Formula for preparing brake pads by utilizing acicular ceramic fiber

A technology of ceramic fiber and brake pads, which is applied in the direction of brake parts, friction linings, mechanical equipment, etc., can solve the problems of high thermal conductivity, unsatisfactory braking performance and braking comfort, etc., to reduce thermal conductivity, Excellent high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

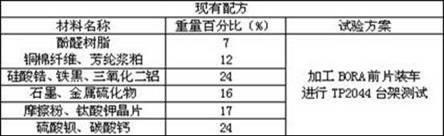

[0014]

[0015]

[0016]

[0017]

[0018] According to above formula according to the production technology processing sample of prior art is tested, the result is:

[0019] FAW-Volkswagen BORA's original supporting brake pads are metal-less friction pads produced by Germany's TMD company. During use, the braking distance at a speed of 100 kilometers is 52.6 meters. The TP2044 bench test shows that the friction coefficient is the highest at a speed of 160 km / h. 0.26, and the brake friction coefficient is around 0.30 at 500°C.

[0020] After using the processed brake pad of the formula A of the present invention, the braking distance at a speed of 100 kilometers is 43.8 meters. In the TP2044 bench test, the lowest point of the friction coefficient is 0.29 at a speed of 160Km / h, and the friction coefficient is 0.35 at 500°C.

[0021] The original brake pads for FAW-Volkswagen A6 are metal-less friction pads produced by TMD Company in Germany. During use, the braking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com