Process oil, process for production of deasphalted oil, process for production of extract, and process for production of process oil

A technology for deasphalting oil and processing oil, which is applied in the petroleum industry, petroleum wax recovery, lubricating composition, etc. Good physical properties and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

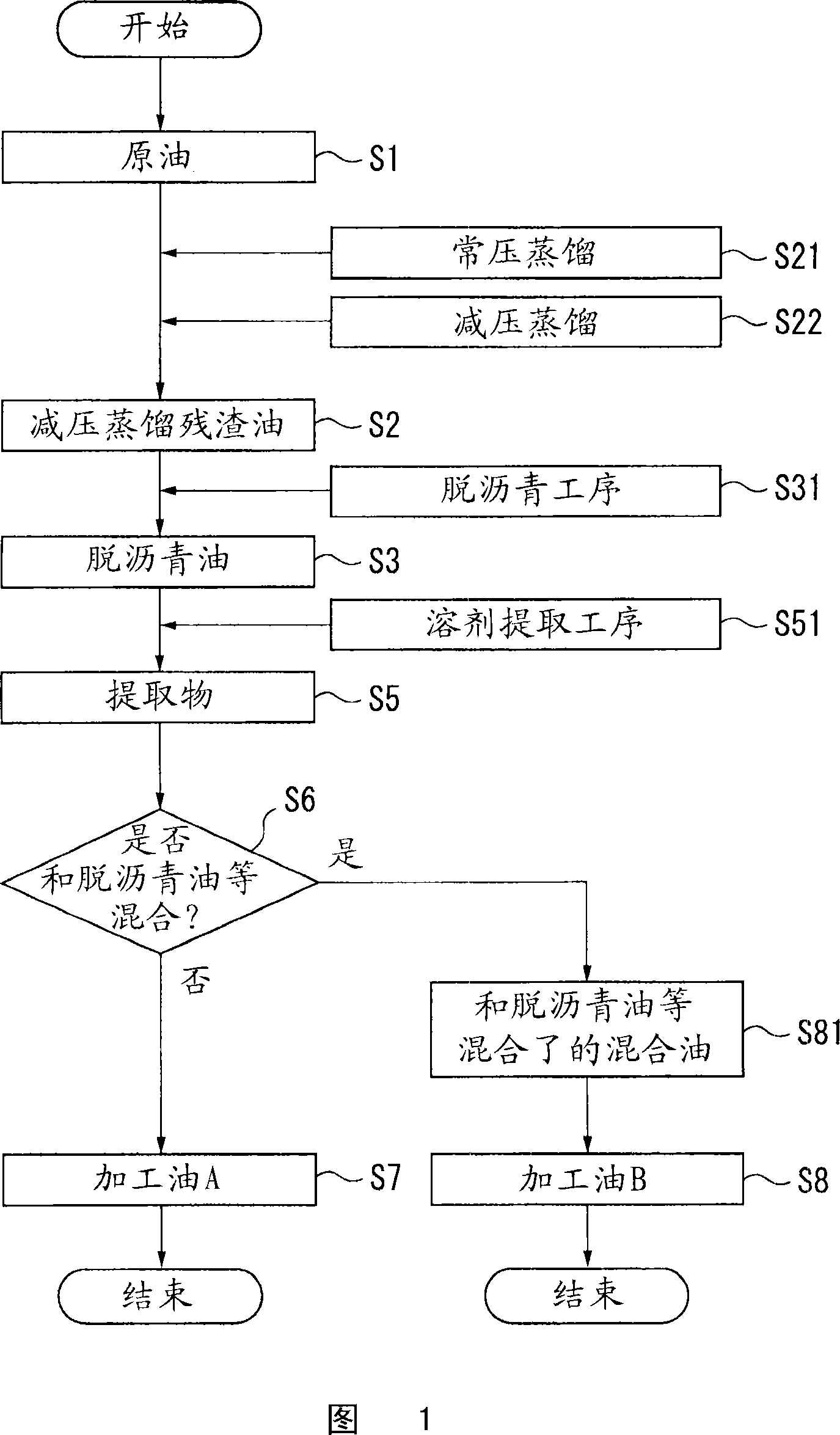

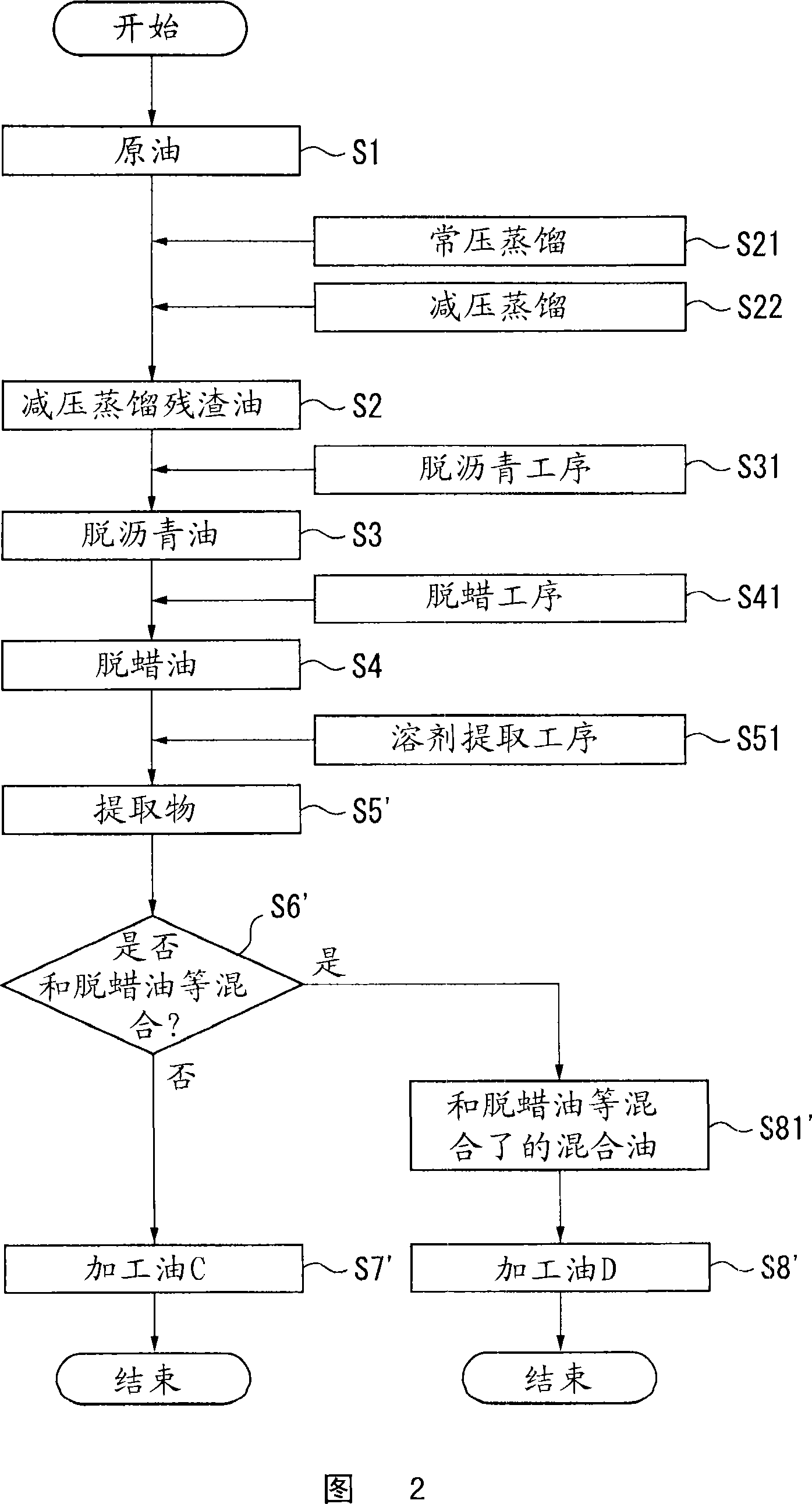

[0087] Next, the processing oil and the manufacturing method of the processing oil in the first embodiment of the present invention will be described.

[0088] The processed oil of this embodiment adopts the deasphalted oil obtained by deasphalting the vacuum residual oil of crude oil as a raw material, and has the following properties (a) to (f):

[0089] (a) polycyclic aromatic hydrocarbon (PCA) content: less than 3% by mass;

[0090] (b) Viscosity (100°C): 40-70mm 2 / s;

[0091] (c) Aniline point: 85-100°C;

[0092] (d) Flash point: above 250°C;

[0093] (e) content of aromatic hydrocarbons: 40-55% by mass;

[0094] (f) Content of polar substances: 10-15% by mass;

[0095] (a) Polycyclic aromatic hydrocarbon (PCA) content

[0096] The PCA content of the processing oil of this embodiment is less than 3% by mass, preferably less than 2.5% by mass. Considering the problem of carcinogenicity, in regions such as Europe, the handling of mineral oil with a PCA of 3% by mass...

no. 2 Embodiment approach

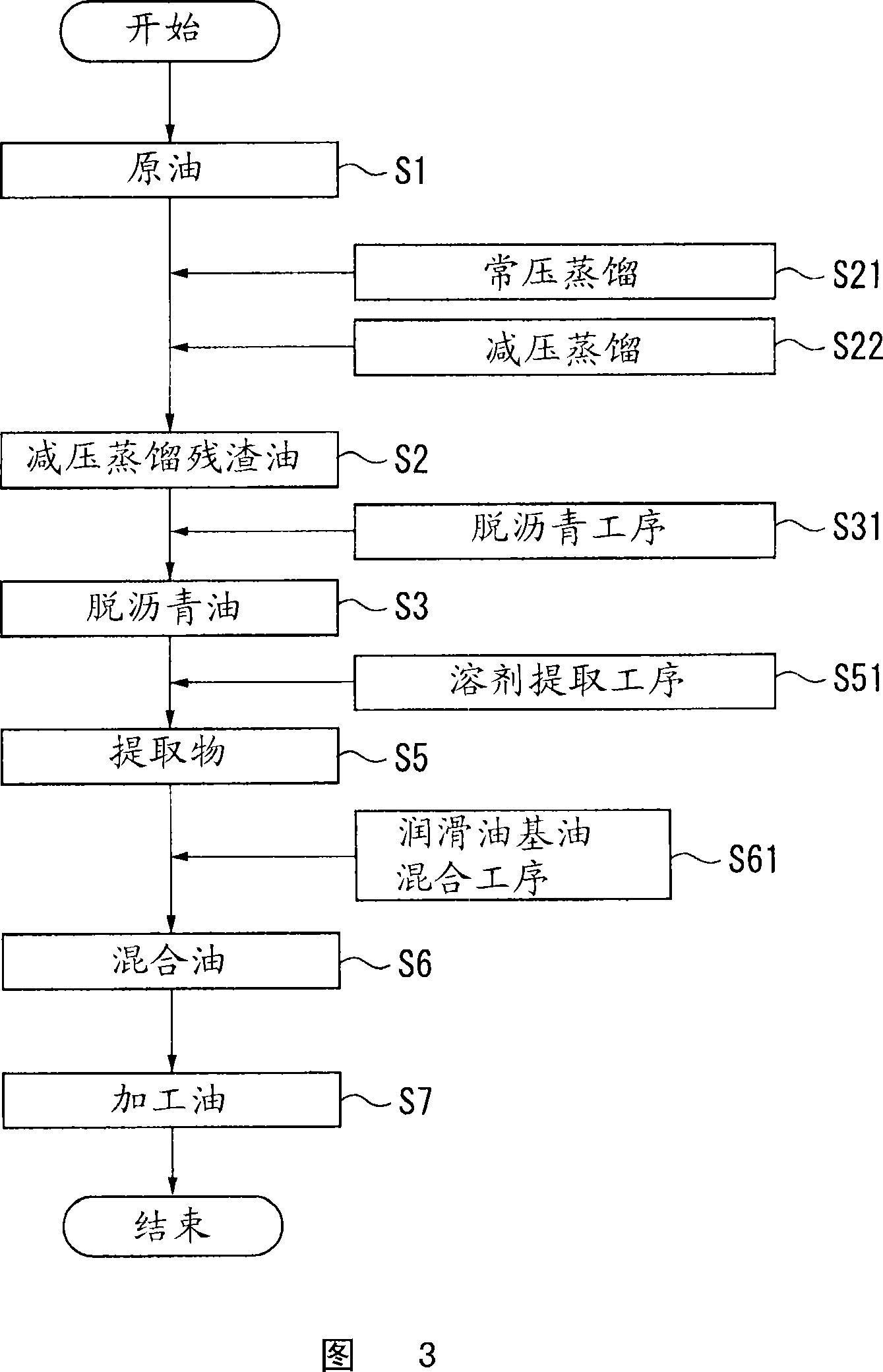

[0166] Next, the processing oil and the method for producing the processing oil in the second embodiment of the present invention will be described.

[0167] The processed oil of this embodiment is a deasphalted oil obtained by deasphalting the vacuum residue of crude oil by solvent extraction, and the obtained extract and lubricating oil base oil with polycyclic aromatic hydrocarbon content (PCA) less than 3% by mass The one obtained by mixing has the following properties (a), (i) to (n):

[0168] (a) polycyclic aromatic hydrocarbon (PCA) content: less than 3% by mass;

[0169] (i) Viscosity (100°C): 30-80mm 2 / s;

[0170] (j) Aniline point: below 90°C;

[0171] (k) Flash point: above 240°C;

[0172] (l) Content of benzo(a)pyrene: 1 mass ppm or less;

[0173] (m) Content of specific aromatic compounds: 10 mass ppm or less;

[0174] (n) Content of polar substances: 10 to 30% by mass;

[0175] (a) Polycyclic aromatic hydrocarbon (PCA) content

[0176] The PCA content of...

Embodiment 1

[0239] (Deasphalting process)

[0240] Using propane as a solvent, deasphalting the vacuum residual oil obtained from the atmospheric distillation and vacuum distillation of Middle Eastern crude oil to obtain deasphalting oil A. The yield of the deasphalted oil was 38% by mass based on the vacuum residual oil, and the viscosity of the deasphalted oil A at 100°C was 37.6mm 2 / s.

[0241] (Dewaxing process)

[0242] Using a mixed solvent of methyl ethyl ketone and toluene (mixing ratio: methyl ethyl ketone / toluene=40 / 60), dewax the deasphalted oil A so that the pour point is 12.5°C to obtain dewaxed oil a. The yield of dewaxed oil A was 93% by mass based on deasphalted oil.

[0243] (Solvent extraction process)

[0244] Further, this dewaxed oil A was subjected to solvent extraction using furfural as a solvent with a solvent ratio of 10 and an extraction temperature of 145° C. to obtain extract A at a yield of 62% by mass based on deasphalted oil. This extract A was used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com