Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106 results about "Aniline point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The aniline point of an oil is defined as the minimum temperature at which equal volumes of aniline (C₆H₅NH₂) and lubricant oil are miscible, i.e. form a single phase upon mixing.. The value gives an approximation for the content of aromatic compounds in the oil, since the miscibility of aniline, which is also an aromatic compound suggests the presence of similar (i.e. aromatic) compounds in the oil. The lower the aniline point, the greater is the content of aromatic compounds in the oil.

Lubricating oil formulations

Lubricating oil compositions having excellent thermal and oxidative stability, wear control, copper corrosion control and compatibility with seal materials comprising a mineral oil having a) a Viscosity Index of greater than 110 and an aniline point of greater than 110 DEG C. and / or b) a linear+single ring paraffin content of greater than 68 wt %, and at least one polymer selected from olefin (co) polymer(s), polyalkyl (meth) acrylate(s) and mixtures thereof. The lubricating oil compositions are particularly useful as manual transmission and axle lubricants.

Owner:AFTON CHEM INTANGIBLES

Modified hydrocarbon cleaning agent

The invention relates to the technical field of the cleaning agent, in particular to a modified hydrocarbon cleaning agent. The main technical scheme in the invention is as follows: additives are added in the hydrocarbon cleaning agent which contains solvent without aromatic hydrocarbons, solvent with low aromatic hydrocarbons and C10-13 normal paraffin or isoparaffin, namely alcohol additive, ester additive and ether additive are added in the hydrocarbon cleaning agent D40, D60, D65 and D80 and the hydrocarbon cleaning agent C10, C11, C12 and C13 to ensure that the modified hydrocarbon cleaning agent has high cleaning capability, high KB value, low aniline point, low cost, little odor and high recovery rate, can be used to clean macromolecular pollutants such as wax, resin, printing ink and rosin and can be heated for cleaning in a special device.

Owner:广东新球清洗科技股份有限公司

Lubricating oil composition

ActiveUS20070287643A1Improve wear resistanceEasy to keepOrganic compound preparationLiquid carbonaceous fuelsAniline pointAutomatic transmission

Owner:NIPPON OIL CORP

Lubricating base oil and lubricating oil composition

The invention provides a lubricating base oil with a saturated component content of 90% by mass or greater, a proportion of cyclic saturated components of no greater than 40% by mass of the saturated components, a viscosity index of 110 or greater, an aniline point of 106 or greater and an ε-methylene proportion of 14-20% of the total constituent carbons, as well as a lubricating oil composition comprising the lubricating base oil.

Owner:NIPPON OIL CORP +1

Rust inhibitor for highly paraffinic lubricating base oil

A rust inhibitor providing a pass in the TORT B rust test, comprising a solubility improver, a mixture of amine phosphates, and an alkenyl succinic compound. A finished lubricant comprising the rust inhibitor and a lubricating base oil. A finished lubricant having a kinematic viscosity at 40° C. between about 90 and 1700 cSt that passes the TORT B rust test, comprising a highly paraffinic base oil and a solubility improver having an aniline point less than 50° C. A finished lubricant that passes the TORT B rust test, comprising a Fischer-Tropsch wax, oligomerized olefins, or mixture thereof; and a solubility improver. A process for making a lubricant, comprising blending together: a) a mixture of amine phosphates, b) an alkenyl succinic compound, and c) a highly paraffinic lubricating base oil. A method of improving the rust inhibition of a lubricating oil by incorporating a solubility improver having an aniline point <10° C.

Owner:CHEVROU USA INC

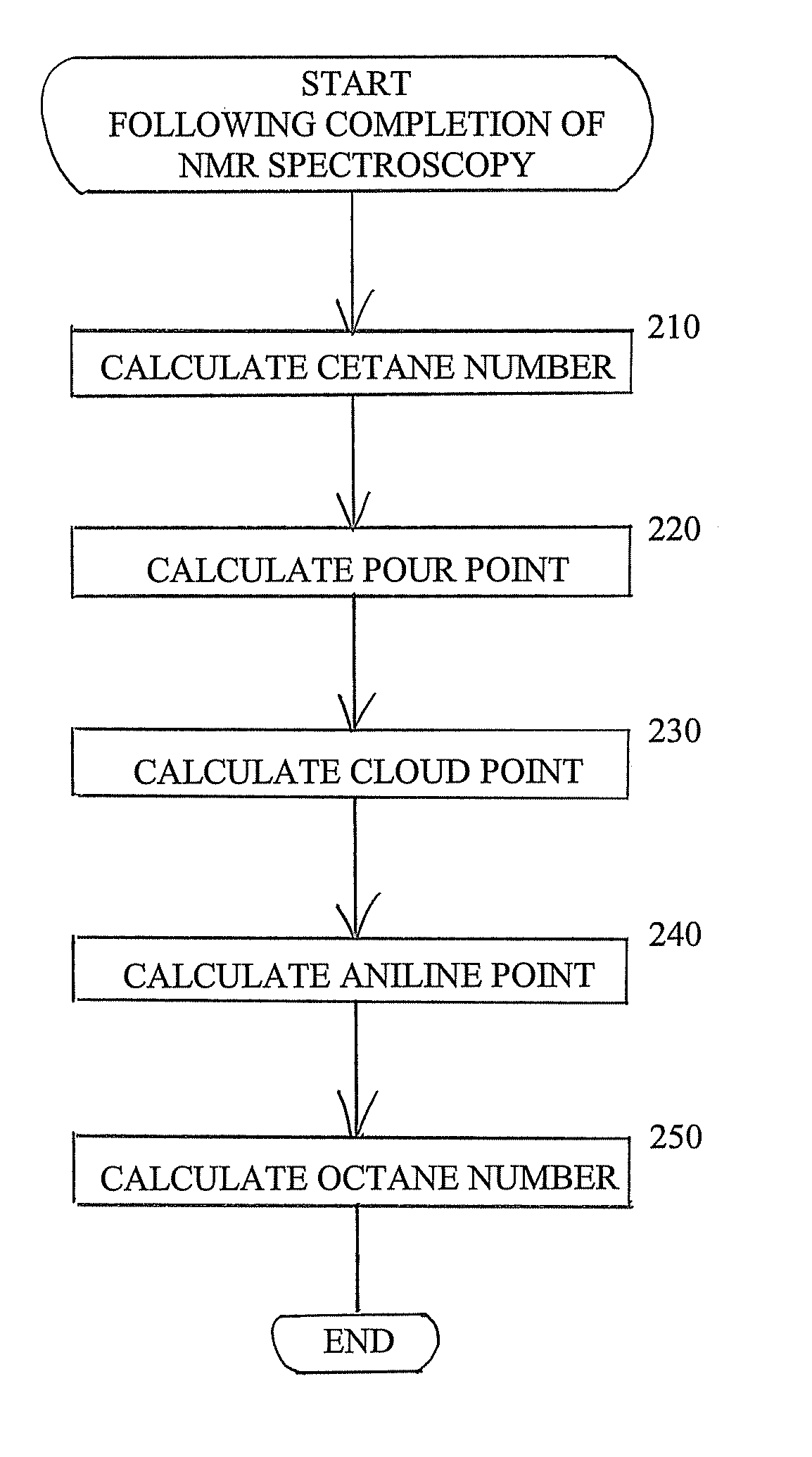

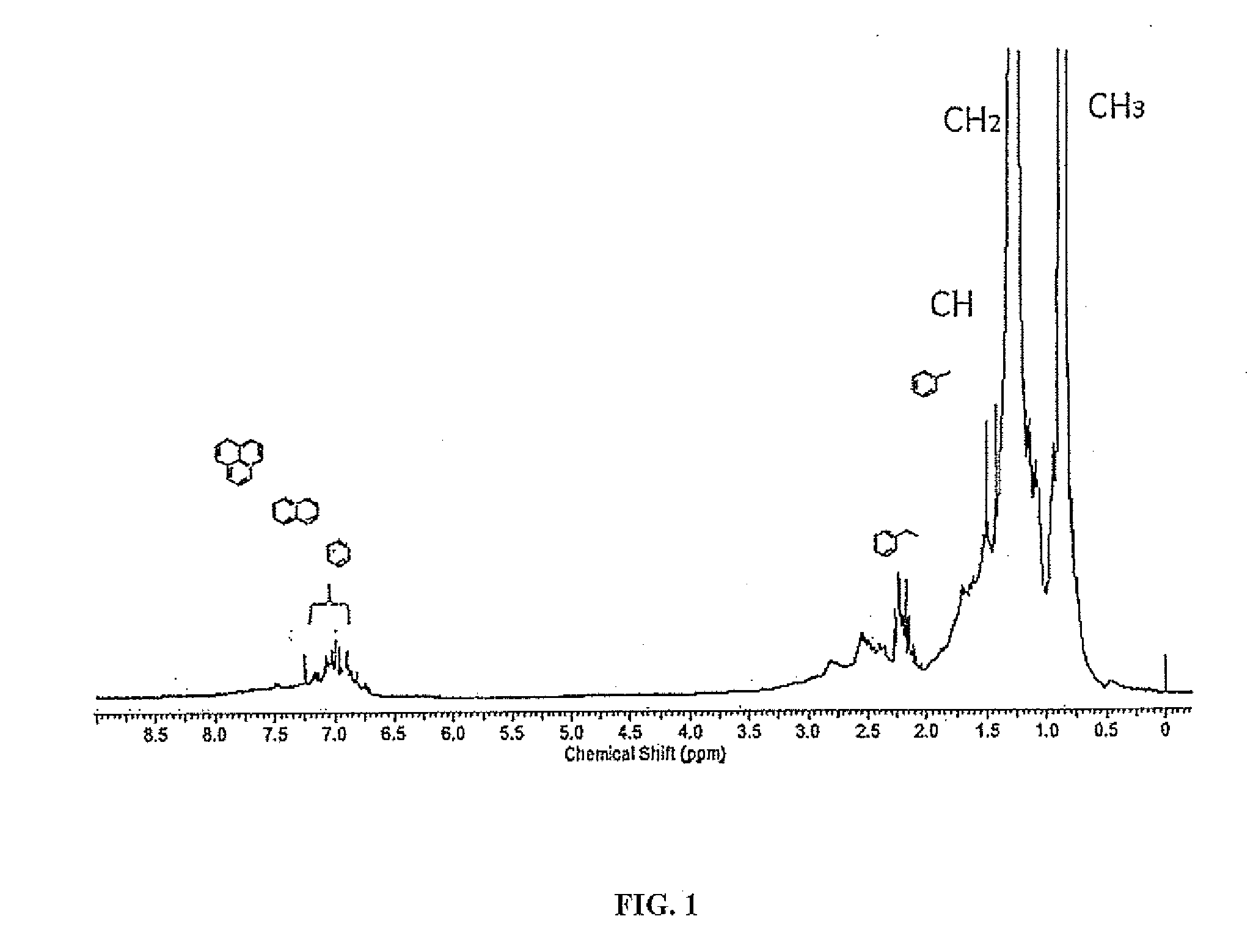

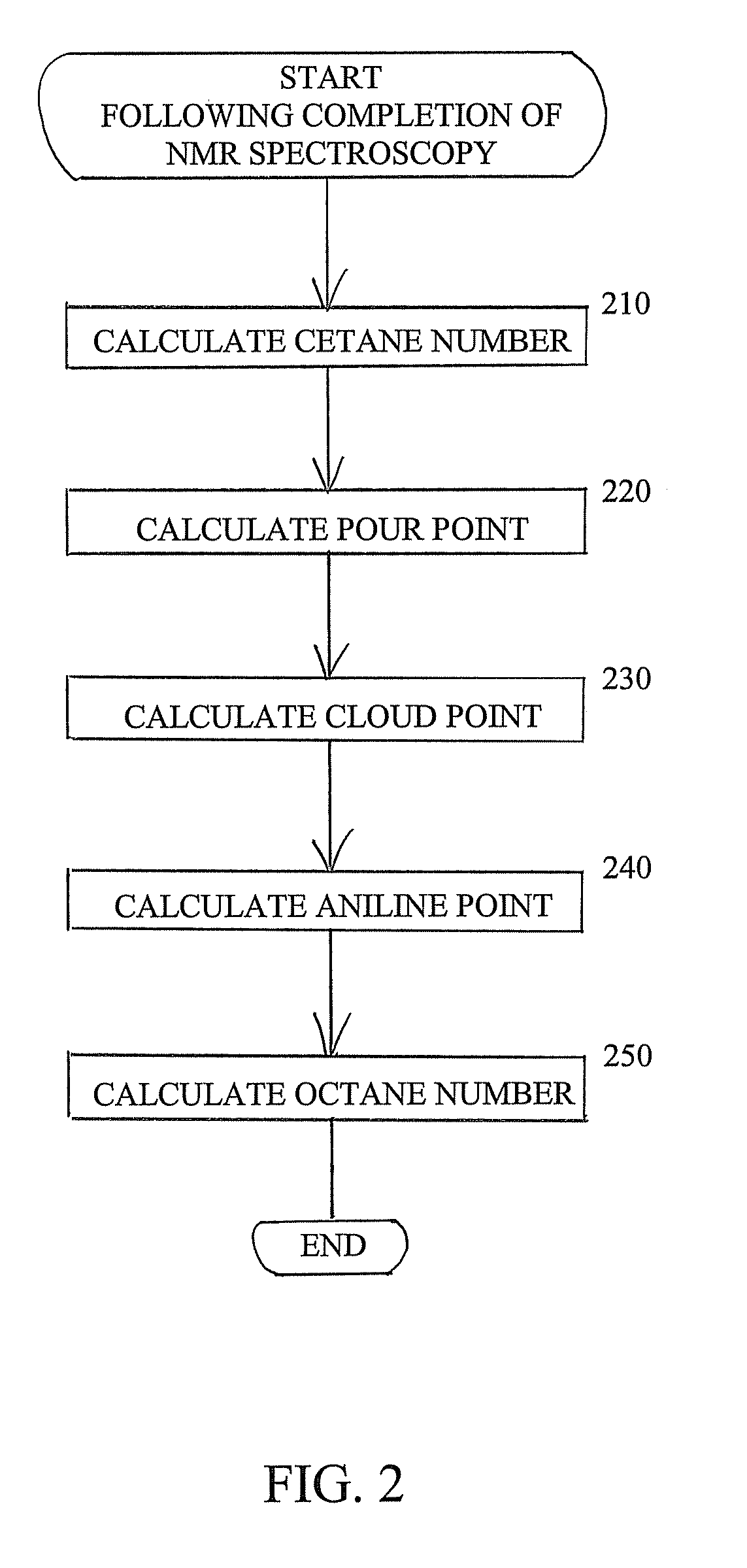

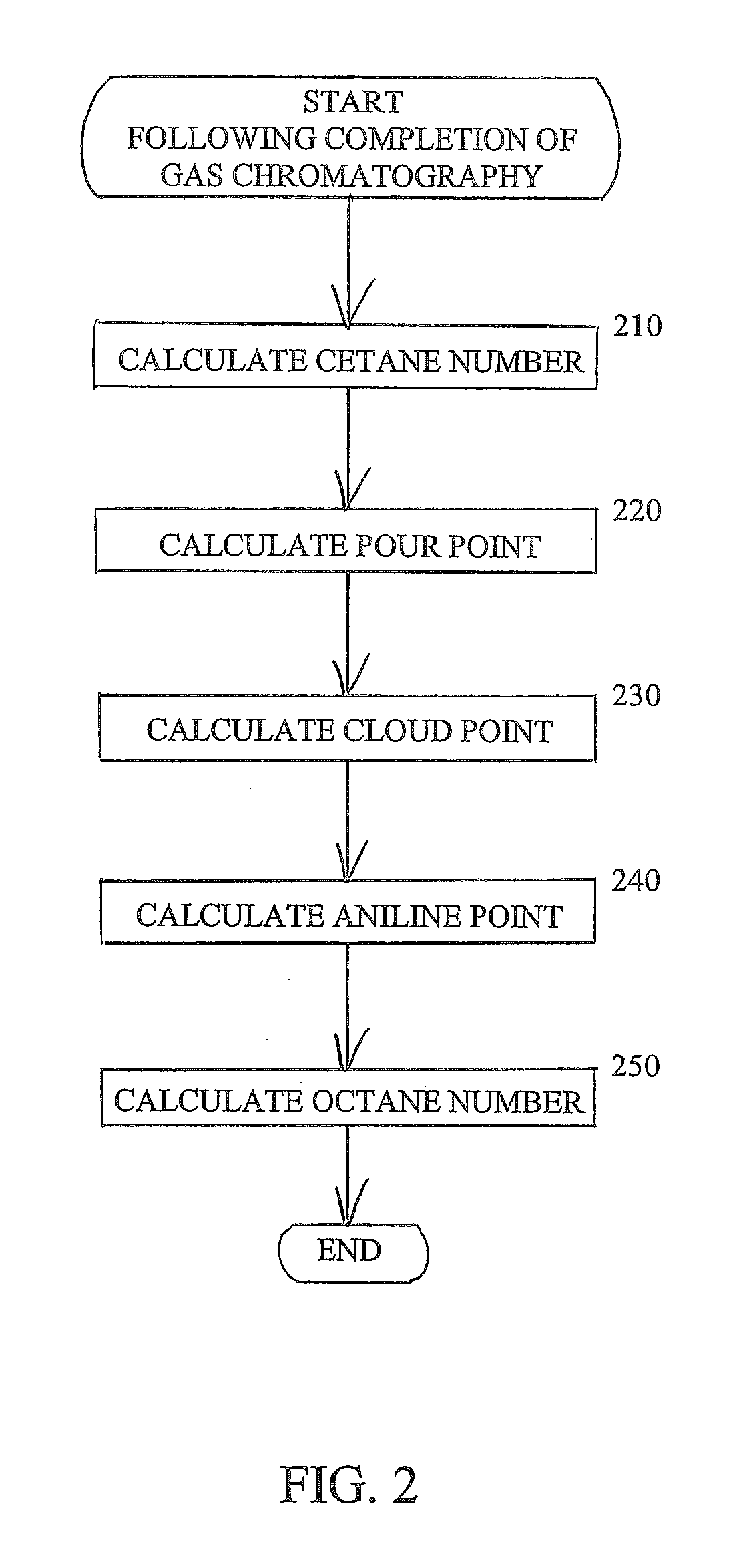

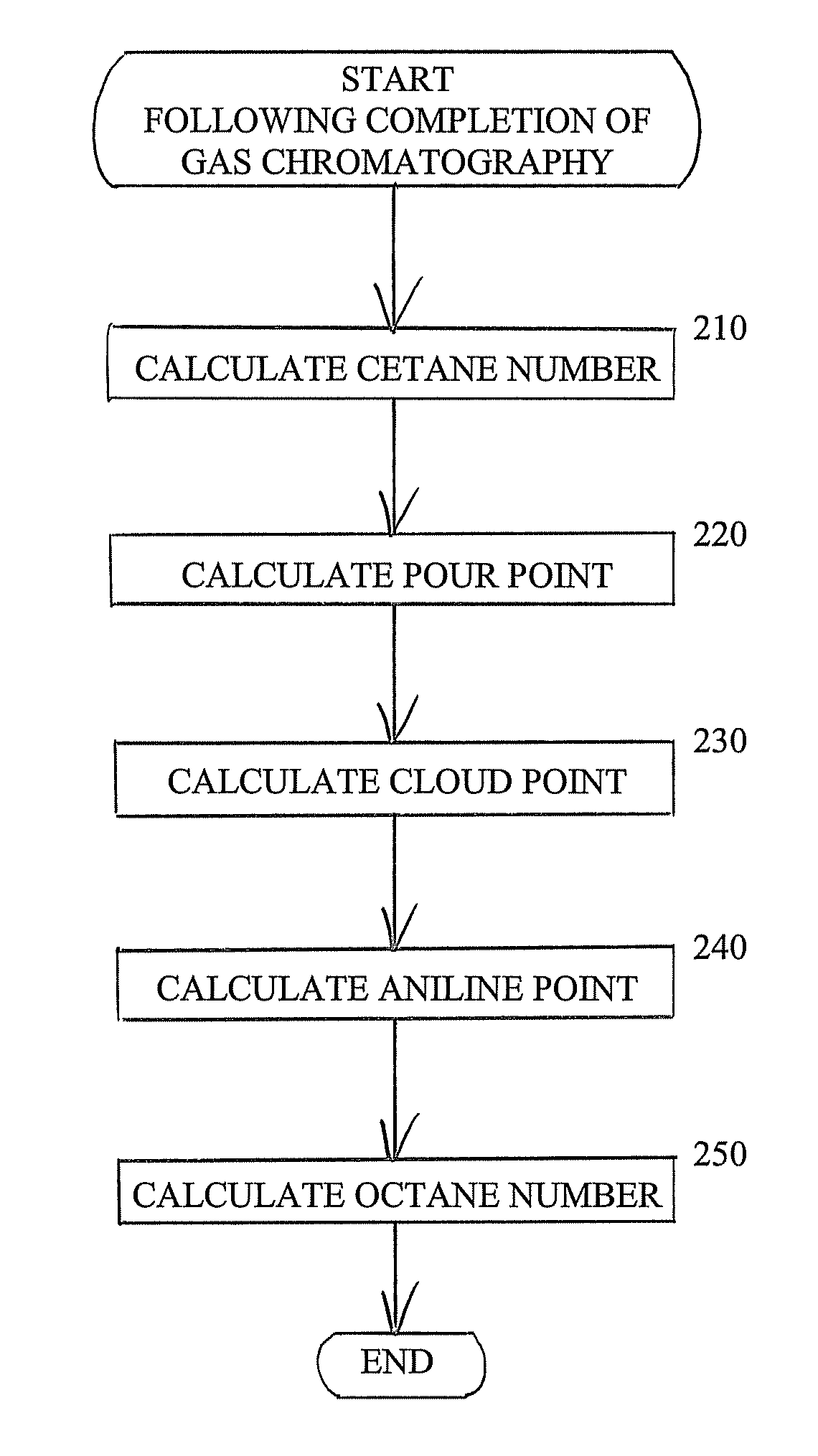

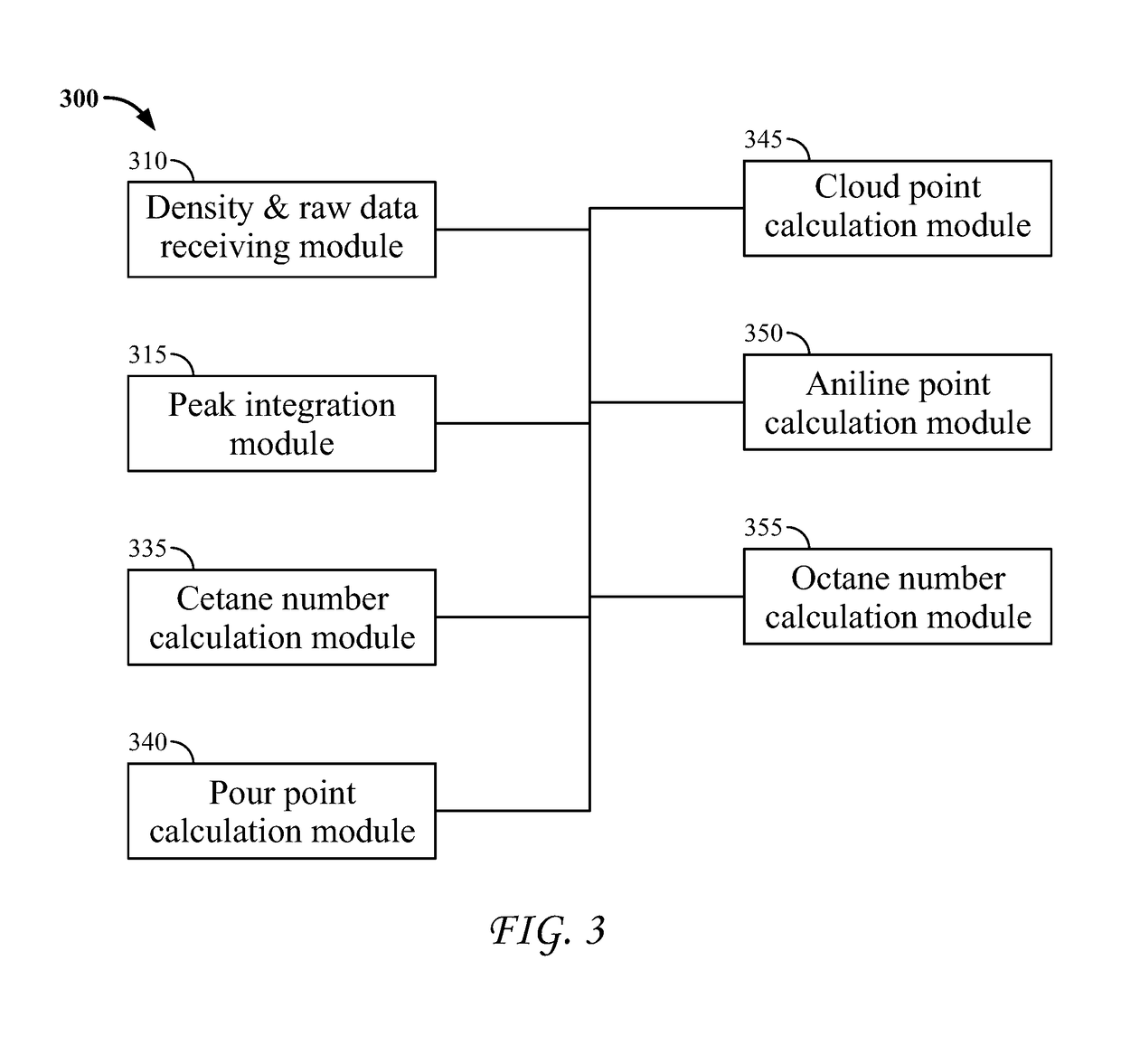

Characterization of crude oil by nmr spectroscopy

InactiveUS20150106027A1Provide informationImprove oil qualityMeasurements using NMR spectroscopyAnalysis using nuclear magnetic resonanceAniline pointSpectroscopy

A system and a method for applying 13C or 1H NMR spectroscopy to a sample of crude oil in order to calculate the cetane number, pour point, cloud point, aniline point and octane number of a gas oil fraction of the crude oil.

Owner:SAUDI ARABIAN OIL CO

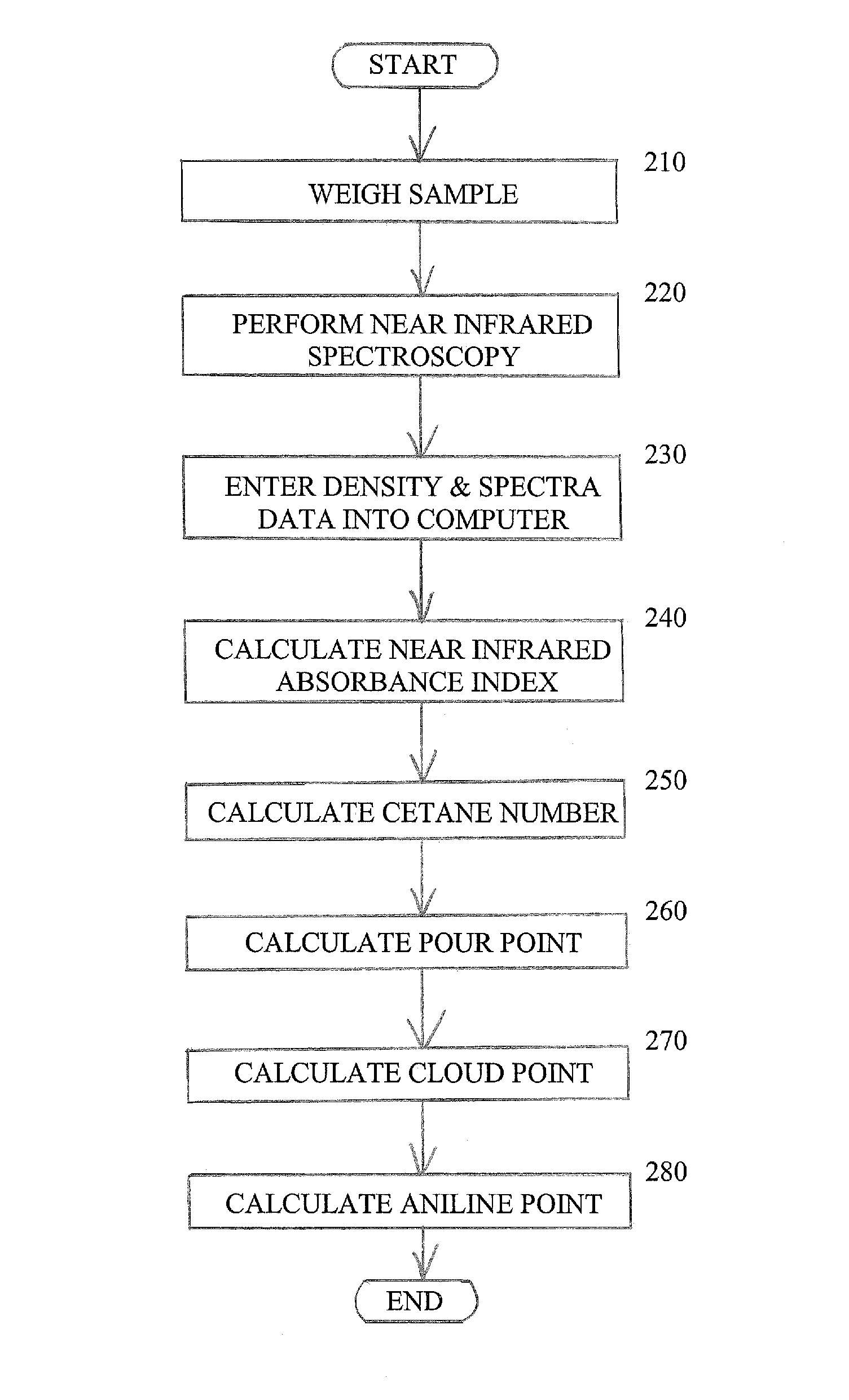

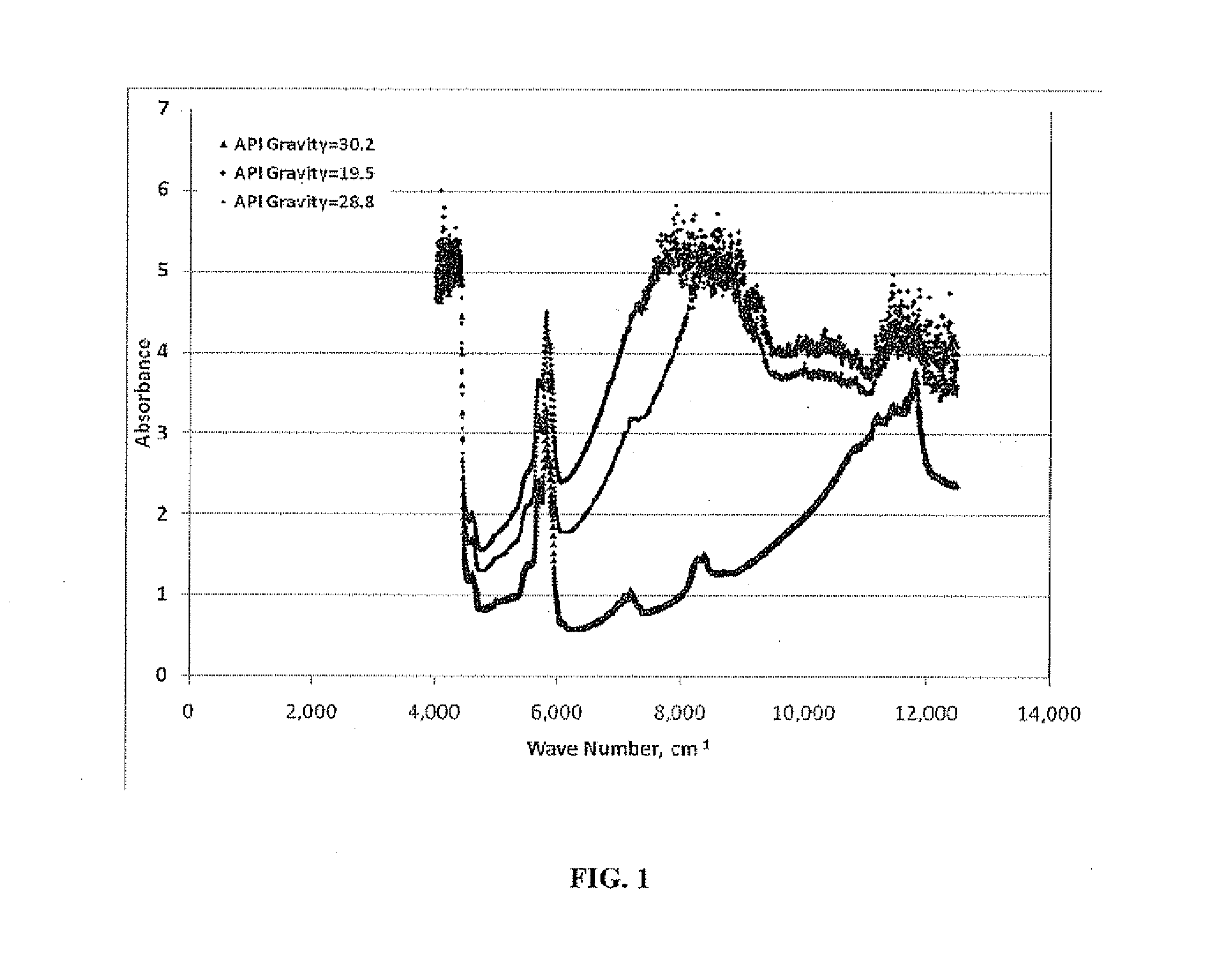

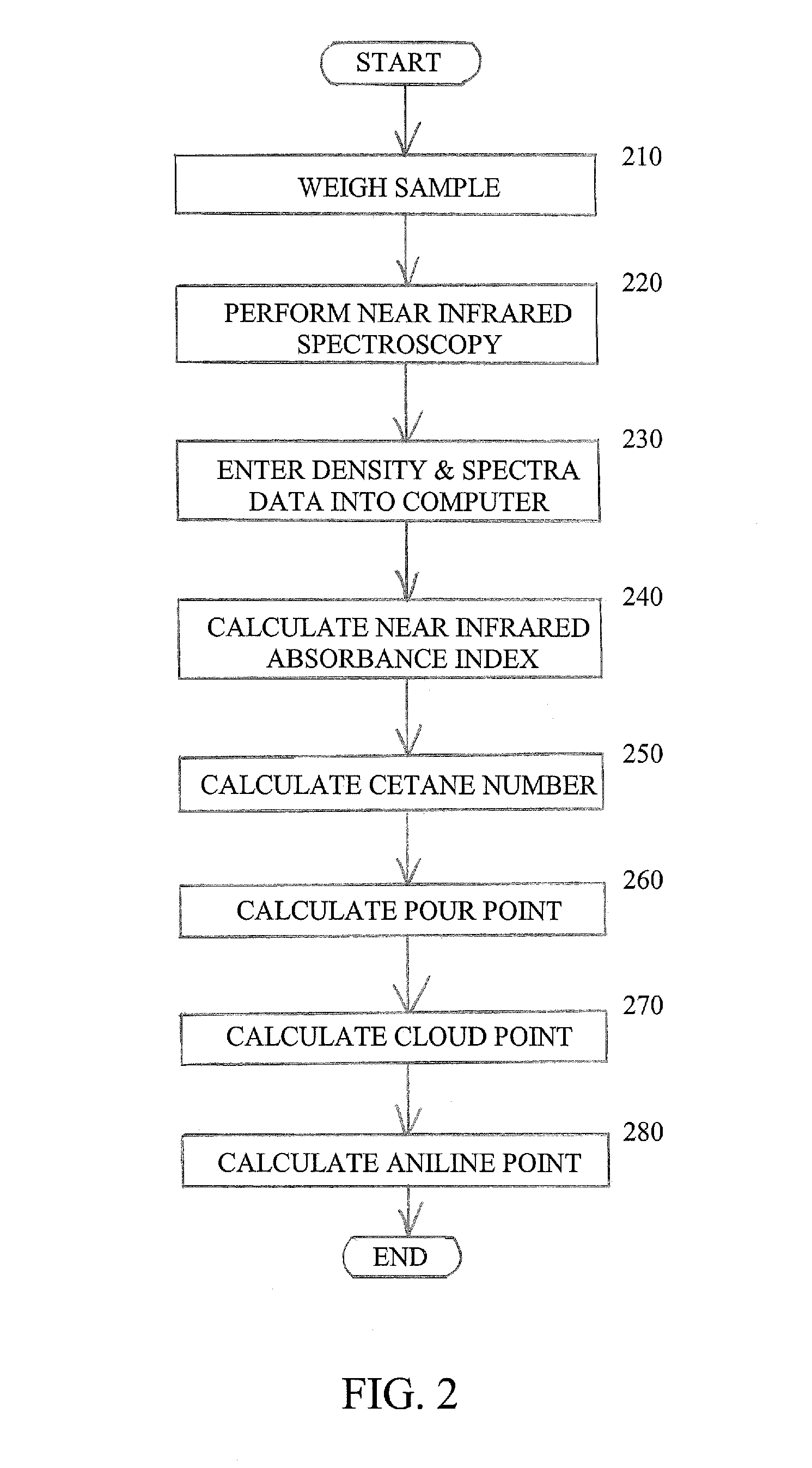

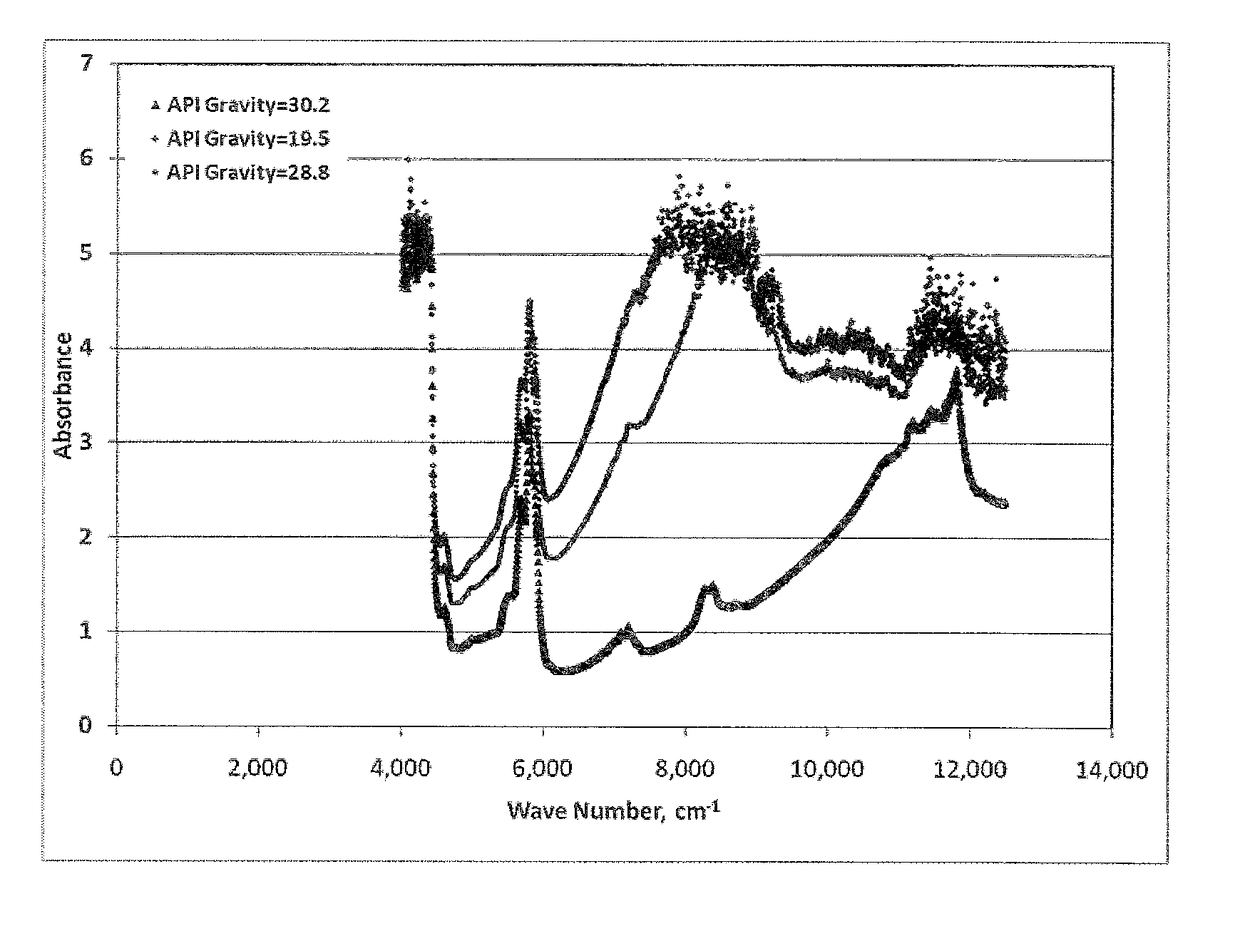

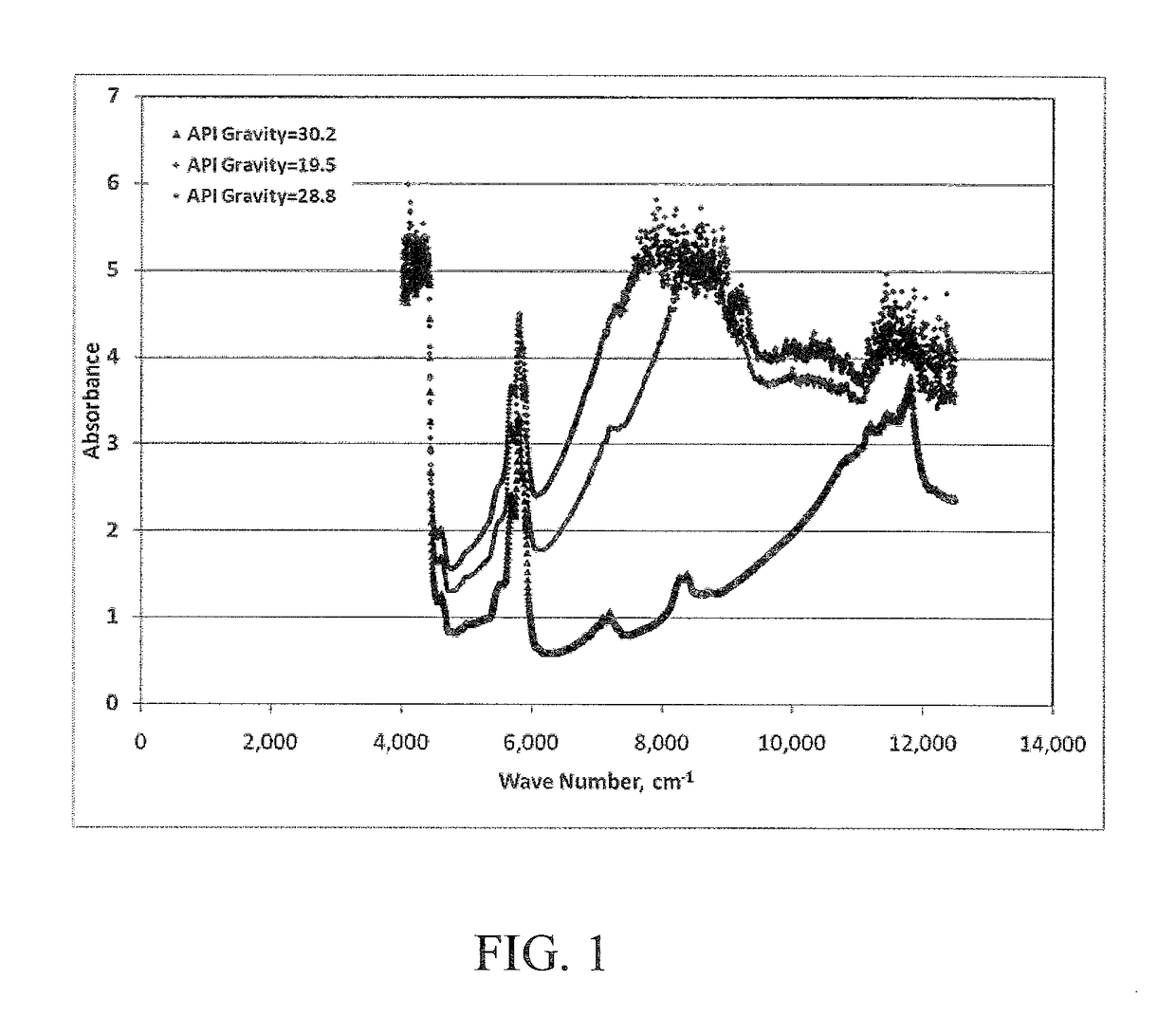

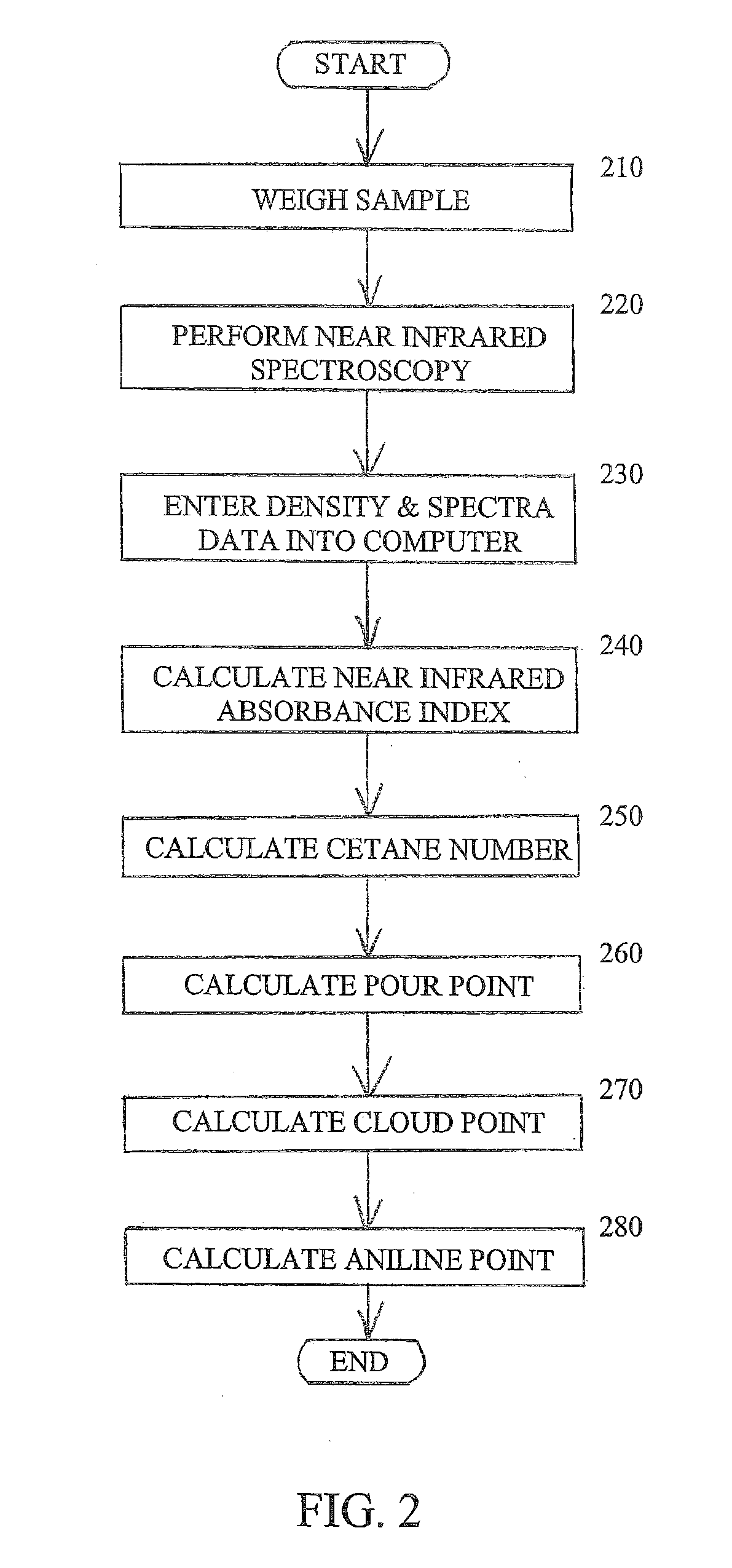

Characterization of crude oil by near infrared spectroscopy

InactiveUS20150106031A1Provide informationImprove oil qualityMaterial analysis by optical meansAbsorption/flicker/reflection spectroscopyAniline pointCloud point

A system and a method for calculating the cetane number, pour point, cloud point and aniline point of a gas oil fraction of a crude oil from the density and near infrared spectroscopy of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

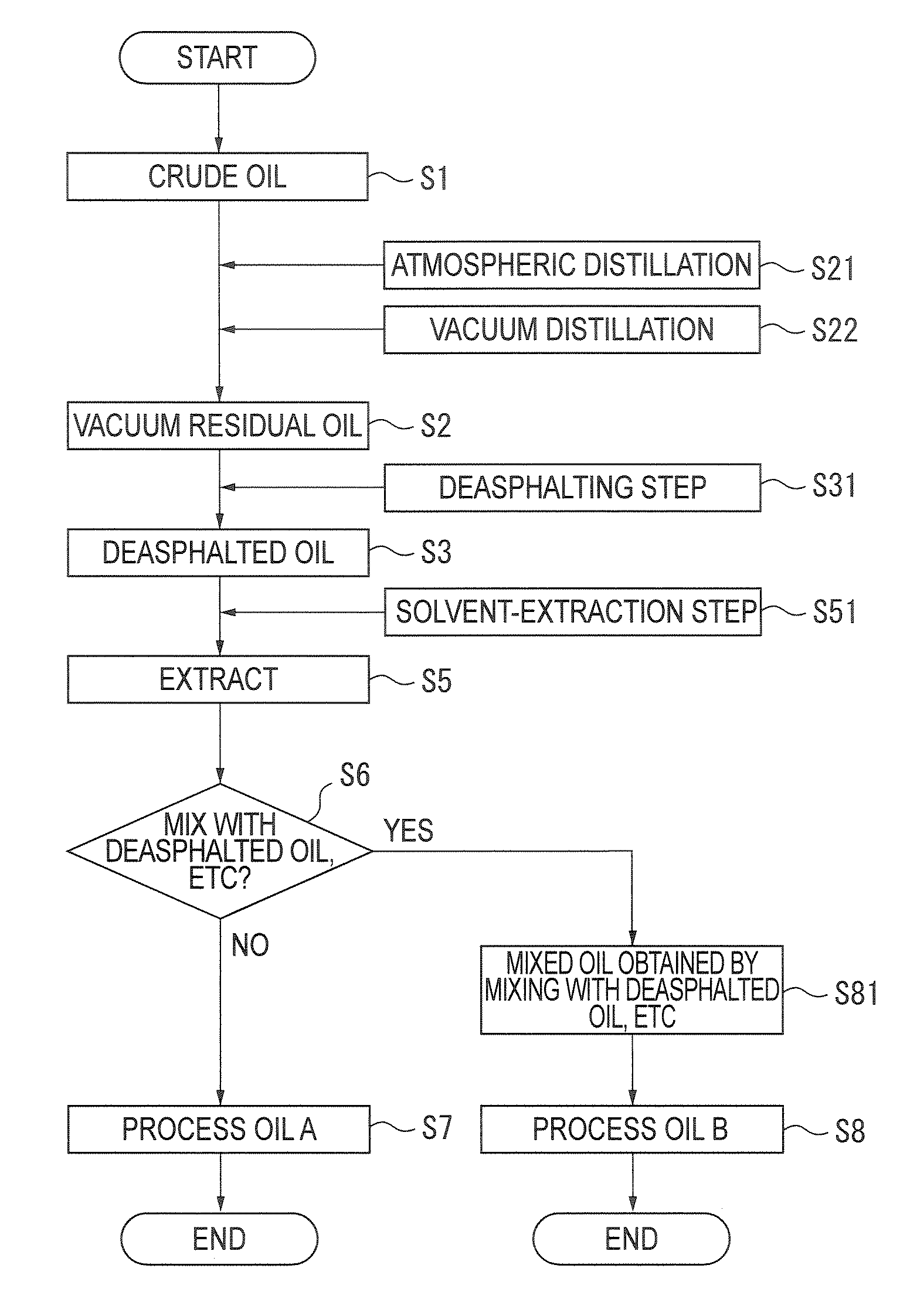

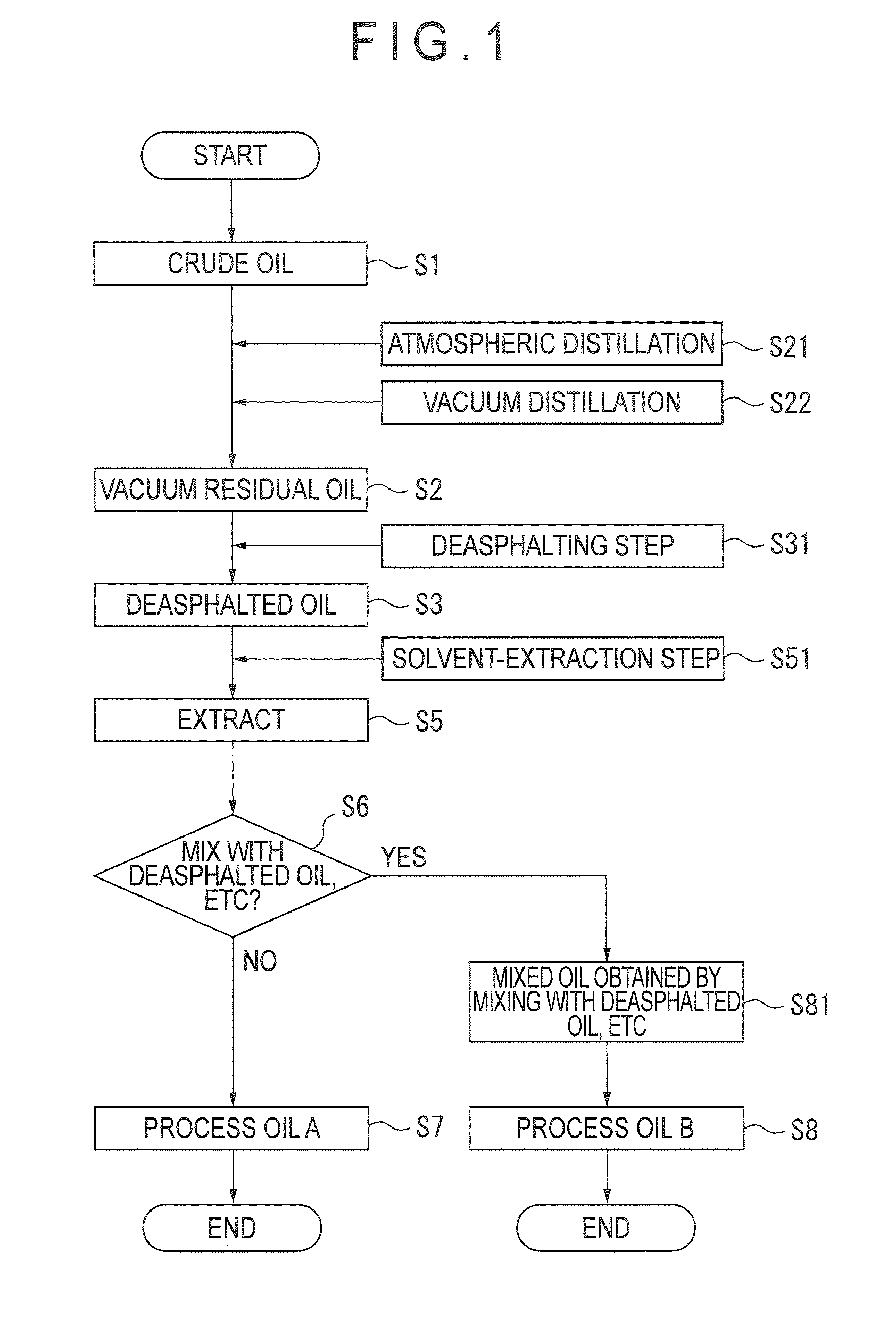

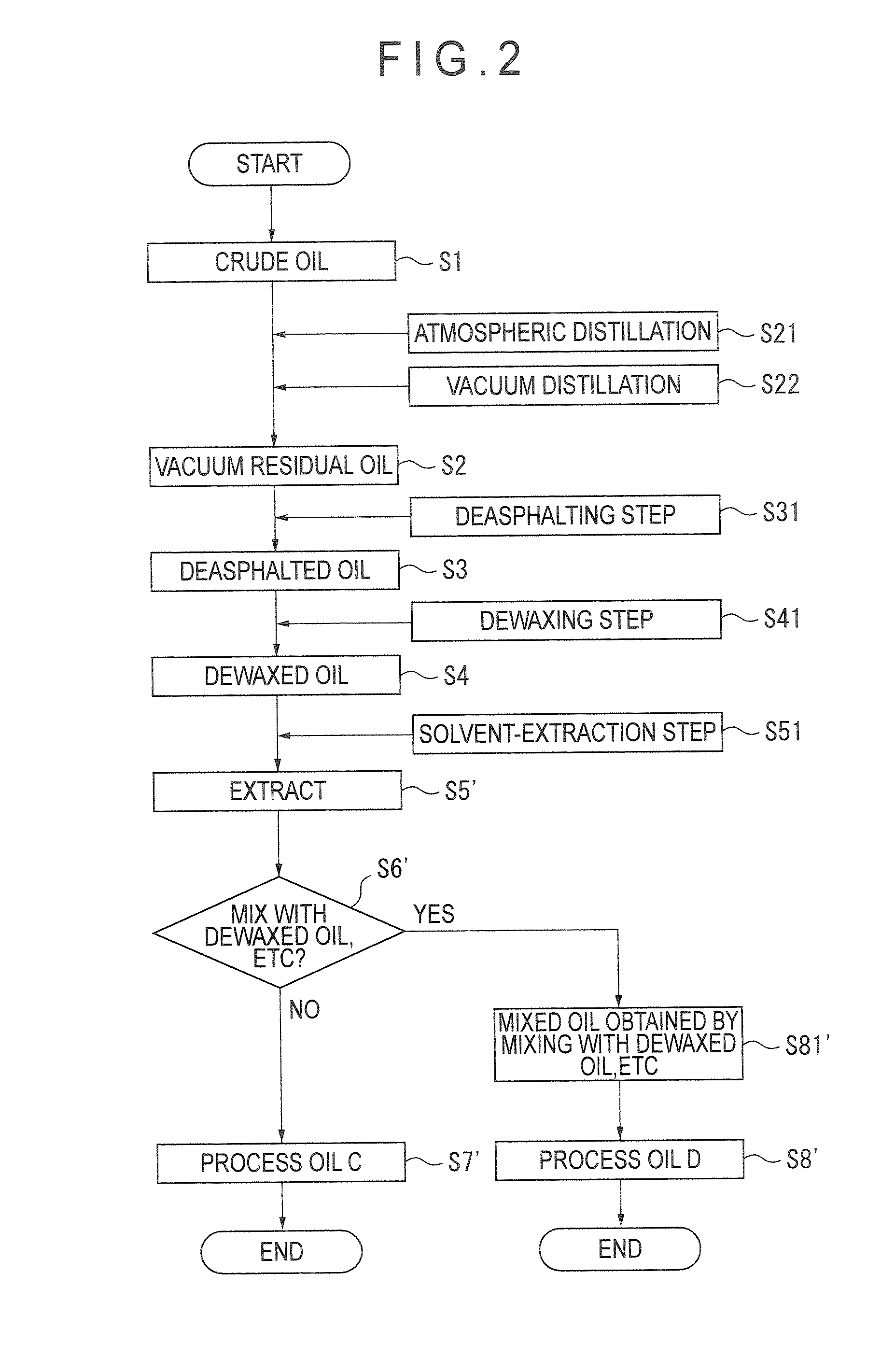

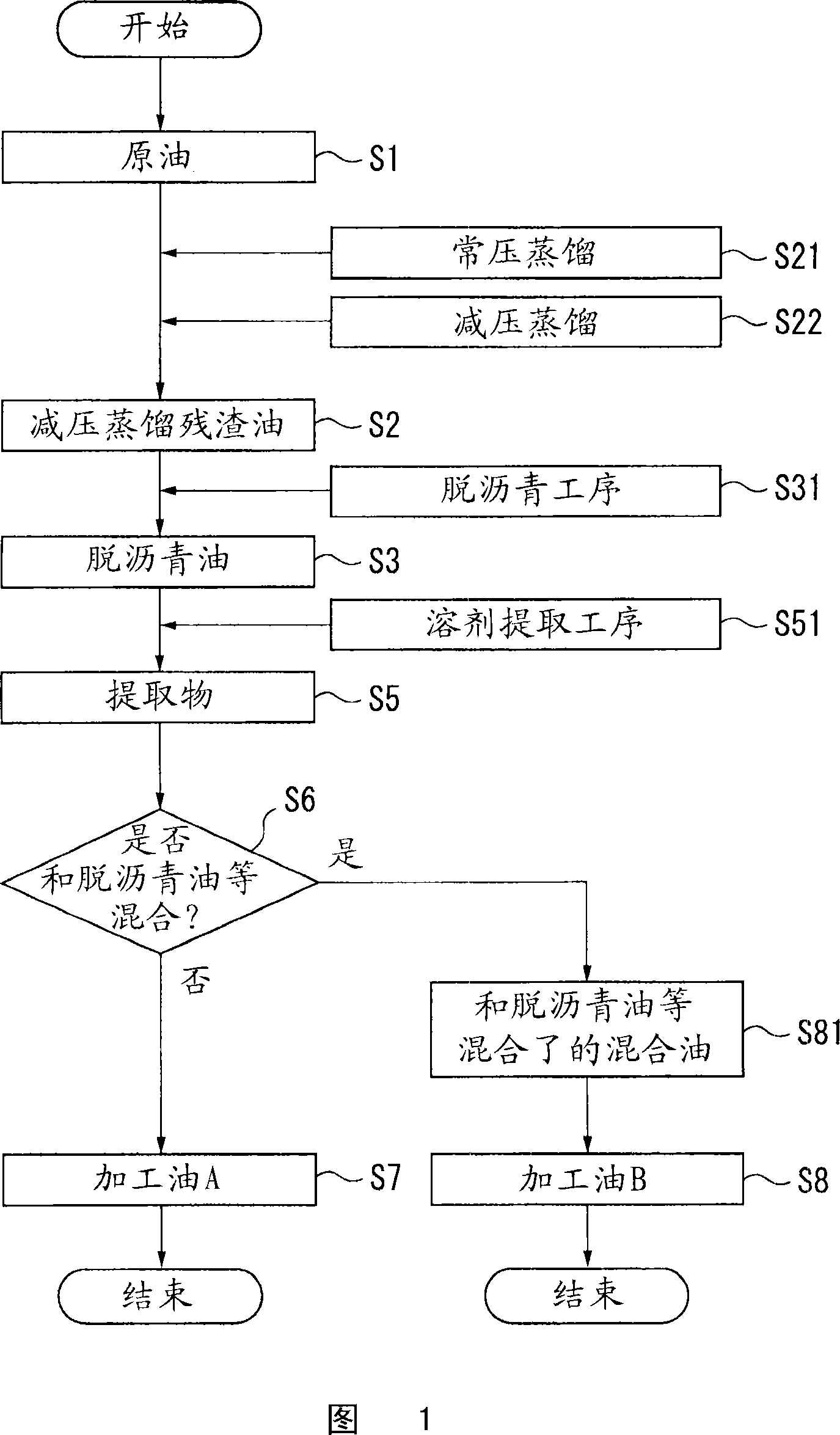

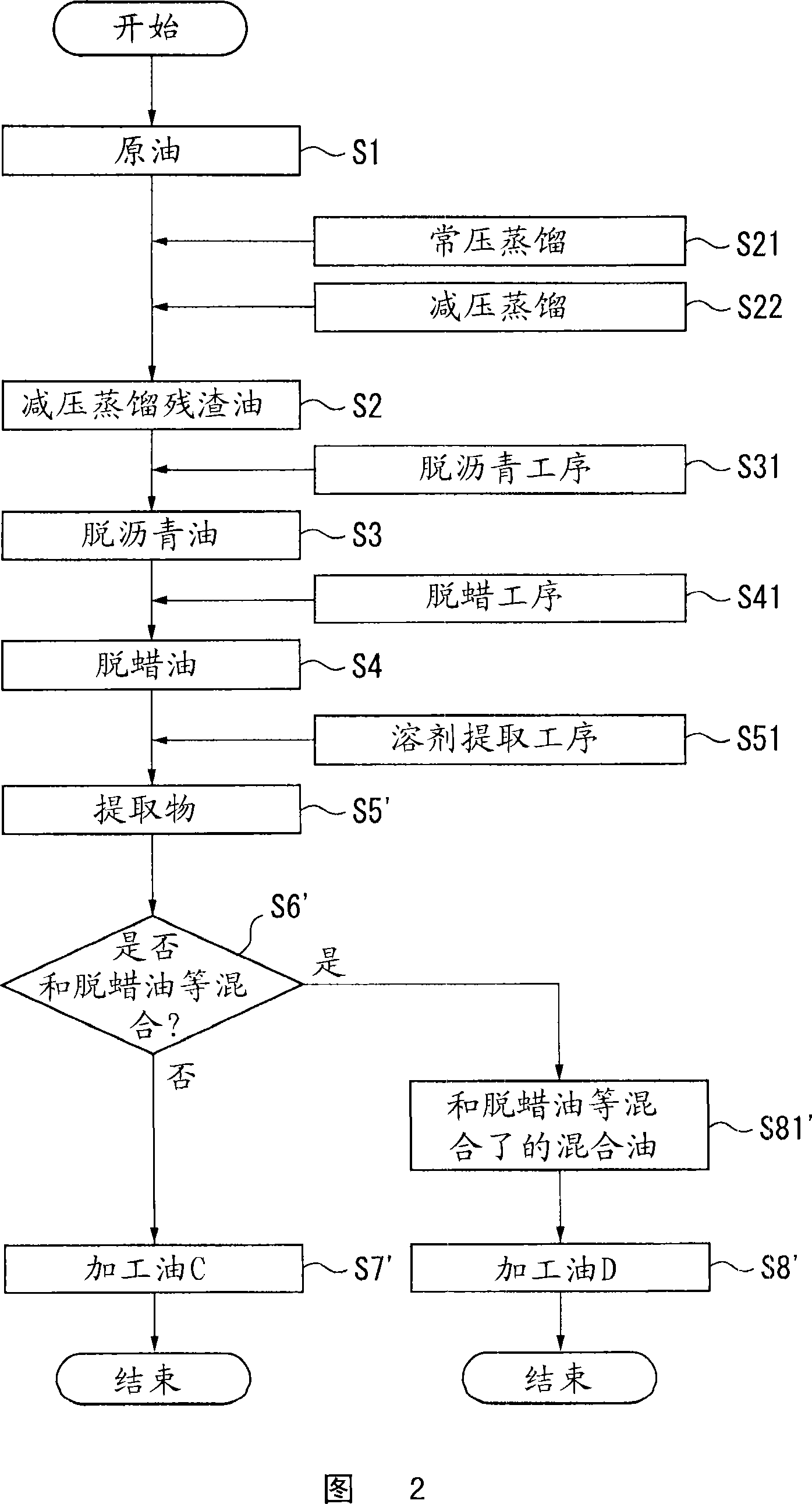

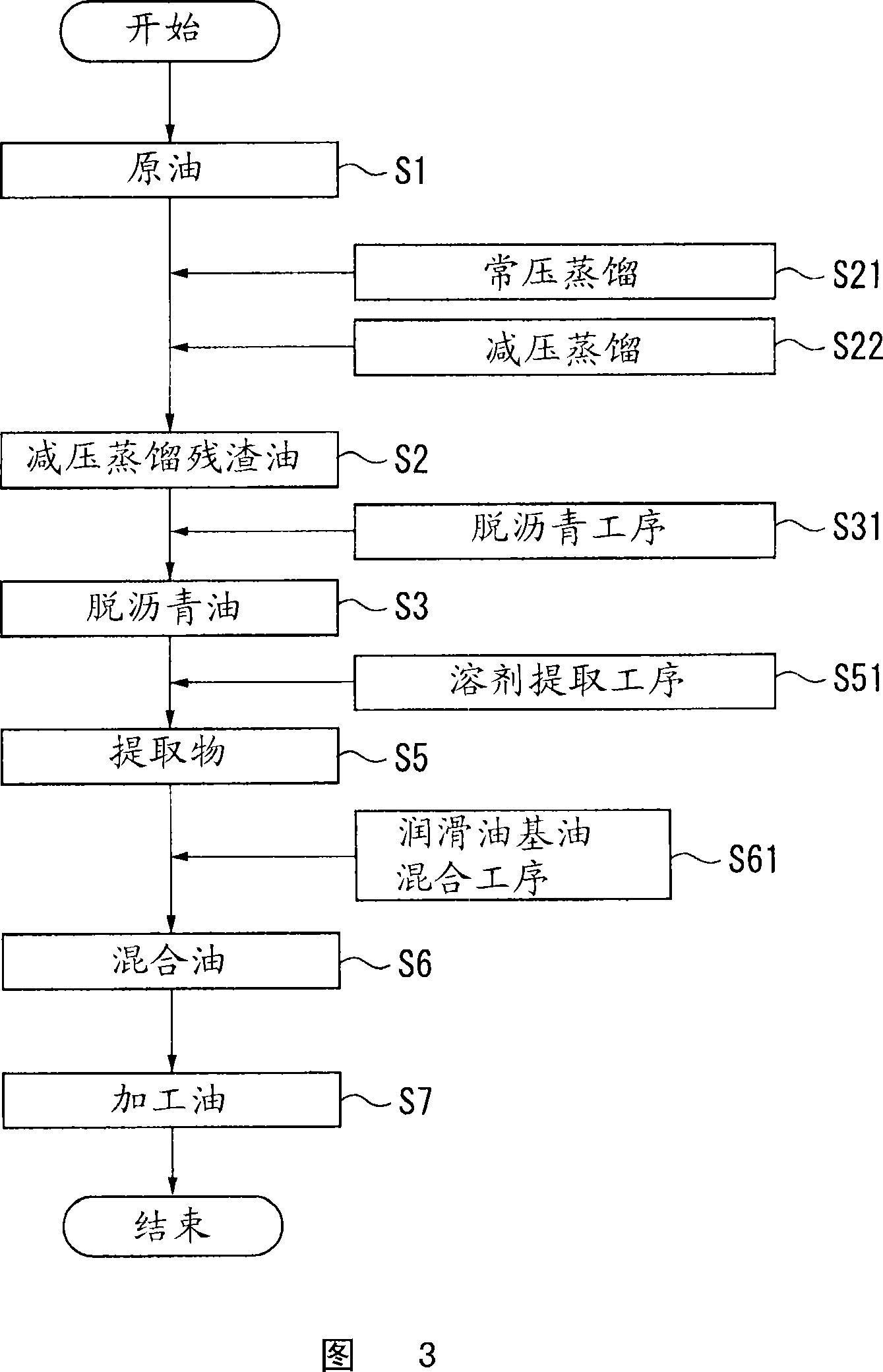

Process oil, process for production of deasphalted oil, process for production of extract, and process for production of process oil

InactiveUS20090020453A1Improve securityProvide accuratelyWorking-up pitch/asphalt/bitumen by selective extractionLiquid carbonaceous fuelsAniline pointResidual oil

The present invention is related to a process oil using as a raw material a deasphalted oil obtained by deasphalting a vacuum residual oil of a crude oil and a manufacturing method of the process oil, the process oil having properties of:(a) a polycyclic aromatics (PCA) content of less than 3 mass %;(b) a viscosity (100° C.) of 40 to 70 mm2 / s;(c) an aniline point of 85 to 100° C.;(d) a flash point of 250° C. or higher;(e) an aromatic hydrocarbon content of 40 to 55 mass %; and(f) a polar substance content of 10 to 15 mass %.The present invention is also related to a process oil and a manufacturing method of the process oil, the process oil obtained by mixing: an extract obtained by deasphalting and solvent-extracting a vacuum residual oil of a crude oil; and a lubricant base oil having a polycyclic aromatics (PCA) content of less than 3 mass %, and having properties of:(a) a polycyclic aromatics (PCA) content of less than 3 mass %;(i) a viscosity (100° C.) of 30 to 80 mm2 / s;(j) an aniline point of 90° C. or lower;(k) a flash point of 240° C. or higher;(l) a benzo(a)pyrene content of 1 mass ppm or less;(m) a specified aromatic compound content of 10 mass ppm or less; and(n) a polar substance content of 10 to 30 mass %.

Owner:IDEMITSU KOSAN CO LTD

Process for making shock absorber fluid

A process to make a shock absorber fluid having improved performance properties, the properties including an air release after 1 minute by DIN 51381 of less than 0.8 vol %, a kinematic viscosity at 100° C. less than 5 mm2 / s and an aniline point greater than or equal to 95° C., or meeting the specifications for Kayaba 0304-050-0002 or VW TL 731 class A. The shock absorber fluid is made by blending a base oil having less than 10 wt % naphthenic carbon and a high viscosity index with low levels of (or no) viscosity index improver and pour point depressant.

Owner:CHEVROU USA INC

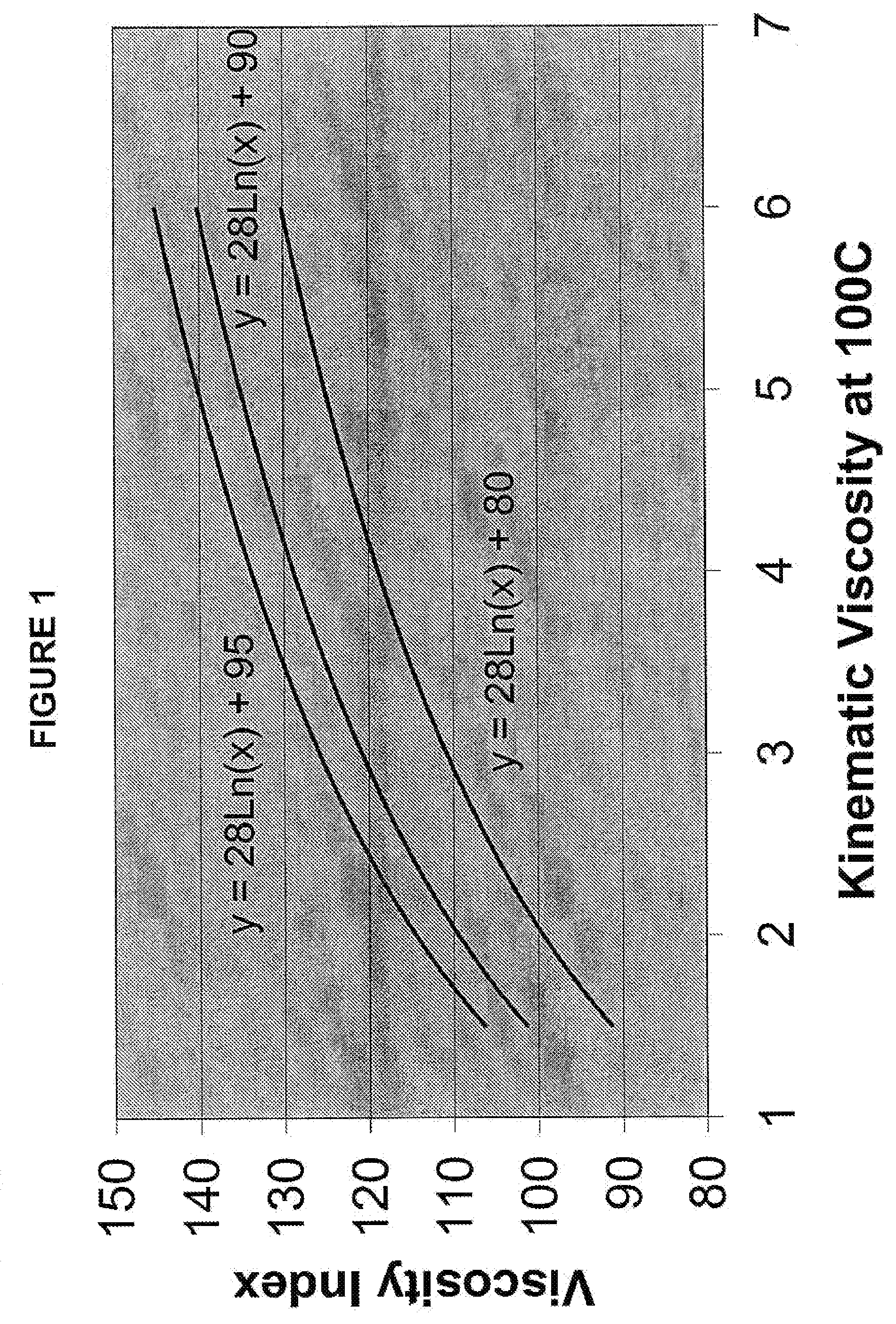

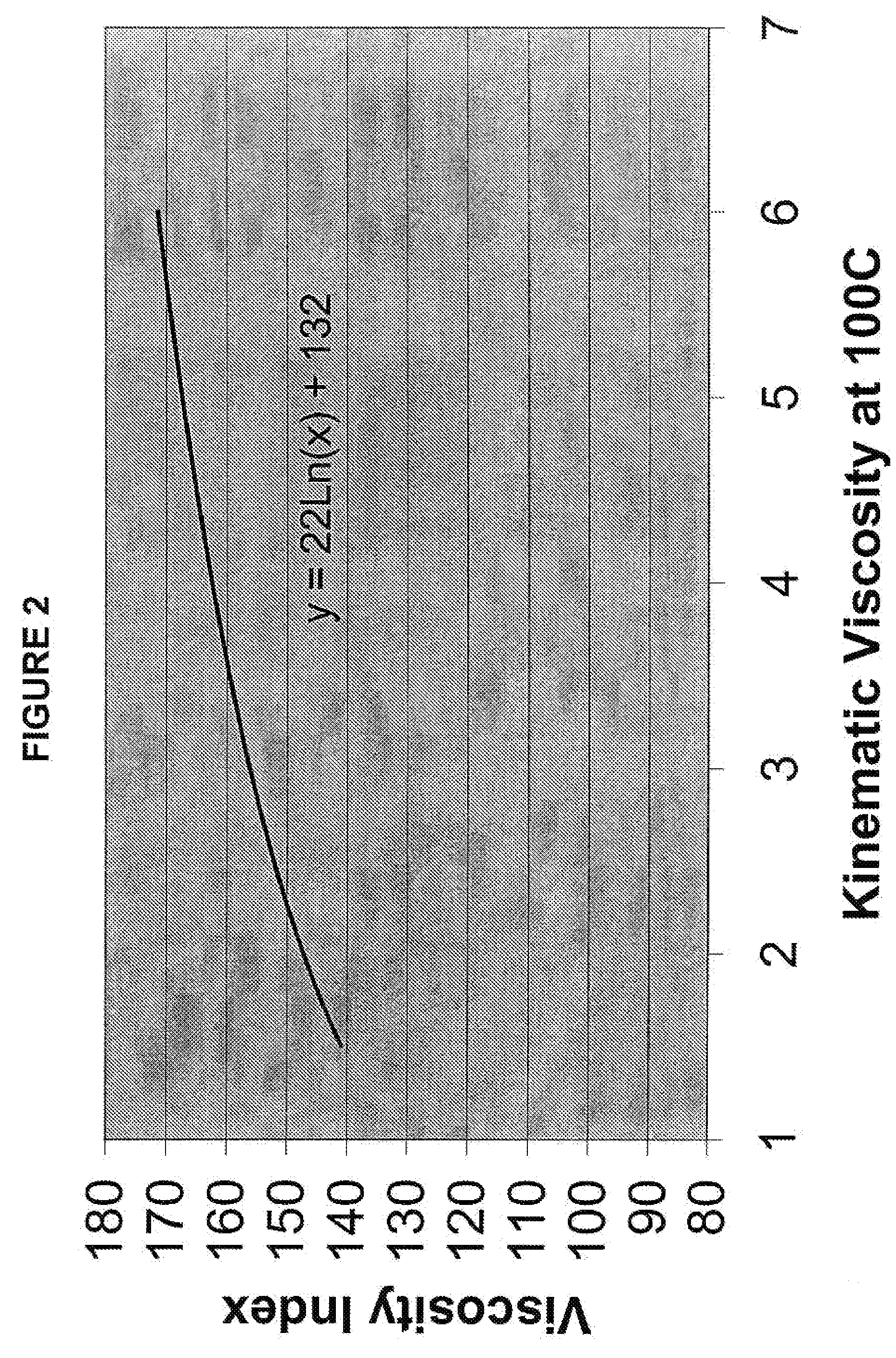

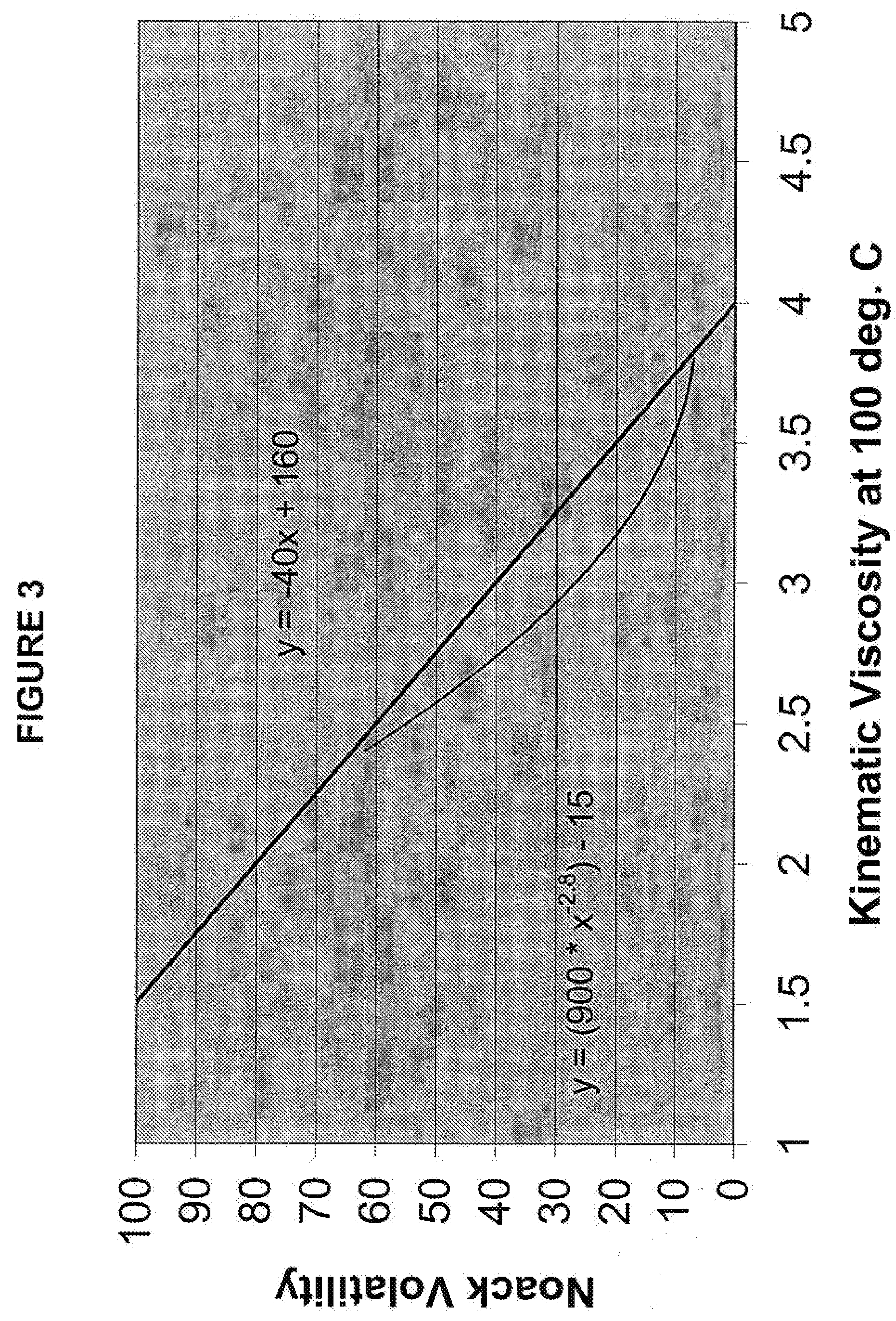

Lube base oil and lubricating oil composition

InactiveUS20060166844A1Reduction of evaporation lossLow viscosityLiquid carbonaceous fuelsBase-materialsAniline pointAntioxidant

The invention provides a lube base oil other than silicone oil having a kinematic viscosity of 12 mm2 / s or below at 40° C., exhibiting, in Noack test (250° C., 1 hr), an evaporation loss of 30 mass % or below and / or a flash point of 200° C. or higher, and exhibiting an aniline point of 60° C. or higher. There is also provides a lubricating oil composition comprising the lube base oil mixed with at least one additive selected from the group consisting of an antioxidant, a viscosity index improver, a detergent dispersant, a friction reducing agent, a metal inactivator, a pour point depressant, an abrasion resisting agent, a defoamer, and an extreme-pressure additive. The lube base oil and the lubricating oil composition realize reduction of evaporation loss despite being of low viscosity and excellent compatibility with organic materials.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil composition for internal combustion engine

ActiveUS20100075875A1Excellent in high-temperature detergencyRetention of engine performanceLiquid carbonaceous fuelsAdditivesAniline pointChemical composition

A lubricating oil composition for an internal combustion engine. The lubricating oil composition includes: (A1) a lubricant base oil as a main component having a kinematic viscosity at 100 degree C. being 1 to 8 mm2 / s, pour point being −15 degree C. or less, aniline point being 100 degree C. or more, paraffinic content in saturates being 40 mass % or more, monocyclic naphthenic content being 25 mass % or less, bicyclic to hexacyclic naphthenic content being 35 mass % or less, iodine number being 2 or less, and ratio of tertiary carbon to the total carbon atoms composing the (A1) being 6.3% or more. The total mass of the composition is: (B) 0.005 to 0.5 mass % of a metallic detergent as metal content; (C1) 0.005 to 0.2 mass % of a boron-containing succinimide ashless dispersant as boron content; and (D) 0.005 to 0.2 mass % of a metal salt of phosphorus-containing acid as phosphorus content.

Owner:NIPPON OIL CORP

Lub. compsn. for freezer

The present invention provided a low-viscosity lubricating oil composition which is effective for power saving, deposits little sludge on a compressor's delivery valve even after a long-term use, can prevent a slide part from being worn in spite of its low viscosity, and can allow a stable refrigerating machine operation without lowering its efficiency over a long period of time. The lubricating oil composition for the refrigerating machine using a 3 or 4C hydrocarbon as a refrigerant has a kinematic viscosity of 8 to 150 mm2 / s (0[deg.]C), a sulfur content of not higher than 500 ppm, and an aniline point of not lower than 50[deg.]C. Desirably, the lubricating oil composition for the refrigerating machine comprises a mineral-oil-based lubricating oil having a kinematic viscosity at 0[deg.]C of 10 to 100 mm2 / s, a viscosity index of not lower than 80, a sulfur content of not higher than 500 ppm, an aniline point of not lower than 50[deg.]C, and an aromatic component content of not higher than 10 wt.% (as measured by column chromatography).

Owner:JAPAN ENERGY CORP

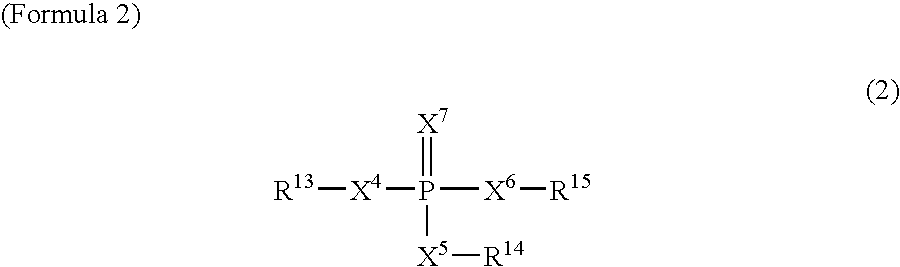

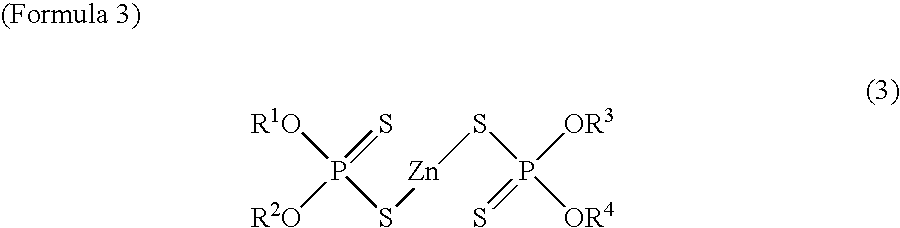

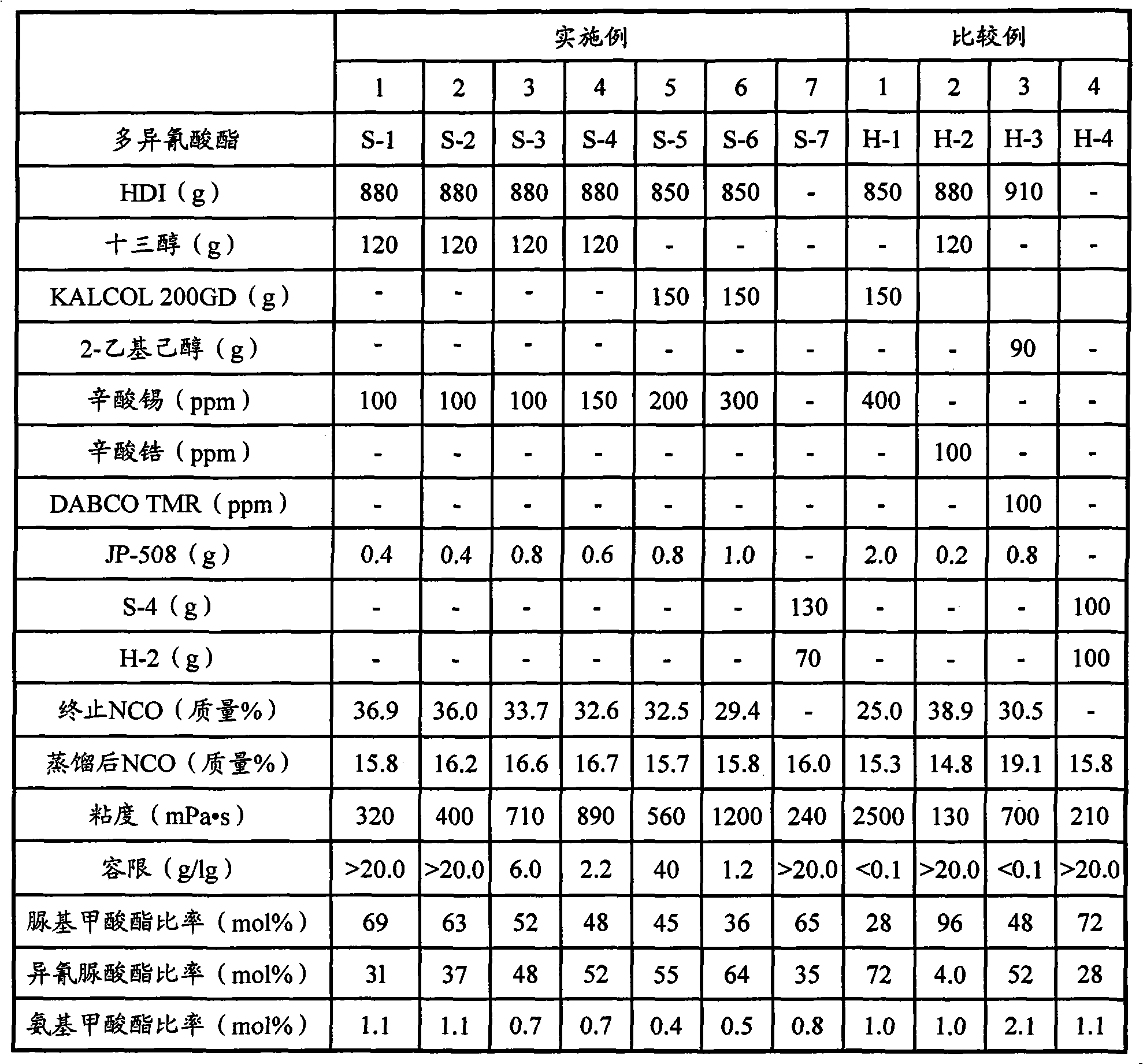

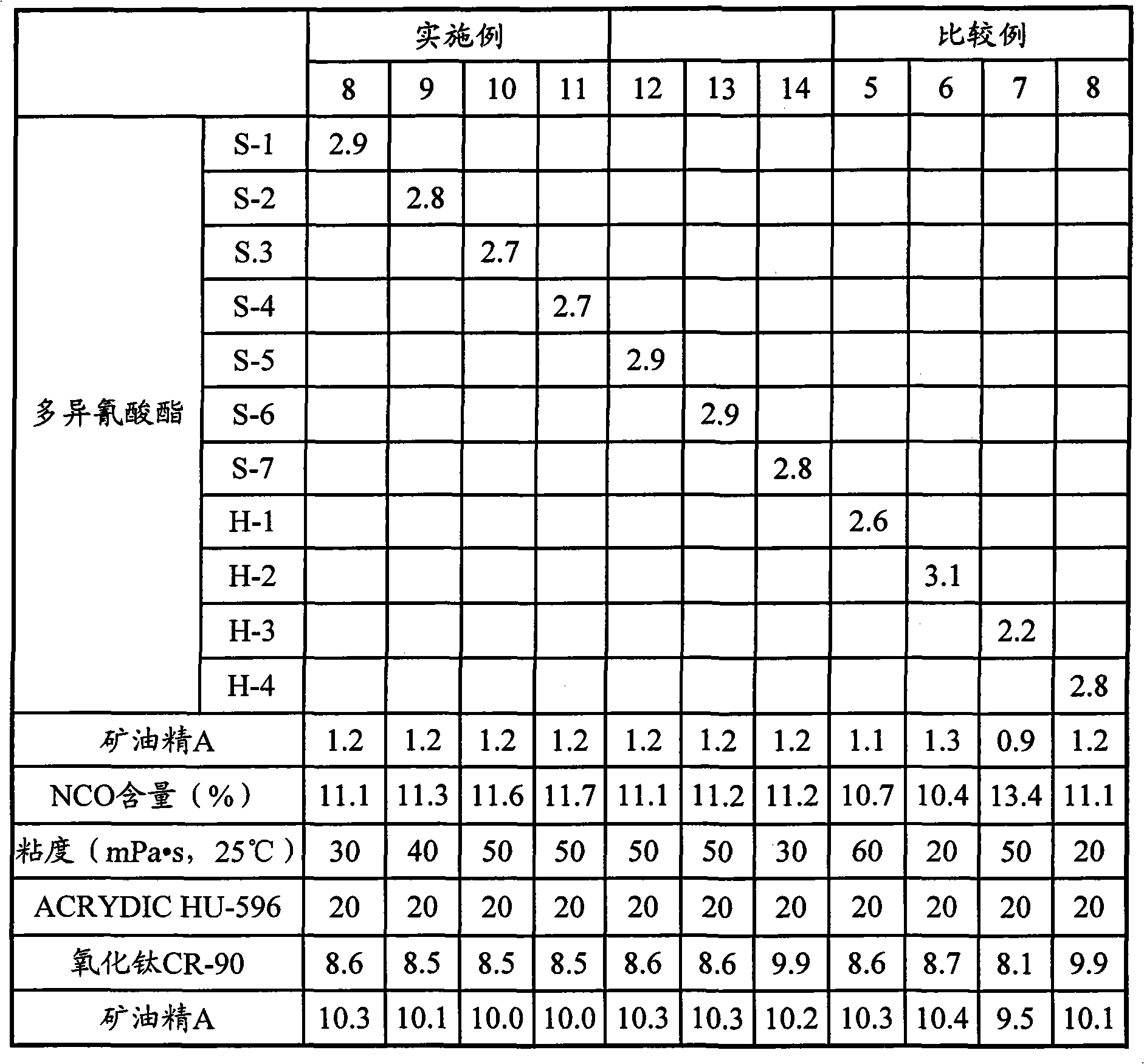

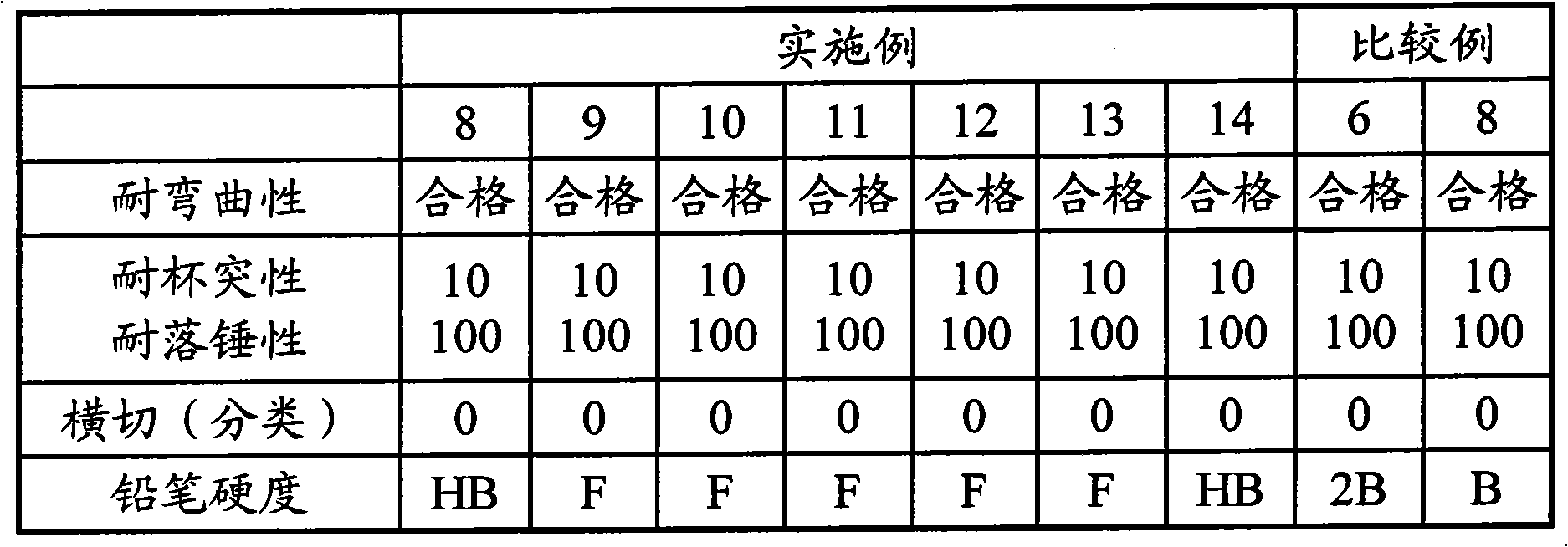

Polyisocyanate composition and two-package type coating composition using the same

ActiveCN102015815AImprove solubilityGood compatibilityOrganic chemistryPolyurea/polyurethane coatingsAllophaneAniline point

Disclosed is a polyisocyanate composition containing a polyisocyanate, which is obtained by reacting hexamethylene diisocyanate and an aliphatic monoalcohol having 11-20 carbon atoms, and a low-polarity organic solvent having an aniline point of 10-70 DEG C or a low-polarity organic solvent having a mixed aniline point of 5-50 DEG C. The polyisocyanate contains an allophanate group, an isocyanurate group and a urethane group in a molecule, and the molar ratio between the allophanate group and the isocyanurate group, namely allophanate group / isocyanurate group, is from 70 / 30 to 30 / 70. The composition is soluble in a low-polarity organic solvent, and has excellent compatibility with a polyol compound. Consequently, the composition can provide a coating film having excellent physical properties such as surface hardness.

Owner:NIPPON POLYURETHANE IND CO LTD

Functional fluid compositions

A functional fluid comprising a base oil with a high viscosity index, wherein the functional fluid has a kinematic viscosity at 100° C. between 2.5 and 5.0 mm2 / s, a low Brookfield viscosity, a high aniline point, and excellent air release. Shock absorber fluids with improved performance, comprising a particular base oil, wherein the improved performance includes high viscosity index, low Brookfield viscosity, high aniline point, excellent air release and high flash point.

Owner:CHEVROU USA INC

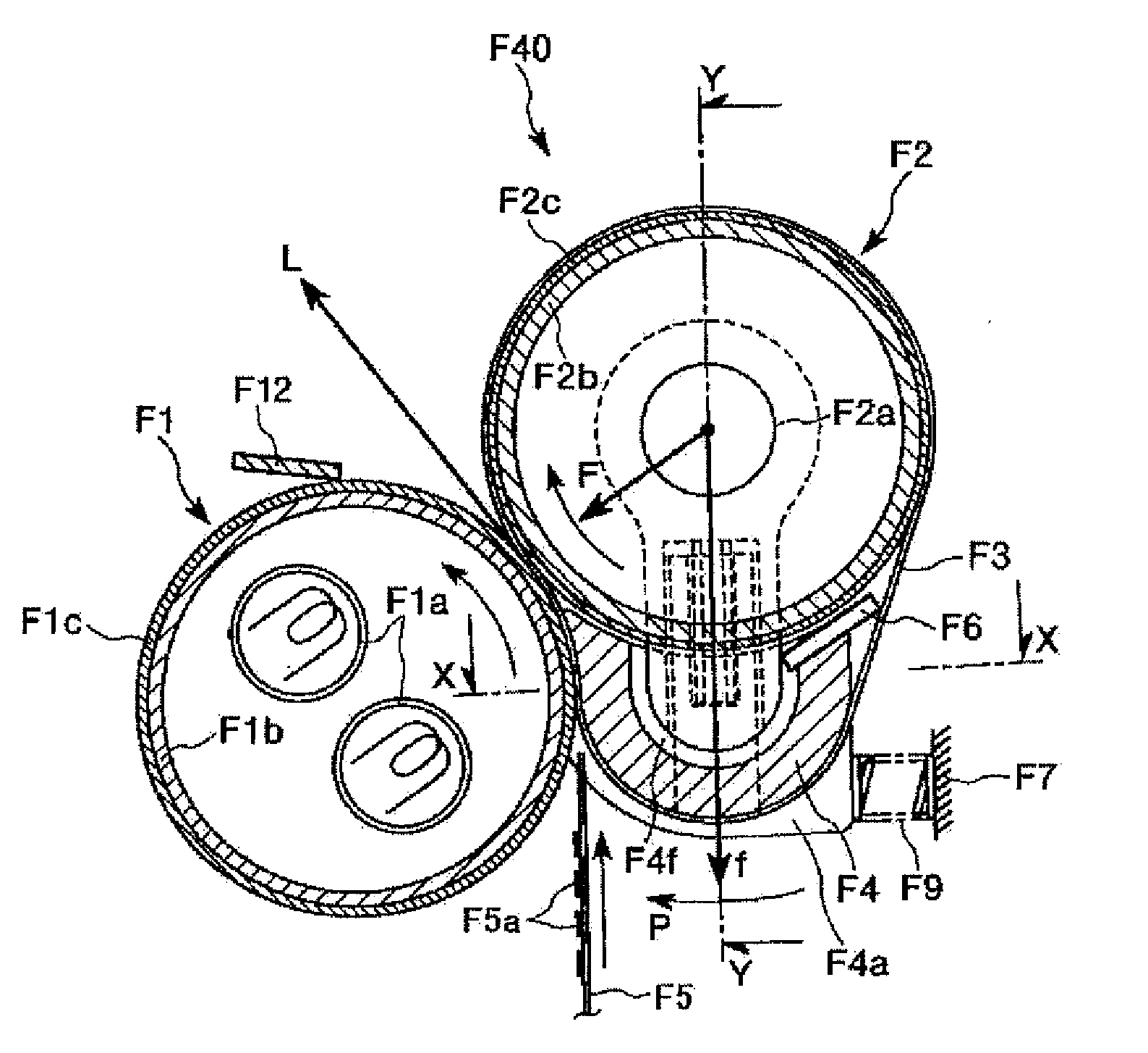

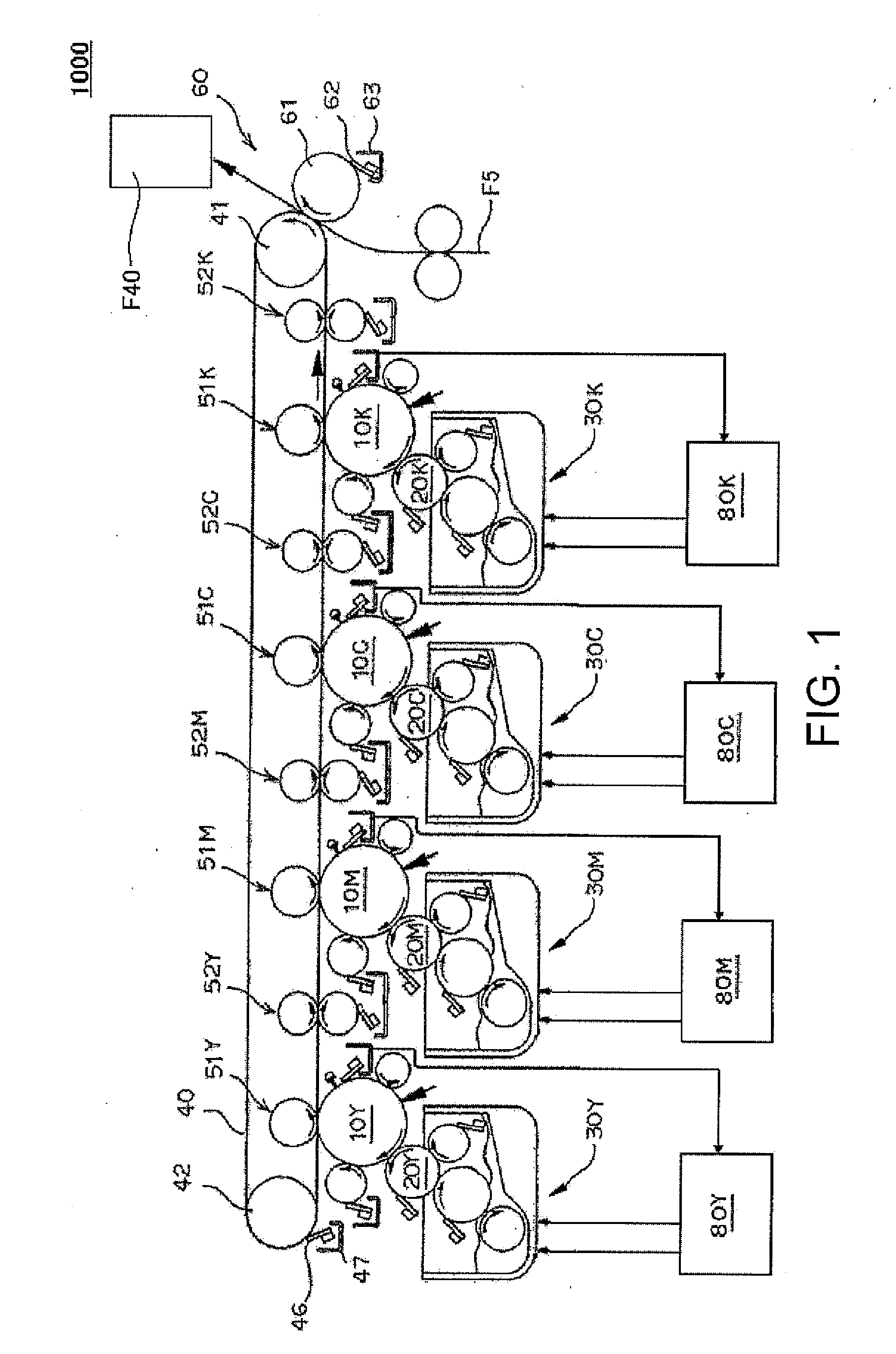

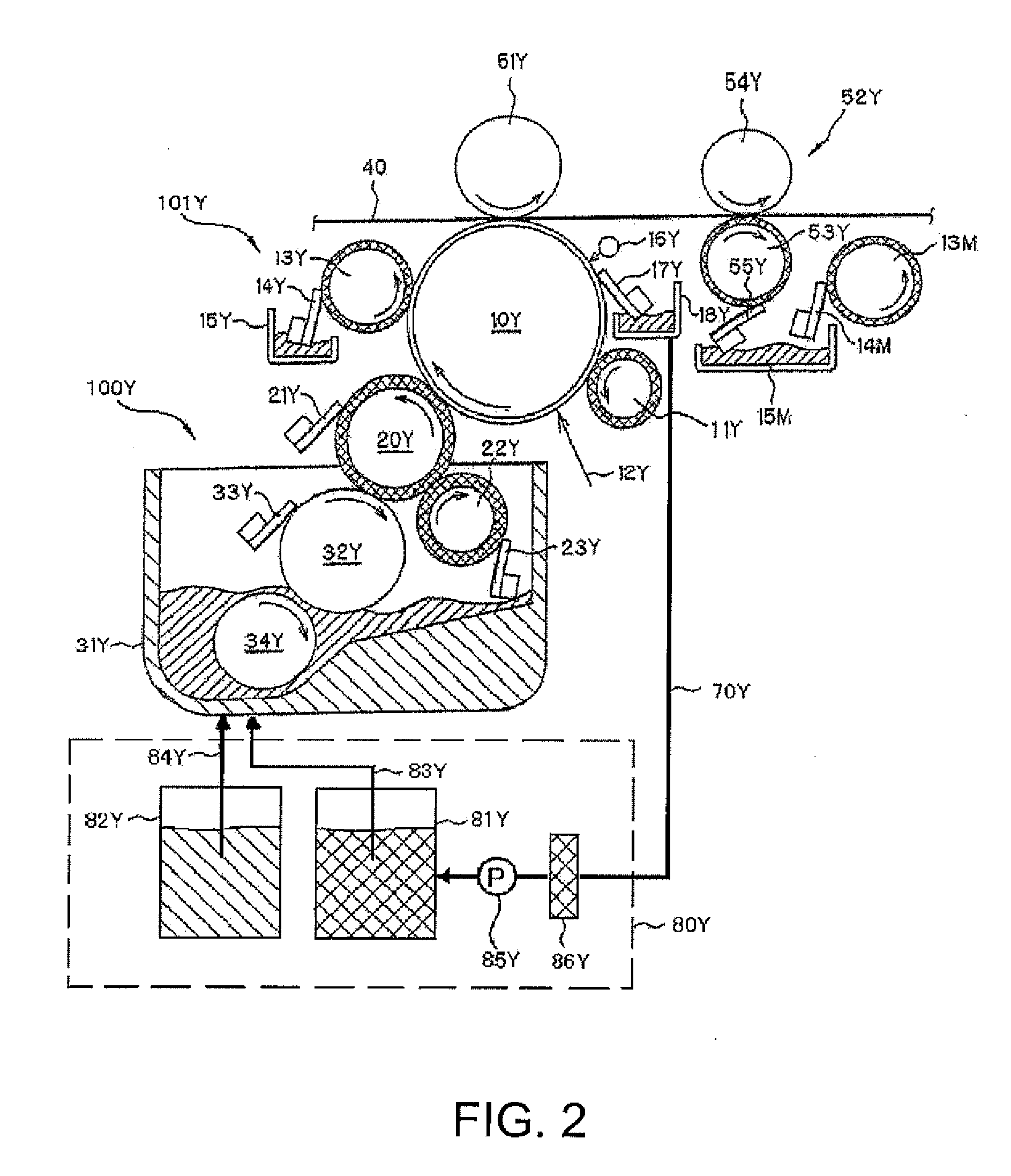

Liquid Developer and Image Forming Apparatus

InactiveUS20080299481A1Good storage stabilityLow temperature fixing propertyElectrographic process apparatusDevelopersAniline pointEngineering

A liquid developer includes: toner particles containing mainly a resin material, and a nonvolatile insulating liquid, the toner particles containing a liquid having a formulation that is different from the insulating liquid, and the liquid contained in the toner particles having an aniline point that is lower than that of the insulating liquid.

Owner:SEIKO EPSON CORP

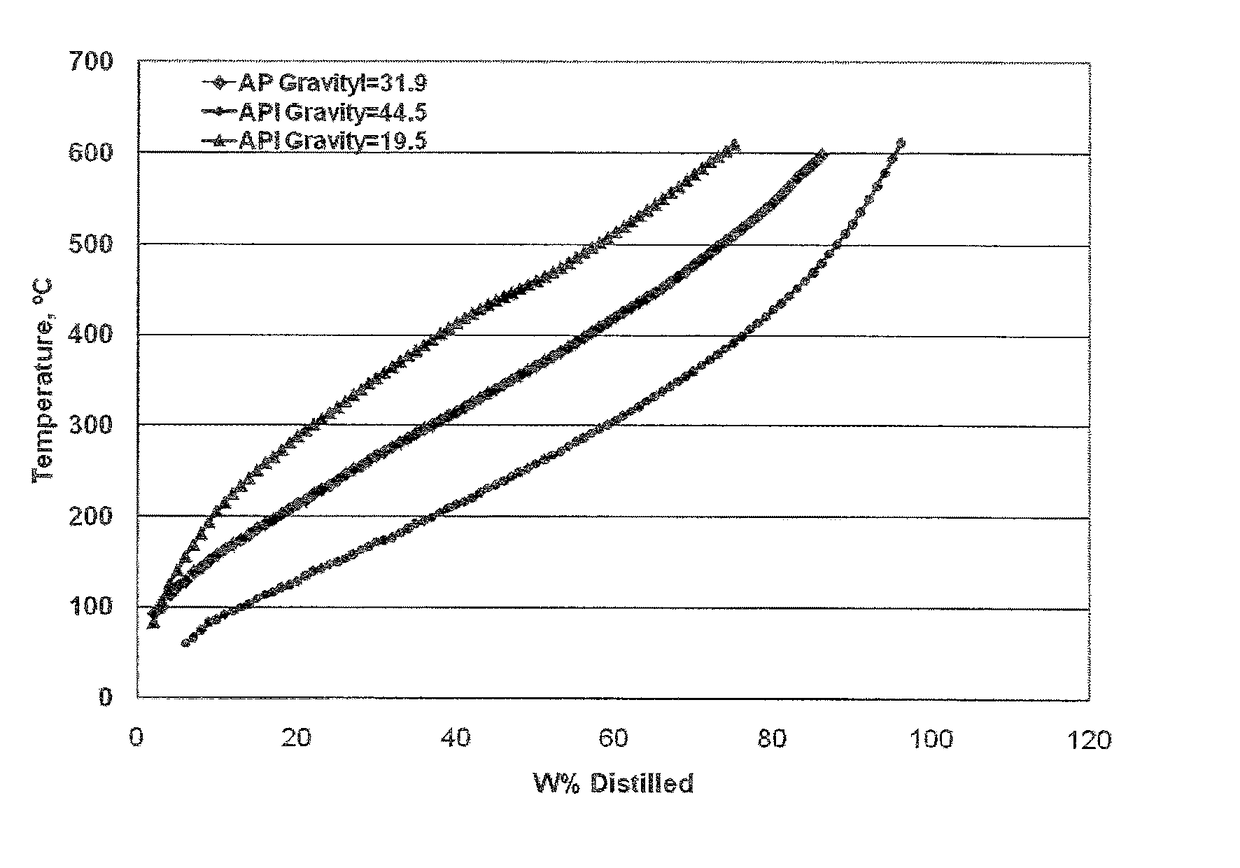

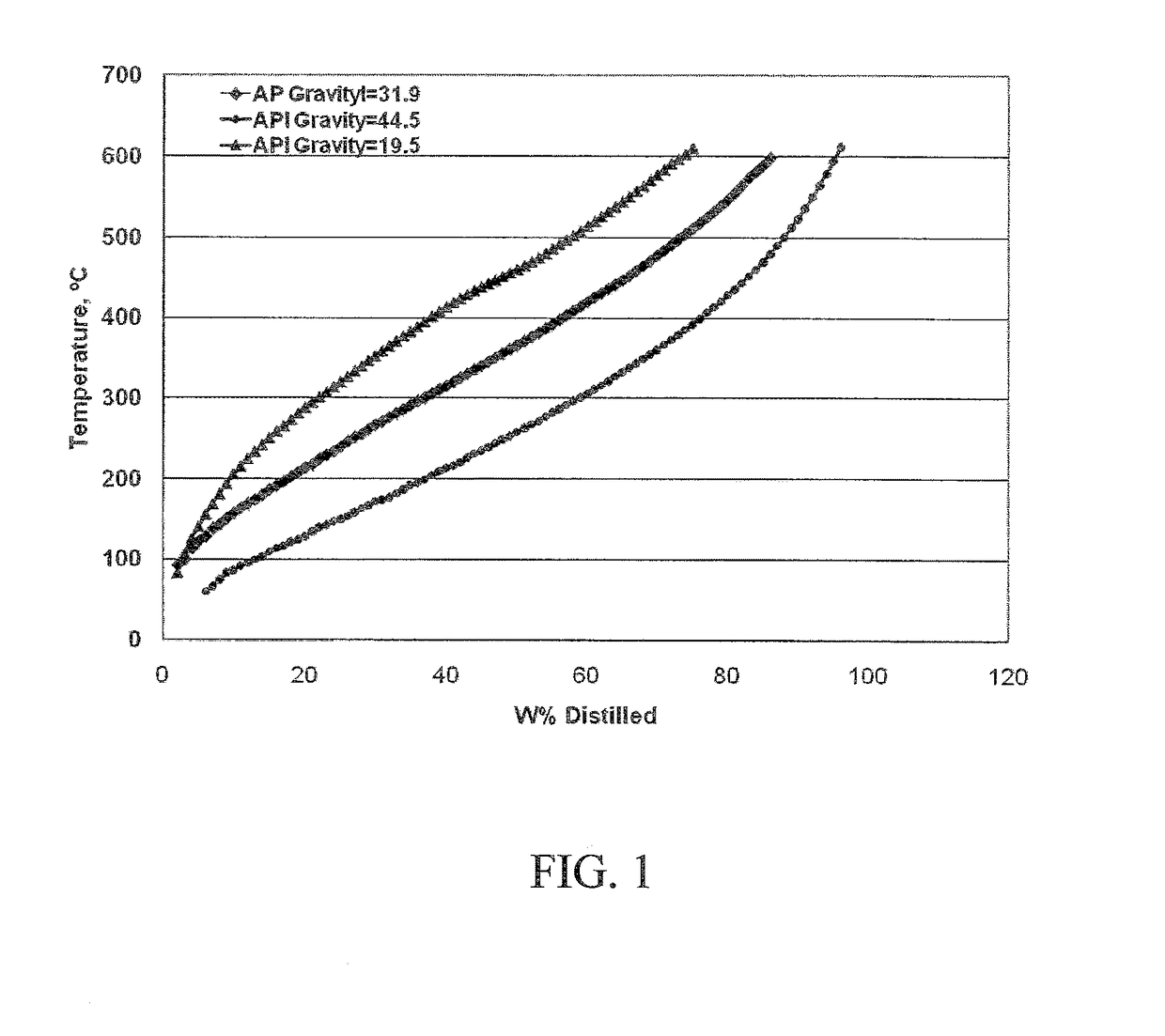

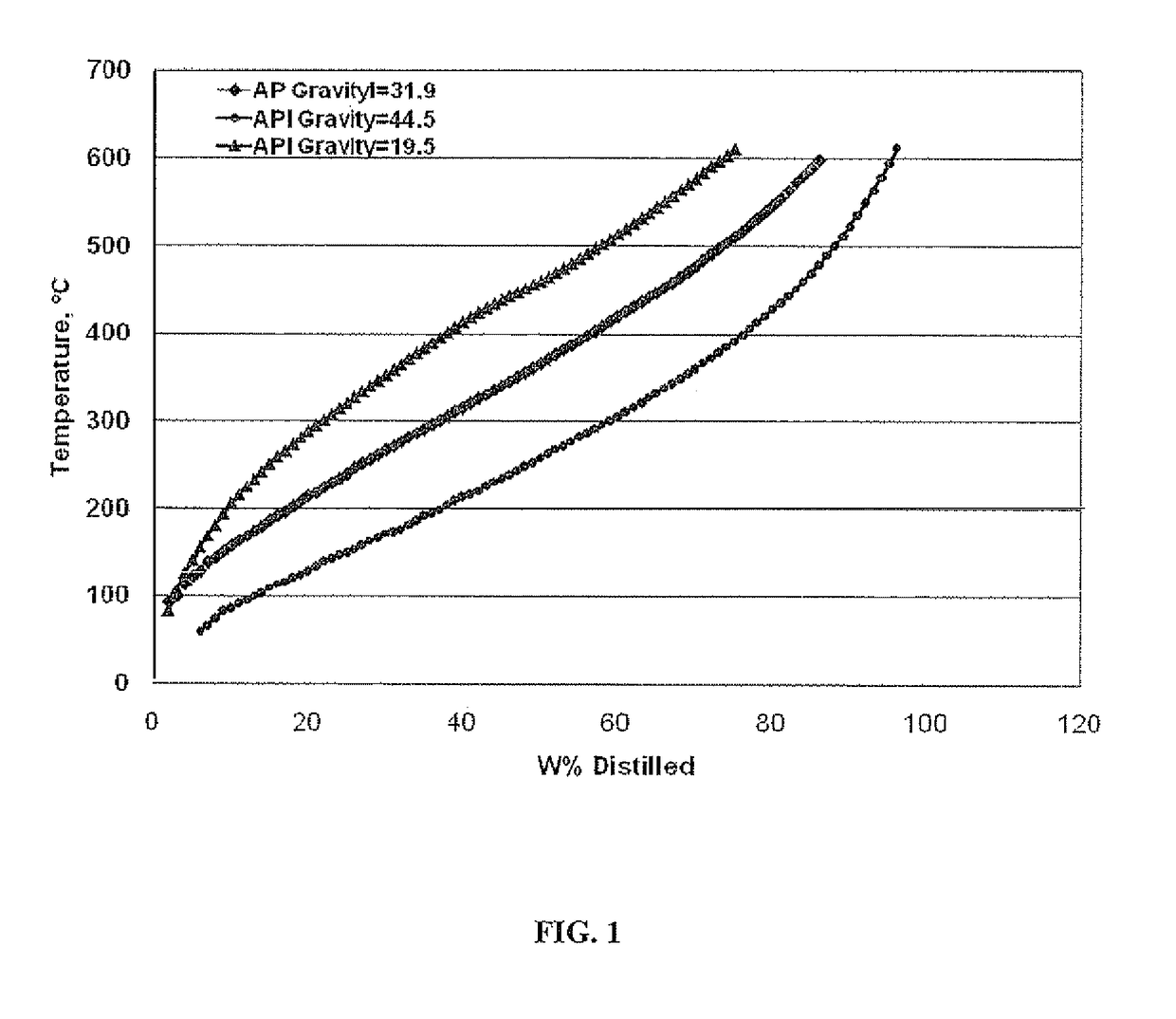

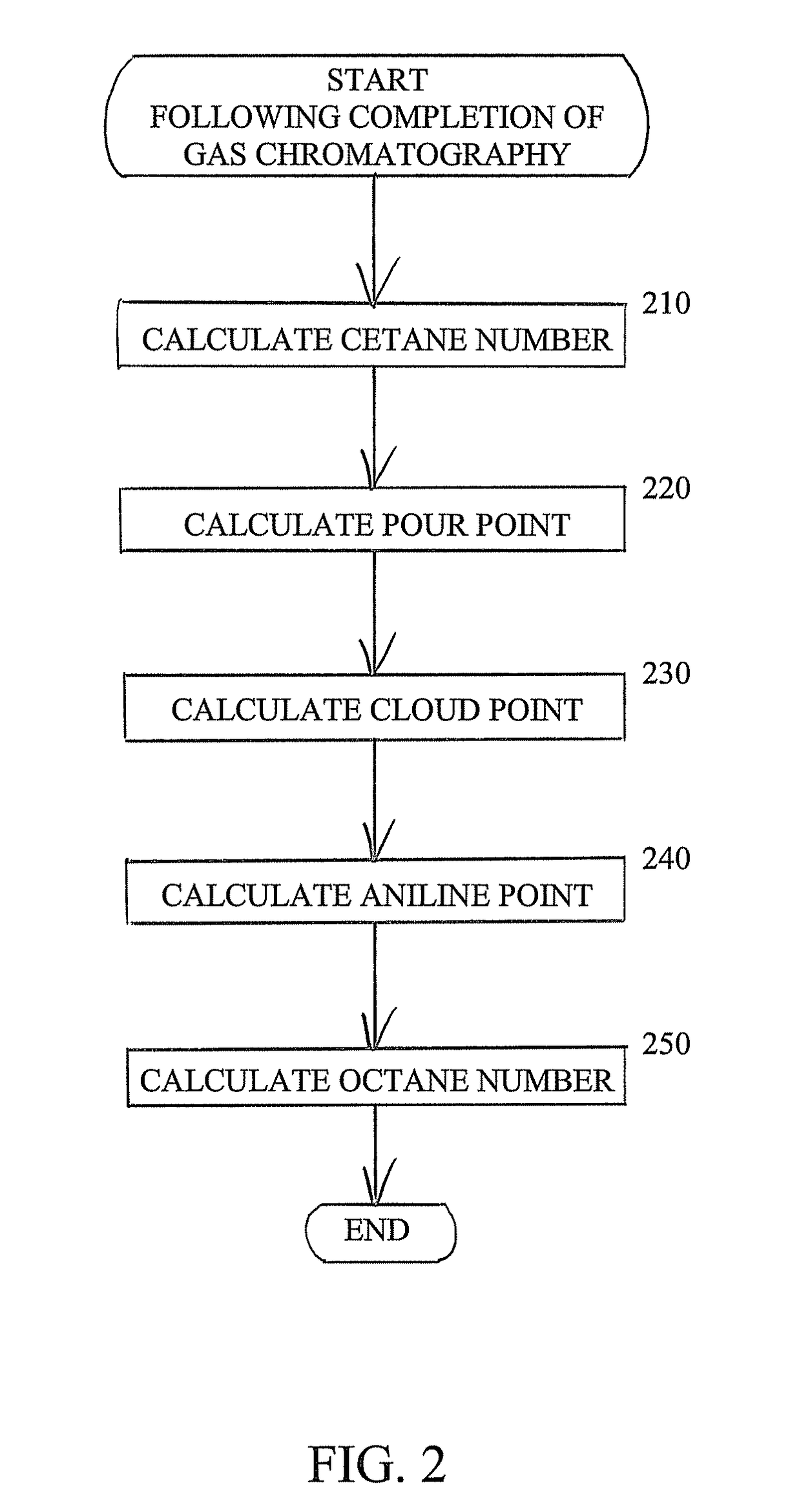

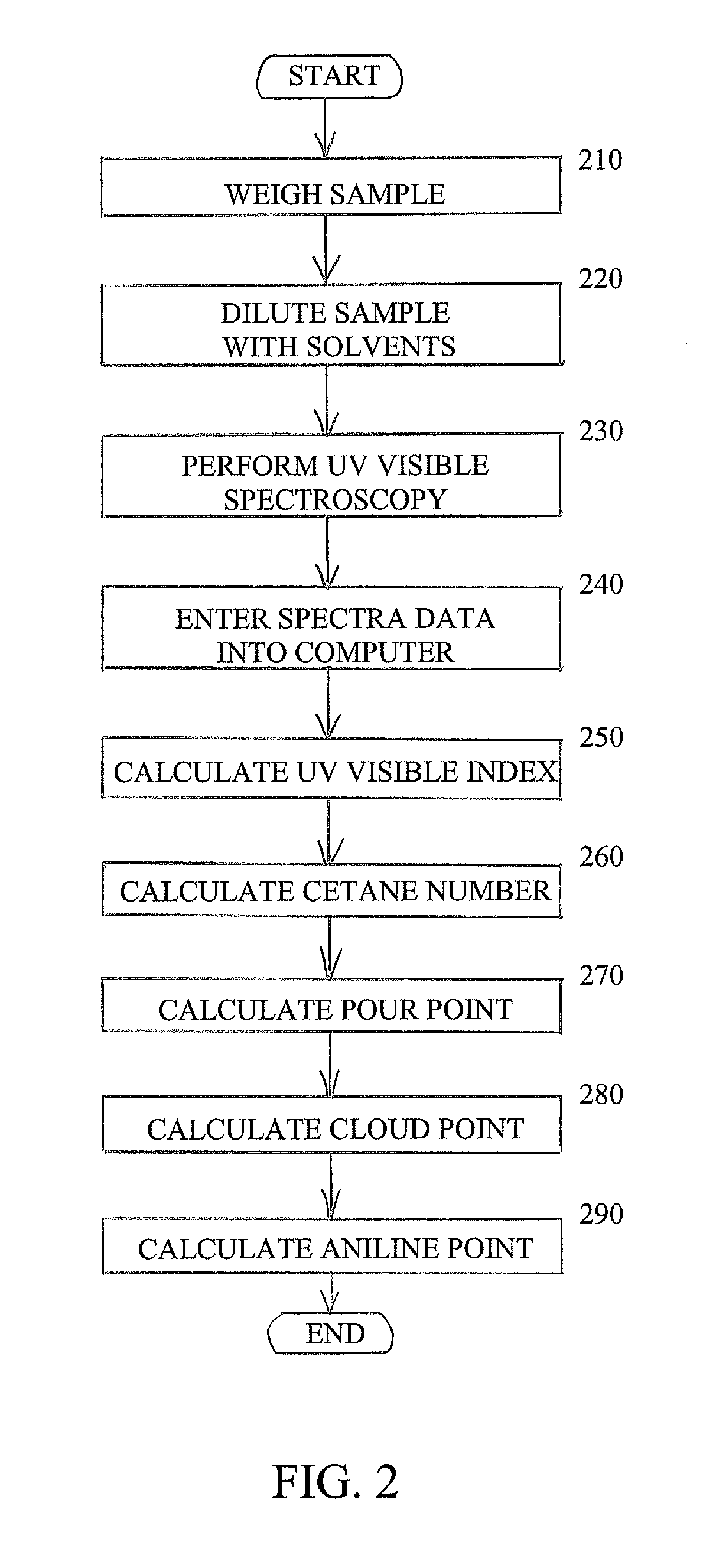

Characterization of crude oil by simulated distillation

ActiveUS20170363591A1Provide informationImprove oil qualityComponent separationColor/spectral properties measurementsAniline pointGas phase

A system and a method is provided for calculating and assigning one or more indicative properties (e.g., cetane number, pour point, cloud point and / or aniline point) of a fractions of a crude oil sample based upon gas chromatographic simulated distillation data.

Owner:SAUDI ARABIAN OIL CO

Characterization of crude oil by simulated distillation

ActiveUS9816919B2Provide informationImprove oil qualityComputation using non-denominational number representationColor/spectral properties measurementsAniline pointDistillation

Owner:SAUDI ARABIAN OIL CO

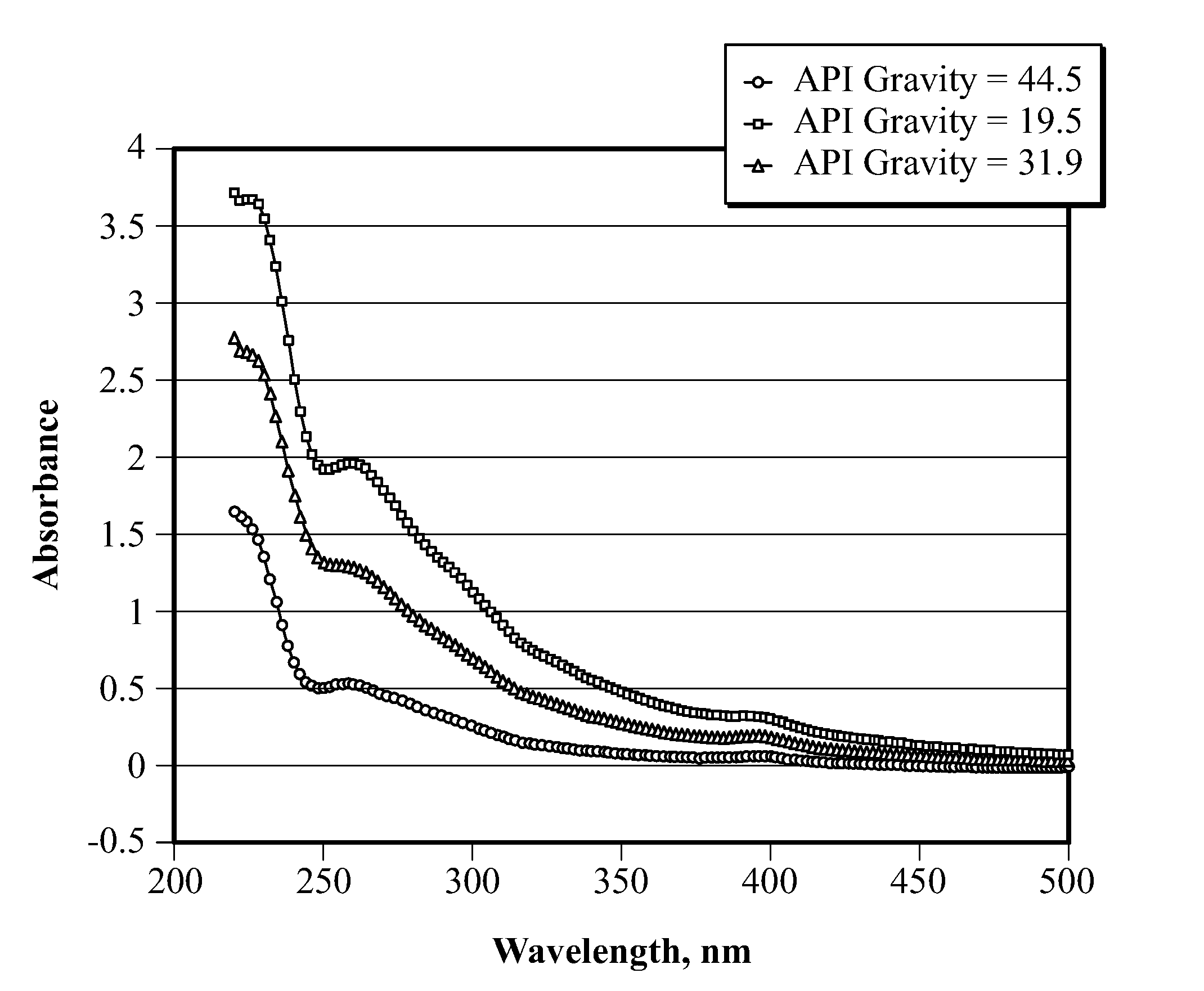

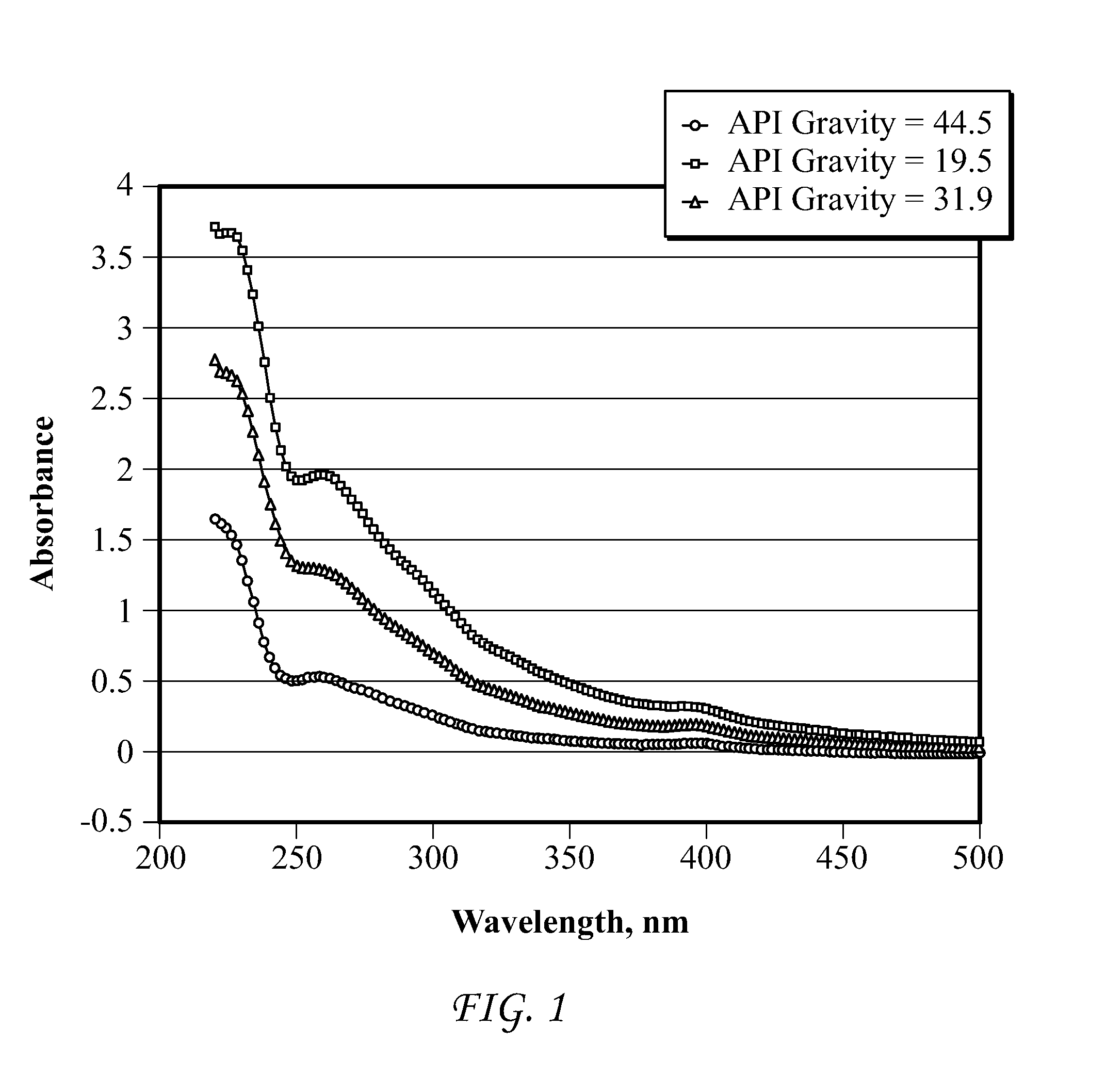

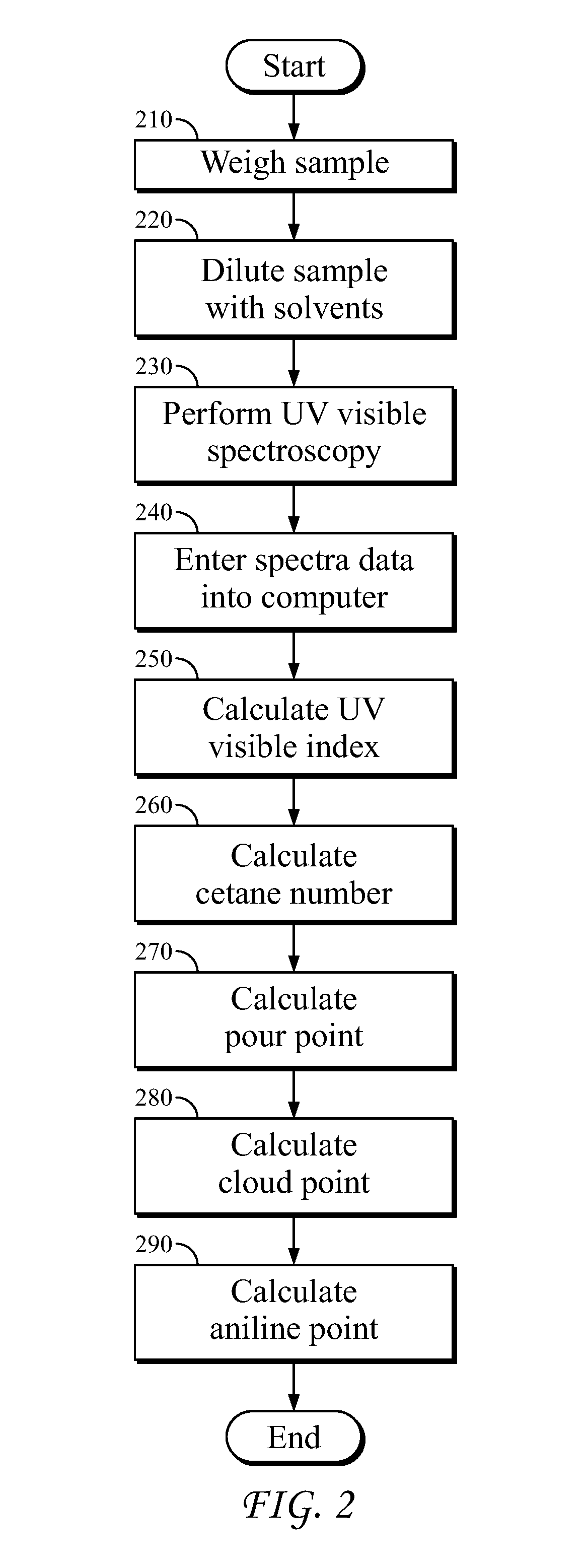

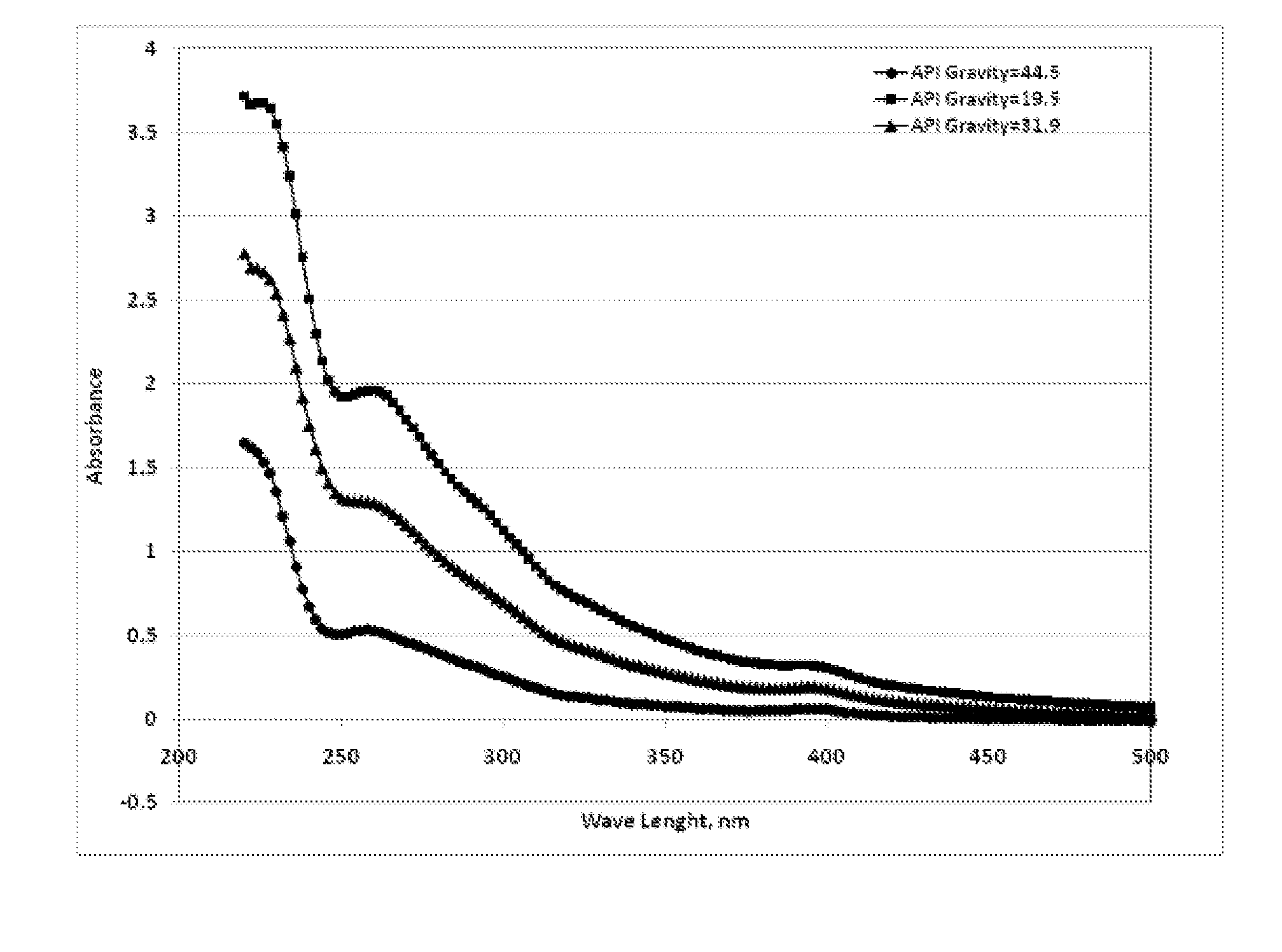

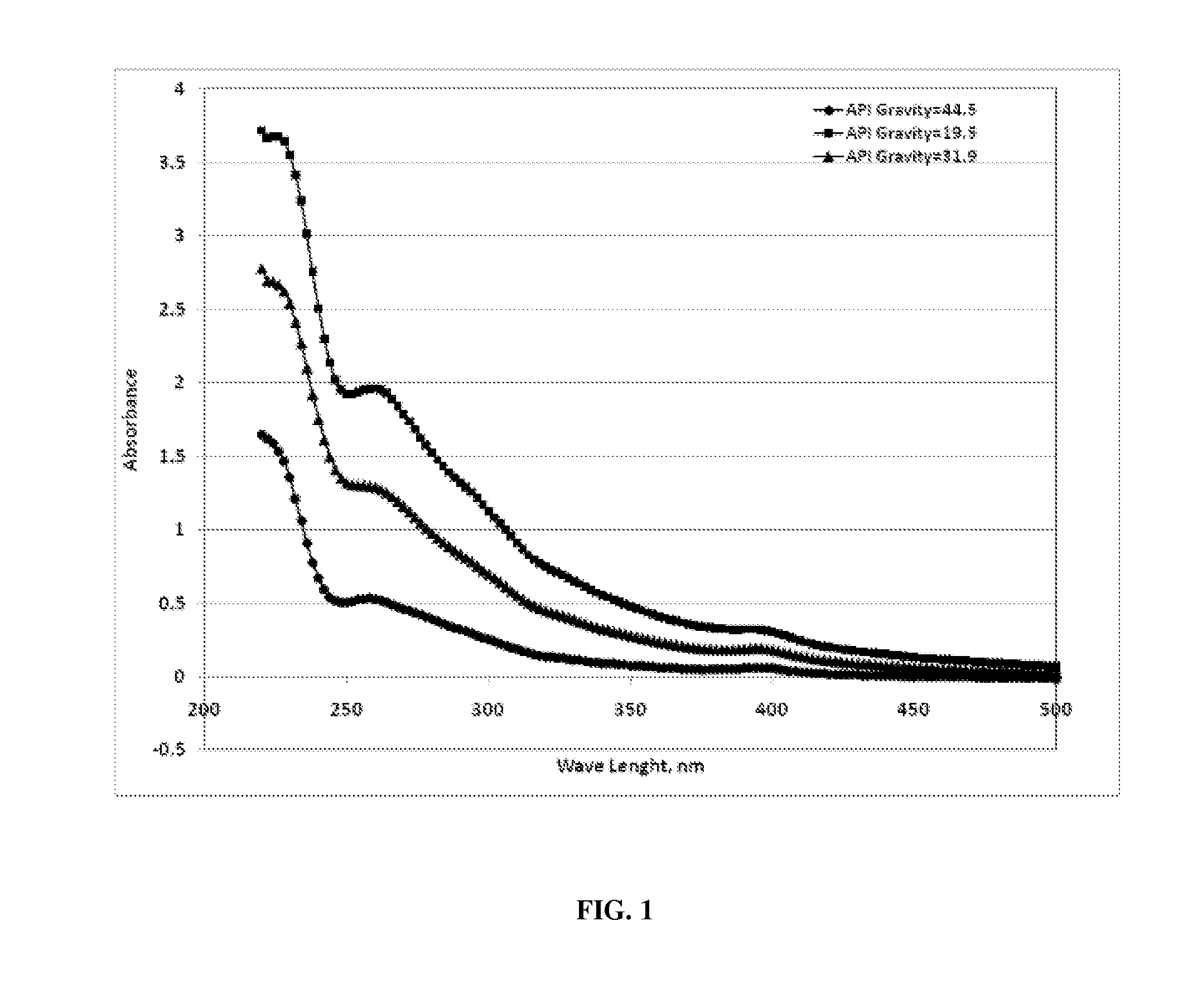

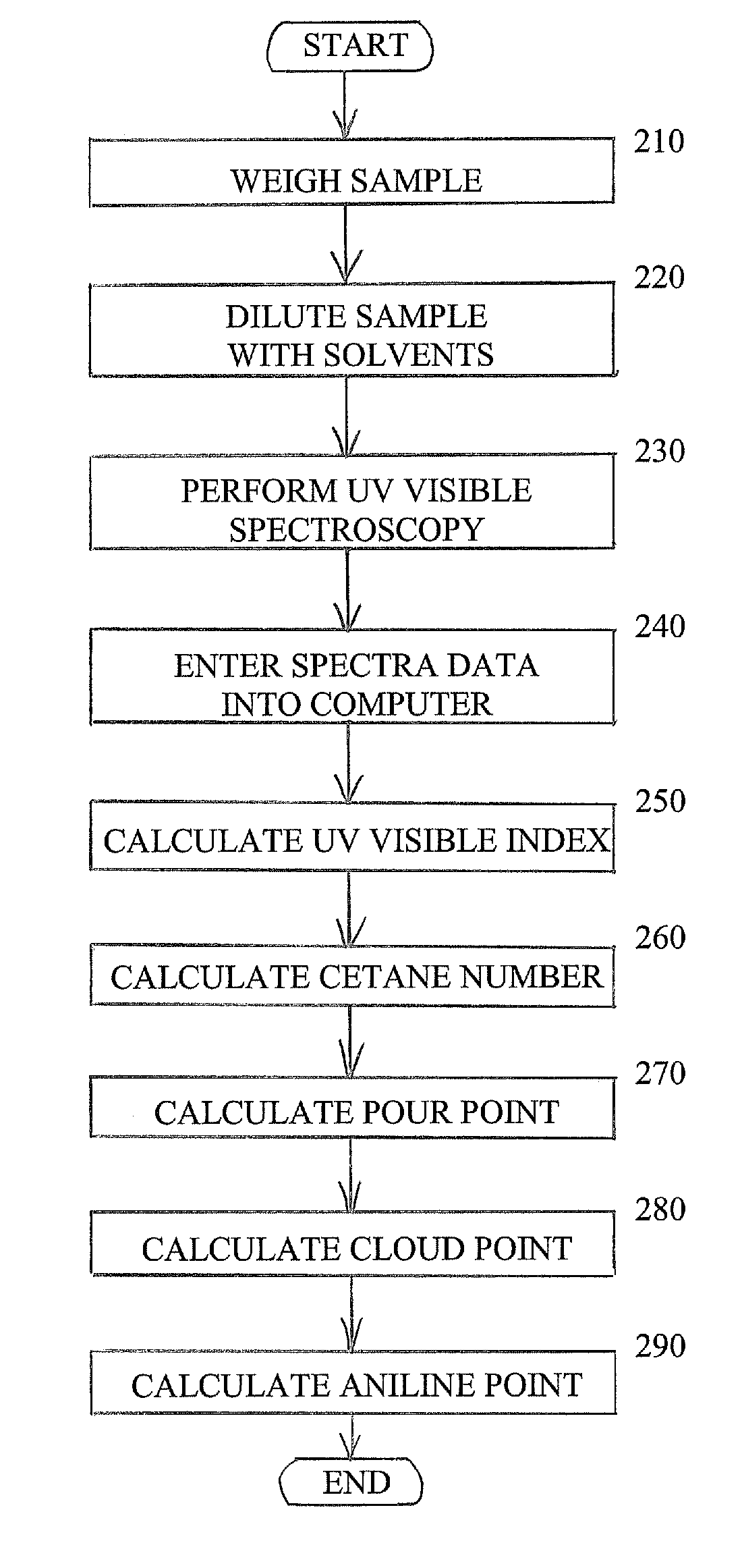

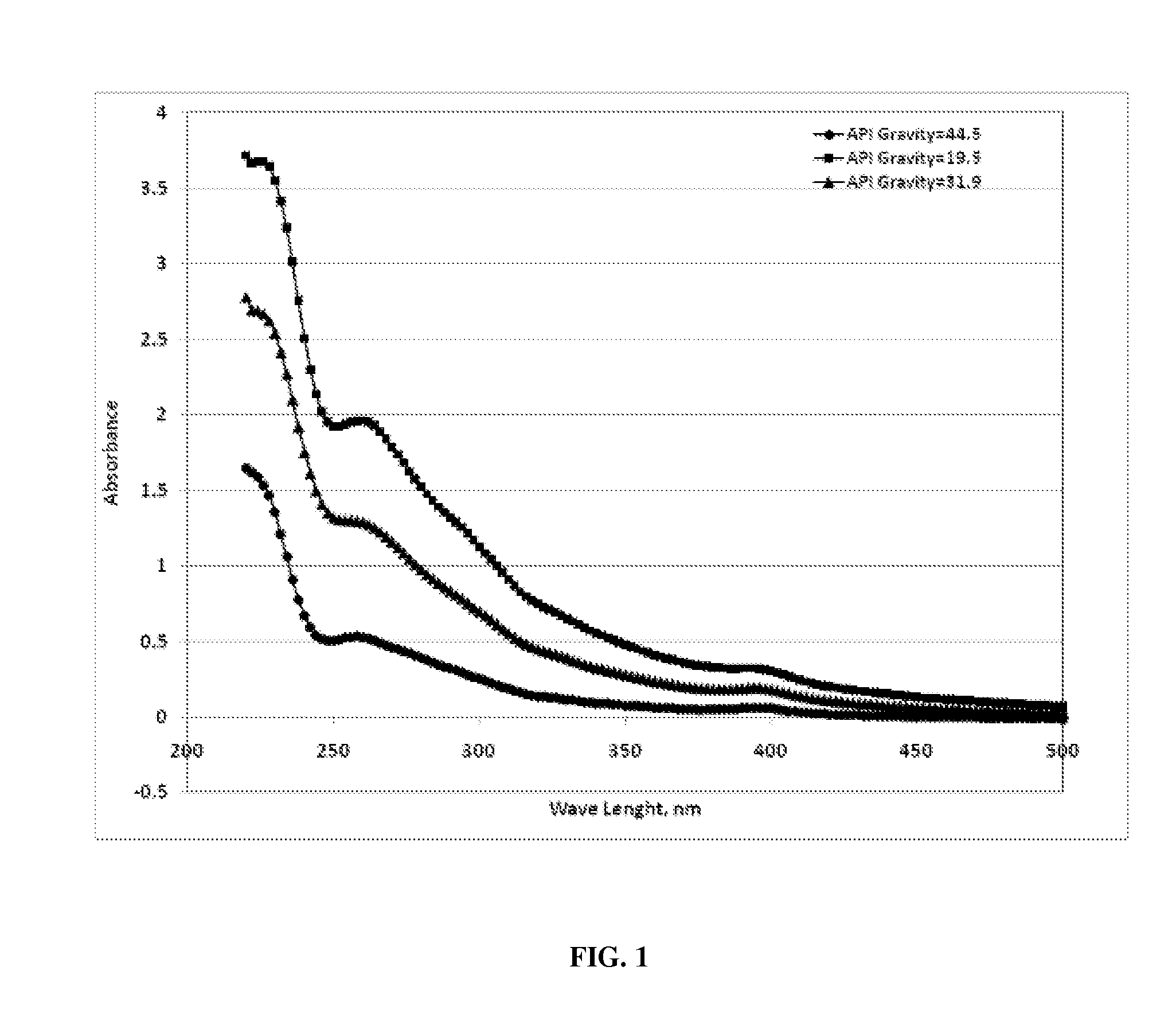

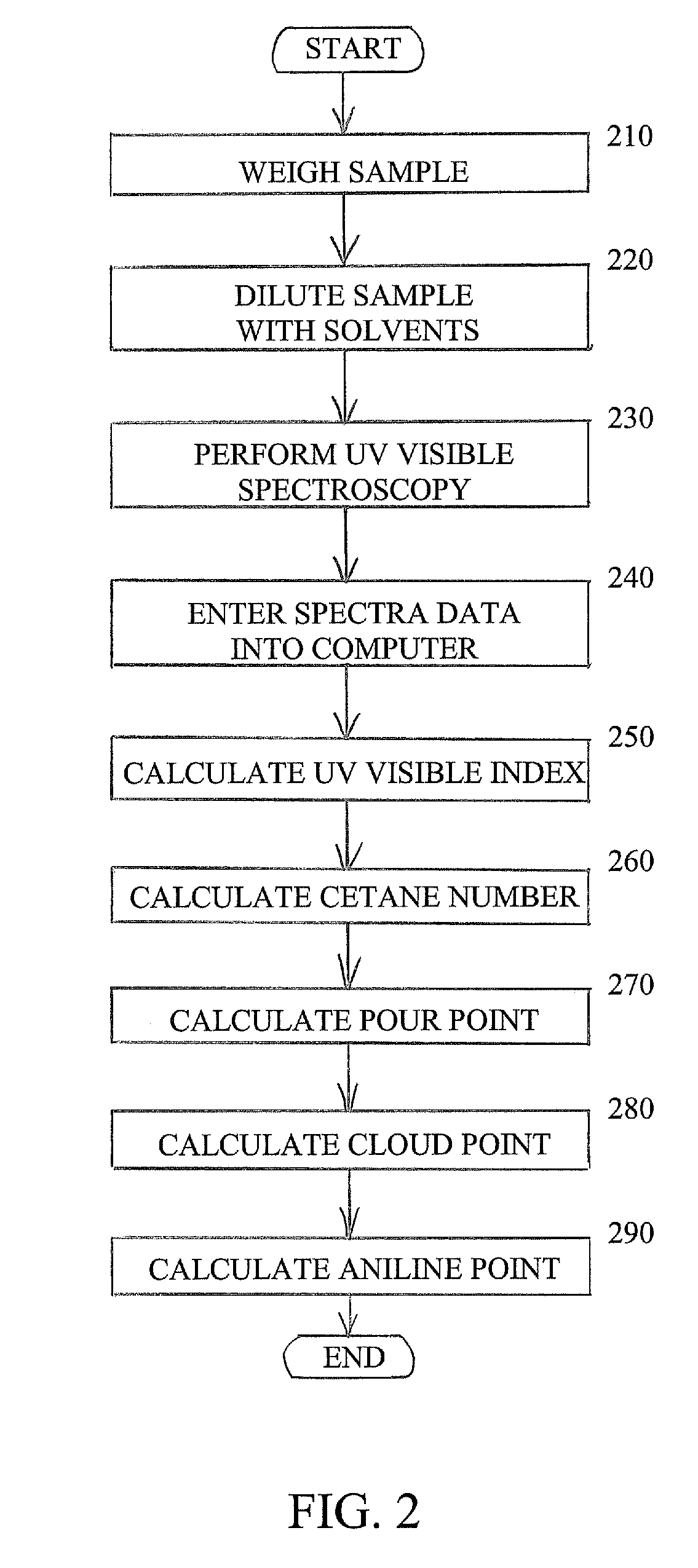

Characterization of crude oil by ultraviolet visible spectroscopy

ActiveUS20160187253A1Provide informationImprove oil qualityColor/spectral properties measurementsMaterial testing goodsAniline pointCloud point

A system and a method for calculating and assigning an indicative value, such as cetane number, pour point, cloud point and aniline point, of a fraction of an oil sample based on an index calculated and assigned from ultraviolet visible spectroscopy data of the oil sample.

Owner:SAUDI ARABIAN OIL CO

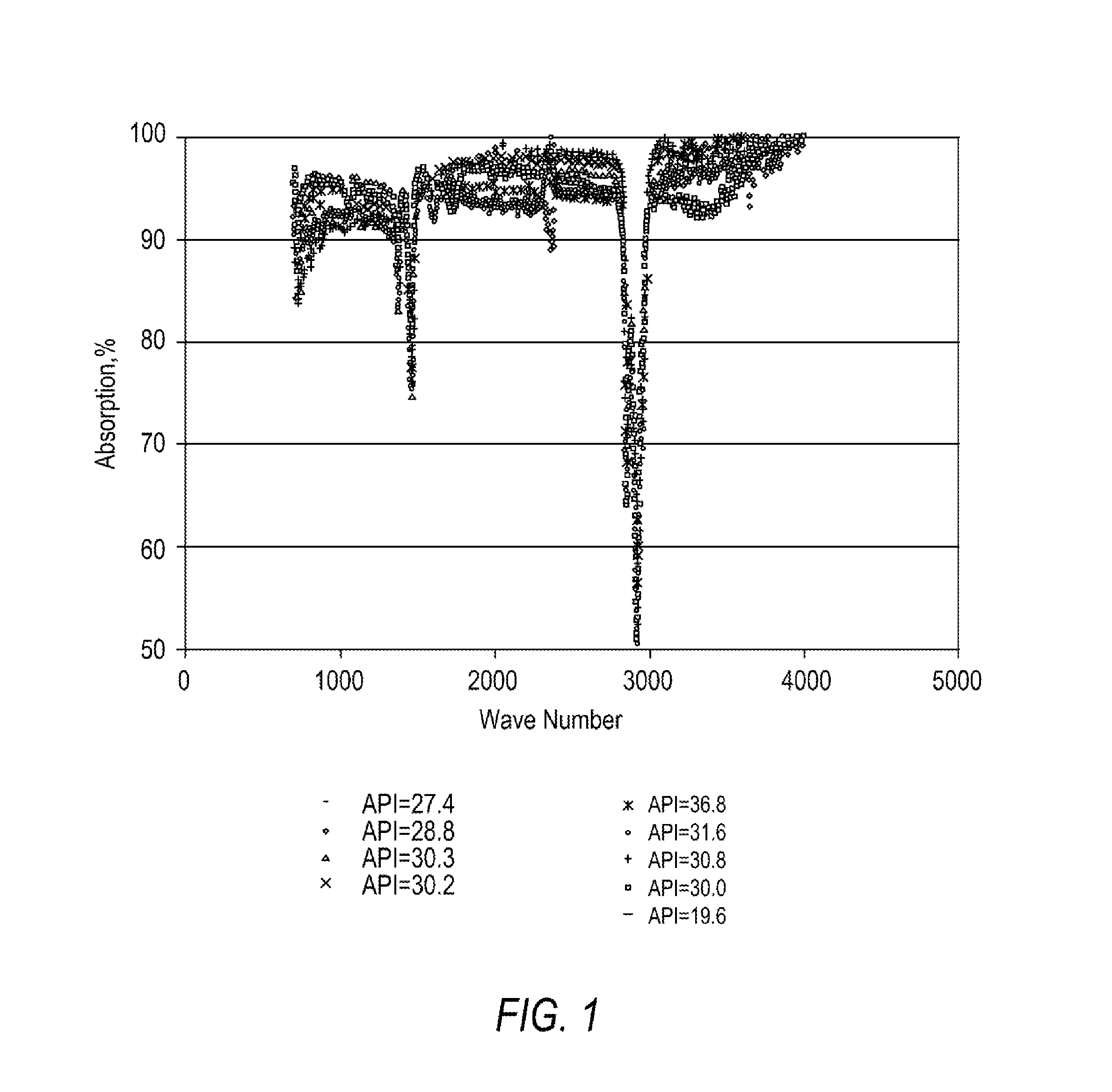

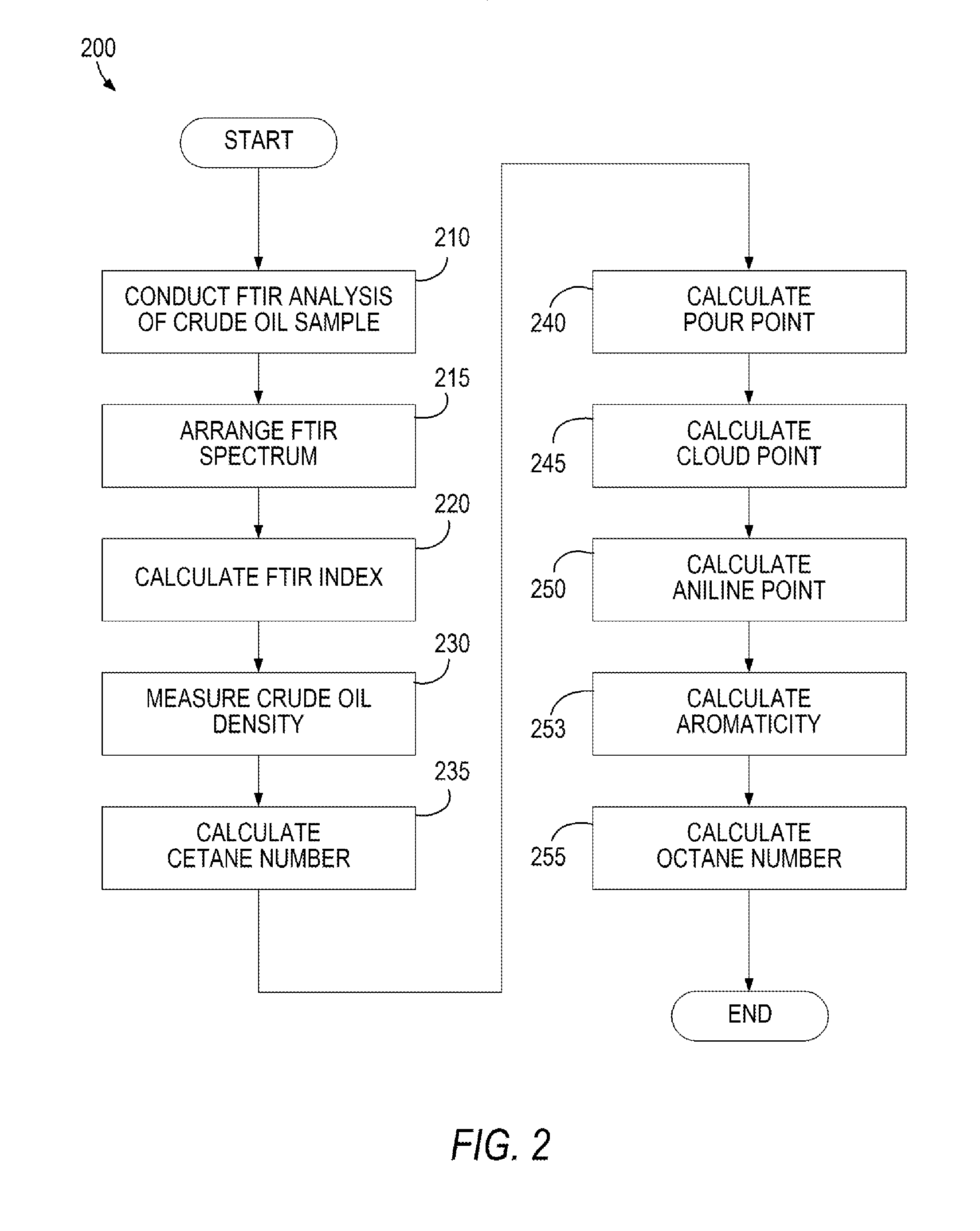

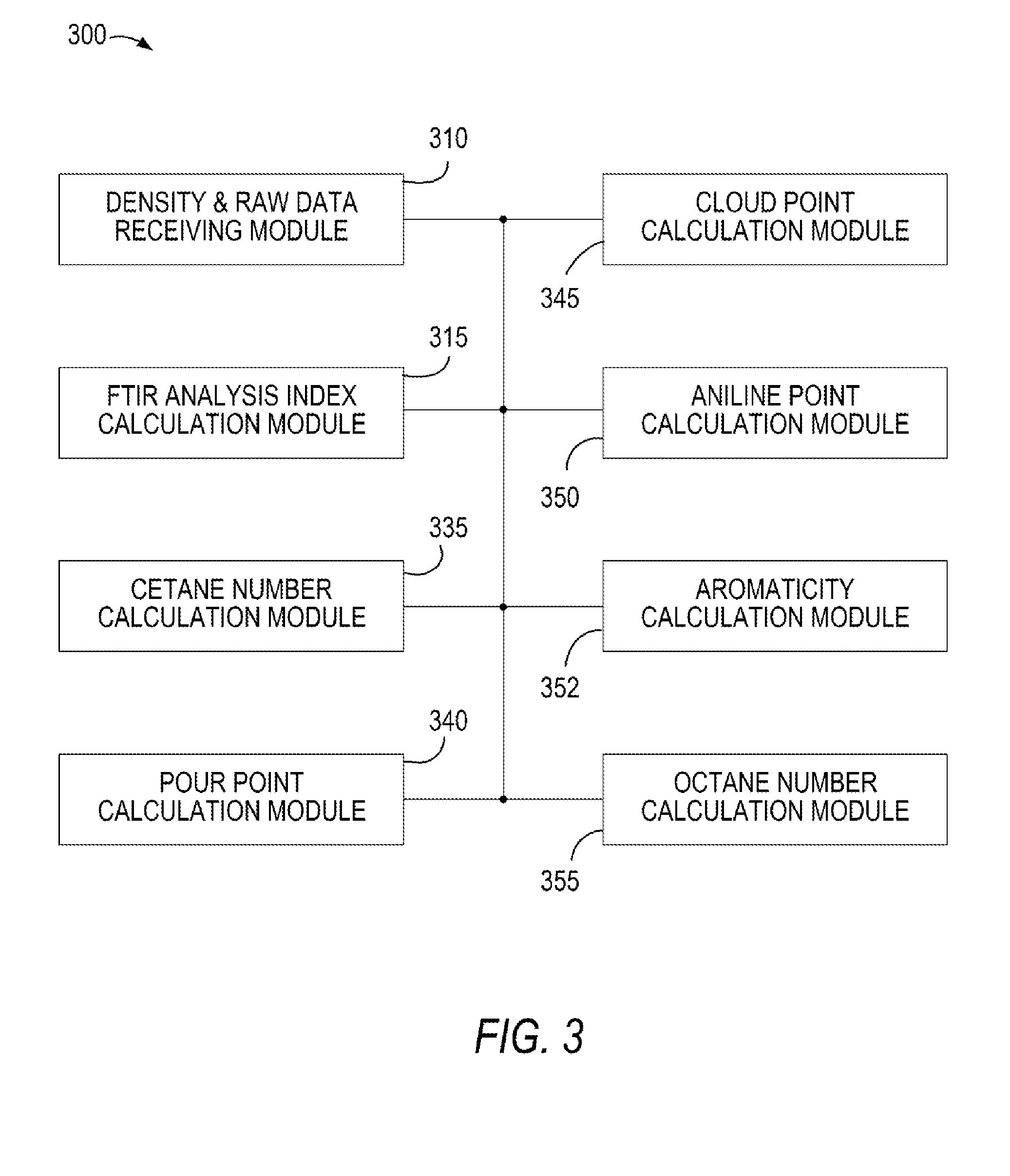

Characterization of crude oil and its fractions by fourier transform infrared spectroscopy (FTIR) analysis

InactiveUS20160195507A1Improve oil qualityTransmissivity measurementsMaterial testing goodsAniline pointCloud point

A system and a method are provided for calculating the cetane number, pour point, cloud point, aniline point, aromaticity, and / or octane number of a crude oil and its fractions from the density and Fourier transform infrared spectroscopy (FTIR) of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Lube Base Oil and Lubricating Oil Composition

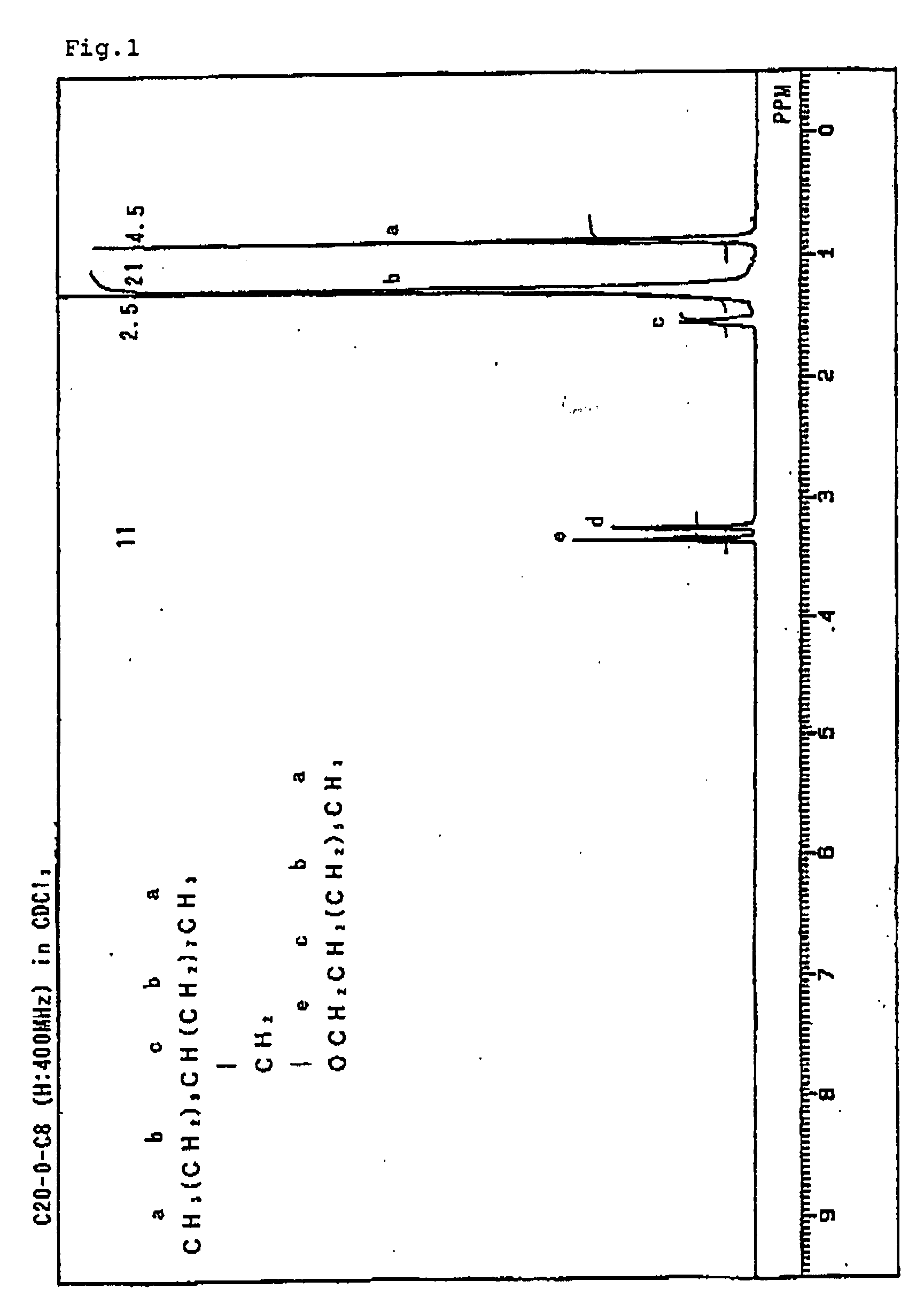

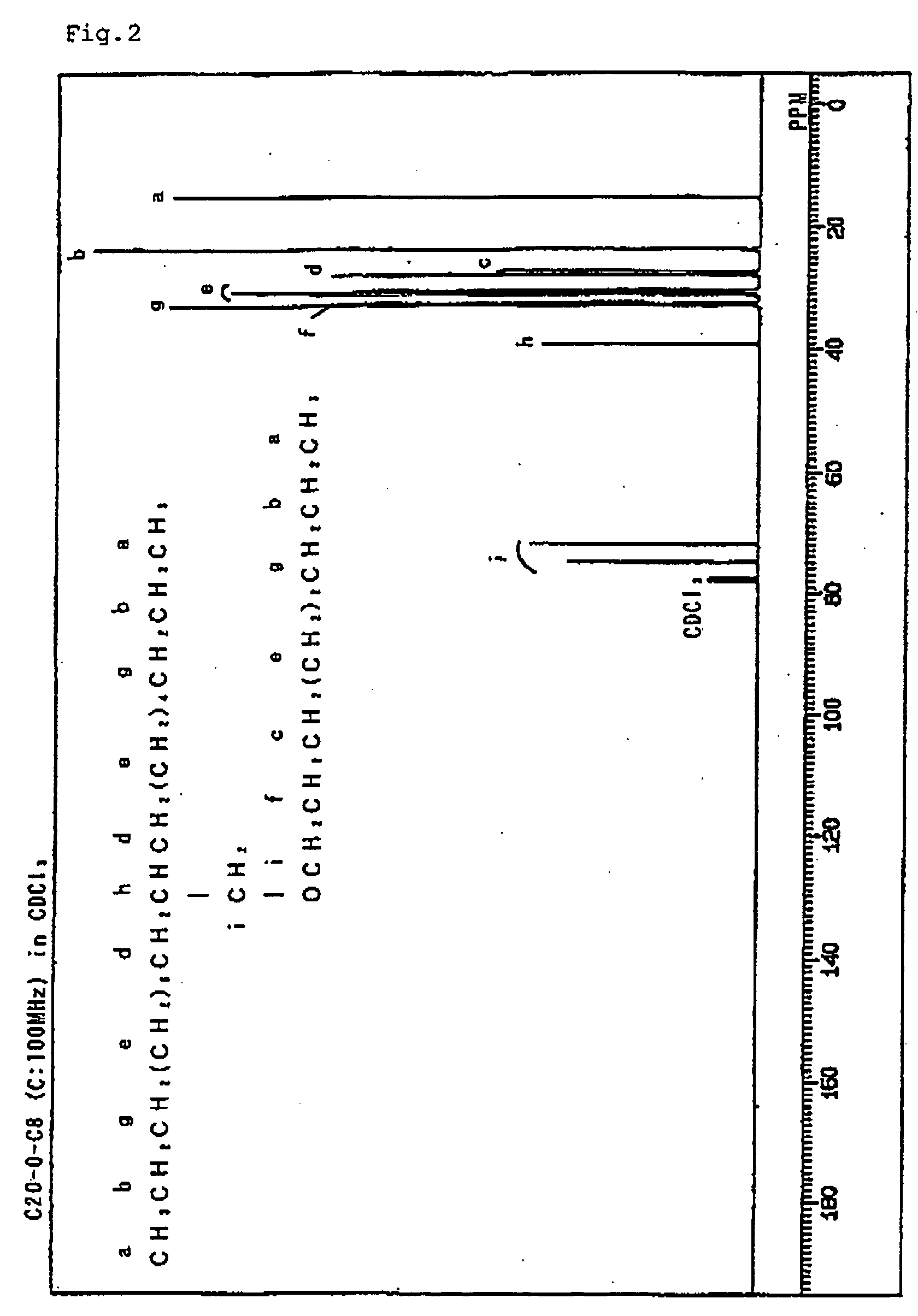

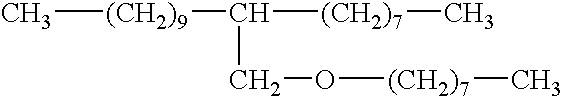

ActiveUS20070225180A1Low viscosityImprove energy savingTin organic compoundsAdditivesAniline pointEther

Provided is a lube base oil capable of giving a lubricating oil composition which has a low viscosity, but is small in evaporation amount has a low coefficient of friction and excellent adaptability for organic materials, and is suitable for use in a high-temperature atmosphere and a lubricating oil composition containing the lube base oil and having such properties. The lube base oil comprises as a main component an ether compound represented by the general formula R1—O—R2 (wherein R1 and R2 each independently represents an alkyl group having 2 to 26 carbon atoms) has a kinematic viscosity at 100° C. of 3.5 mm2 / s or lower, has a mass loss through evaporation as measured through Noack test (at 250° C.; 1 hour) of 30% by mass or lower and / or has a flash point of 200° C. or higher, and has an aniline point of 60° C. or higher. The lubricating oil composition comprises (A) the lube base oil and (B) an organomolybdenum compound incorporated therein in an amount of 100 to 2,000 ppm by mass in terms of molybdenum amount based on a total amount of the composition.

Owner:IDEMITSU KOSAN CO LTD

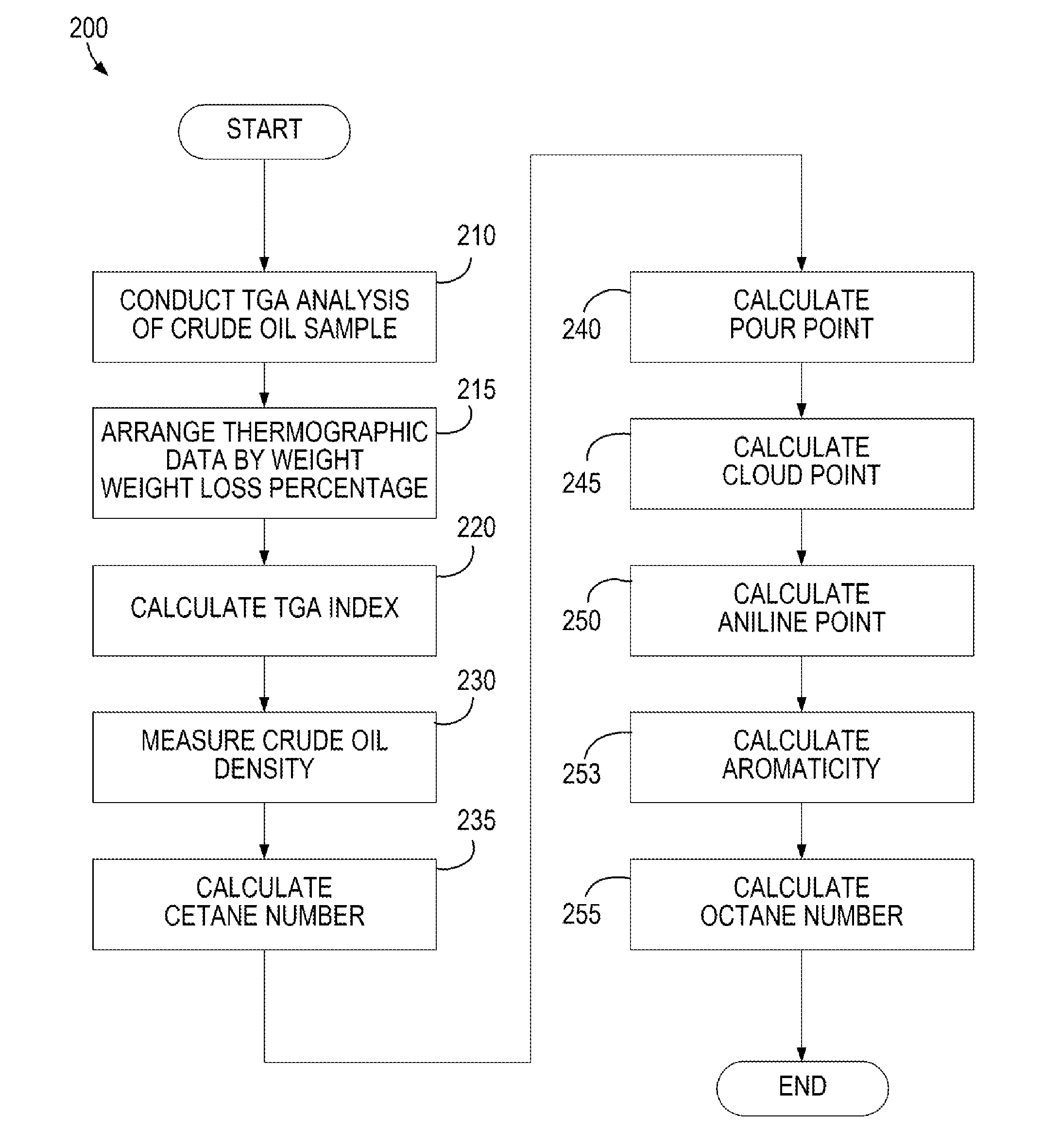

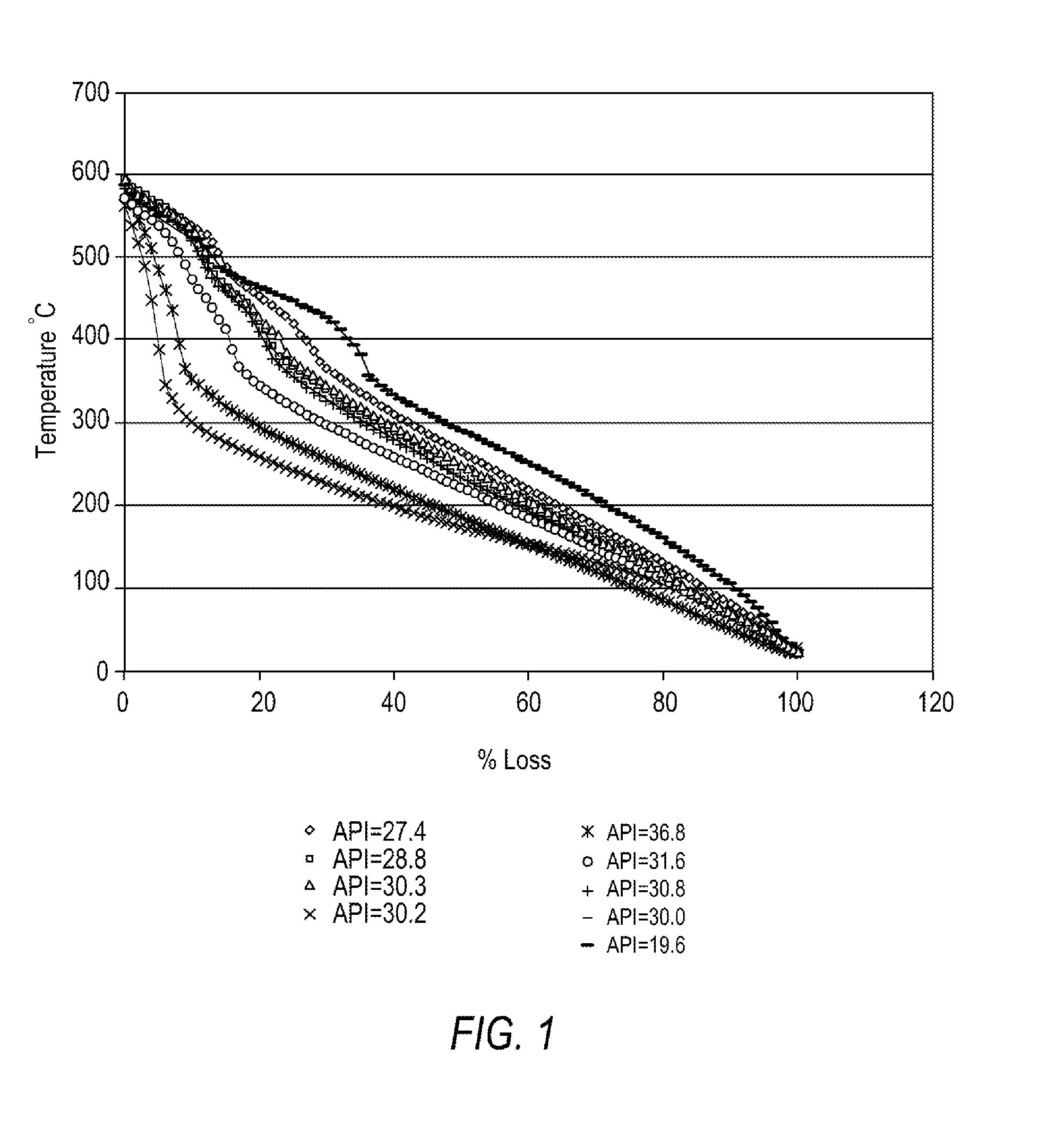

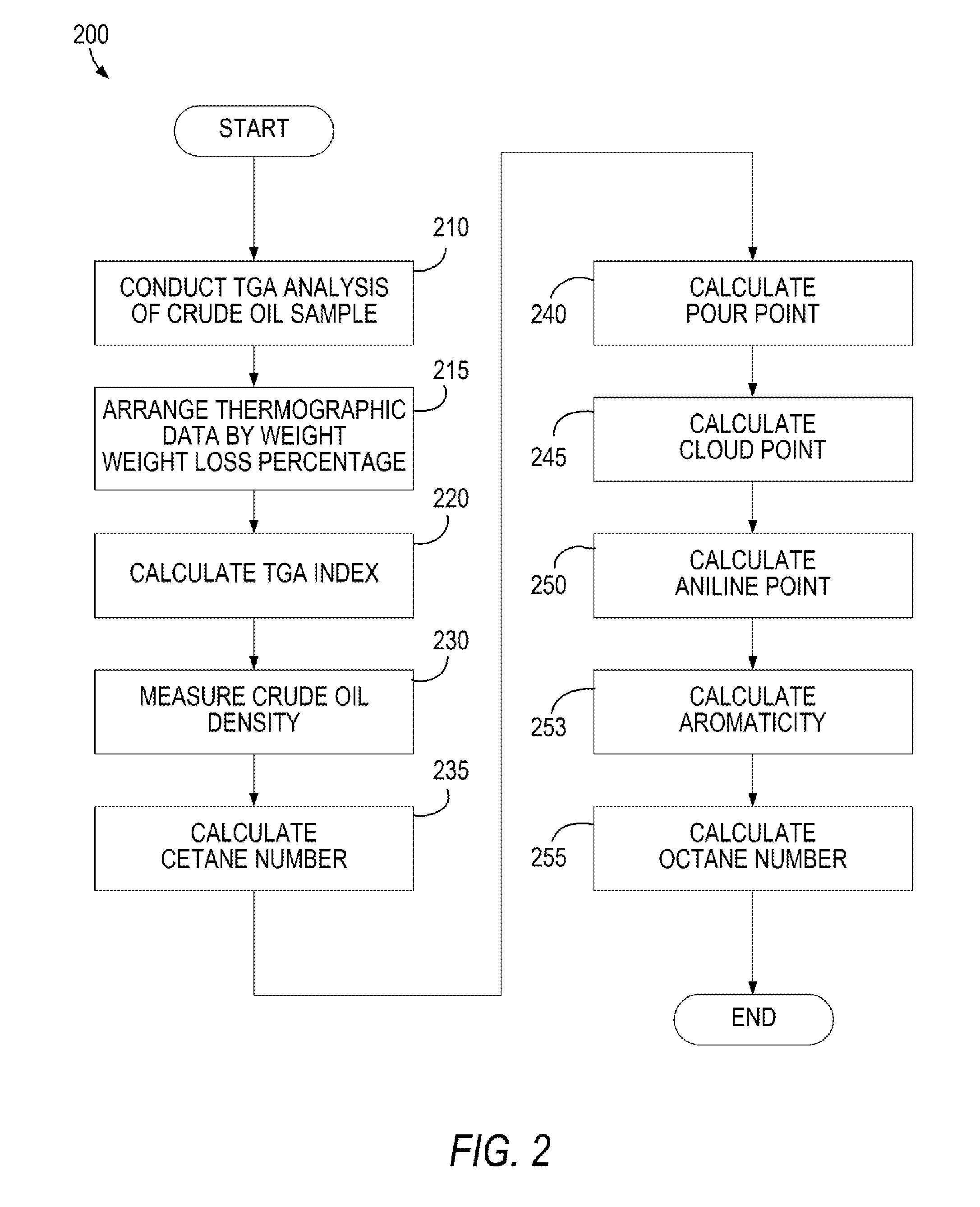

Characterization of crude oil and its fractions by thermogravimetric analysis

ActiveUS20160195481A1Improve oil qualityWeighing by removing componentMaterial thermal analysisChemical physicsAniline point

A system and a method are provided for calculating the cetane number, pour point, cloud point, aniline point, aromaticity, and / or octane number of a crude oil and its fractions from the density and thermogravimetric analysis (TGA) of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

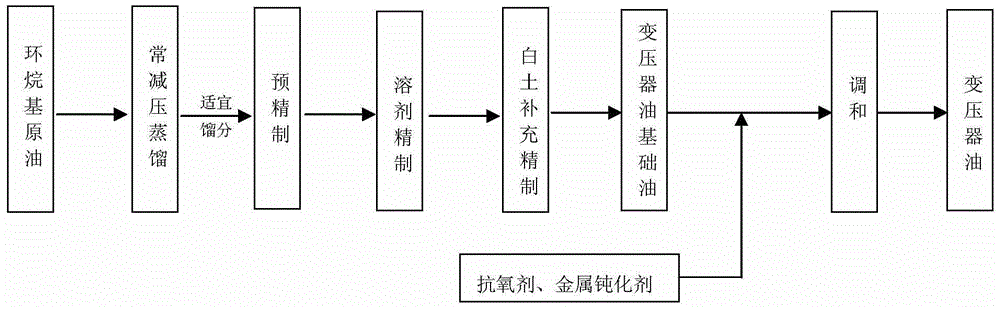

Electrical insulation oil and preparation thereof

ActiveCN101372645AImprove electrical performanceAvoid destructionThickenersAdditivesAniline pointTransformer

This invention is related to an electric insulating oil and preparation method, which have low pour point and excellent hydrogen absorbency even if not using the pour inhibitor that can worsen the electric performance, and prevent the insulative damage caused by the upward floating when the moisture content mixed inside the transformer is frozen, such that the flash point is higher and the fatalness of occurring fire is lower. And this invention has no causticity to the copper because of without having the sulfur and has excellent electric performance, so that the practicality is excellent. The electric insulating oil is characterized that: the pour point is not greater than 45 below zero; the kenematic viscosity (40 degrees centigrade) is 6mm (2) to 10 mm (2); the flash point (PM) is not smaller than 135 degrees centigrade; the density (20 degrees centigrade) is not greater than 0.895kg / L; the aniline point is 63 to 90 degrees centigrade; the sulfur content is less than 3 weight ppm; the nitrogen content is not greater than 3 weight ppm; the basic nitrogen content is not greater than 1 weight ppm; the aromatic series content is not smaller than 5 weight%; and the antioxidant of 0.05 weight% to 0.5 weight% is contained.

Owner:JAPAN ENERGY CORP

Composition for heat cycle system, and heat cycle system

ActiveUS9957430B2Improve the lubrication effectImprove cycle performanceCompressorCompression machines with non-reversible cycleAniline pointWorking fluid

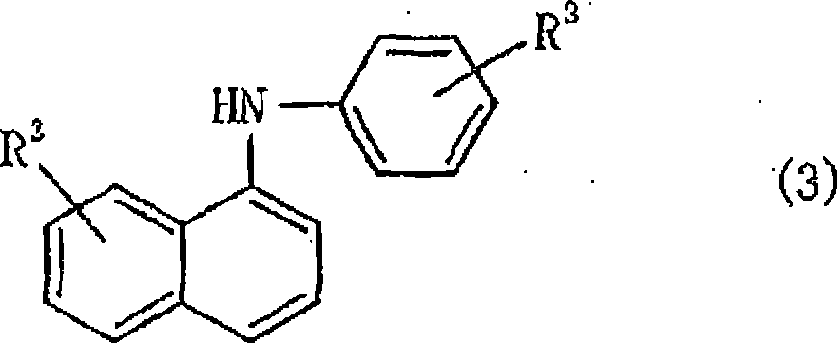

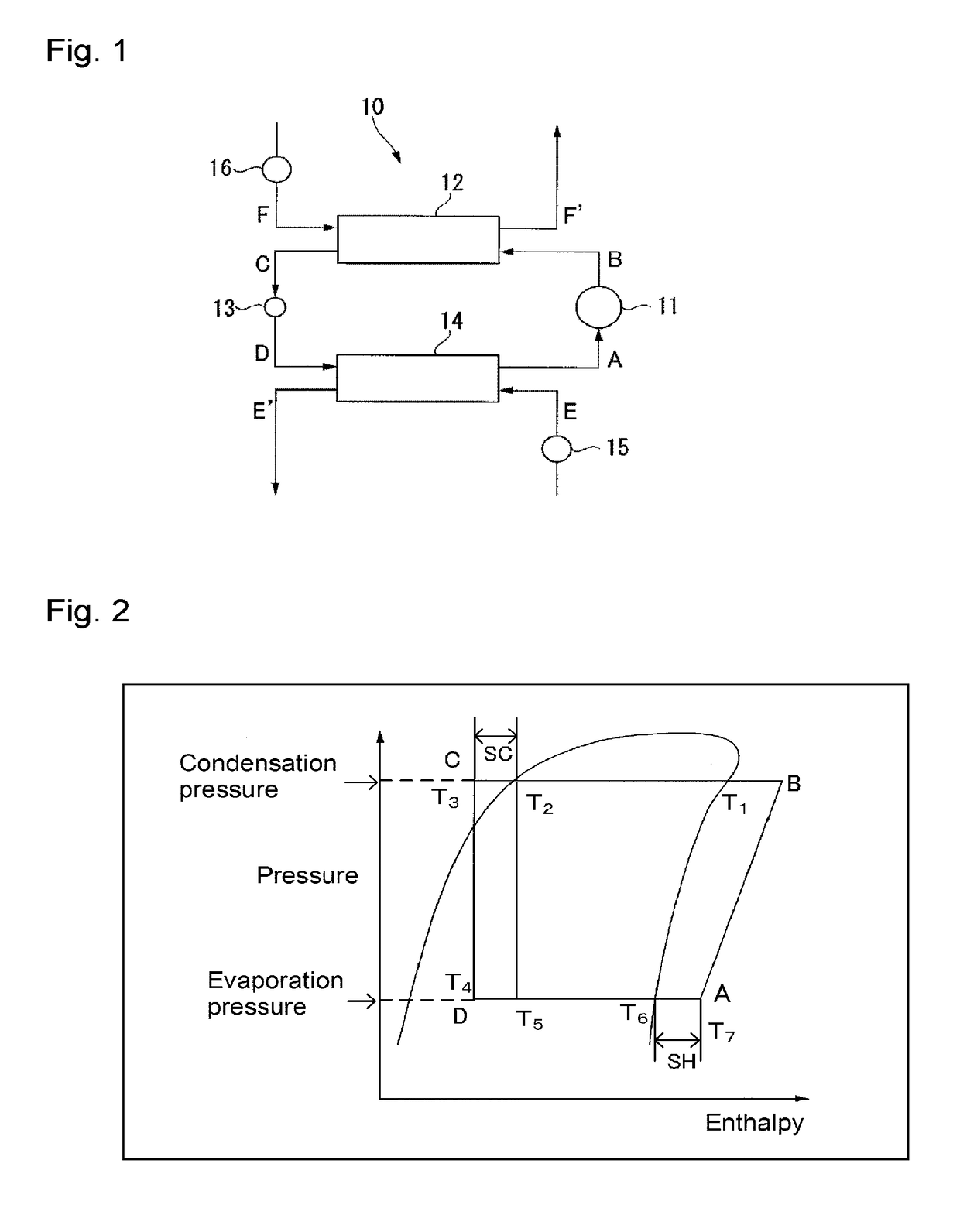

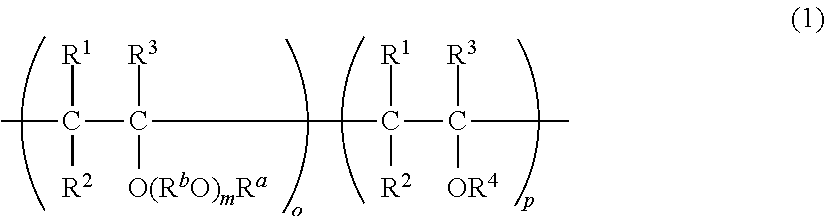

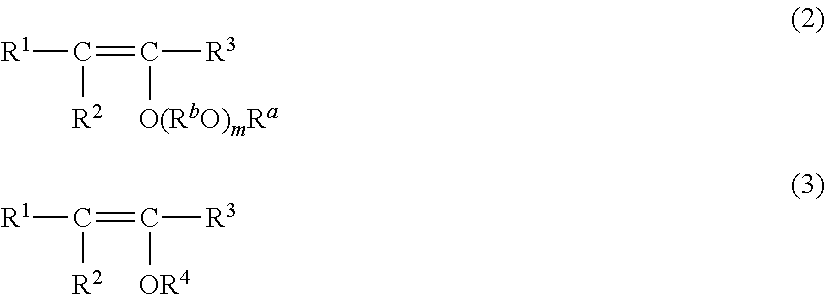

A composition for a heat cycle system and a heat cycle system employing the composition are provided. The composition has favorable lubricating properties and contains a working fluid for heat cycle and a refrigerant oil. The working fluid contains an unsaturated fluorinated hydrocarbon compound having a specific structure. The working fluid has a low global warming potential and can replace R410A. The refrigerant oil has a breakdown voltage of at least 25 kV, a hydroxyl value of at most 0.1 mgKOH / g, and an aniline point of at least −100° C. and at most 0° C.

Owner:ASAHI GLASS CO LTD

Characterization of crude oil by ultraviolet visible spectroscopy

ActiveUS9285307B2Provide informationImprove oil qualityColor/spectral properties measurementsMaterial testing goodsAniline pointCloud point

A system and a method for calculating the cetane number, pour point, cloud point and aniline point of a gas oil fraction of crude oil from the density and ultraviolet visible spectroscopy of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

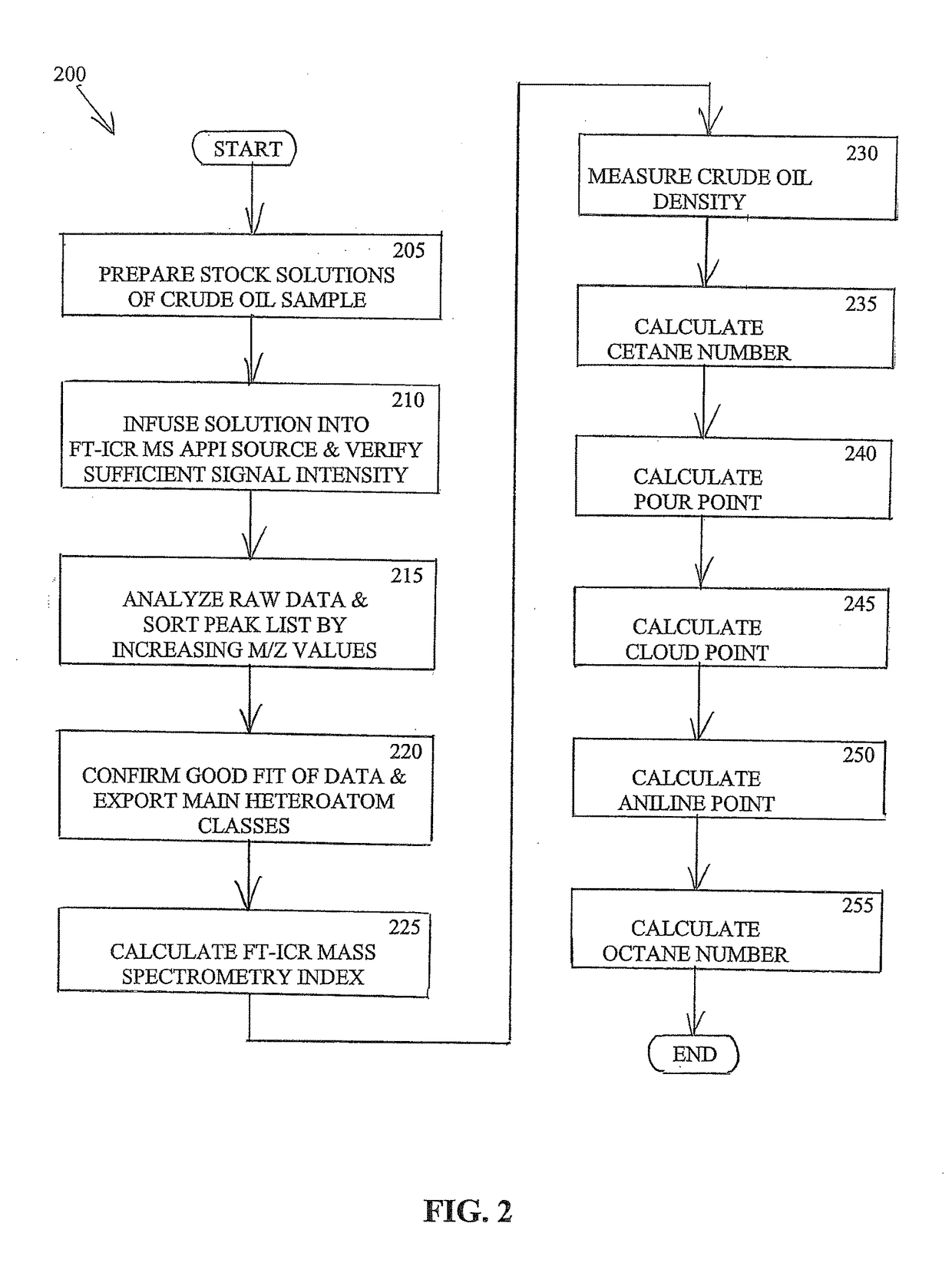

Characterization of crude oil by fourier transform ion cyclotron resonance mass spectrometry

ActiveUS20170363602A1Provide informationImprove oil qualityChemical property predictionOmegatronsAniline pointCloud point

A system, method and computer program product are provided for calculating one or more indicative properties, e.g., one or more of the cetane number, octane number, pour point, cloud point and aniline point of oil fractions, from the density and Fourier transform ion cyclotron resonance mass spectrometry (FT-ICR MS) of a sample of an oil sample.

Owner:SAUDI ARABIAN OIL CO

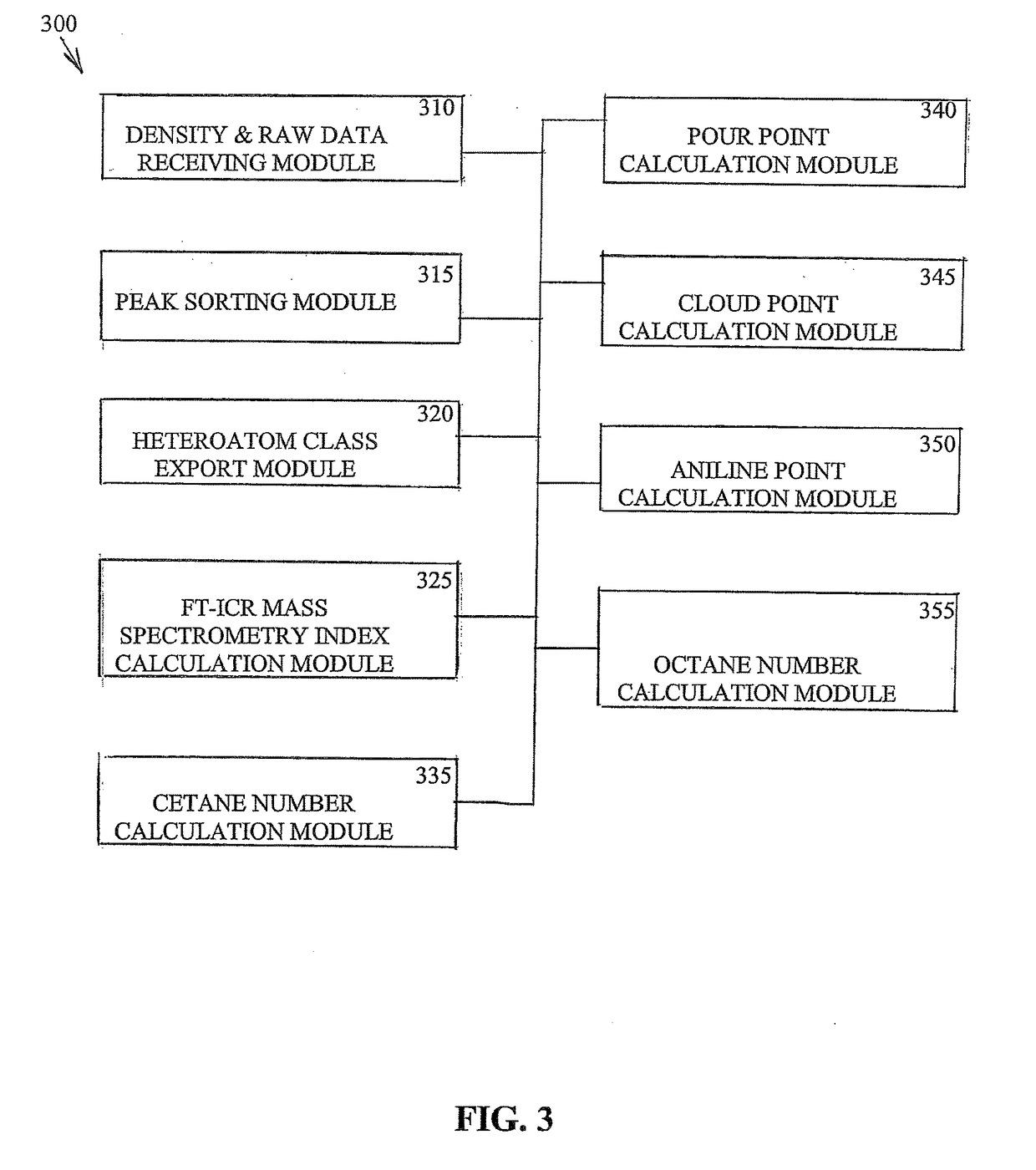

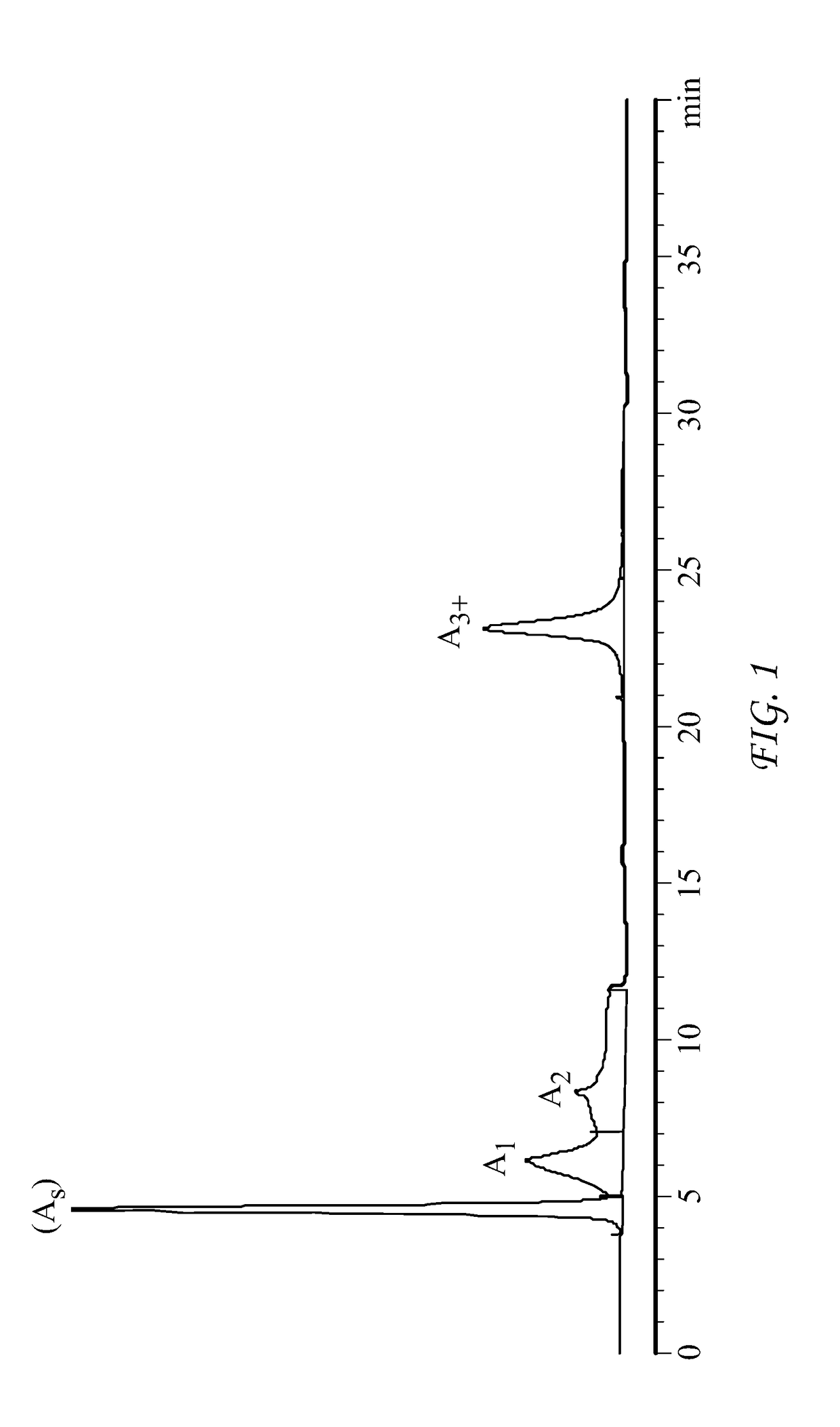

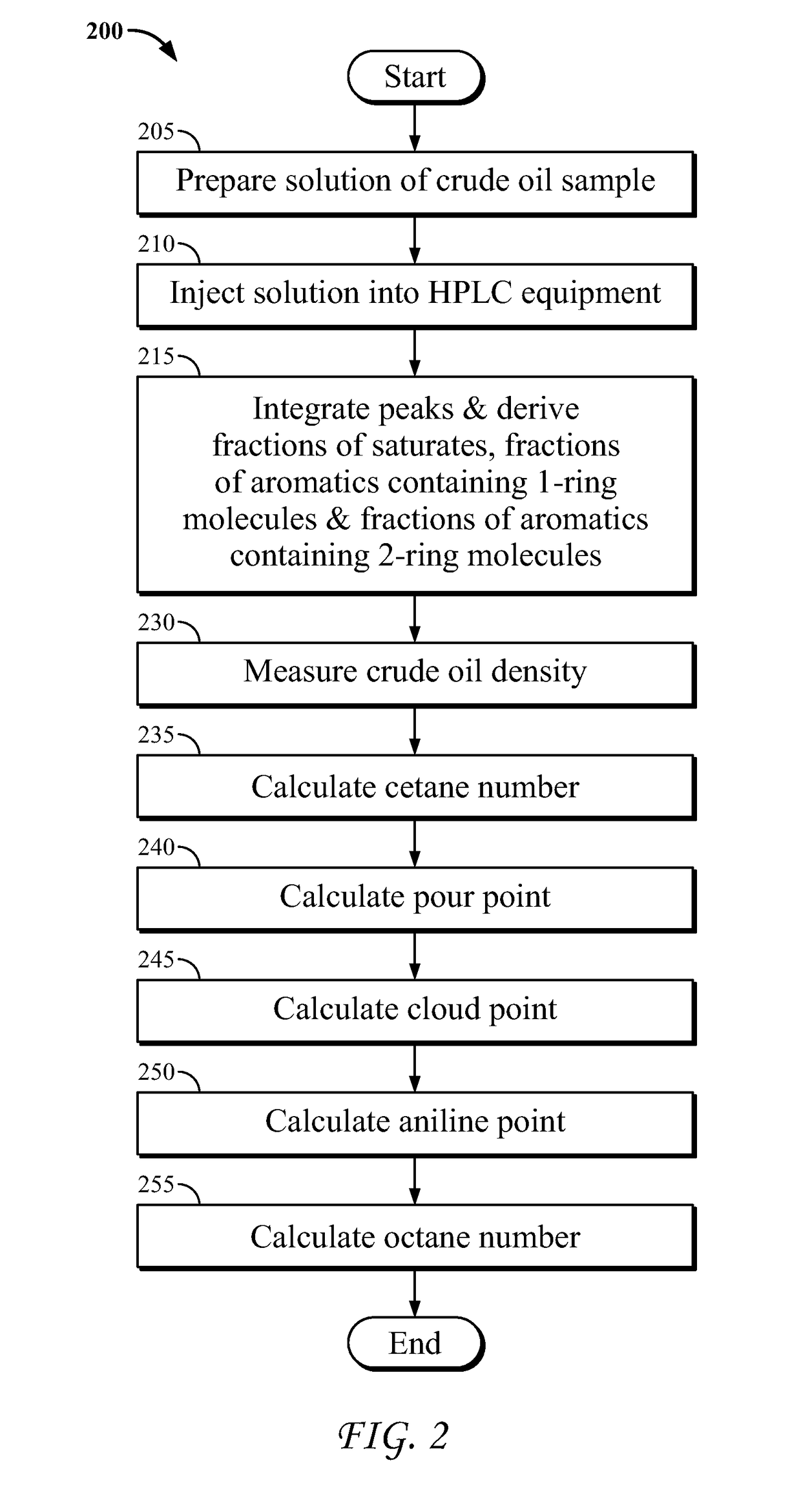

Characterization of crude oil by high pressure liquid chromatography

ActiveUS20170363603A1Provide informationImprove oil qualityComponent separationMaterial testing goodsAniline pointHigh pressure liquid chromatography procedure

A system and a method are provided for calculating one or more indicative properties, e.g., one or more of the cetane number, octane number, pour point, cloud point and aniline point of oil fractions, from the density and high pressure liquid chromatography (HPLC) data of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Characterization of crude oil by ultraviolet visible spectroscopy

ActiveUS20160011102A1Obtained relatively rapidly and inexpensivelyProvide informationColor/spectral properties measurementsMaterial testing goodsAniline pointCloud point

A system and a method for calculating the cetane number, pour point, cloud point and aniline point of a gas oil fraction of crude oil from the density and ultraviolet visible spectroscopy of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Characterization of crude oil by near infrared spectroscopy

ActiveUS20170363540A1Save producer and marketerProvide informationMaterial analysis by optical meansMaterial testing goodsAniline pointAtmospheric sciences

A system and a method for calculating and assigning one or more indicative properties (e.g., cetane number, pour point, cloud point, aniline point) of a fraction of an oil sample based on an index calculated and assigned based on near infrared spectroscopy data of the sample.

Owner:SAUDI ARABIAN OIL CO

Process oil, process for production of deasphalted oil, process for production of extract, and process for production of process oil

InactiveCN101184804AImprove securityGood physical propertiesBase-materialsPetroleum wax recoveryPolycyclic aromatic hydrocarbonAniline point

Disclosed are: a process oil produced by using a deasphalted oil which is produced by deasphalting a vacuum residual oil from crude oil as a starting material, the process oil having the following properties (a) to (f) and; a process for producing the process oil: (a) polycyclic aromatic hydrocarbon (PCA) content: less than 3% by mass; (b) viscosity (at 100 DEG C): 40 to 70 mm<2> / s; (c) aniline point: 85 to 100 DEG C; (d) flash point: 250 DEG C or higher; (e) aromatic hydrocarbon content: 40 to 55% by mass; and (f) polar substance content: 10 to 15% by mass. Also disclosed are: a process oil produced by mixing an extract which is produced by deasphalting a vacuum residual oil from crude oil and then extracting the resultant product with a solvent with a lubricating base oil which has a polycyclic aromatic hydrocarbon (PCA) content of less than 3% by mass, the process oil having the following properties (a) and (i) to (n) and; a process for producing the process oil: (a) polycyclic aromatic hydrocarbon (PCA) content: less than 3% by mass; (i) viscosity (at 100 DEG C): 30 to 80 mm<2> / s; (j) aniline point: 90 DEG C or lower; (k) flash point: 240 DEG C or higher; (l) benzo(a)pyrene content: 1 ppm by mass or less; (m) content of specific aromatic hydrocarbons: 10 ppm by mass or less; and (n) polar substance content: 10 to 30% by mass.

Owner:IDEMITSU KOSAN CO LTD

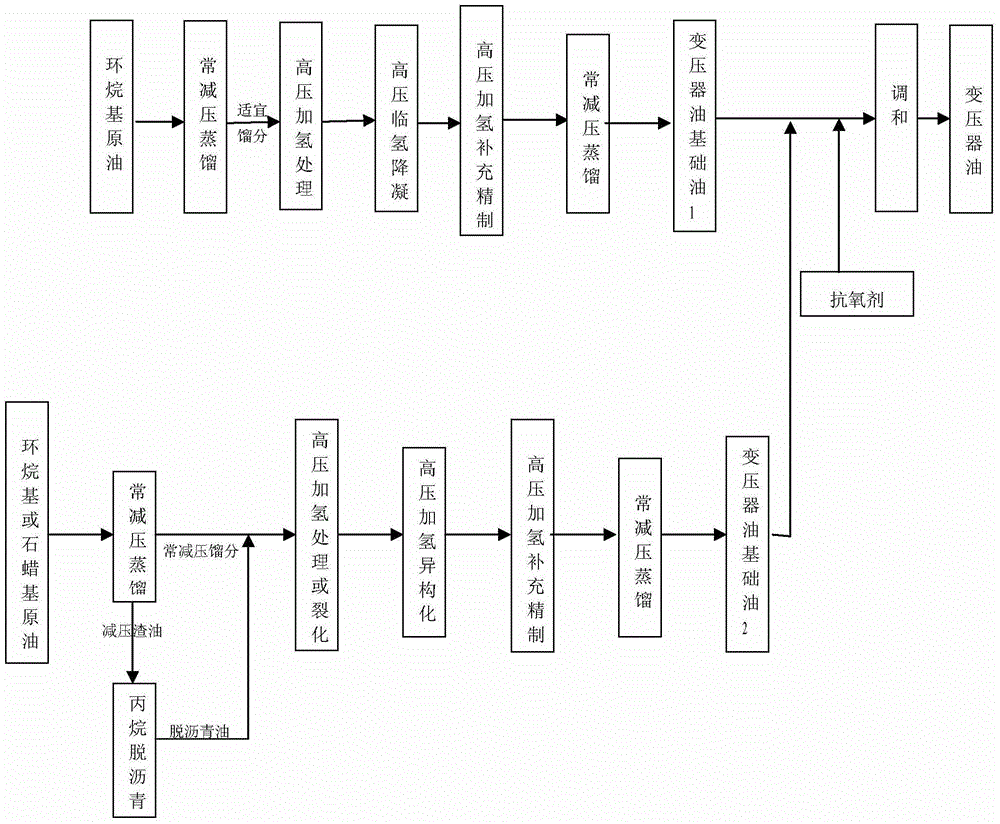

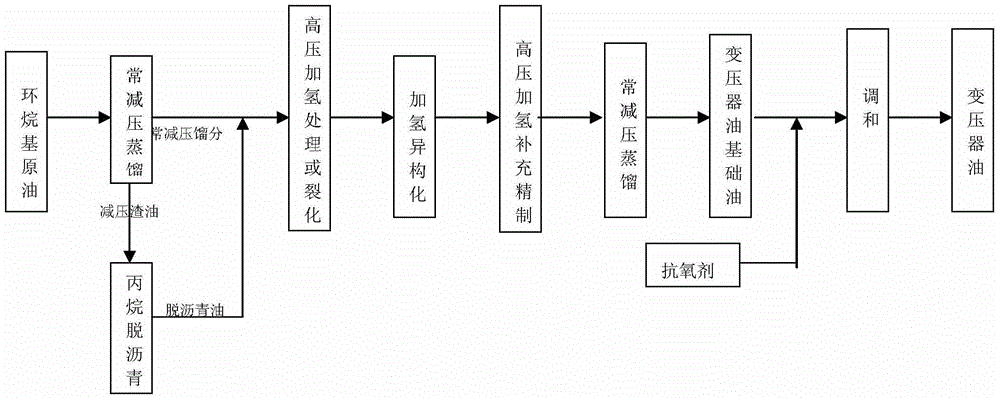

Production method for high-grade naphthenic transformer oil

InactiveCN104694219AImprove electrical performanceGood anti-gassing performanceBase-materialsHydrogenAniline point

The invention relates to a production method for high-grade naphthenic transformer oil. The production method comprises the following steps: preparing base oil 1 from naphthenic crude atmospheric and vacuum fraction by using combined process of high pressure hydrotreatment-high pressure hydrodewaxing-high pressure hydrofinishing-distillation; preparing base oil 2 from naphthenic crude or paraffinic crude fraction by using combined process of high pressure hydrotreatment or cracking-high pressure hydroisomerization-high pressure hydrofinishing-distillation; and blending the base oil 1 with the base oil 2 in proportion, adding 0.3 to 0.40% of 2,6-di-t-butyl p-cresol (DBPC) anti-oxidant and carrying out blending. The high-grade naphthenic transformer oil meets requirements on I -30 DEG C transformer oil (special) prescribed in the standards GB2536-2011 and IEC60296-2012; and the produced transformer oil has the gassing property of + 35 mu L / min, an aniline point of no more than 84 DEG C, a CP value in carbon type analysis of less than 50%, good electrical performance and anti-gassing performance, excellent antioxidation performance and good dissolving performance.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com