Imitation stone concrete decorative boards and preparation method thereof

A concrete and imitation stone technology, which is applied in covering/lining, construction, building structure, etc., can solve the problems of difficult acquisition, transportation and processing, non-renewable resources of stone, and damage to the ecological environment, so as to achieve realistic imitation stone effect, Good aesthetics and improved water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

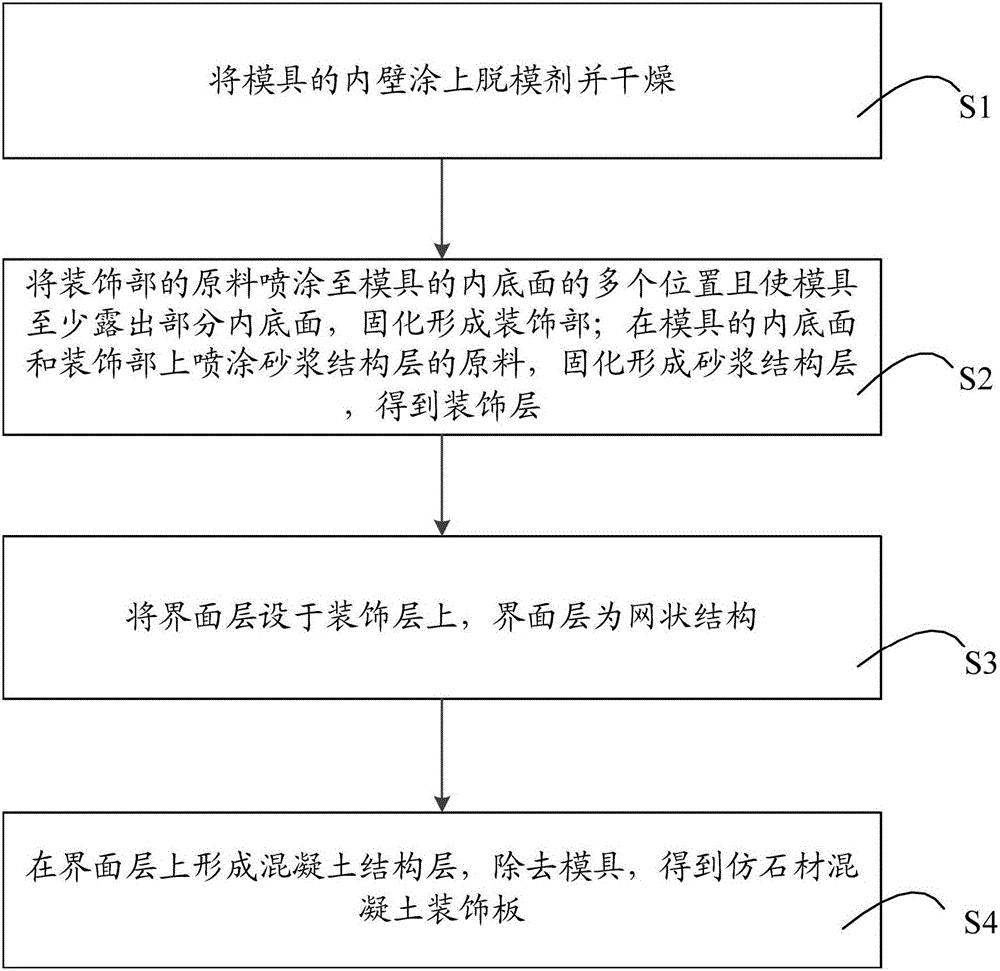

[0045] see figure 1 , the present invention also provides a preparation method of the above-mentioned imitation stone concrete decorative board, comprising the following steps.

[0046] Step S1, coating the inner wall of the mold with a release agent and drying it. Step S1 is a pretreatment step of the mould.

[0047] This is conducive to the demoulding of the subsequent imitation stone concrete decorative board. If the step S2 is performed before the release agent is dried, the release agent may float up, thereby affecting the smooth progress of the release agent and the strength of the imitation stone concrete decorative board.

[0048] Preferably, the mold is a glass panel mold. The use of the mold can make the gloss of the decorative layer very high, and the surface of the obtained decorative layer is similar to a polished stone surface, and can replace stone for interior and exterior wall decoration of buildings.

[0049] Step S2, spraying the raw material of the deco...

Embodiment 1

[0063] The stone-like concrete decorative board includes a concrete structure layer, an interface layer and a decorative layer arranged in sequence.

[0064] The raw material of the concrete structure layer is super high strength concrete. The interface layer is crack-resistant fiber mesh cloth. The decoration layer includes a mortar structure layer and a plurality of decoration parts distributed on the outer surface of the mortar structure layer, and at least part of the outer surface of the mortar structure layer is exposed. The raw materials of the mortar structure layer are calculated in parts by weight, including 850 parts of white cement, 650 parts of 20-40 mesh quartz sand, 250 parts of 40-70 mesh quartz sand, 100 parts of 325 mesh quartz sand, and 90 parts of polycarboxylate superplasticizer , 0.2 parts of cellulose ether, 105 parts of water and 5.5 parts of titanium dioxide. The raw materials of the decoration part are calculated in parts by weight, including 850 pa...

Embodiment 2

[0071] The stone-like concrete decorative board includes a concrete structure layer, an interface layer and a decorative layer arranged in sequence.

[0072] The raw material of the concrete structure layer is super high strength concrete. The interface layer is steel mesh. The decoration layer includes a mortar structure layer and a plurality of decoration parts distributed on the outer surface of the mortar structure layer, and at least part of the outer surface of the mortar structure layer is exposed. The raw materials of the mortar structure layer are calculated in parts by weight, including 900 parts of white cement, 700 parts of 20-40 mesh quartz sand, 300 parts of 40-70 mesh quartz sand, 150 parts of 325 mesh quartz sand, and 110 parts of polycarboxylate superplasticizer , 0.3 parts of cellulose ether, 110 parts of water and 6 parts of iron yellow. The raw materials of the decoration part are calculated in parts by weight, including 900 parts of white cement, 700 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com