Water-based antiseptic paint for automotive chassis and preparation method thereof

A technology of automobile chassis and anti-corrosion paint, which is applied in the field of paint to achieve the ideal effect of protecting the environment, strong adhesion, and salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Example 1 Synthesis of LH-302 resin

[0034] Main raw materials

[0035] 1.1 Material composition

[0036] Epoxy resin E-42, fatty acid, high molecular weight regulator, silicone intermediate, methyl methacrylate (MMA), butyl acrylate (BA), methoxy polyvinyl alcohol methacrylate (MAA) acrylic hydroxy Ethyl acetate (HEA), surfactants, initiators, and mixed non-toxic solvents are all industrial products.

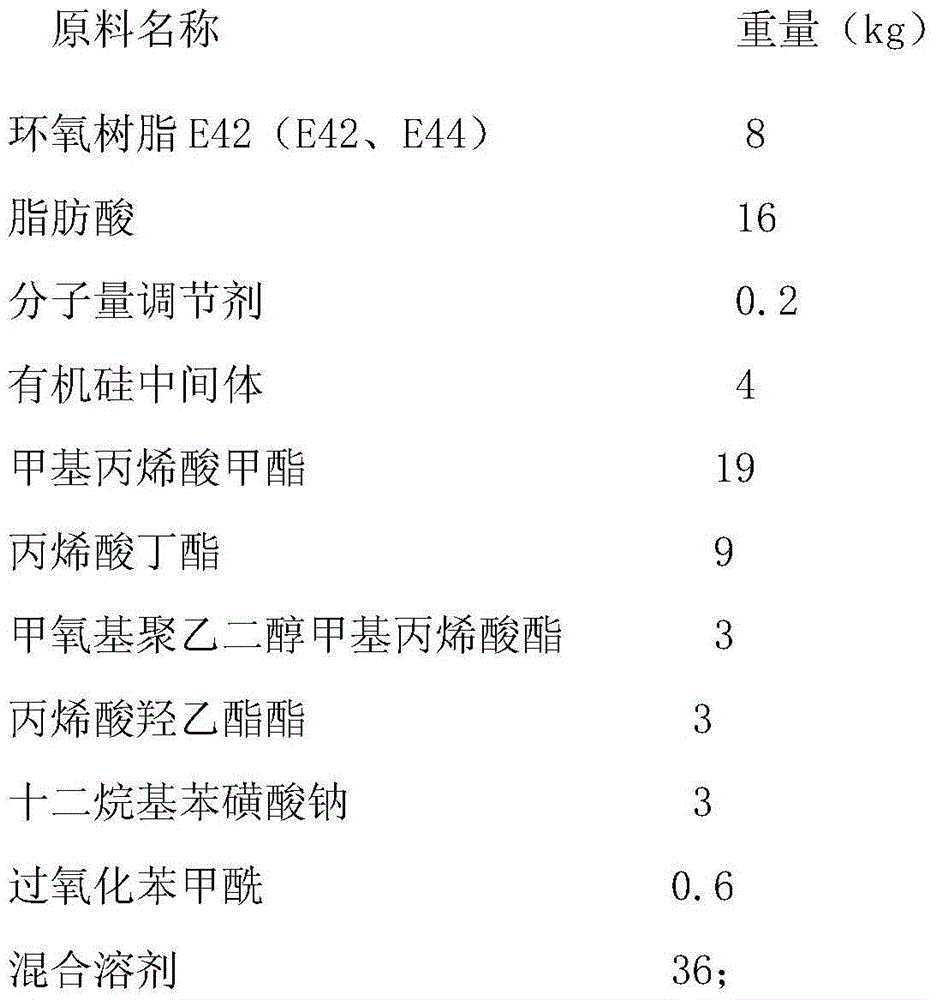

[0037] 1.2 The weight of each component used in resin preparation (kg)

[0038]

[0039] Wherein, the mixed solvent is a mixture of xylene, ethylene glycol ethyl ether acetate, and sec-butyl ester in a volume ratio of 3:1:1;

[0040] 1.3 Synthesis process

[0041] (1) Put the weighed fatty acid into the reactor, add epoxy resin, molecular weight regulator and part of the solvent, and carry out the esterification reaction at 150-160℃. When the acid value drops to 40mgKOH / g, it is regarded as esterification. At the end, the reaction system is cooled to room temperature;

[0042] ...

Embodiment 2

[0045] Example 2. Preparation of finished water-based paint

[0046] 2.1 Material composition of main raw materials

[0047] LH-302 resin (homemade), carbon black (6#), iron black, modified aluminum tripolyphosphate, organic nitrogen zinc salt, ultrafine pigments and fillers, modified fillers, various additives and deionized water are all industrial Product.

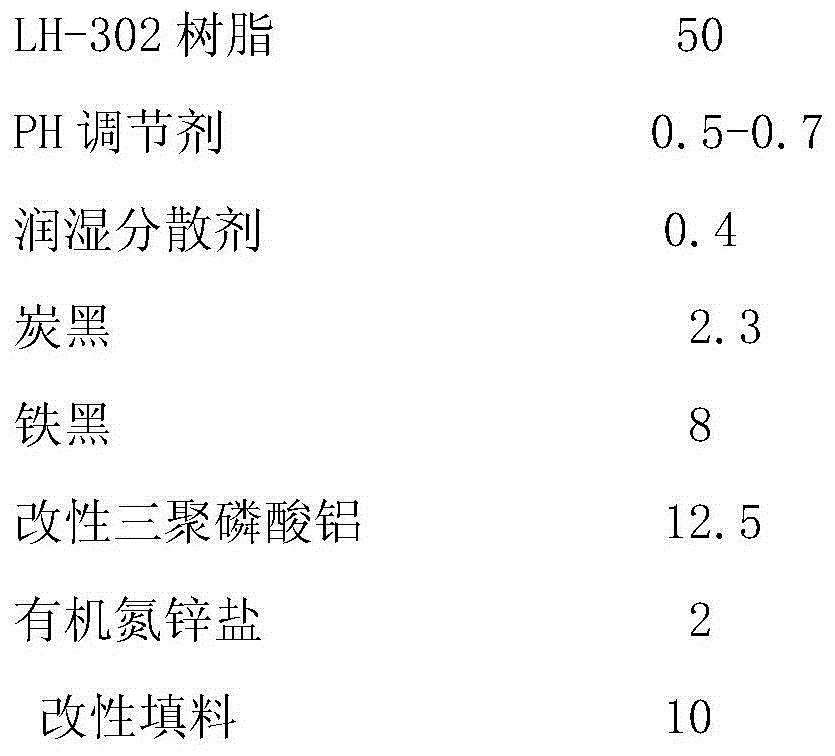

[0048] 2.2 The weight of each component of water-based automobile chassis anticorrosive paint (kg)

[0049]

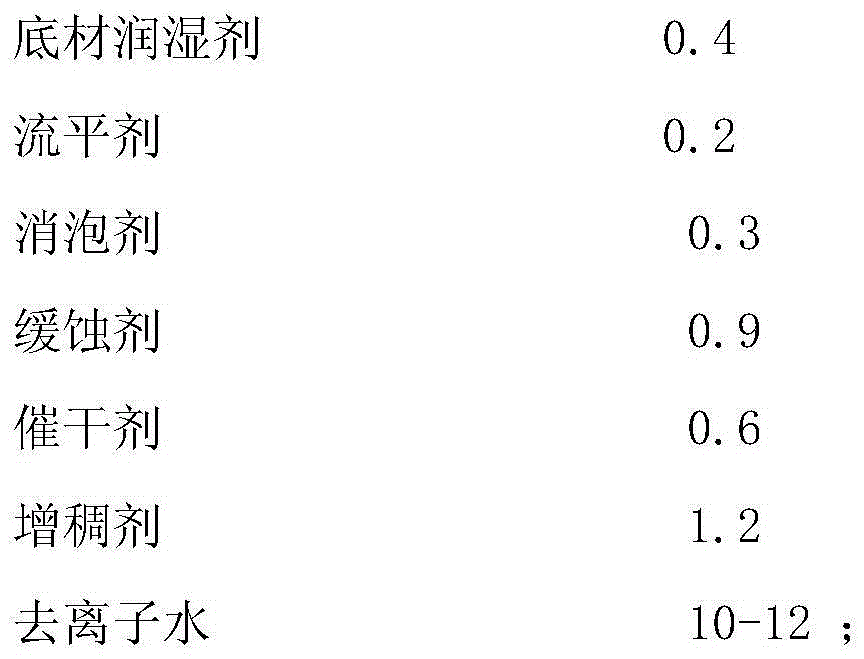

[0050]

[0051] 2.3 Finished paint production process

[0052] (1) Mix the deionized water, wetting and dispersing agent, defoamer, leveling agent, and evenly, and then add part of the resin liquid to adjust the PH value to 8.5-9.0;

[0053] (2) Under stirring, add pigments and fillers, disperse at high speed for 1-1.5h, filter with 80 mesh sieve, the filtered material enters the sand mill to circulate and grind to the fineness ≤25u, discharge, the outlet material temperature ≤60℃ ;

[0054] (3) The materials with qualifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com