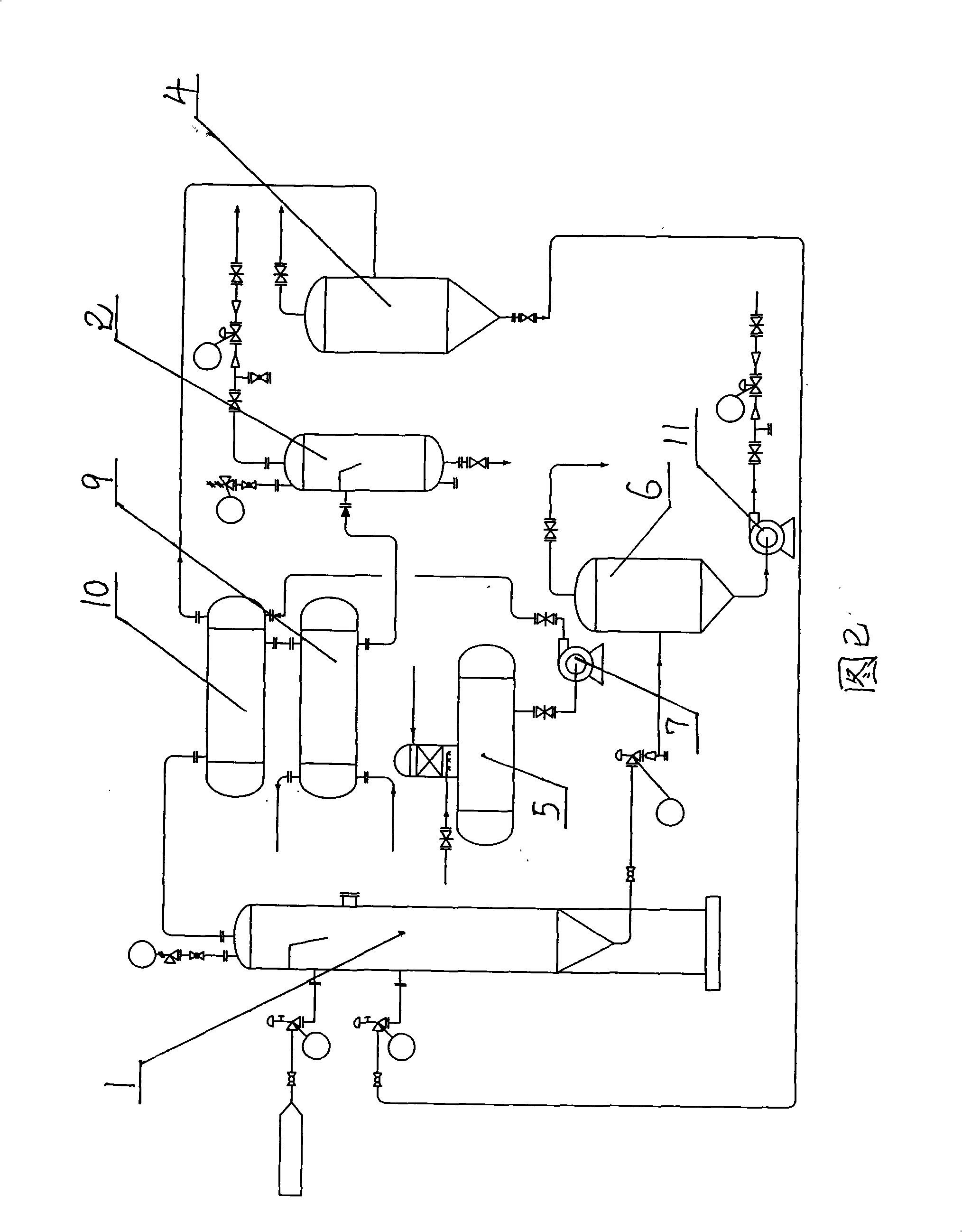

[0012] The process flow shown in Figure 1: a gray water treatment process applied to a graded gasifier, including the following steps, the black water discharged from the graded gasifier and the synthesis gas scrubber is decompressed through their respective pipelines and then enters the high-pressure flash The operating pressure of steam tank 1 and high-pressure flash tank 1 is 150°C and 0.5 MPa. The liquid phase from the high-flash flash in high-pressure flash tank 1 enters vacuum flash tank 6 through a pressure reducing valve for secondary flash evaporation. The operating pressure of the steam tank 6 is 80°C, 0.05MPa (A) (A represents absolute pressure), and the liquid phase flashed out of the vacuum flash tank 6 enters the settling tank relatively lower than the vacuum flash tank 6 by gravity. , the gray water after settlement is recycled; the gas phase from the high-flash flash tank 1 enters the high-flash tank top separator 2 for gas-liquid separation, and part of the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com