Oil and gas field coiled tubing paraffin removal and contaminant release process and tool thereof

A technology for oil and gas fields and tools, which is applied in the field of wax and scale removal technology for coiled tubing in oil and gas fields and its tools, can solve the problems of difficult implementation, high cost, limited removal effect, etc., and achieves the effect of improving removal effect, saving cost and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

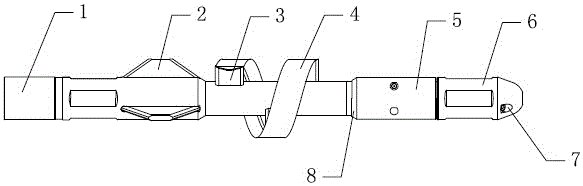

[0033] Such as figure 1 Shown: A wax removal and descaling process and tools for oil and gas field coiled tubing, including the following steps:

[0034] a. Prepare standard conversion joints, motor head assembly, vibrating tool, and weighting rod;

[0035] b. Install the prepared standard conversion joint at the end of the coiled tubing;

[0036] c. Connect the prepared standard motor head assembly, vibrating tool, and weight bar conventional tool to the conversion joint;

[0037] d. Assemble the tool string and connect it to the end of the small coiled tubing;

[0038] e. String the tool pipe into the well, start the pump, and operate according to the pre-designed displacement; at this time, the flushing tool is used to clean the sundries, and then the wax remover mechanically scrapes the remaining wax;

[0039] f. During the operation, it is necessary to lift the pipe string after a certain distance, and observe whether the pipe string is blocked; during the operation, i...

Embodiment 2

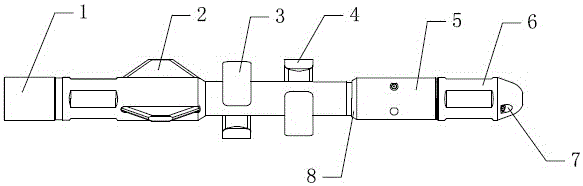

[0048] Such as figure 2Shown: a process for wax removal and descaling of coiled tubing in oil and gas fields and tools thereof, the tool string in the step d is a spiral tool string, including a string body 1, along the string body 1 on the upper part of the string body 1 Several trapezoidal righting blocks 2 are arranged at intervals in the circumferential direction of the centering block 2, and several support blocks 3 are arranged at spiral intervals along the circumferential direction of the pipe string body 1 on the pipe string body 1 below the righting block 2, and a spiral wax scraper 9 is sequentially arranged. Pass through the top of each support block 3 and cover the outer surface of each support block 3, and set a rotating housing 5 under the support block 3 away from the centralizing block 2, and the inner recesses at both ends of the rotating housing 5 shell A bearing 8 is respectively installed on them, a mandrel 6 is arranged on the pipe string body 1 below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com