Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Stone veneer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone veneer is a thin layer of any stone used as decorative facing material that is not meant to be load bearing. Stone cladding is a Stone veneer, or simulated stone, applied to a building or other structure made of a material other than stone. Stone cladding is sometimes applied to concrete and steel buildings as part of their original architectural design.

Simulated stone veneer architectural trim assembly

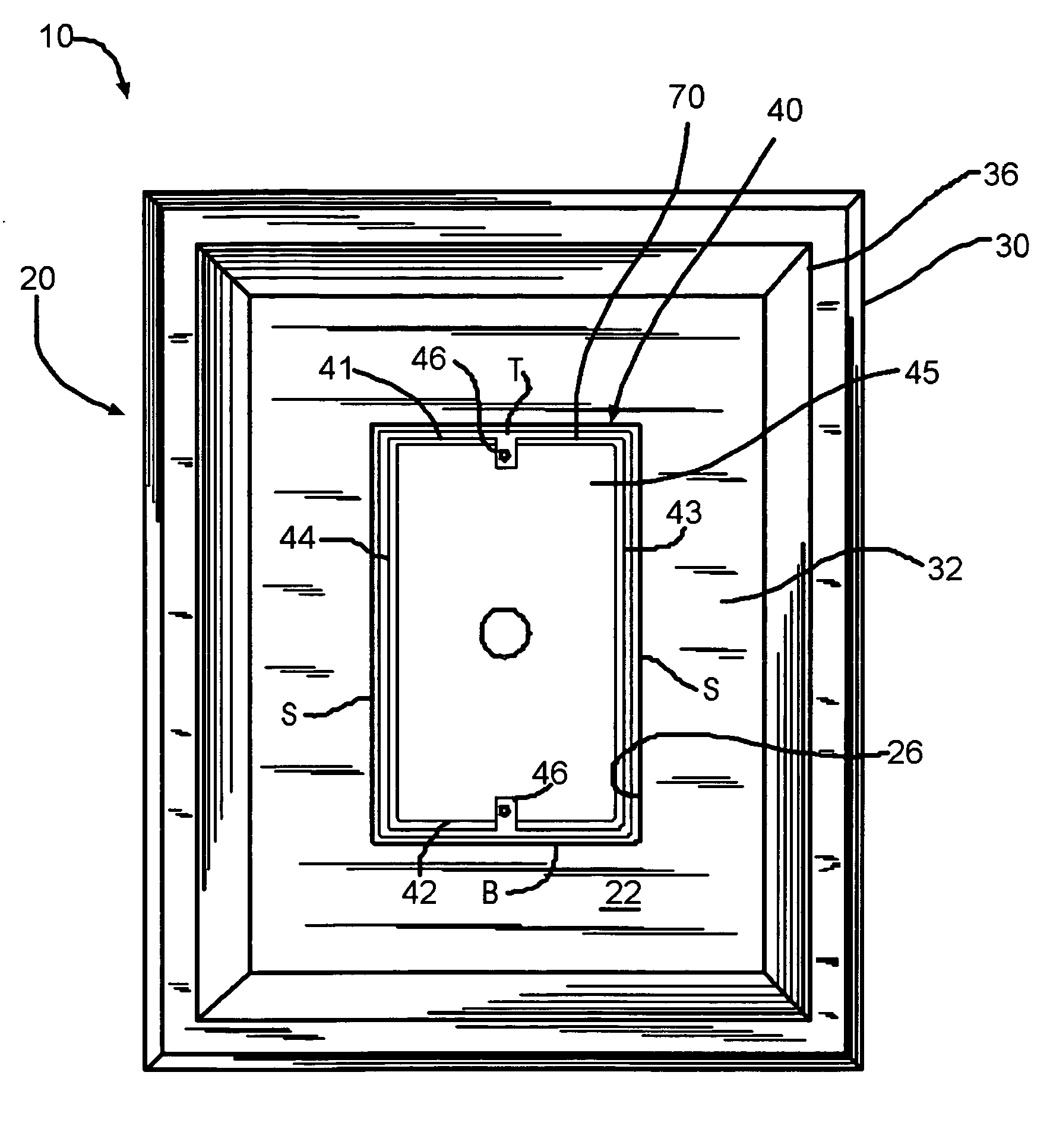

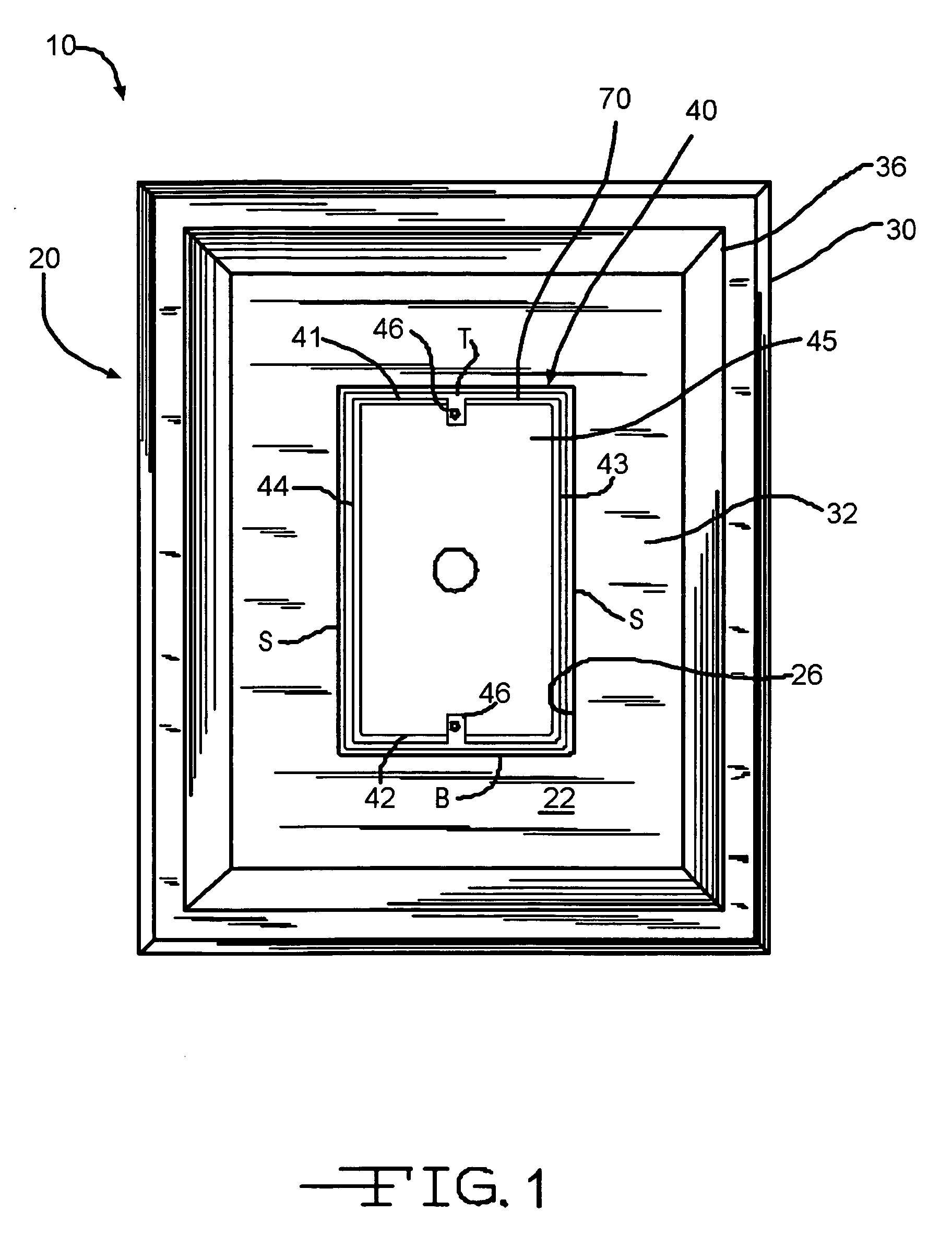

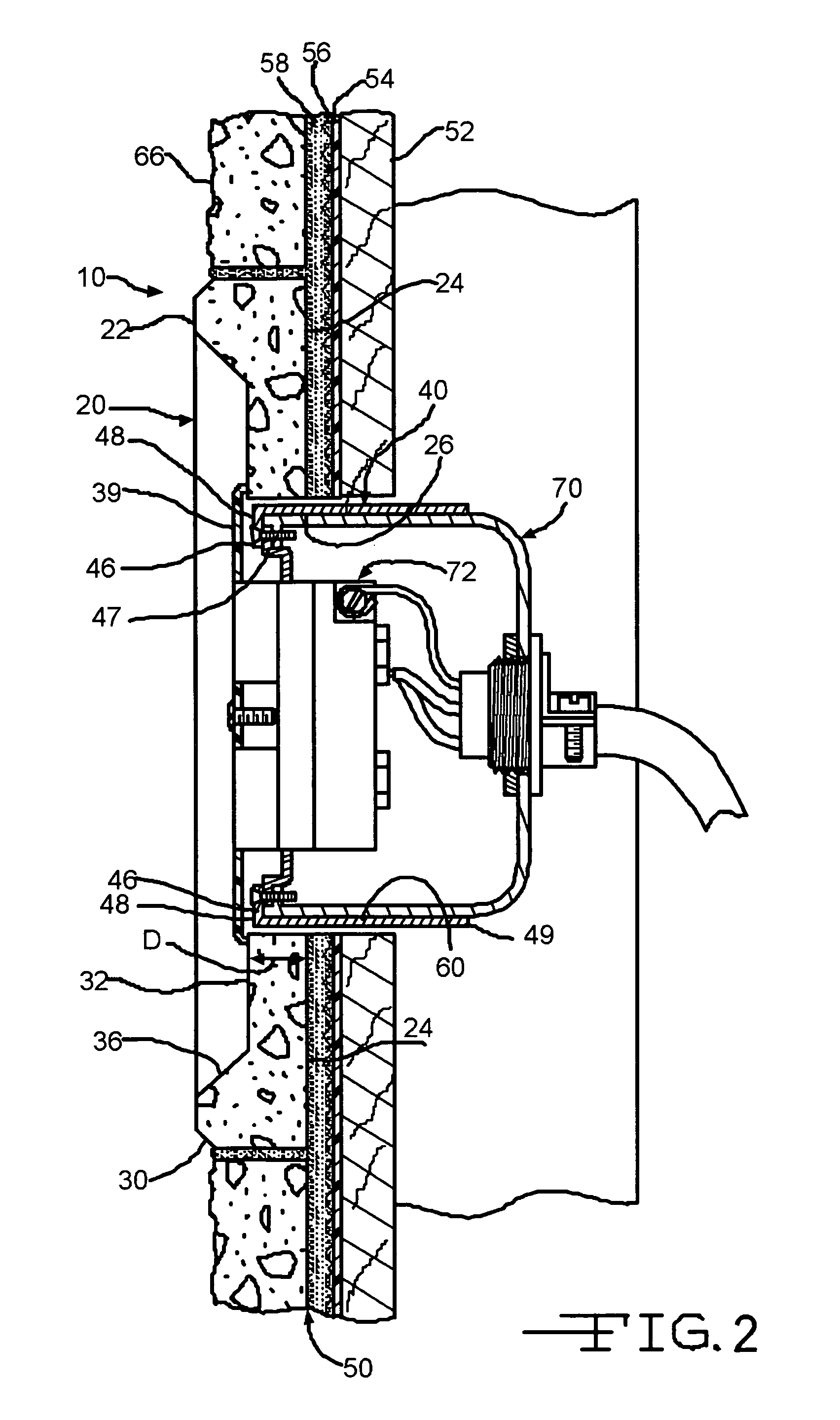

An architectural trim assembly includes a receptacle and a stone veneer trim piece having an orifice that is configured to hold the receptacle within the orifice.

Owner:BORAL STONE PRODS

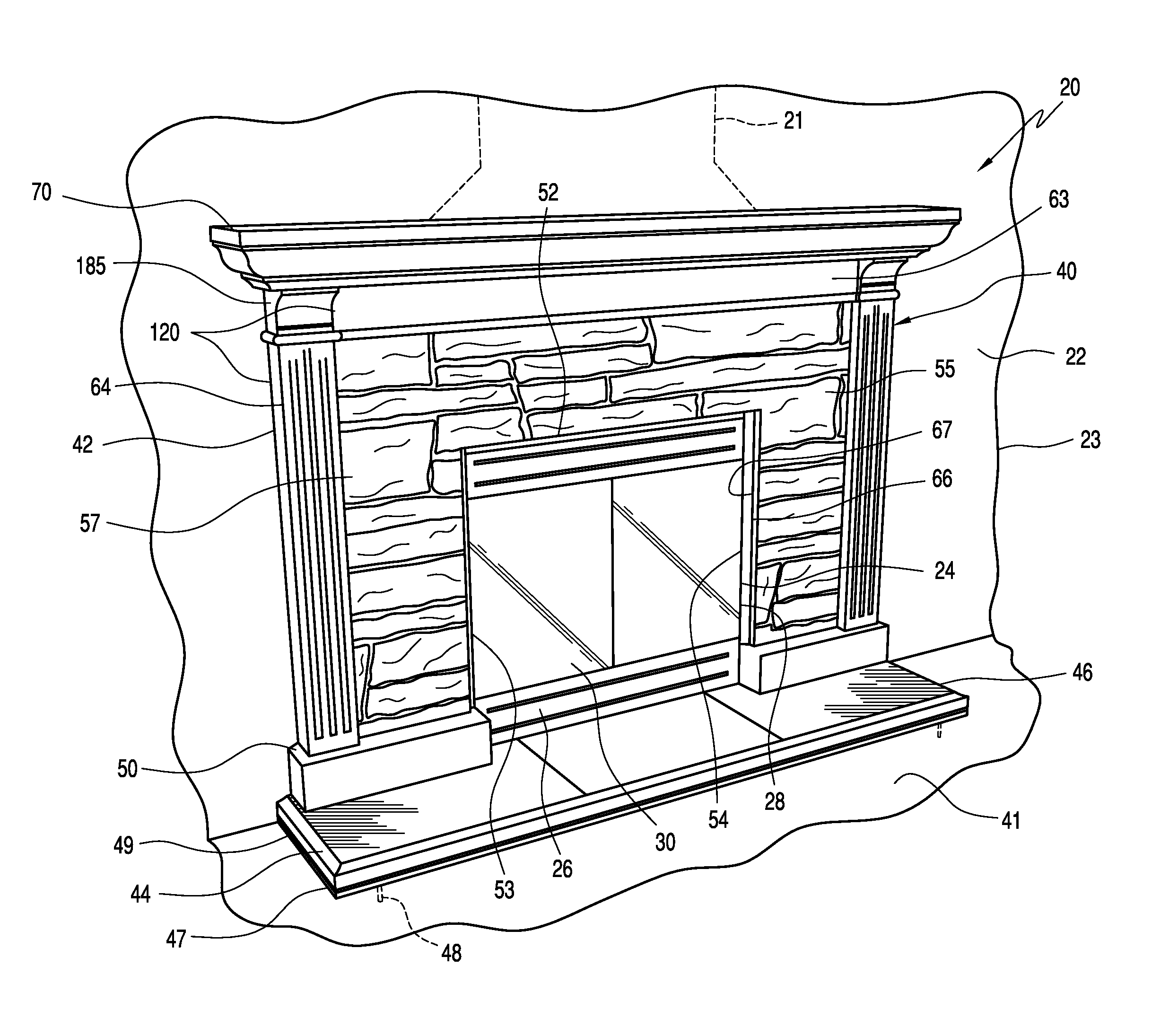

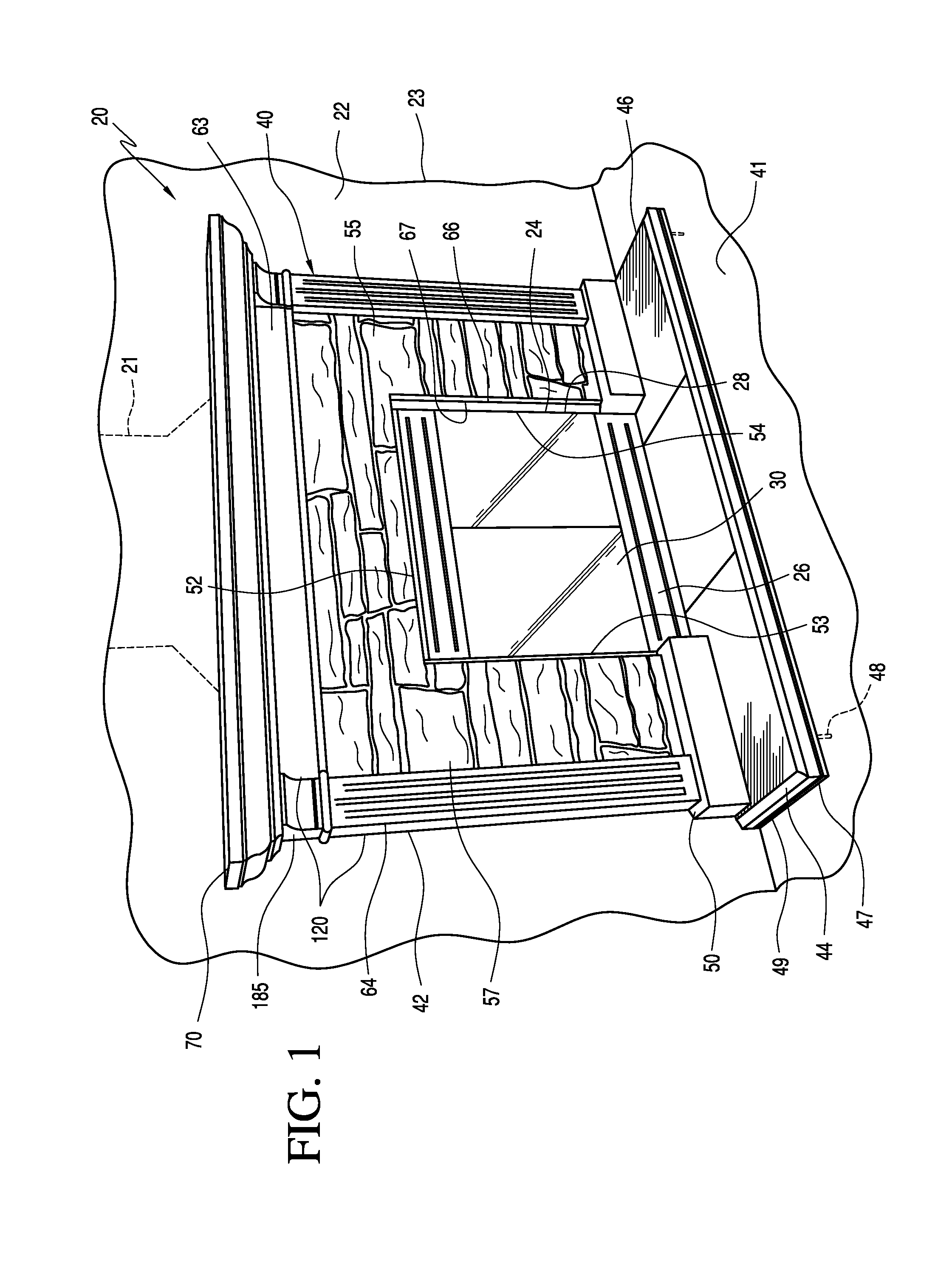

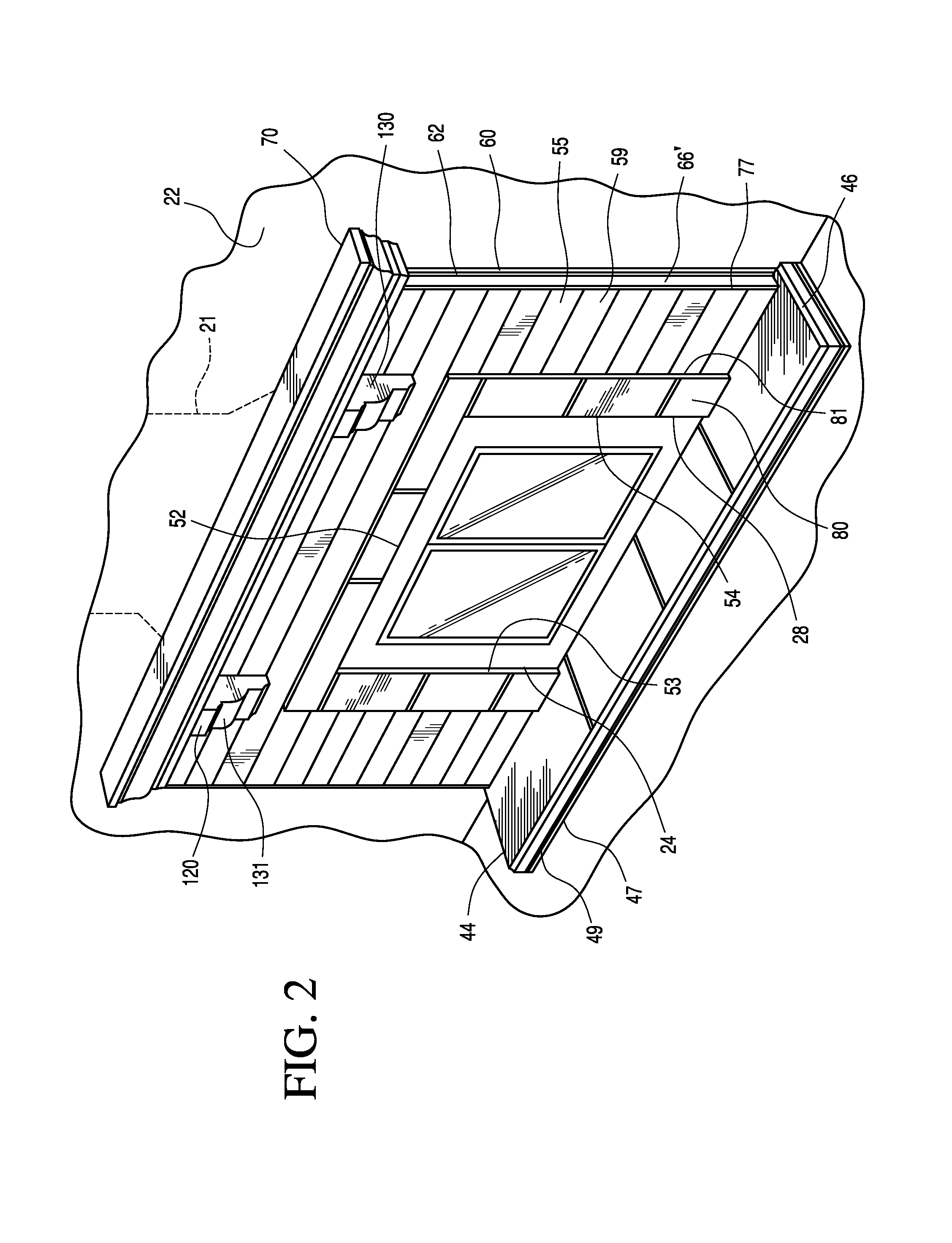

Fireplace surround system and method of making same

A modular fireplace surround assembly for a fireplace opening is formed from a plurality of surround components comprising a first set of components, having a foam core and a manufactured stone veneer shell, located at least 8 inches from the fireplace opening, and a second set of components formed of entirely noncombustible materials including manufactured stone veneer. The first set of components are adapted to receive fasteners that pass through the back member for either direct or indirect mounting to the wall. In one embodiment, the first set of components includes a mantel shelf formed of interconnected, main and top components. The second set of components also establishes a front facing formed of a plurality of modular, interchangeable blocks arranged about the top and sides of the fireplace opening.

Owner:BORAL STONE PRODS

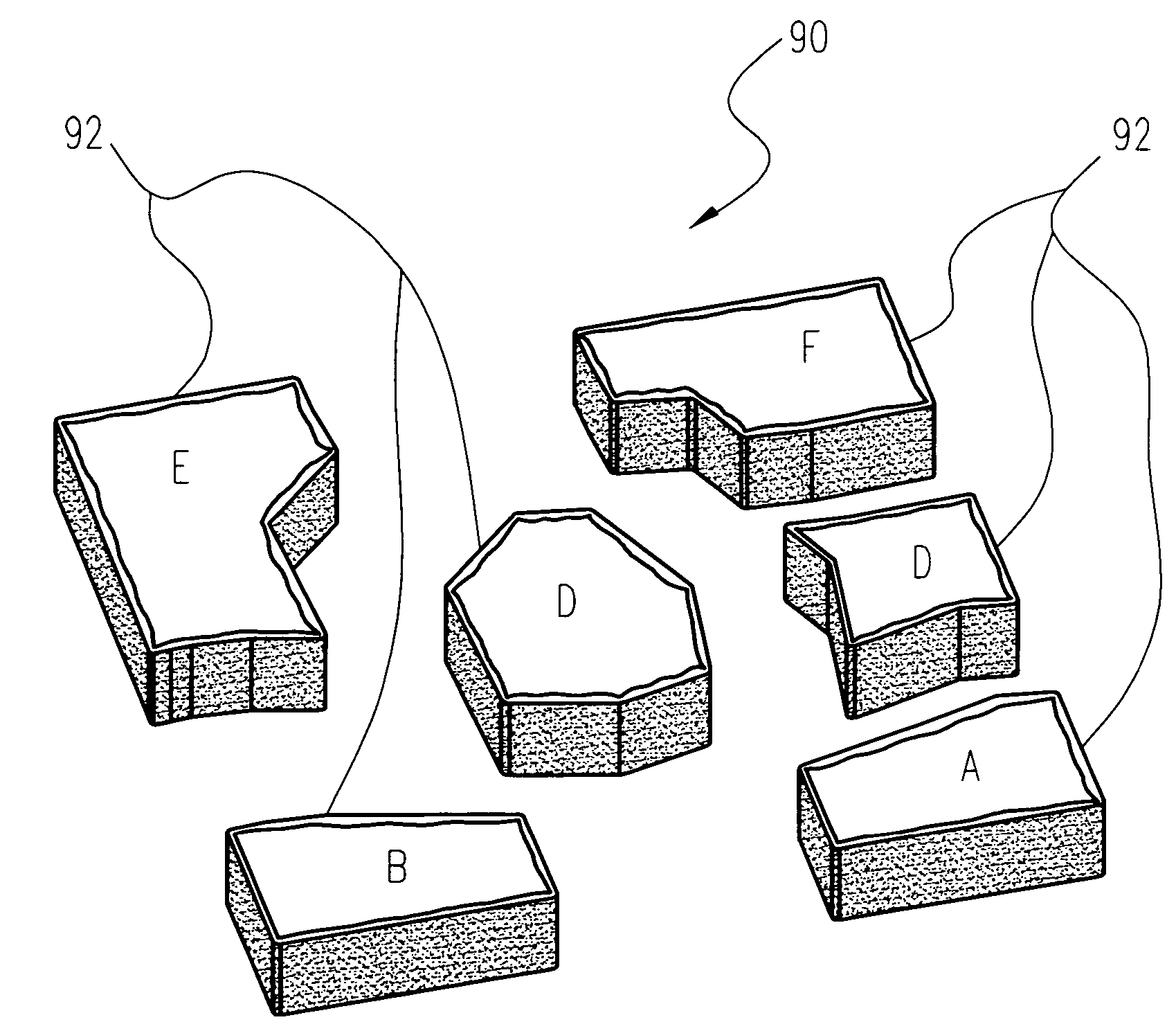

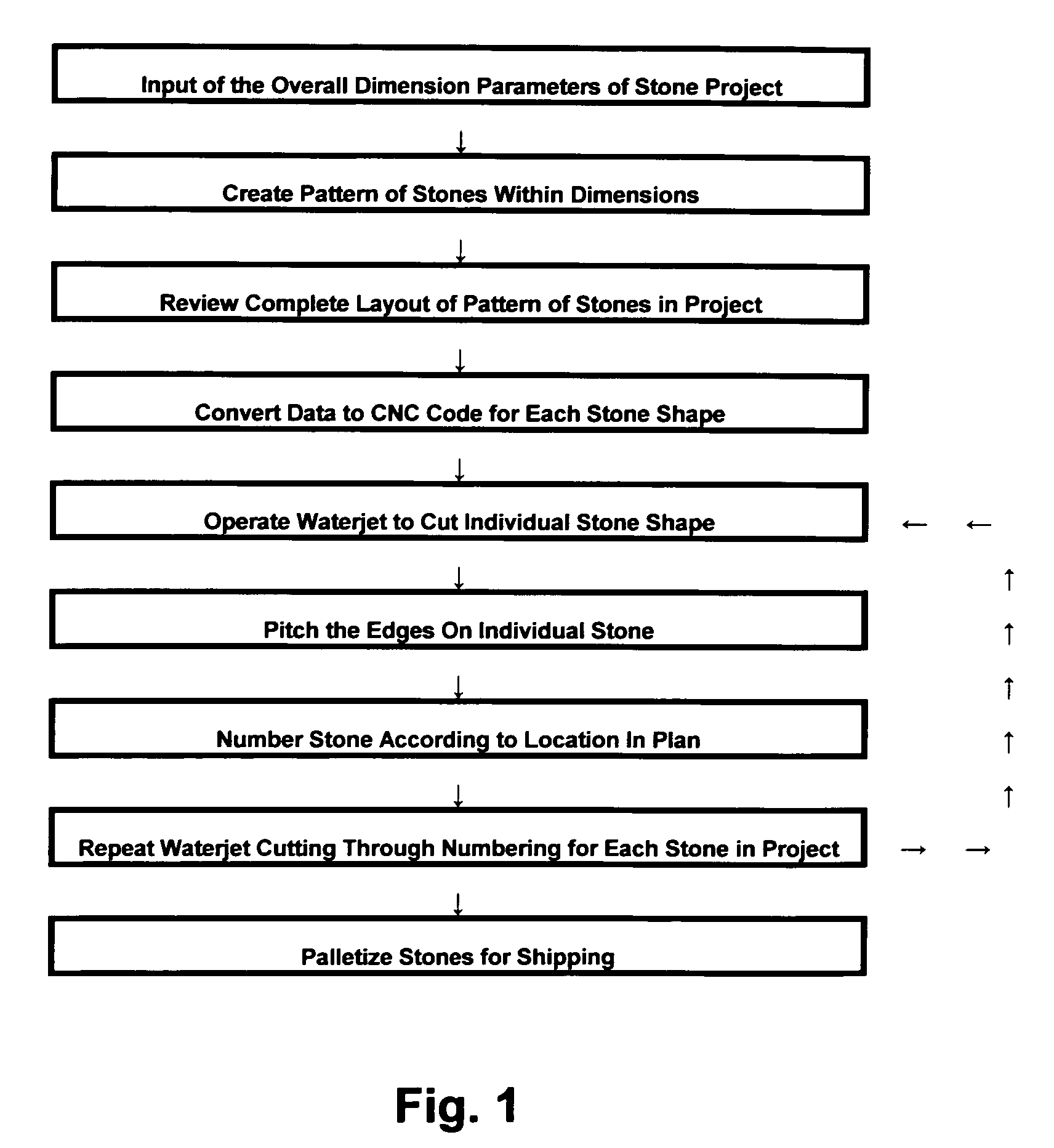

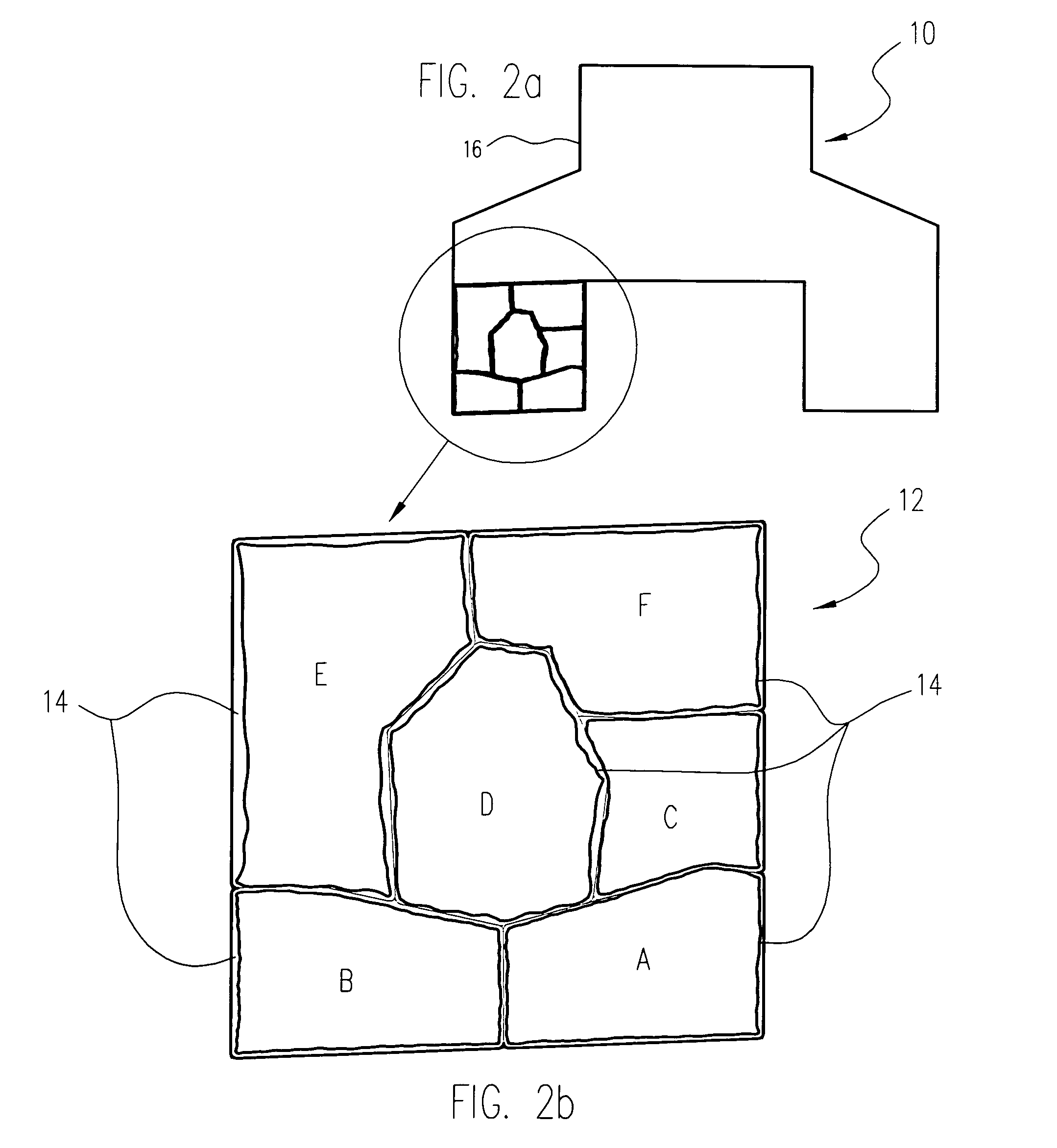

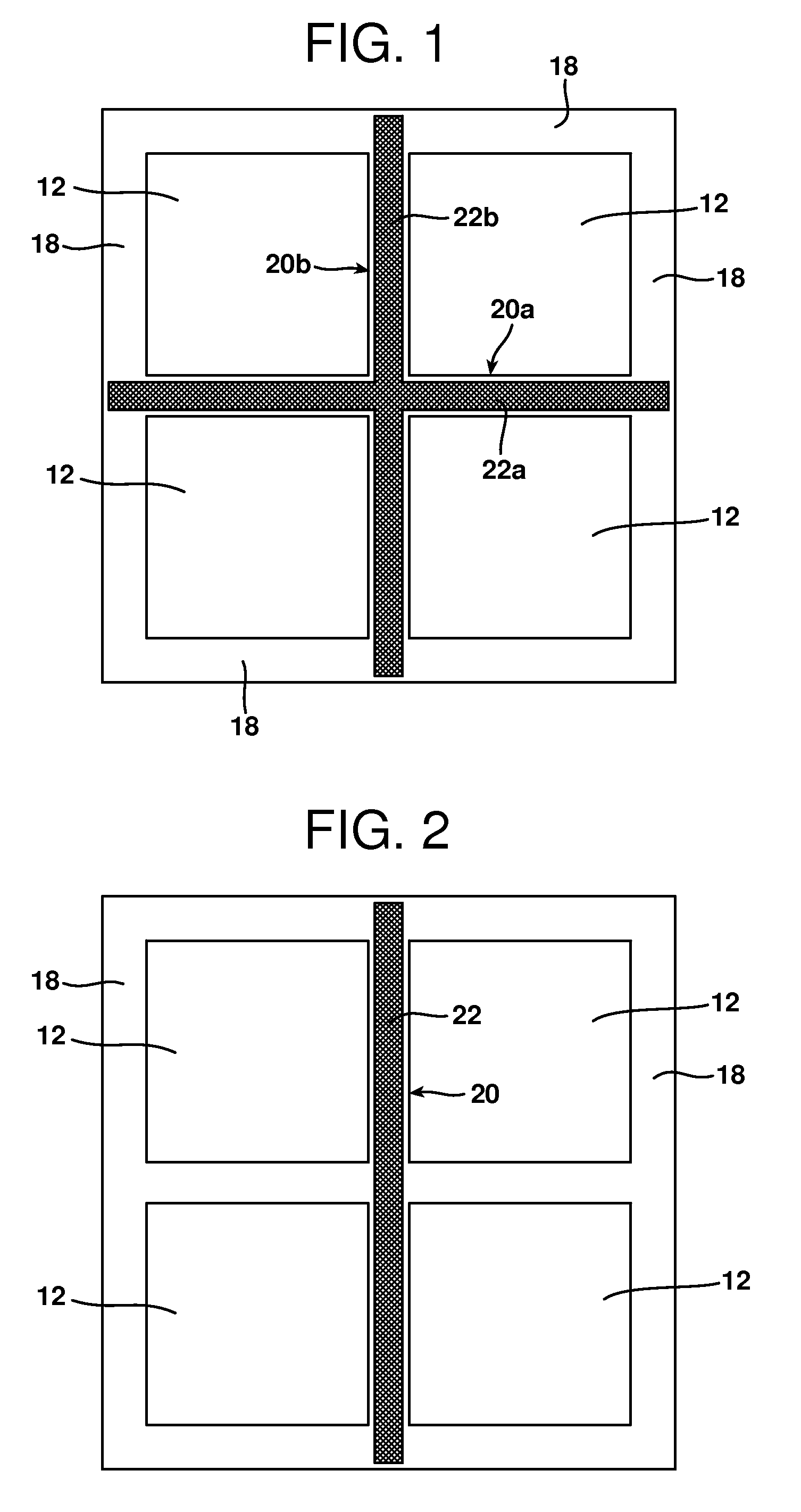

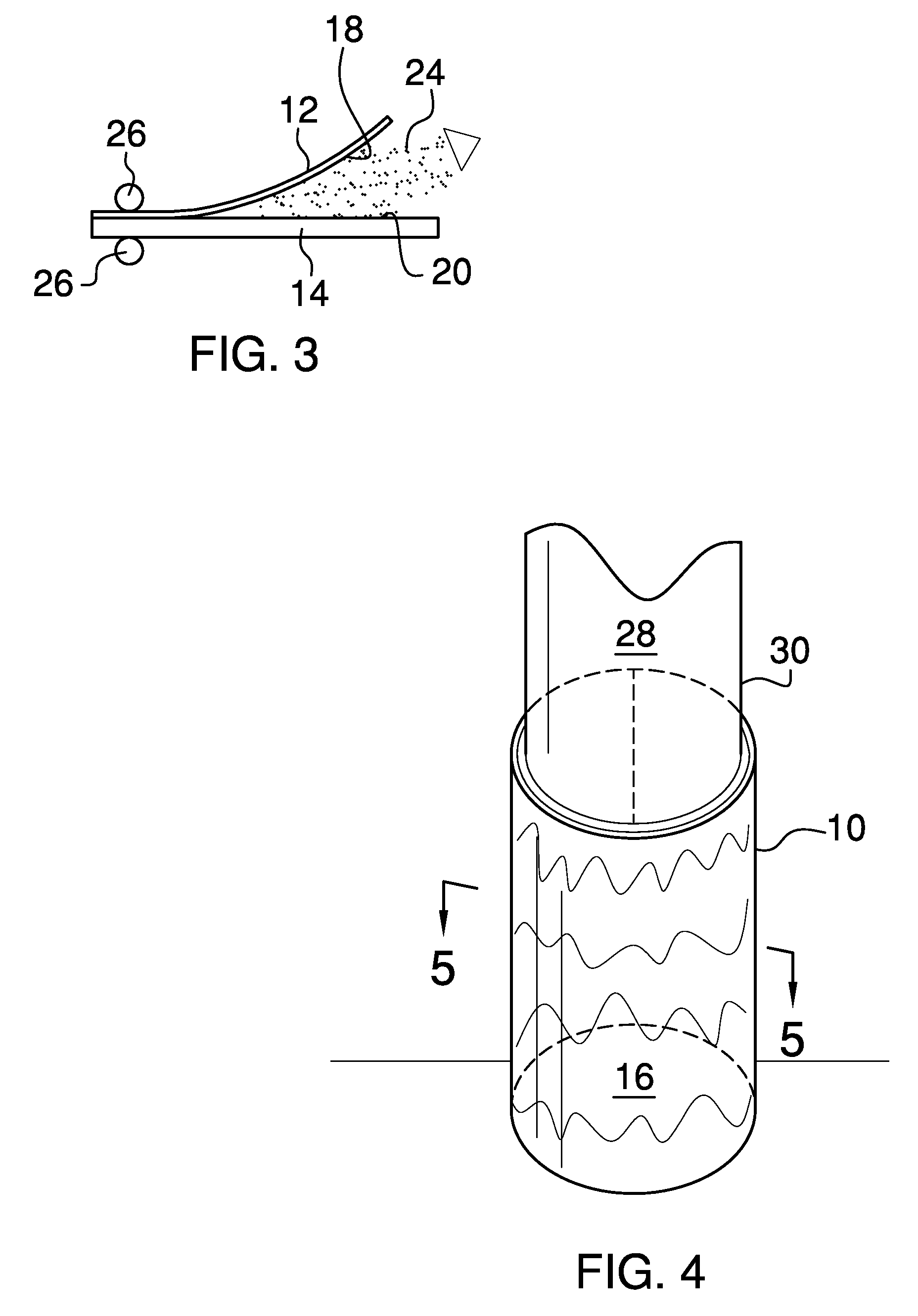

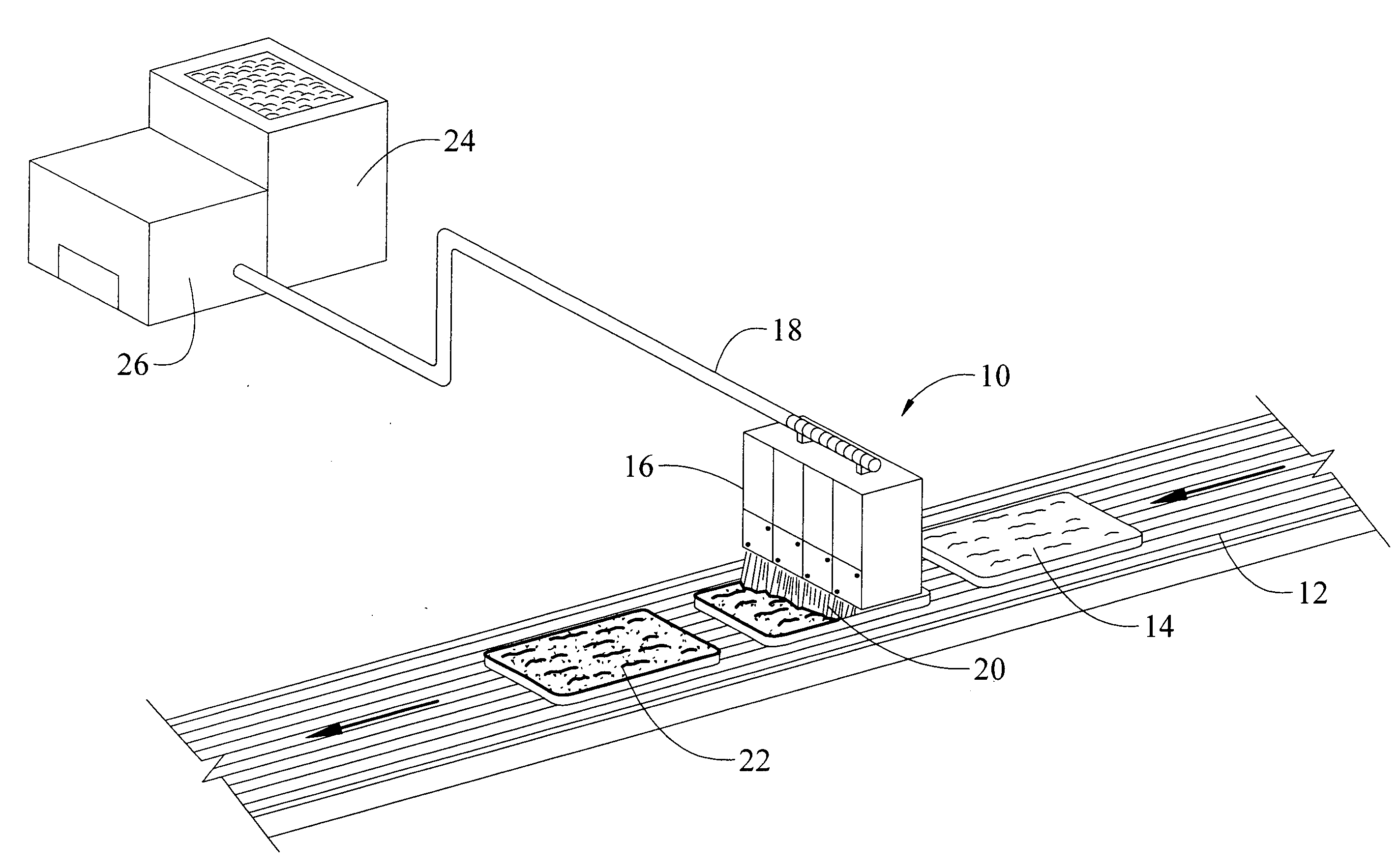

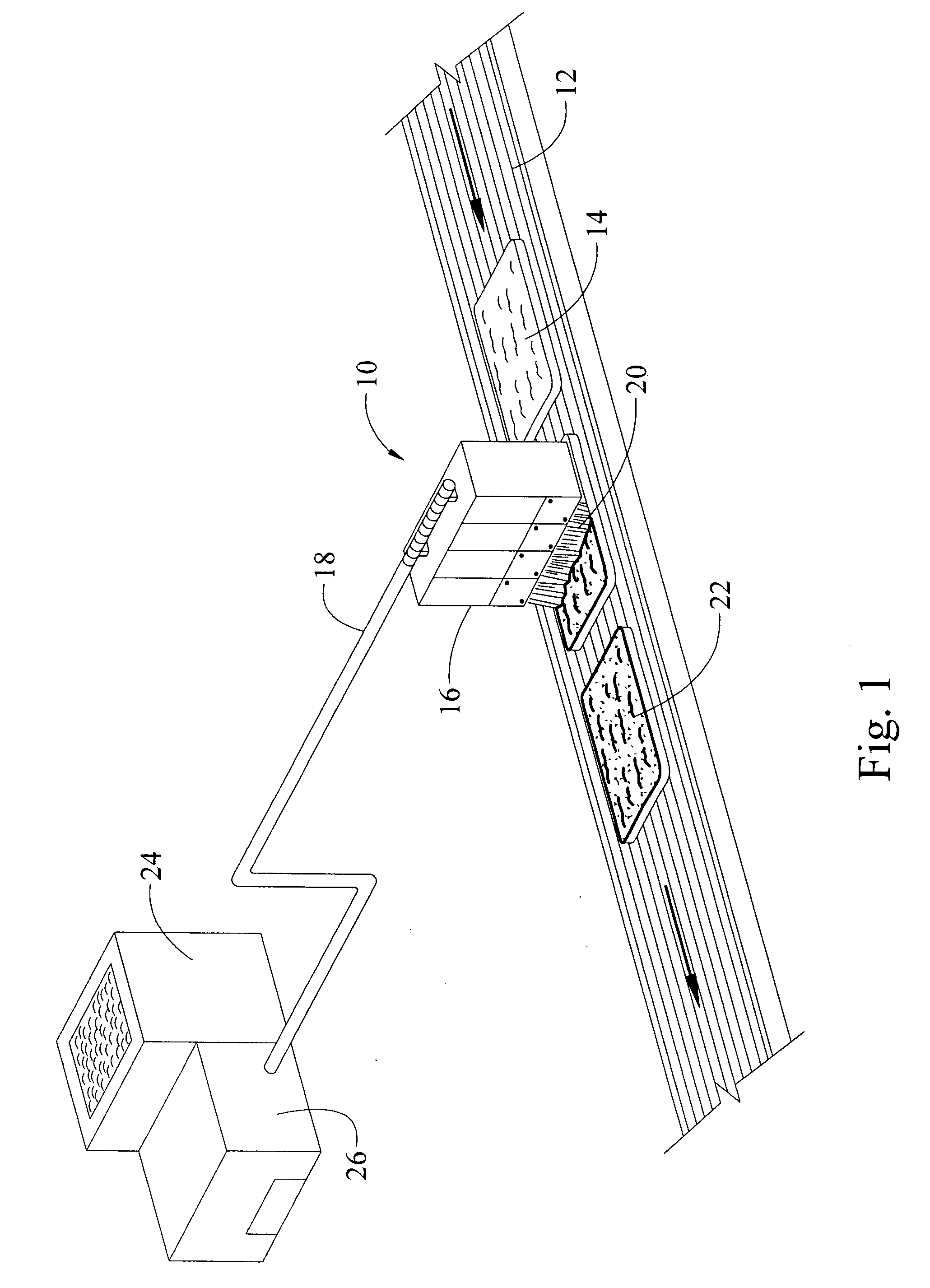

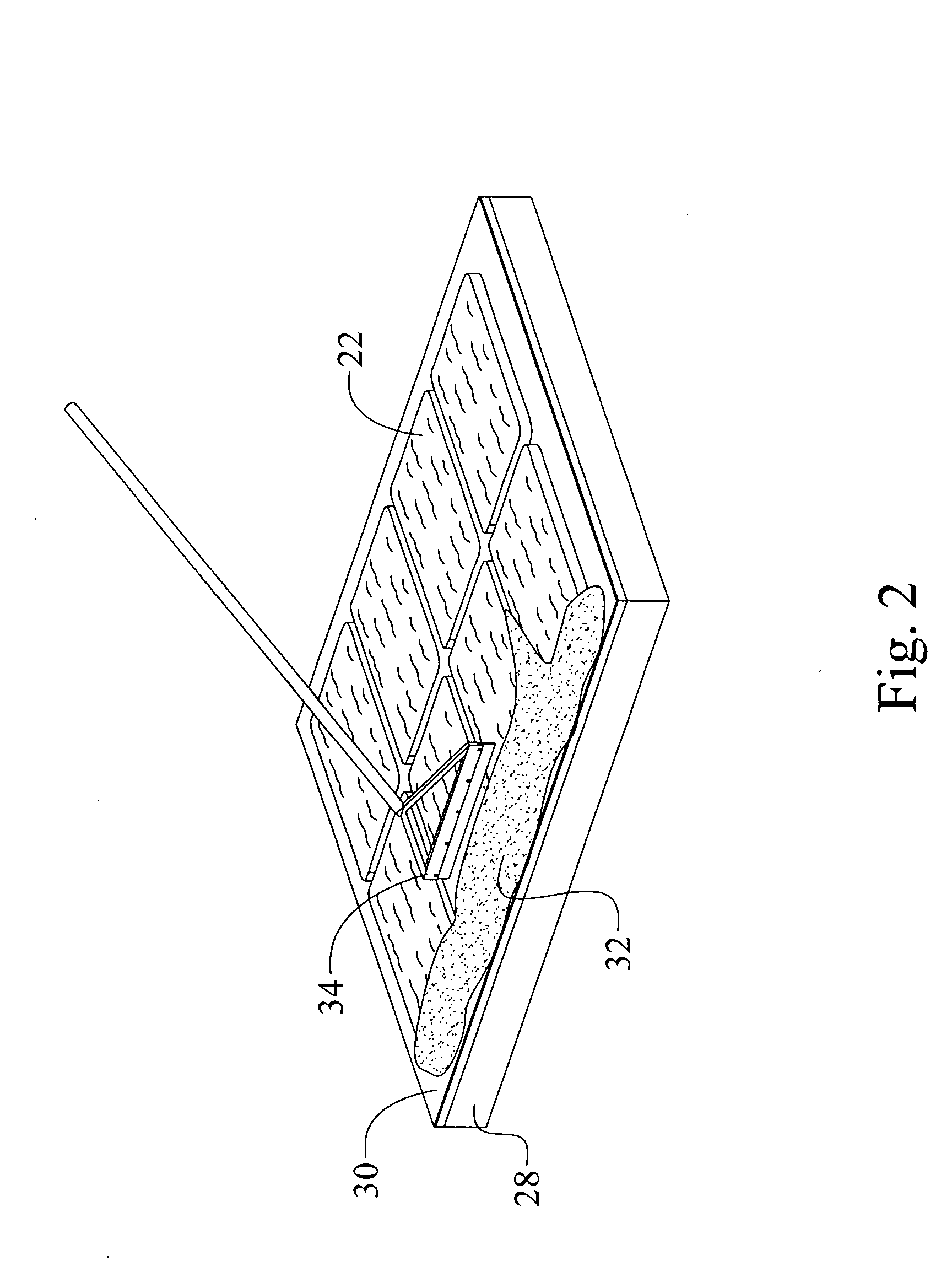

System for designing, previewing, and cutting natural stone veneer to deliver ready for installation

InactiveUS7489984B2Save effortShorten the timeGrinding feed controlAbrasive feedersDesign planEngineering

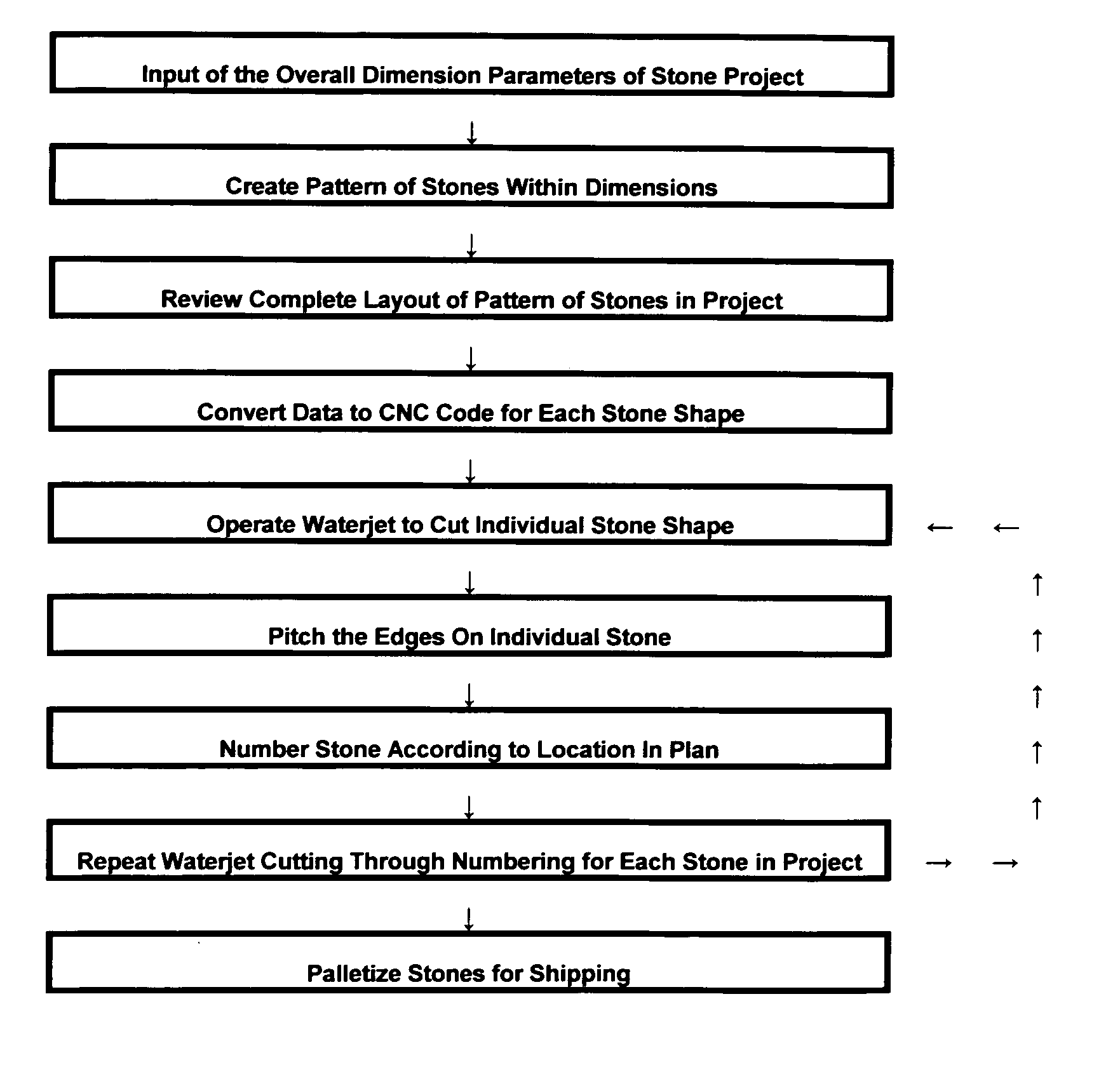

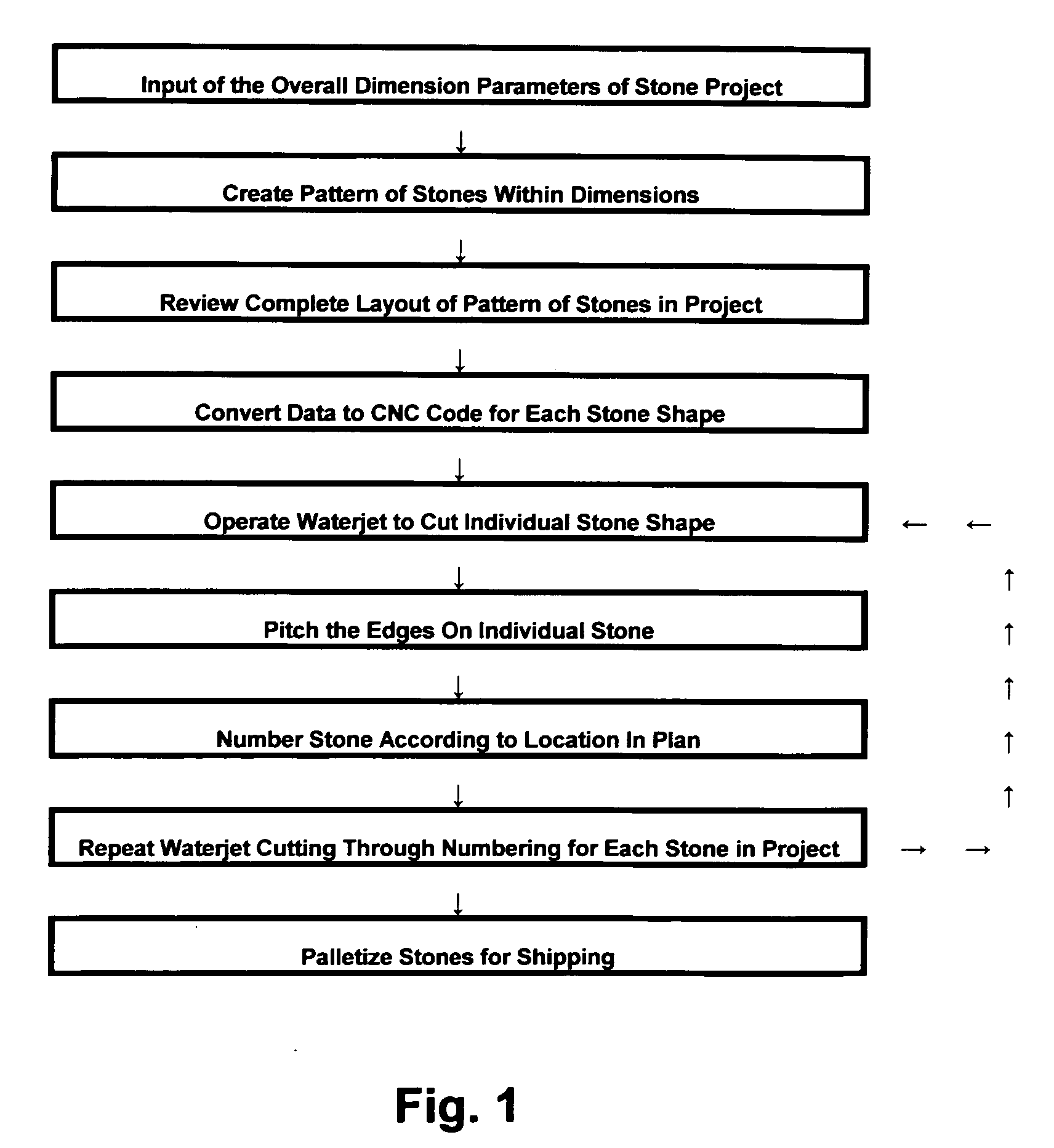

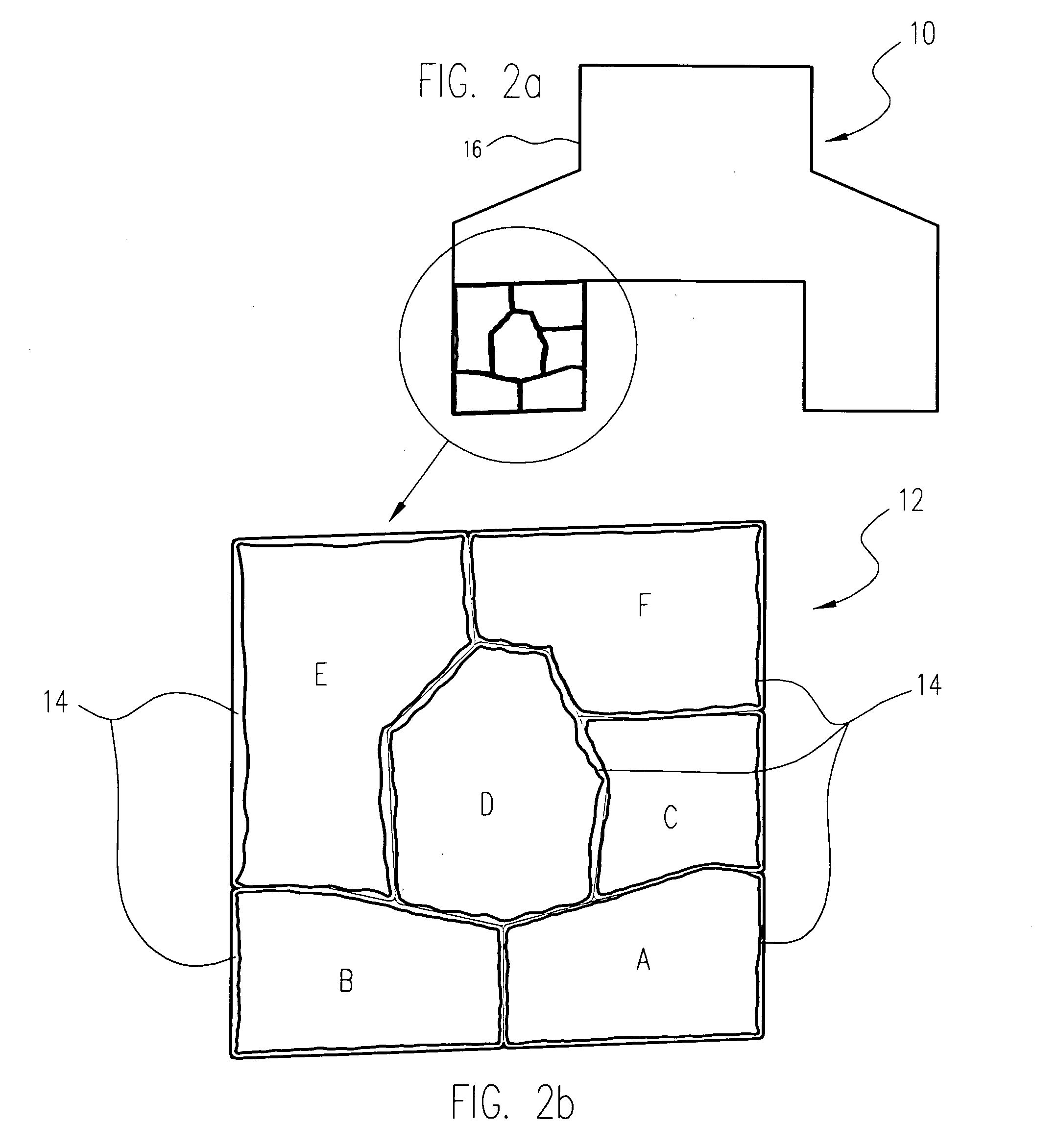

The present invention relates to a method of designing, previewing a stone veneer project in its entirety before a single stone is cut; cutting and finishing the edges of a stone to form interconnecting natural stone veneer components, each having a perimeter of a pre-determined contour and a finished edge, the method comprising: drawing or otherwise importing a design plan comprising overall dimensions and shape of a finished stone veneer project; drawing or otherwise importing a pattern of shape and placement of the stone veneer components within the design plan; programming, scanning or otherwise inputting a plurality of cutting patterns, wherein the cutting patterns are the same or different, each cutting pattern designed to form the stone veneer component having a perimeter of a pre-determined contour; converting the pattern into a machine-readable program to produce a cutting path on an abrasive waterjet machine; loading a cutting path file for the stone veneer component into the abrasive water jet machine; positioning a cutting head of the waterjet machine over the natural stone at a distance of from about 0.3 inch to about 4 inches from a contact surface of the stone; running the cutting path program and cutting through the stone by contacting the contact surface of the stone with a waterjet from the waterjet machine.

Owner:NEW WORLD STONEWORKS

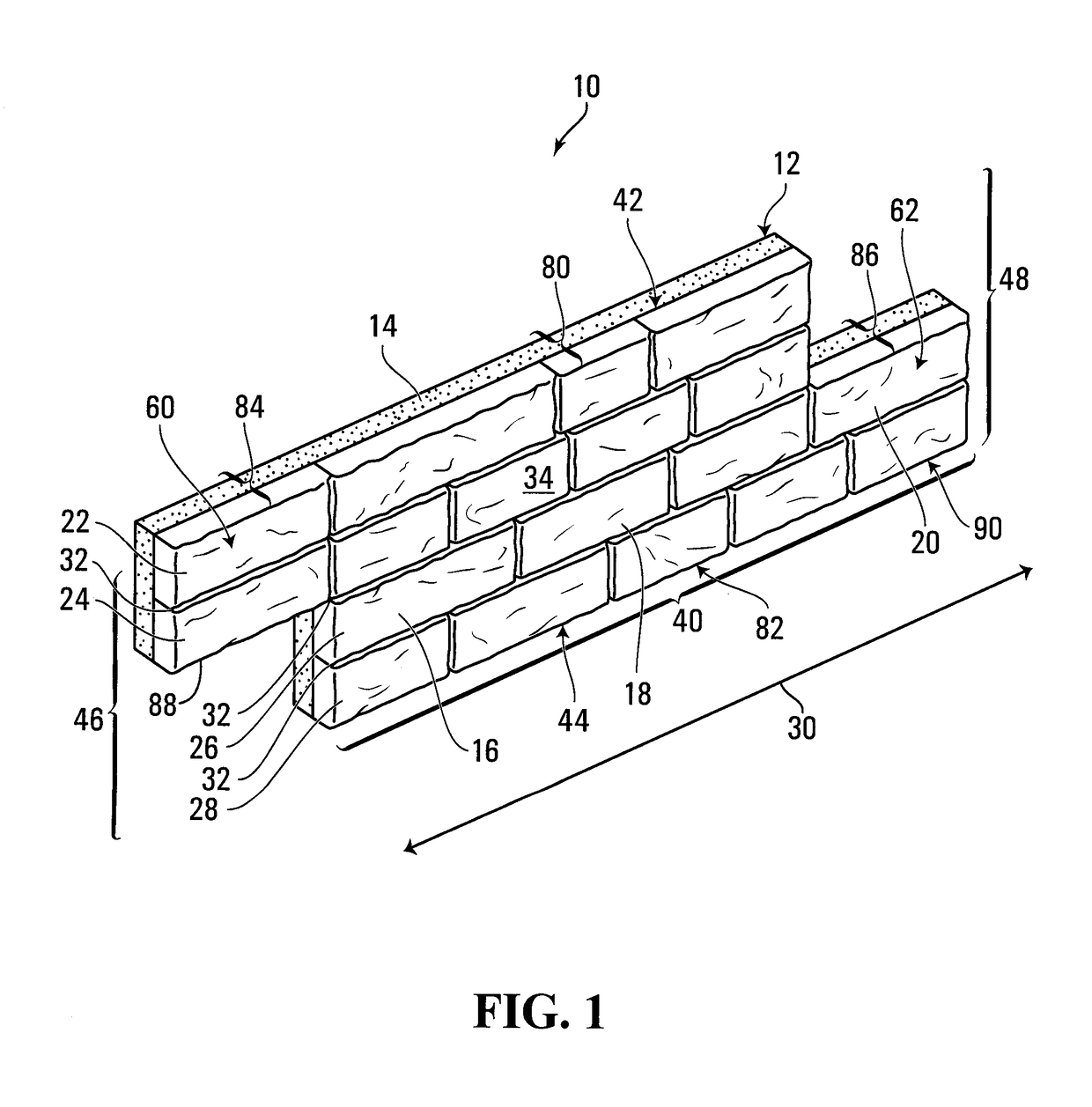

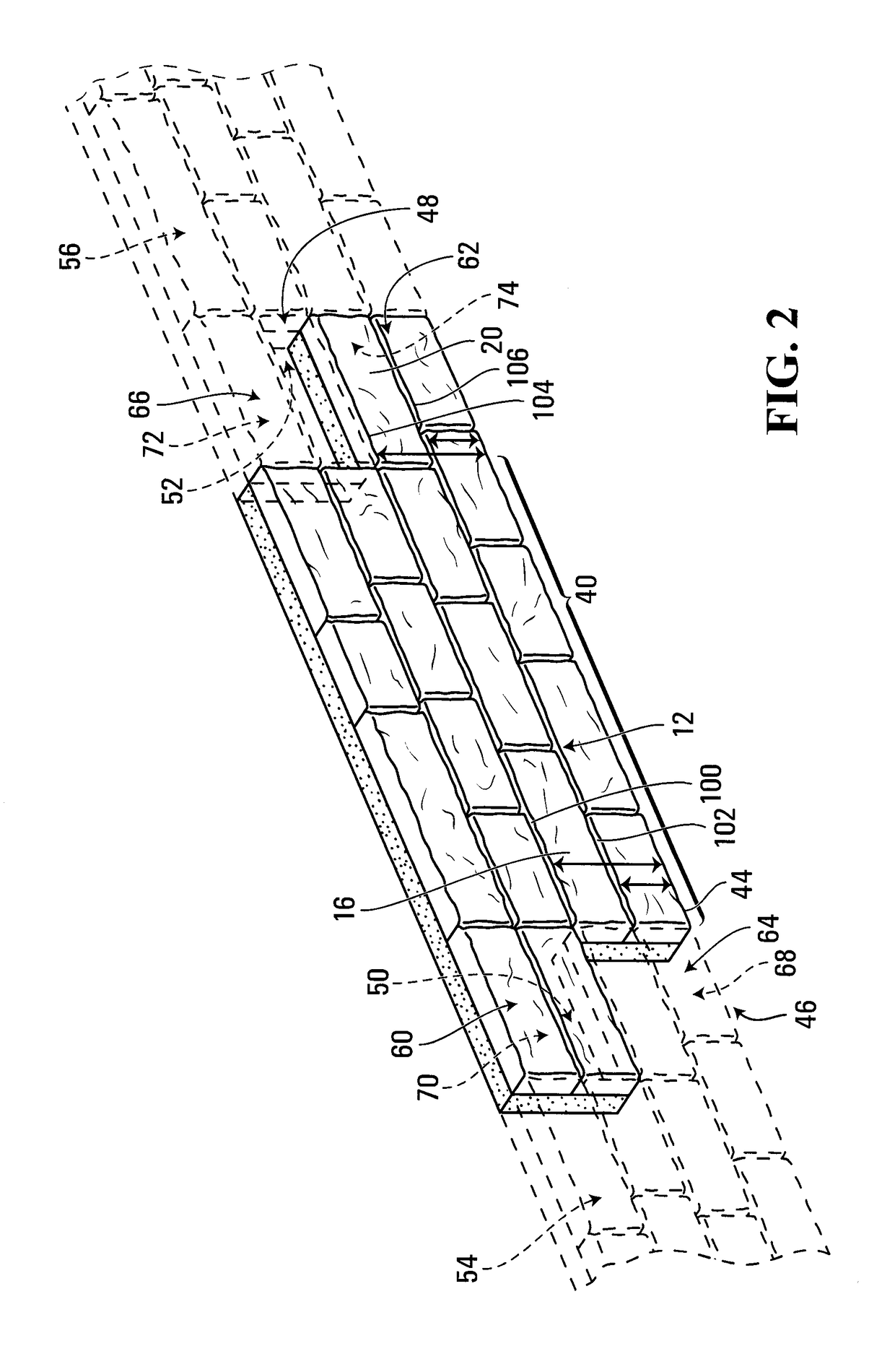

Natural rock panel, natural rock veneer panel and panel support apparatus

An architectural finish element operable to be placed adjacent similar architectural finish elements to form a finished surface on an architectural structure includes a body formed of a rock-based composite material comprising a low density solid particle additive, a plurality of unitary real stone veneer elements bonded to the body in courses extending in a first direction and in a random non-repetitive pattern, the real stone veneer elements having respective face surfaces generally lying in a plane to form an overall face surface of the architectural finish element. The low density solid particle additive is provided in an amount suitable to cause the architectural finish element to have a density of between about 10 to 15 pounds per square foot. The architectural finishing element may be mounted by mounting a portion of a body of at least one dual architectural finish element support to a surface of an architectural structure.

Owner:PACIFIC PREBENCHED

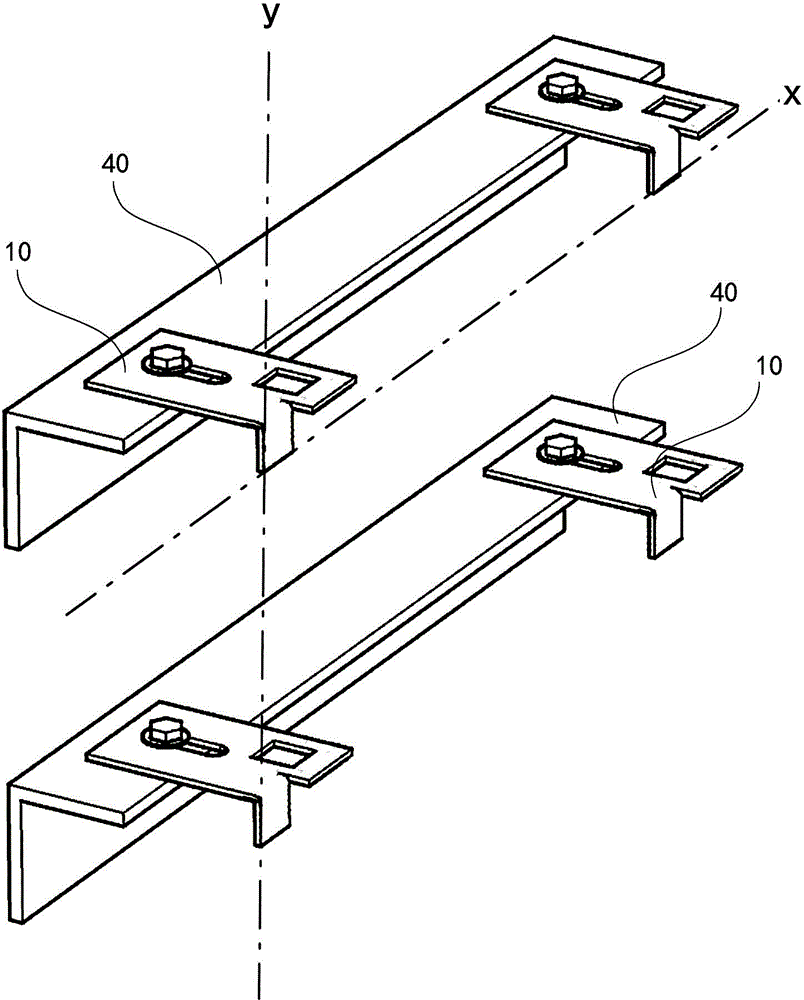

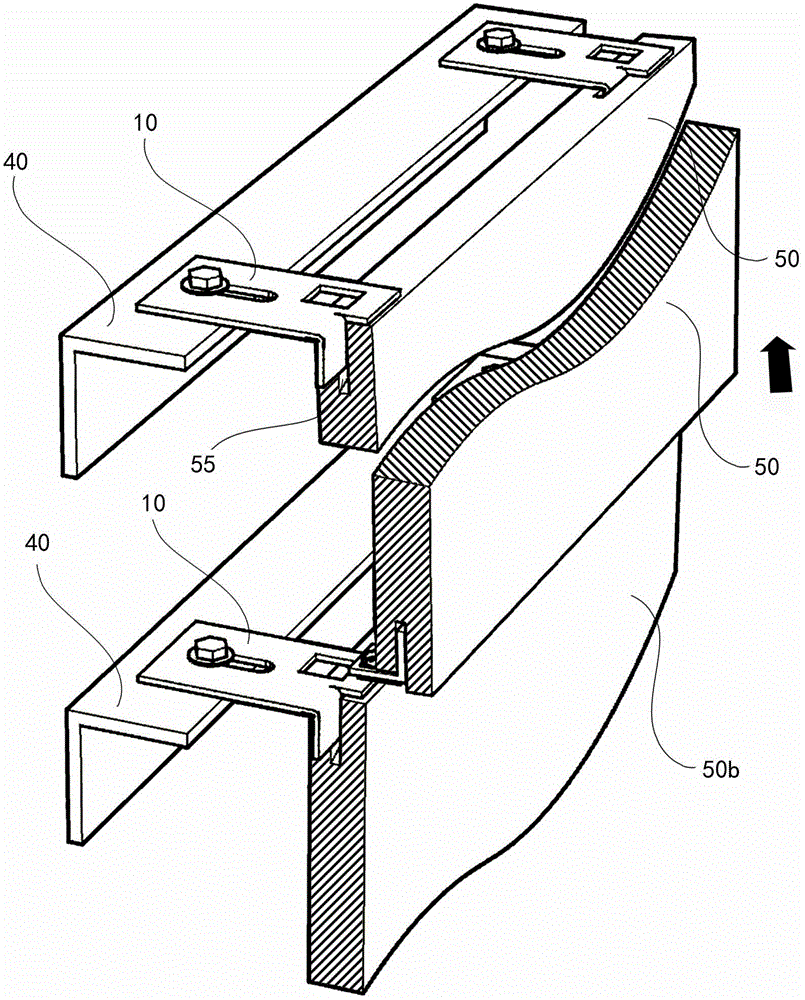

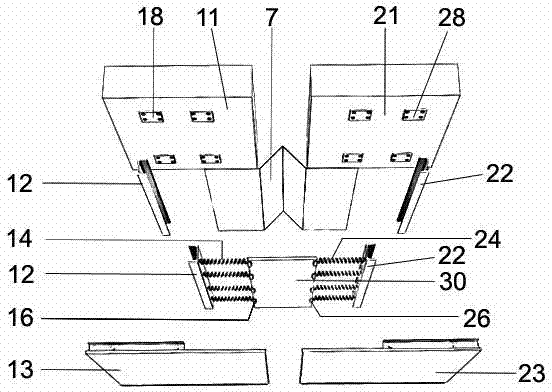

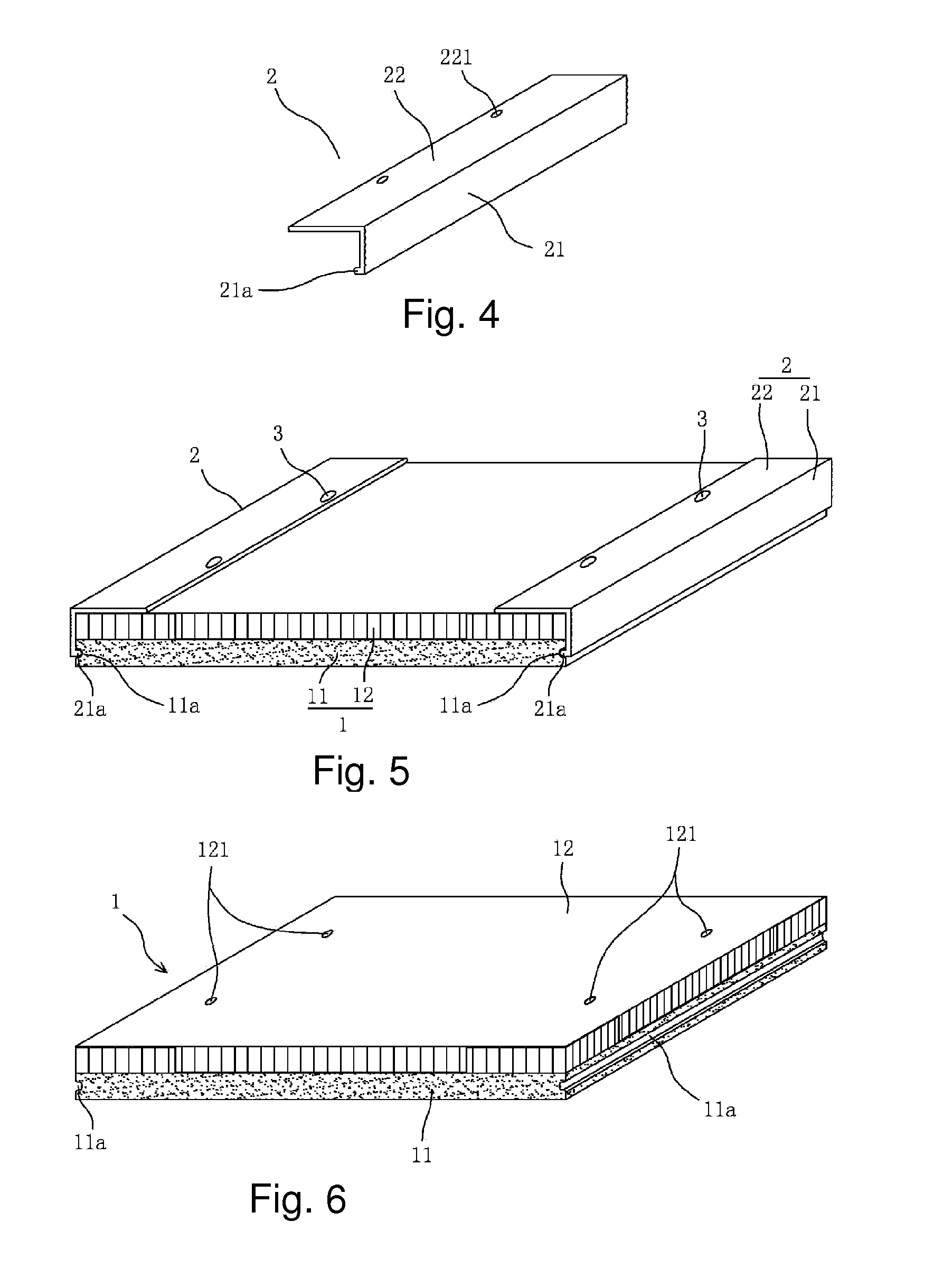

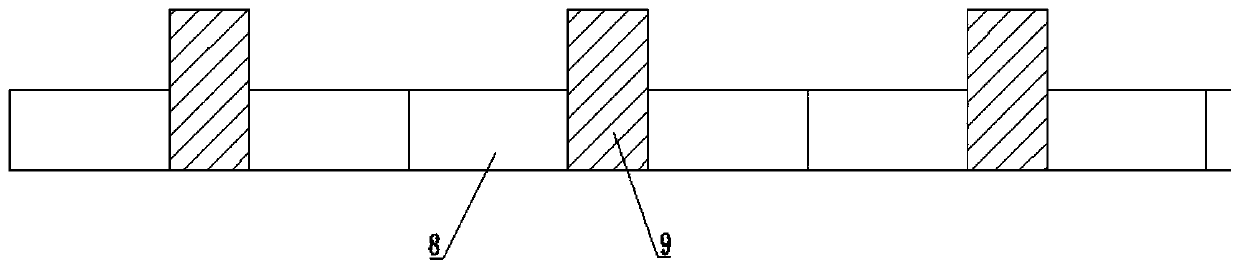

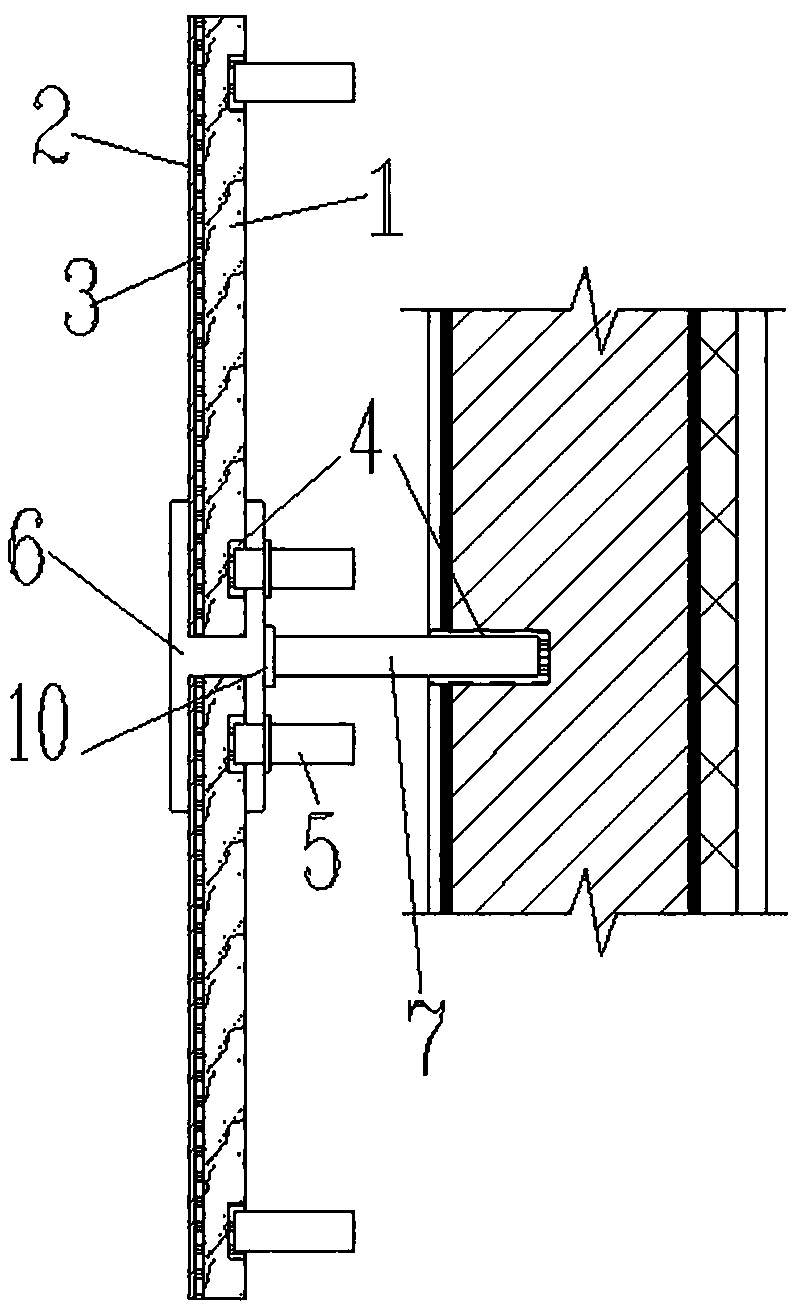

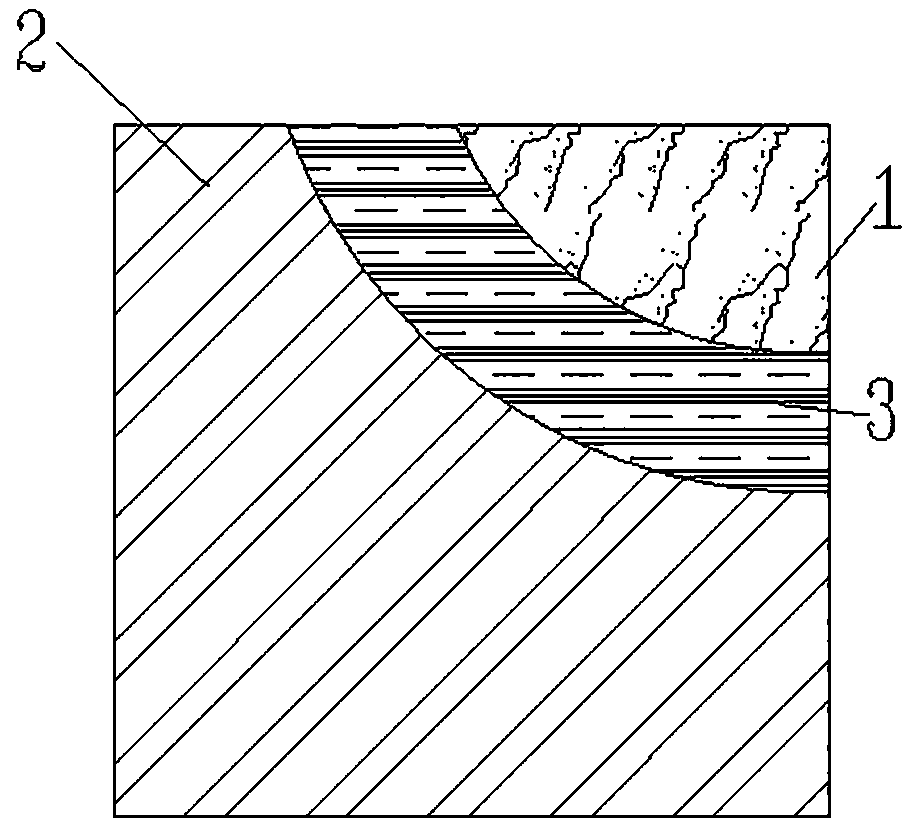

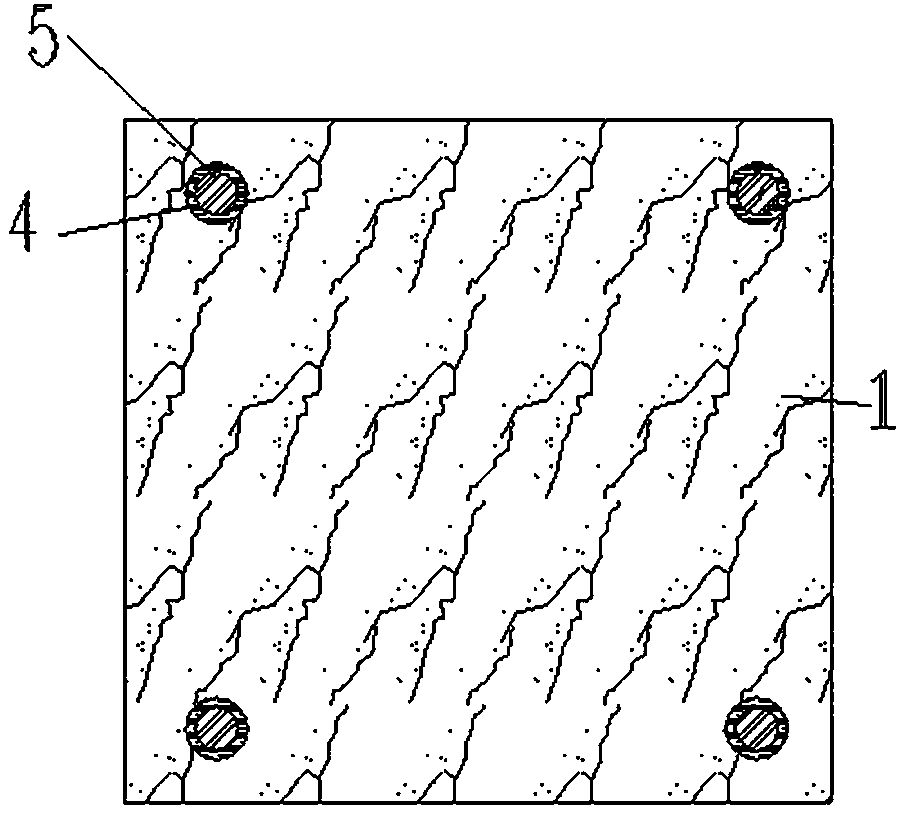

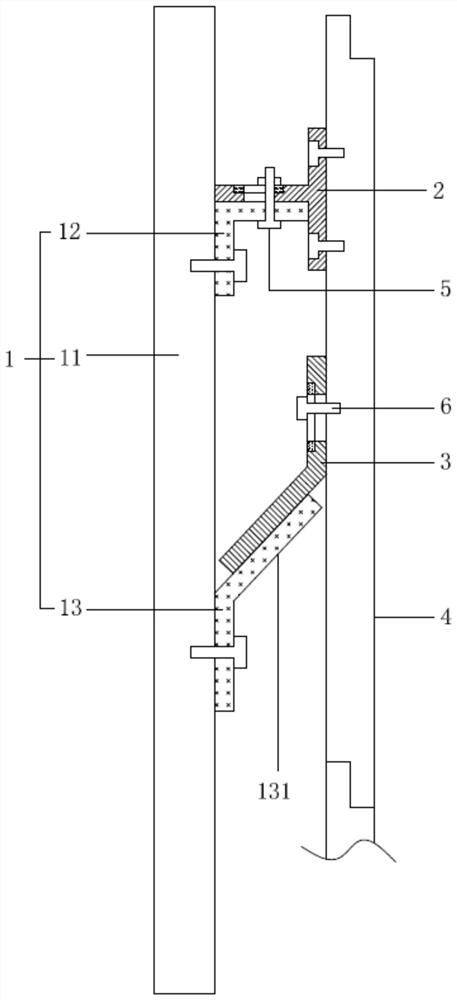

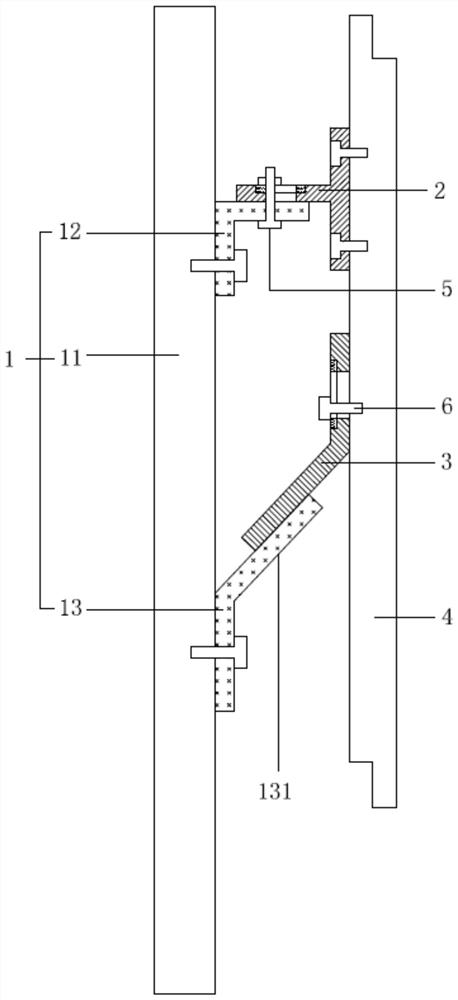

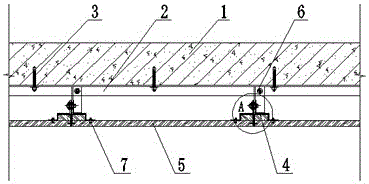

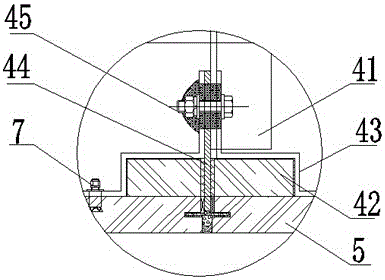

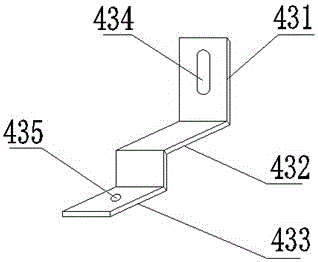

Dry hanging structure assembly and method for mounting stone veneer

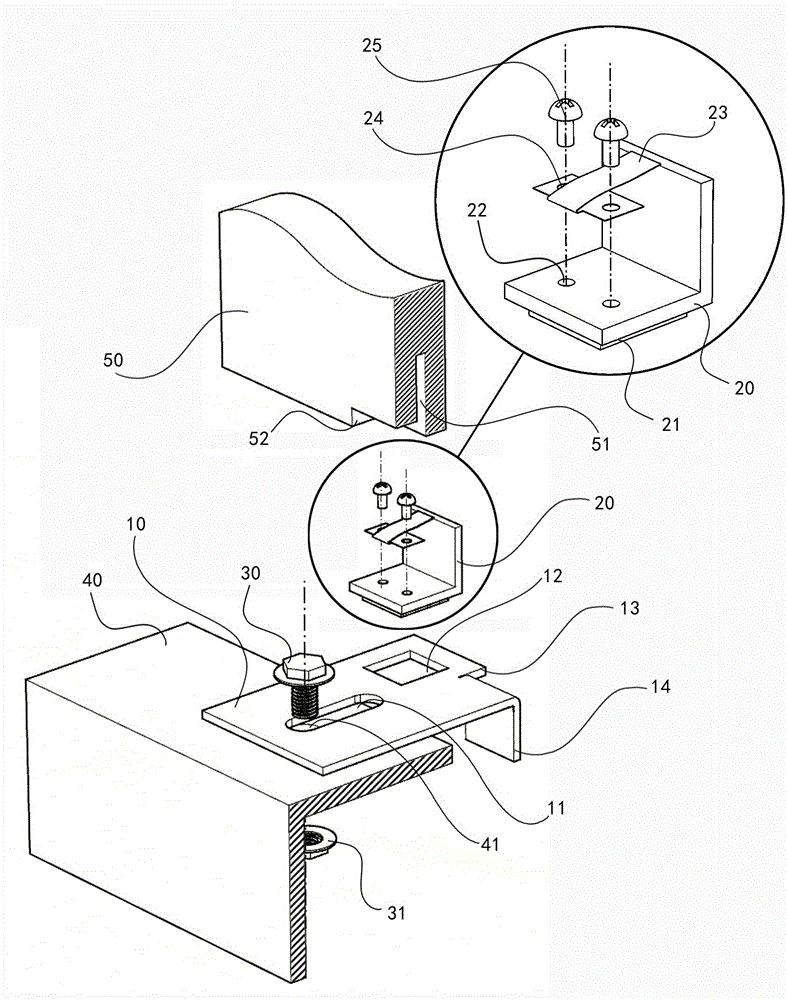

InactiveCN104831896AQuick installationAchieve disassemblyCovering/liningsBuilding material handlingStone veneerSteel structures

The invention discloses a dry hanging structure assembly for mounting a stone veneer. The dry hanging structure assembly consists of an angle steel strip, a hanging piece main body, an angle block, a bolt and the stone veneer, wherein the angle steel strip is mounted on a steel structure or a wall. The dry hanging structure assembly is characterized in that the hanging piece main body is vertically connected with the angle steel strip through the bolt; a lower hook strip in the front of the hanging piece main body and the angle block are cooperatively fixed with an upper hanging groove and a lower hanging groove correspondingly formed in the stone veneer respectively; a limiting groove is formed below the non-viewing surface of the stone veneer and is crossed with the lower hanging groove to form an opening capable of limiting the left-right movement of the angle block; a limiting block is arranged on the angle block and can be arranged in a square positioning hole corresponding to the limiting block. According to the dry hanging structure assembly for mounting the stone veneer, the stone veneer can be quickly disassembled.

Owner:CHONGQING ZHIRE TECH DEV CO

Panel suitable for constructing floor or wall covering

PendingCN110607893AReduce weightReduce thicknessCovering/liningsSolid waste managementMetallurgyStone veneer

The present invention relates to a panel suitable for constructing a floor or wall covering, having a substantially planar top surface, a substantially planar bottom surface, and at least one side edge, wherein the panel has a laminate structure which comprises a core layer basically composed of a composite material comprising a mixture of a ceramic material and a binder, a top layer fixed to thecore layer wherein the top layer comprises stone, ceramic or a real stone veneer, or a ceramic or porcelain ceramic or a stone mosaic.

Owner:财纳福诺木业(中国)有限公司

Granite heat-insulating outer wall coating

The invention discloses an outer wall coating, and in particular relates to a granite outer wall coating, which is suitable for outer wall coatings produced by architectural ornament industry. The granite outer wall coating is prepared from natural granite powder, pure acrylic emulsion, polyvinyl acetate emulsion, polyvinyl alcohol glue, phenylpropyl emulsion, water glass and bentonite in the weight part ratio of 90-110:15-35:5-15:10-20:15-25:0.5-1.5:1-3. The granite outer wall coating is used as the outer wall decorated coating, has the strong stereoscopic impression of coating surfaces, and the appearance is closely similar to that of tiles and stone, so the granite outer wall coating can be used as ideal substitutes of outer wall outer heat-insulating tile veneers and stone veneers; and the granite heat-insulating outer wall coating has the advantages of spectacularity, primitive simplicity, elegance, vivid and natural colors and shapes, scouring resistance, acid-base resistance, high strength and low production cost.

Owner:毛习杰

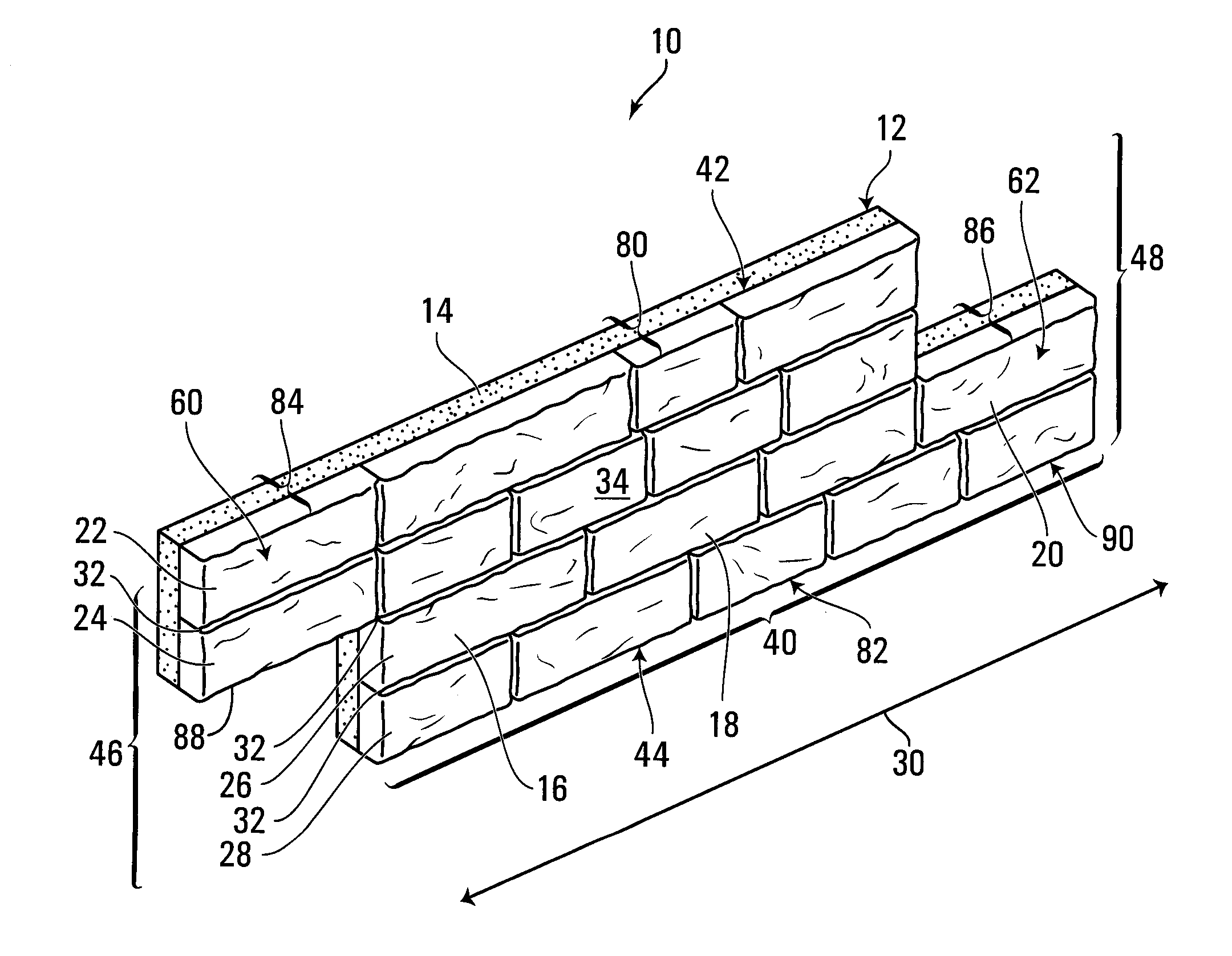

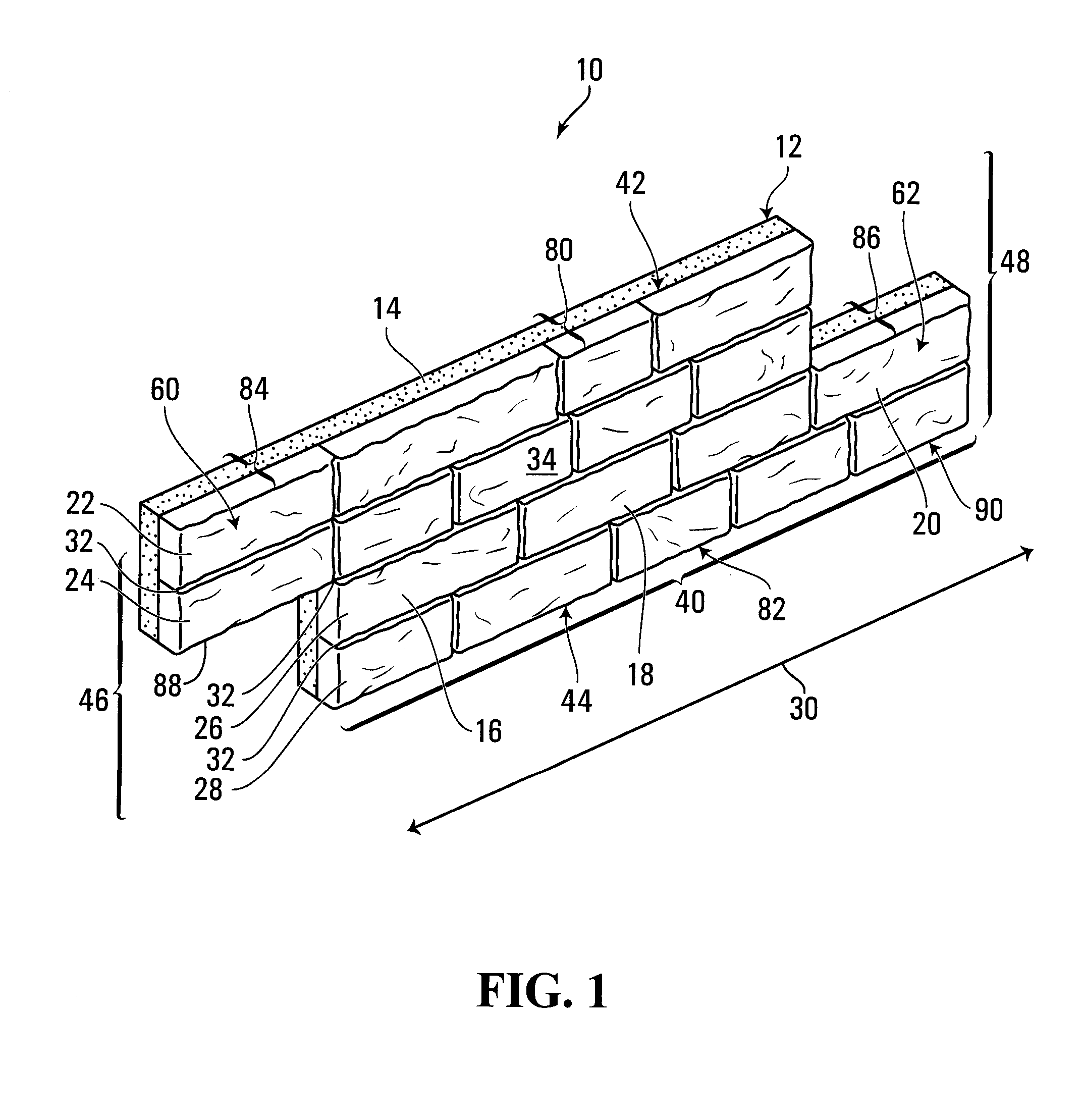

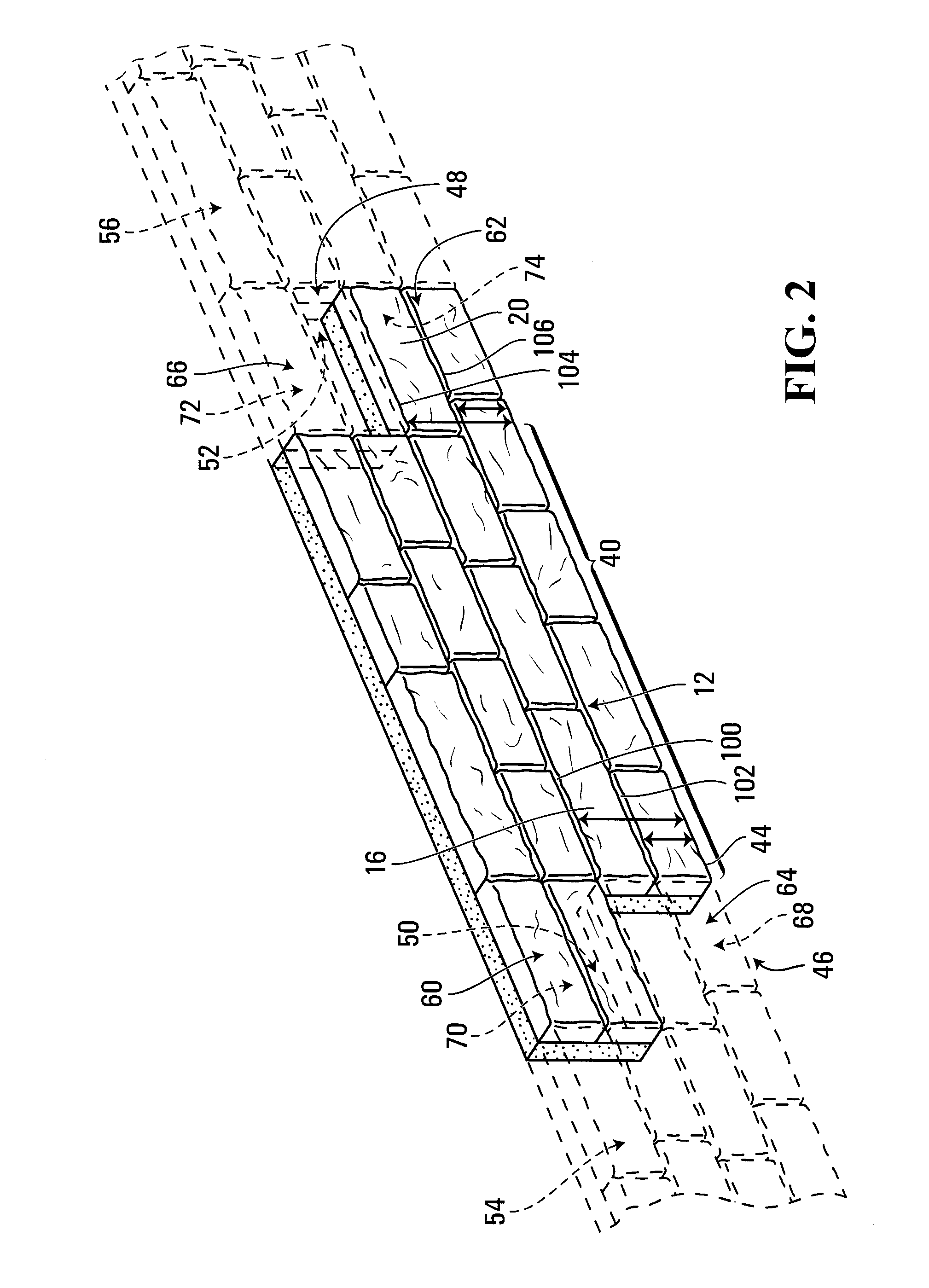

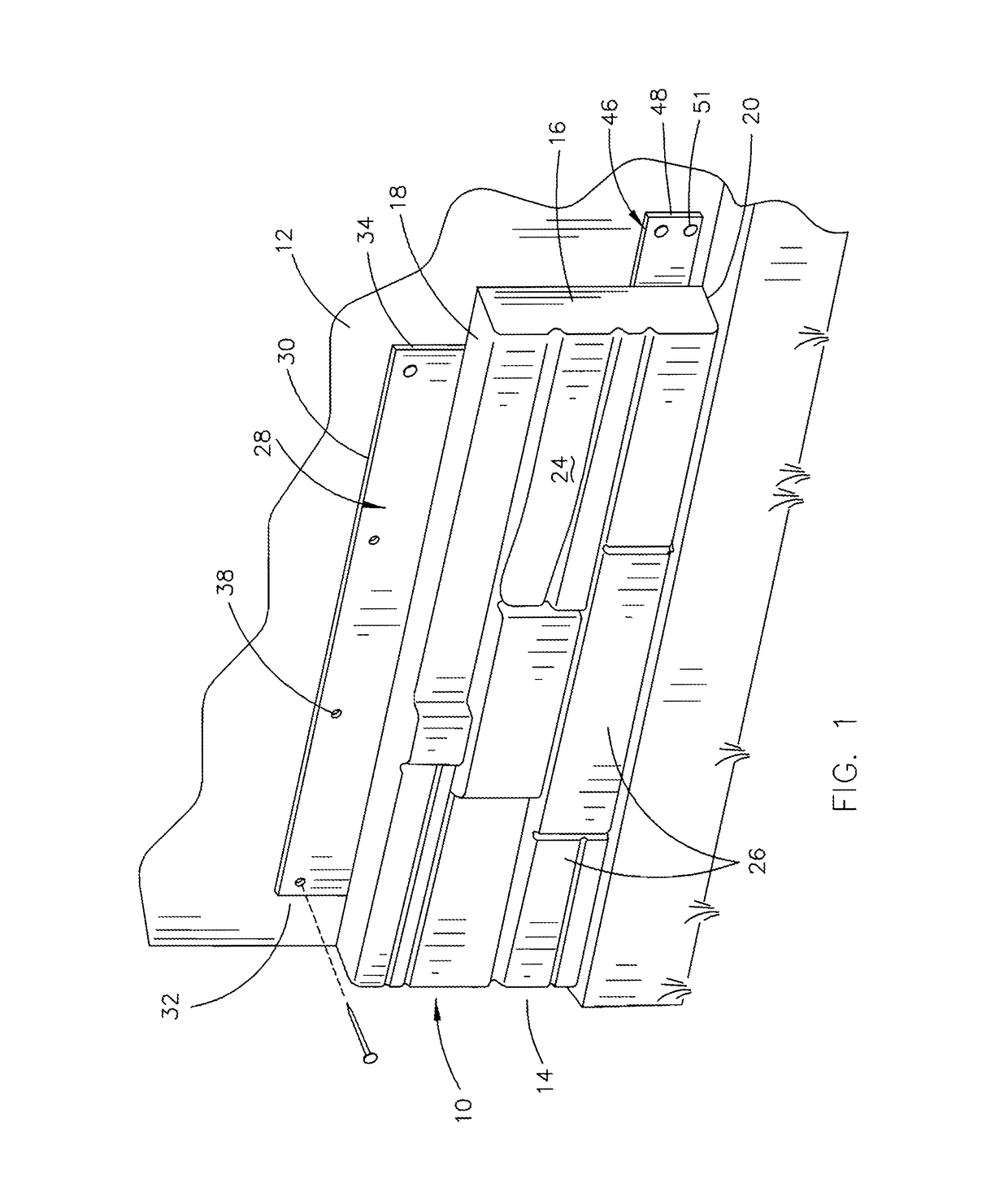

Mortarless stone veneer

A mortarless stone veneer is provided which is in a panel format and which has an upper end, a lower end, a first end, a second end, a front side and a rear side. An upper attachment flange has its lower end embedded in the rear side of the panel so as to extend upwardly therefrom. A first end attachment flange has its inner end embedded in the panel at the first end thereof. A second end attachment flange has its inner end embedded in the panel at the second end. The end attachment flanges are bendably movable between an extended attachment position and a folded position behind the panel.

Owner:COLLISON RYAN W

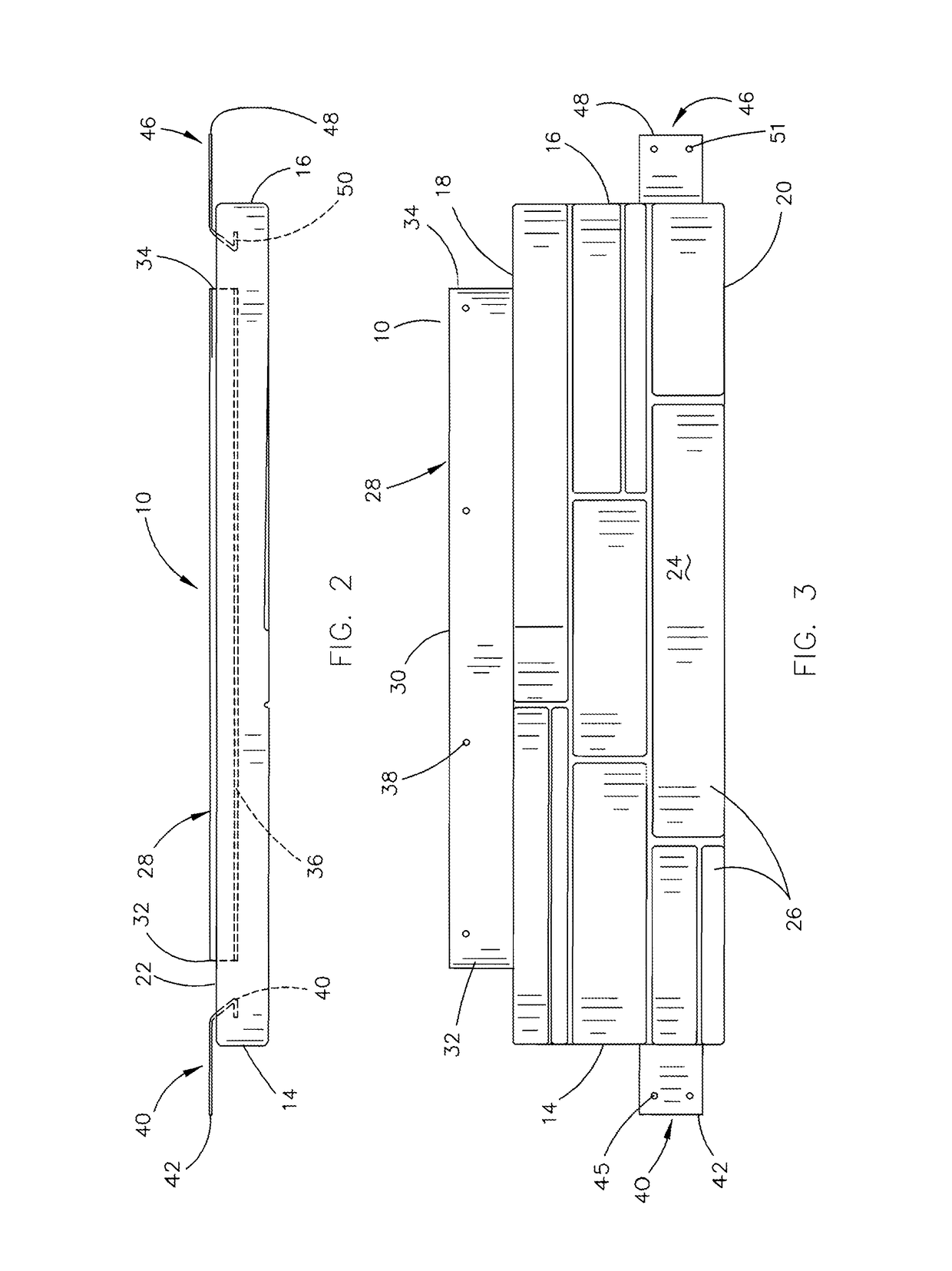

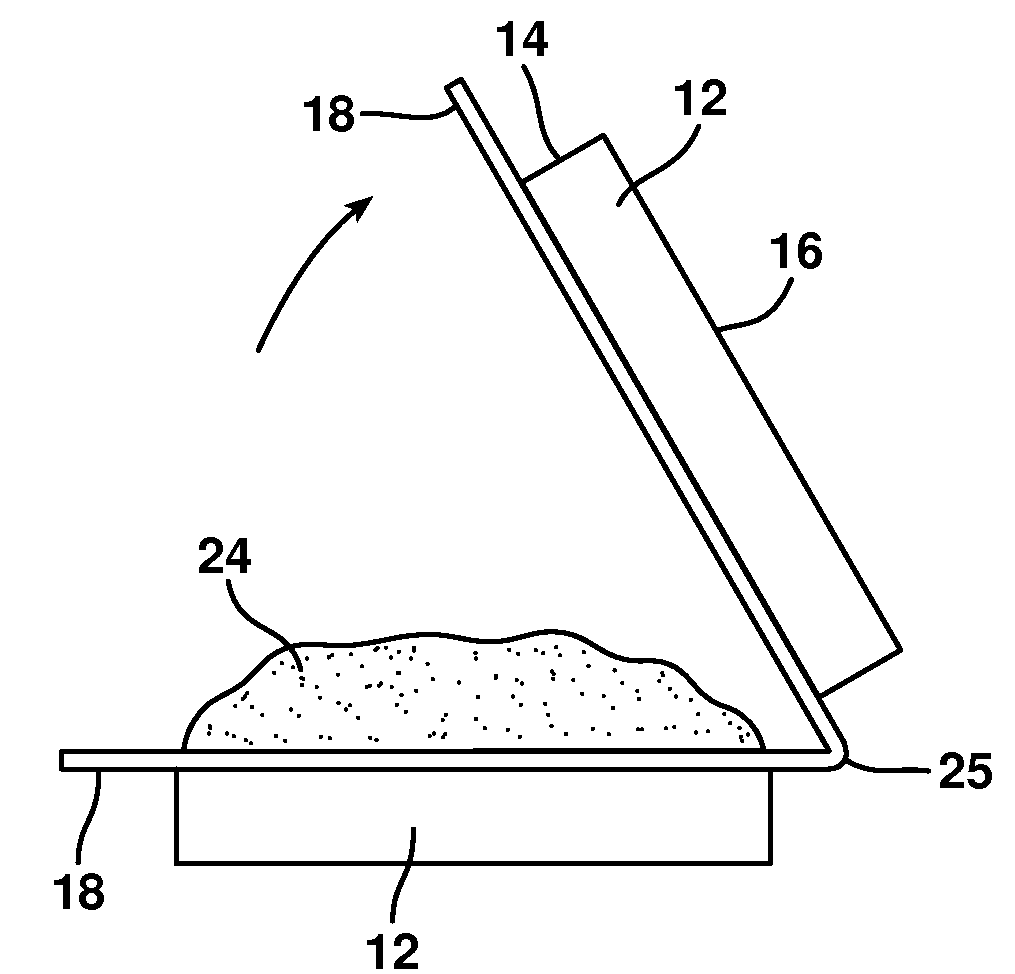

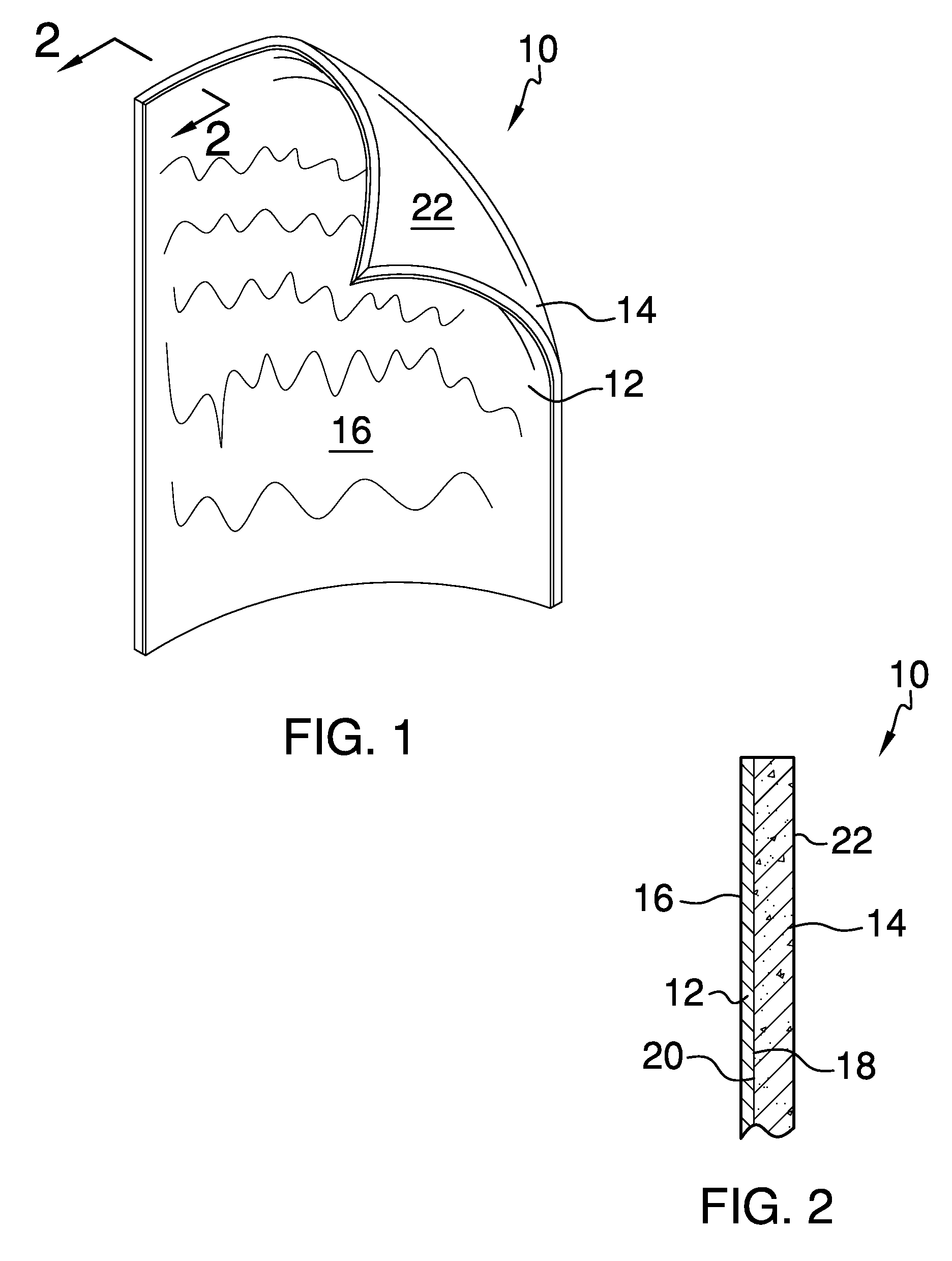

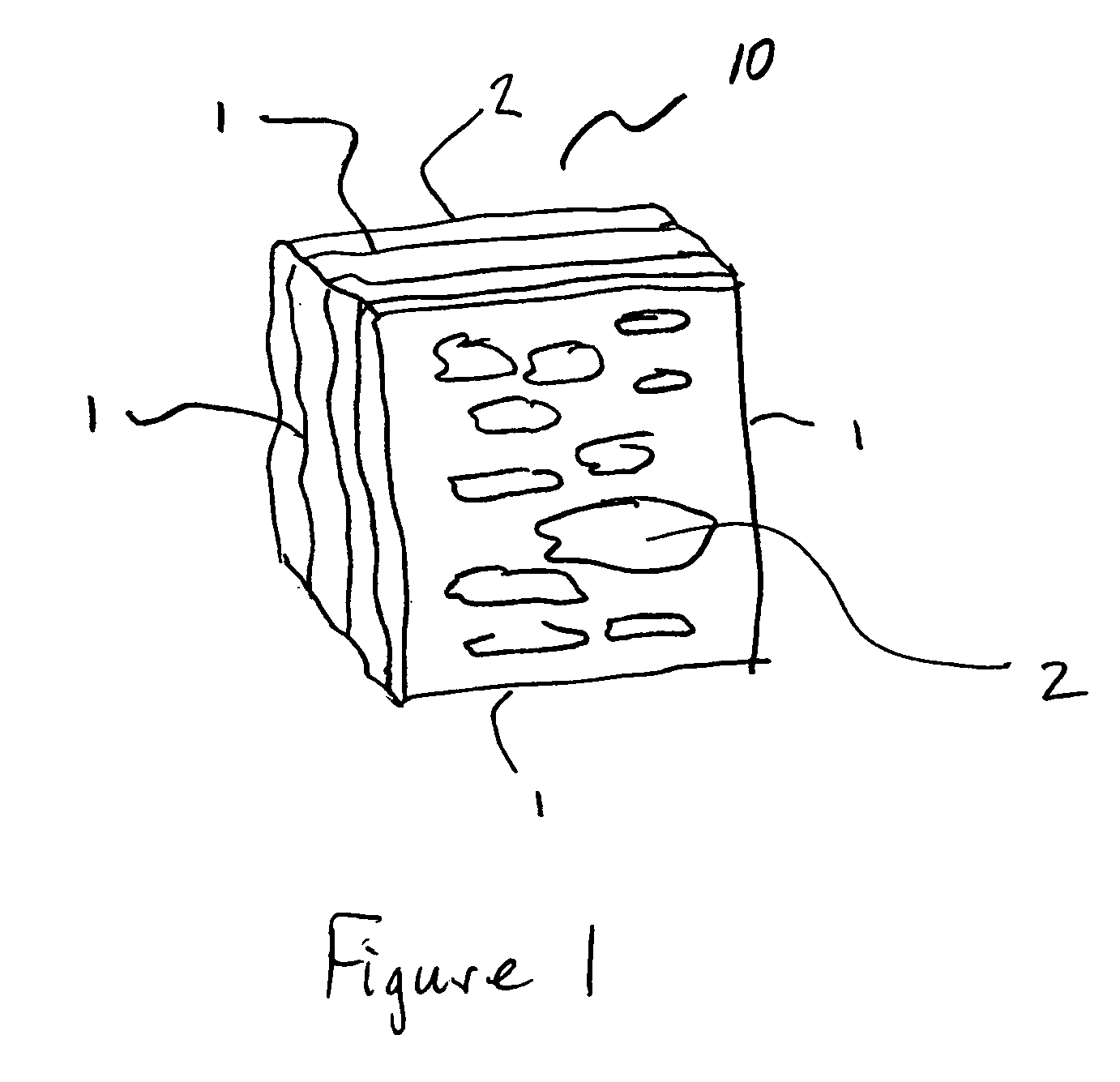

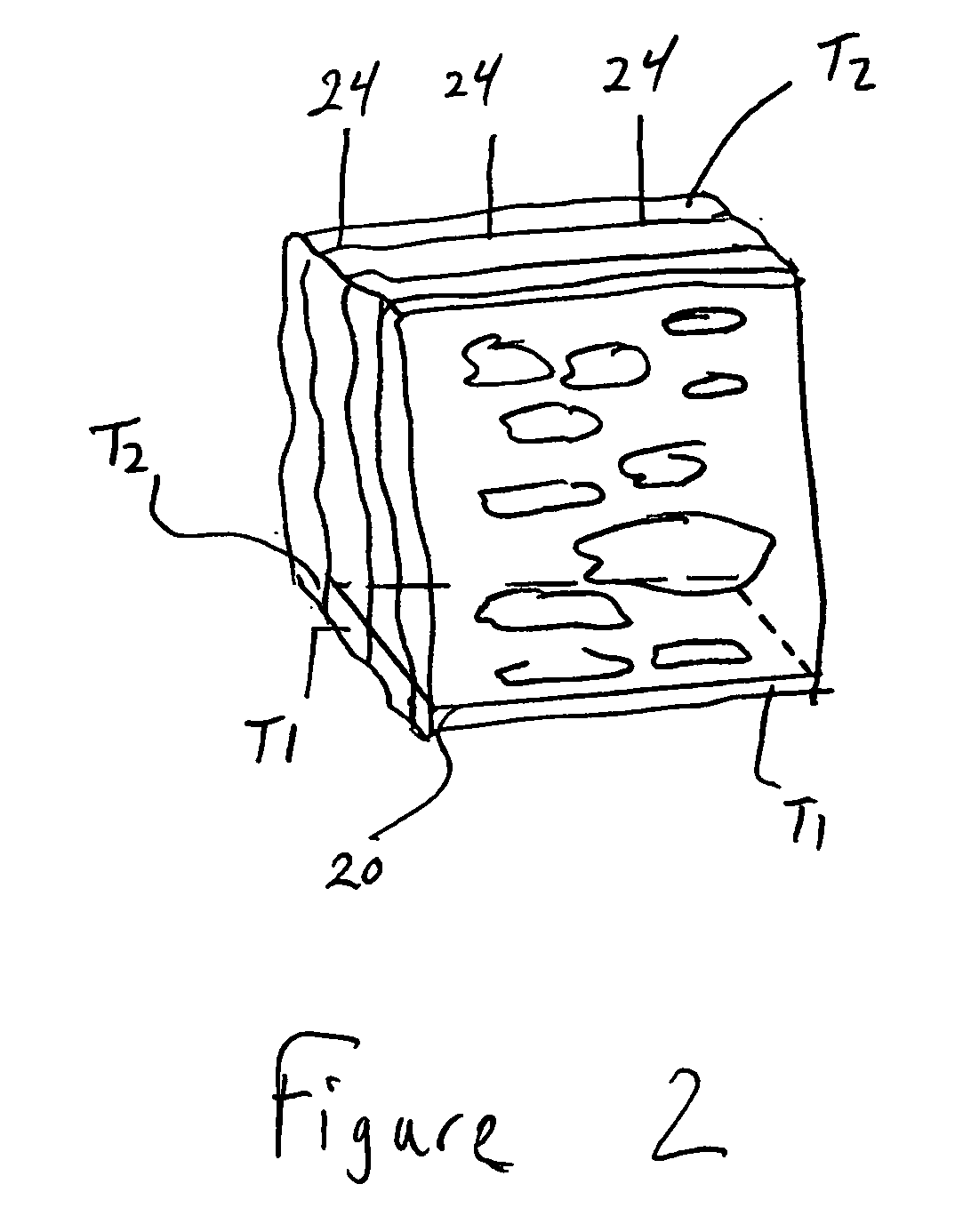

Mold With Reinforced Hinge

InactiveUS20100133725A1Inexpensive materialsImprove mold lifeMouldsConfectioneryEngineeringArtificial stone

Flexible, reinforced polymeric molds for Corning simulated stone veneers is provided. The molds are formed of a single solitary unit containing a plurality of contoured wells. A flange forms an outer portion of the mold and provides a means for grasping the mold so that the mold can be folded and flipped for the extraction of the artificial stones. One or both hinge portions located transversely across the central portion of the mold may be reinforced with an embedded nylon mesh scrim. The scrim increases the tear and tensile strength of the hinge portion. Additionally, the incorporation of the nylon mesh scrim at the hinge portions increases the life of the mold and reduces the occurrence of scrap molds. The polymeric mold advantageously retains its shape after the mold has been removed from the simulated stones, which permits the mold to be used in subsequent stone-molding operations.

Owner:BORAL STONE PRODS

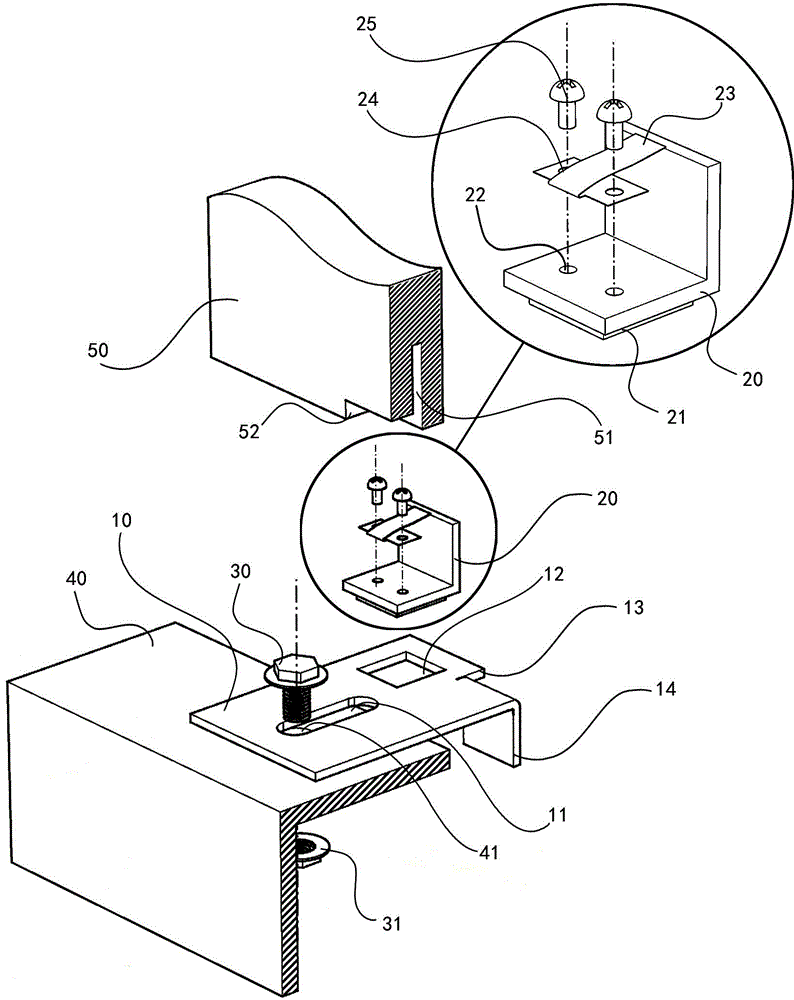

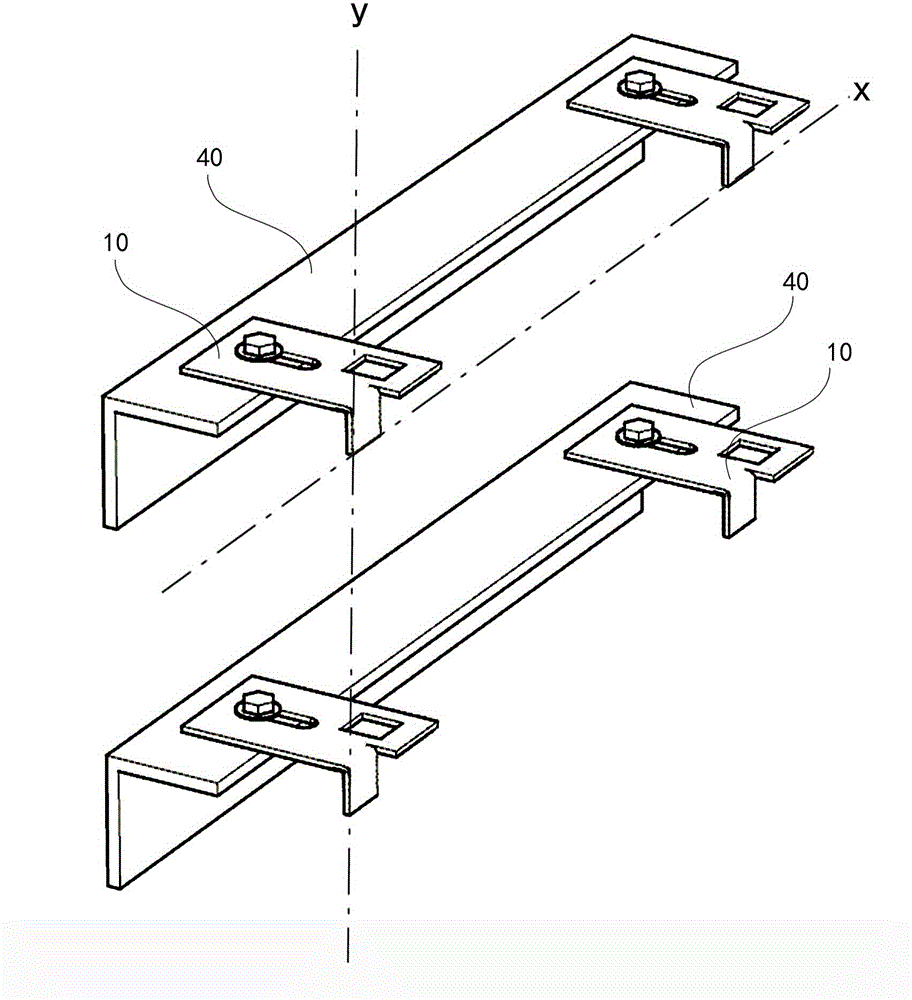

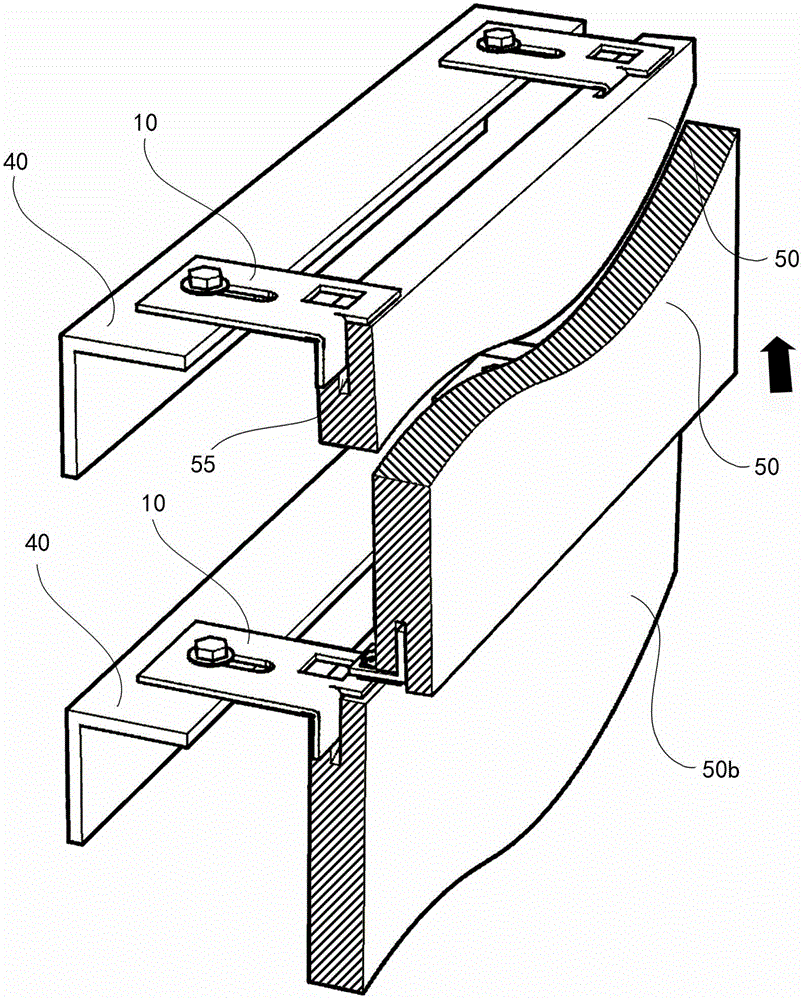

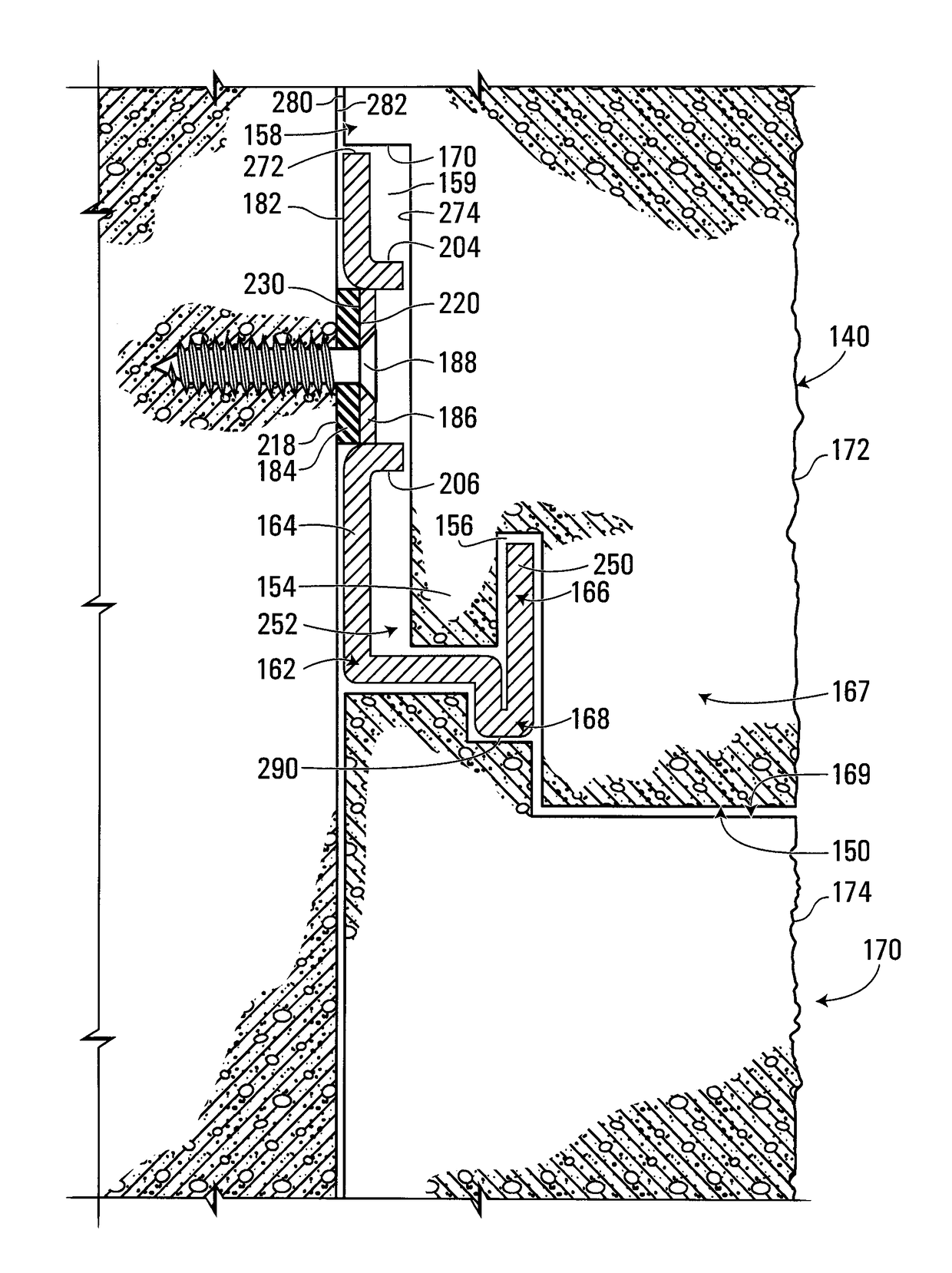

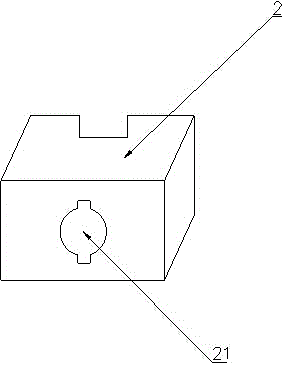

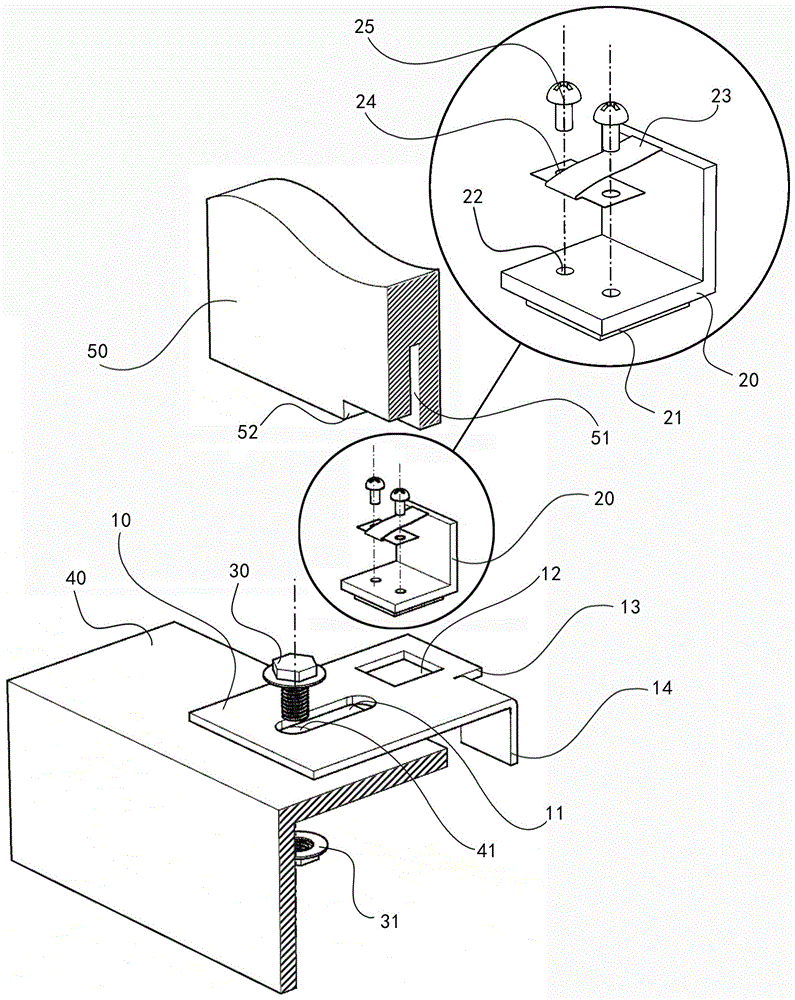

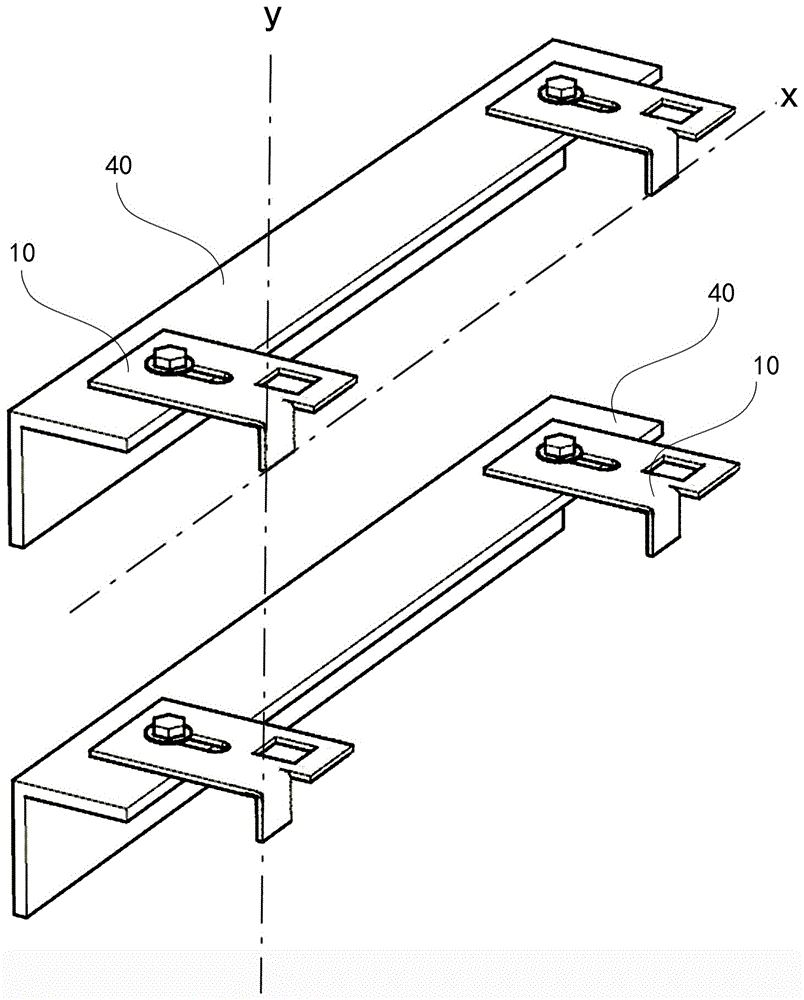

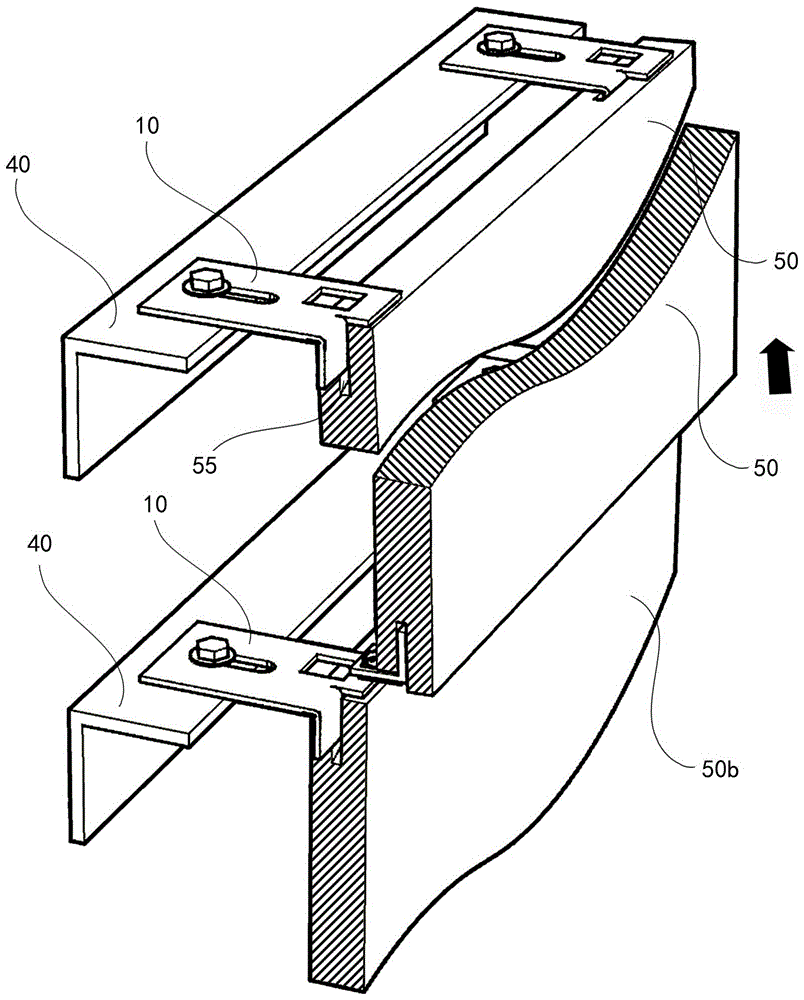

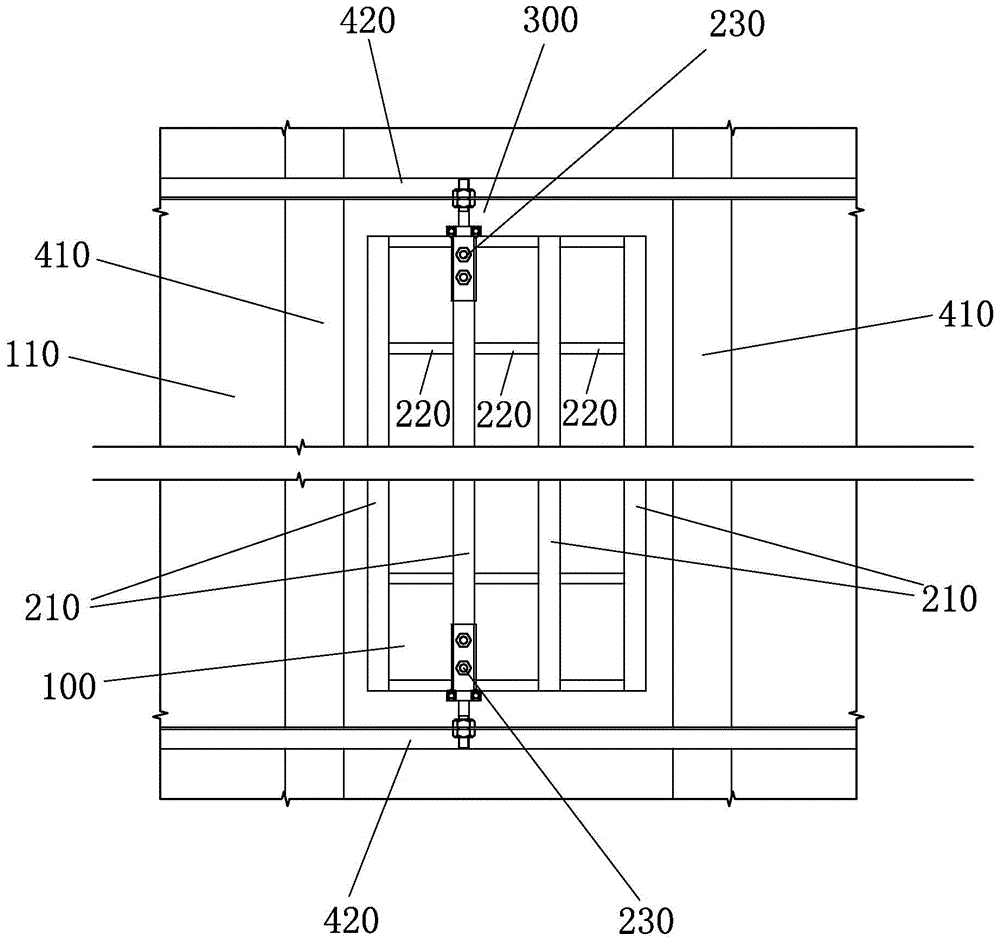

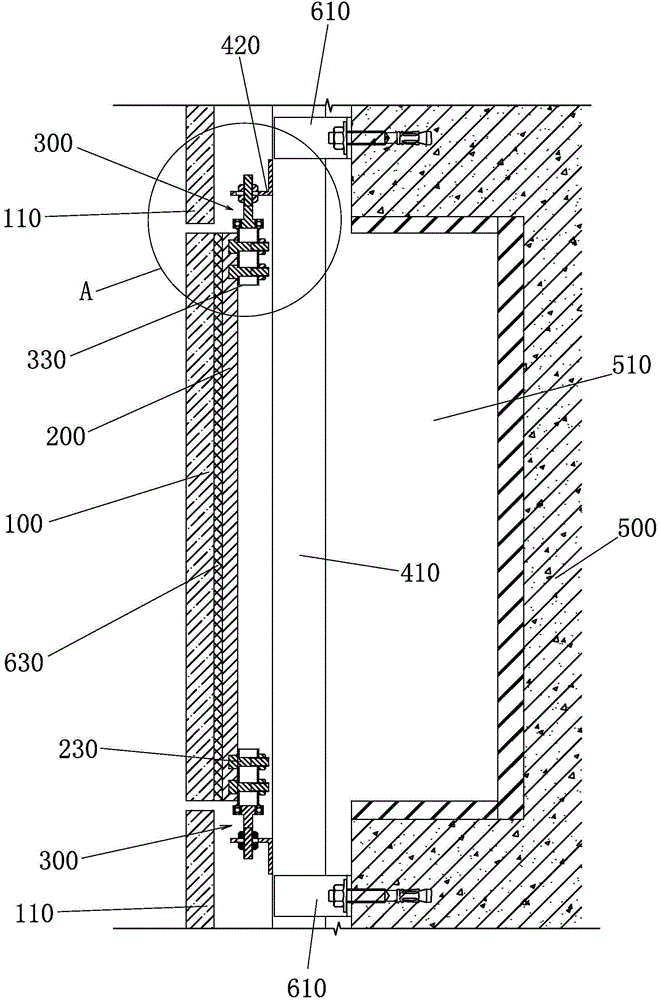

Structural combination and method for mounting stone veneers through push-in type positioning hanging parts

Owner:CHONGQING UNIV +1

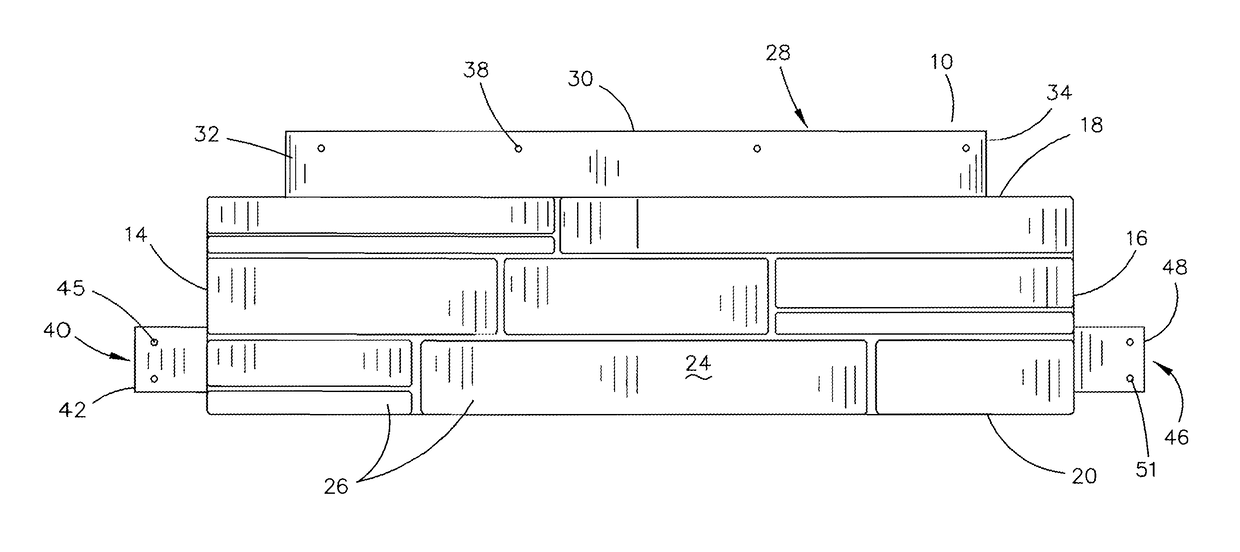

Natural rock panel, natural rock veneer panel and panel support apparatus

An architectural finish element operable to be placed adjacent similar architectural finish elements to form a finished surface on an architectural structure includes a body formed of a rock-based composite material comprising a low density solid particle additive, a plurality of unitary real stone veneer elements bonded to the body in courses extending in a first direction and in a random non-repetitive pattern, the real stone veneer elements having respective face surfaces generally lying in a plane to form an overall face surface of the architectural finish element. The low density solid particle additive is provided in an amount suitable to cause the architectural finish element to have a density of between about 10 to 15 pounds per square foot. The architectural finishing element may be mounted by mounting a portion of a body of at least one dual architectural finish element support to a surface of an architectural structure.

Owner:PACIFIC PREBENCHED

Settlement joint wall ground stone installation structure

ActiveCN102953518ASolve the problem of collision crackingAvoid safety hazardsCovering/liningsGround stoneStructural stability

The invention discloses a settlement joint wall ground stone installation structure, which comprises vertical structural members and horizontal structural members. The vertical structural members are fixedly arranged on a structural wall body. The horizontal structural members are fixedly connected with a face stone. The vertical structural members and the horizontal structural members are fixedly connected together. A movable stone panel assembly is arranged between the vertical structural members closest to the two sides of a settlement joint. The movable stone panel assembly comprises springs and a movable stone veneer. The vertical structural members on the two sides of the movable stone veneer and the two sides of the settlement joint are respectively connected with the movable stone veneer through the springs. The settlement joint wall ground stone installation structure provided by the invention has the advantages that the problem that stones collide and are cracked because a building body is displaced can be solved, the potential safety hazard that the stones fall off are avoided, the troubles in replacing the stones are reduced, the structural stability is improved.

Owner:GOLD MANTIS CONSTR DECORATION

Landscape stone veneer saltpetering-preventing process construction method

The invention discloses a landscape stone veneer saltpetering-preventing process construction method. The method is characterized by comprising the following steps that 1, basic layer construction achieves internal solidness and external smoothness, basic layer face elevation construction is in place, smoothness and precision are achieved, only a bonding layer of 2 cm is left, dry and hard cement mortar is prevented from being used, a low-alkaline dedicated bonder is selected, and the bonding layer porosity is reduced; 2, stone is subjected to six-face protection, on the one hand, a protection agent can permeate into the stone to block stone holes, on the other hand, a face layer is subjected to certain water separation protection, and thus a permeating channel of the stone can be closed. The landscape stone facing saltpetering-preventing process construction method has the advantages that compared with the prior art, according to the technical scheme, the water content in a basic layer is reduced, and water in the basic layer is prevented from flowing out. Alkaliferous matter in a bonding layer material is reduced, the thickness of the bonding layer is reduced, and auxiliary materials are saved. The permeating channel of water is effectively closed, saltpetering of the veneer stone is avoided, and the effect of a landscape stone veneer is improved.

Owner:SUZHOU GARDEN DEV

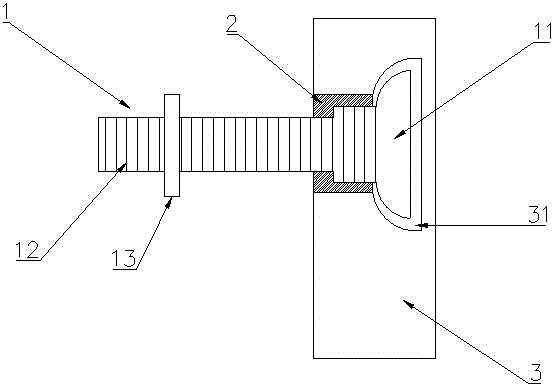

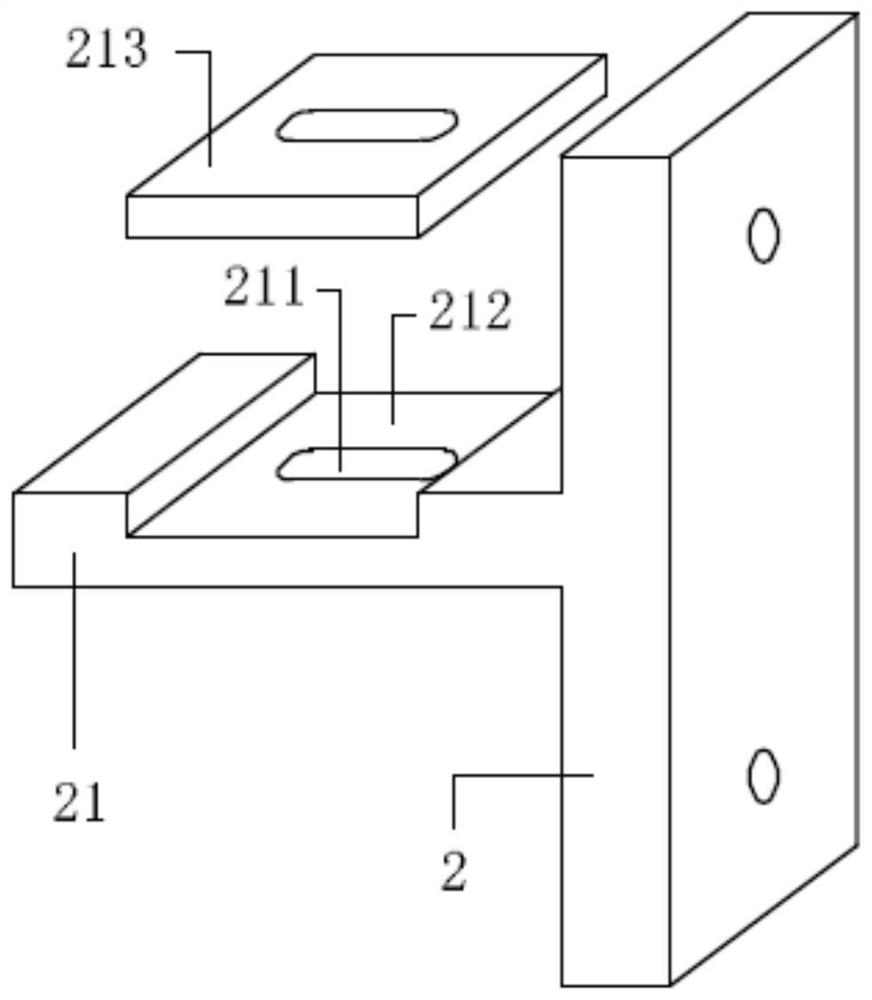

Back bolt combination device for stone veneer installation and installation method thereof

InactiveCN105484465AReduce mechanical costsImprove ease of useCovering/liningsEngineeringStone veneer

The present invention discloses a back bolt combination device for stone veneer installation. The back bolt combination device comprises a stone veneer, a T-shaped screw and a positioning piece; the T-shaped screw comprises a T-shaped countersunk head, a screw and a nut matched with the screw; the T-shaped countersunk head and the screw are fixedly connected; the positioning piece is provided with a hole slot or a through hole for allowing the screw to pass through; the positioning piece and the T-shaped screw combination position is provided with a mutual engaging structure; the back of the stone veneer is provided with an elongated slot; two sides of the bottom of the elongated slot are provided with expanded slots which are partial expanded slots or complete expanded slots; the T-shaped countersunk head is inserted into the elongated slot; and the T-shaped countersunk head positioned at the bottom of the elongated slot is rotated into the preset expanded slots by rotating the screw and is capable of moving left and right along the expanded slots. The back bolt combination device can be moved and adjusted left and right according to the opening direction of the elongated slot, and field application flexibility can be largely improved.

Owner:百益百利(福州)幕墙工程有限公司

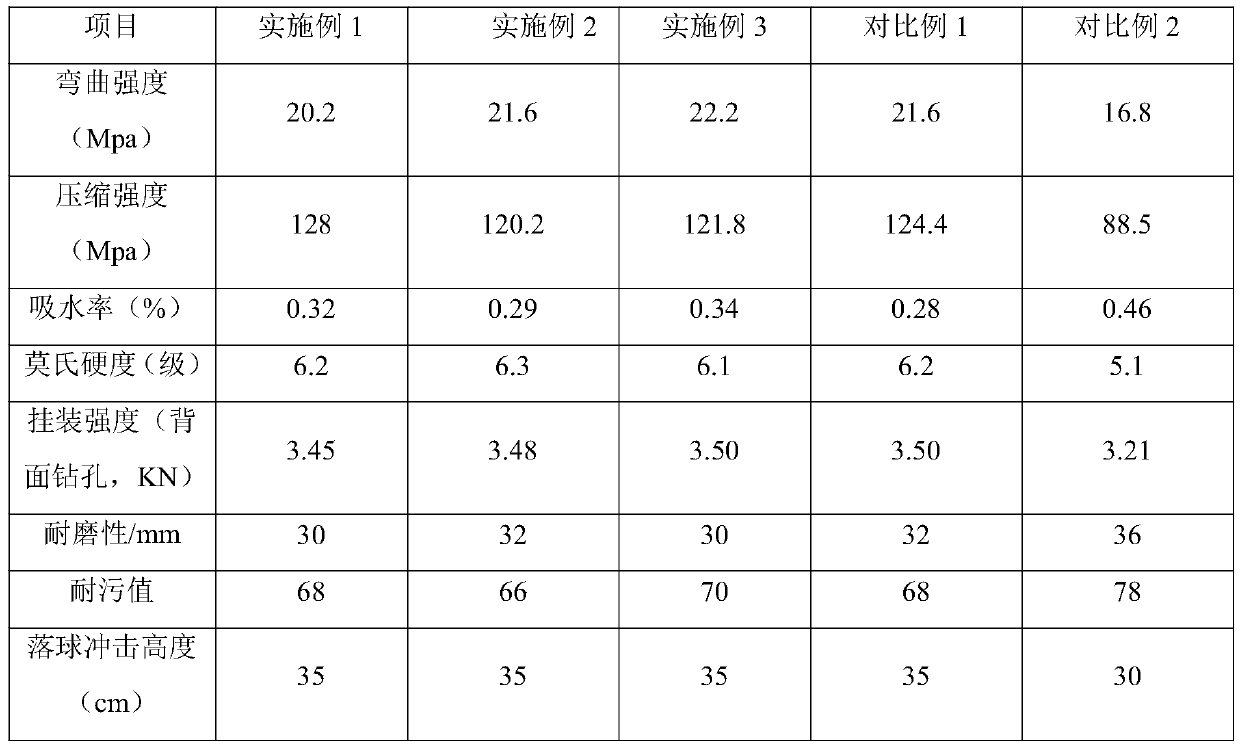

Recycled aggregate artificial artistic stone veneer and preparation method thereof

InactiveCN111517726ASolve the strength problemSolve the durability problemSolid waste managementCeramic shaping apparatusMining engineeringArtificial stone

The invention discloses a recycled aggregate artificial artistic stone veneer and a preparation method thereof. The recycled aggregate artificial artistic stone veneer comprises a surface layer and abase material layer, wherein the surface layer is prepared from the following raw materials in parts by weight: 60 to 70 parts of quartz sand, 6 to 12 parts of quartz powder, 18 to 23 parts of cement,1 to 4 parts of active additive, 2 to 4 parts of emulsion, 0.5 to 0.8 part of water reducing agent, 0.06 to 0.12 part of water retaining agent and 3 to 5 parts of water. The artificial stone has thetexture of natural artistic stone and low price, the problems that the price is high and natural ore resources are insufficient when only natural ore is adopted for manufacturing the artificial art stone plate are solved. And the problems of low strength, insufficient durability, crude appearance color and single darkness of the artificial art stone plate manufactured by only adopting pure recycled aggregate are also solved, and the artificial art stone plate has the advantages of simple construction process, high feasibility, greenness, environmental protection and wide market prospect.

Owner:深圳市绿志新型建材研究院有限公司

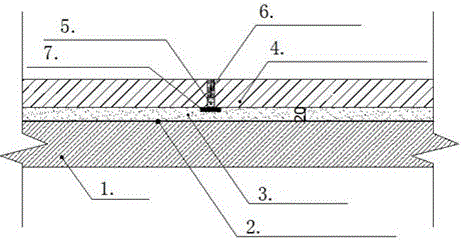

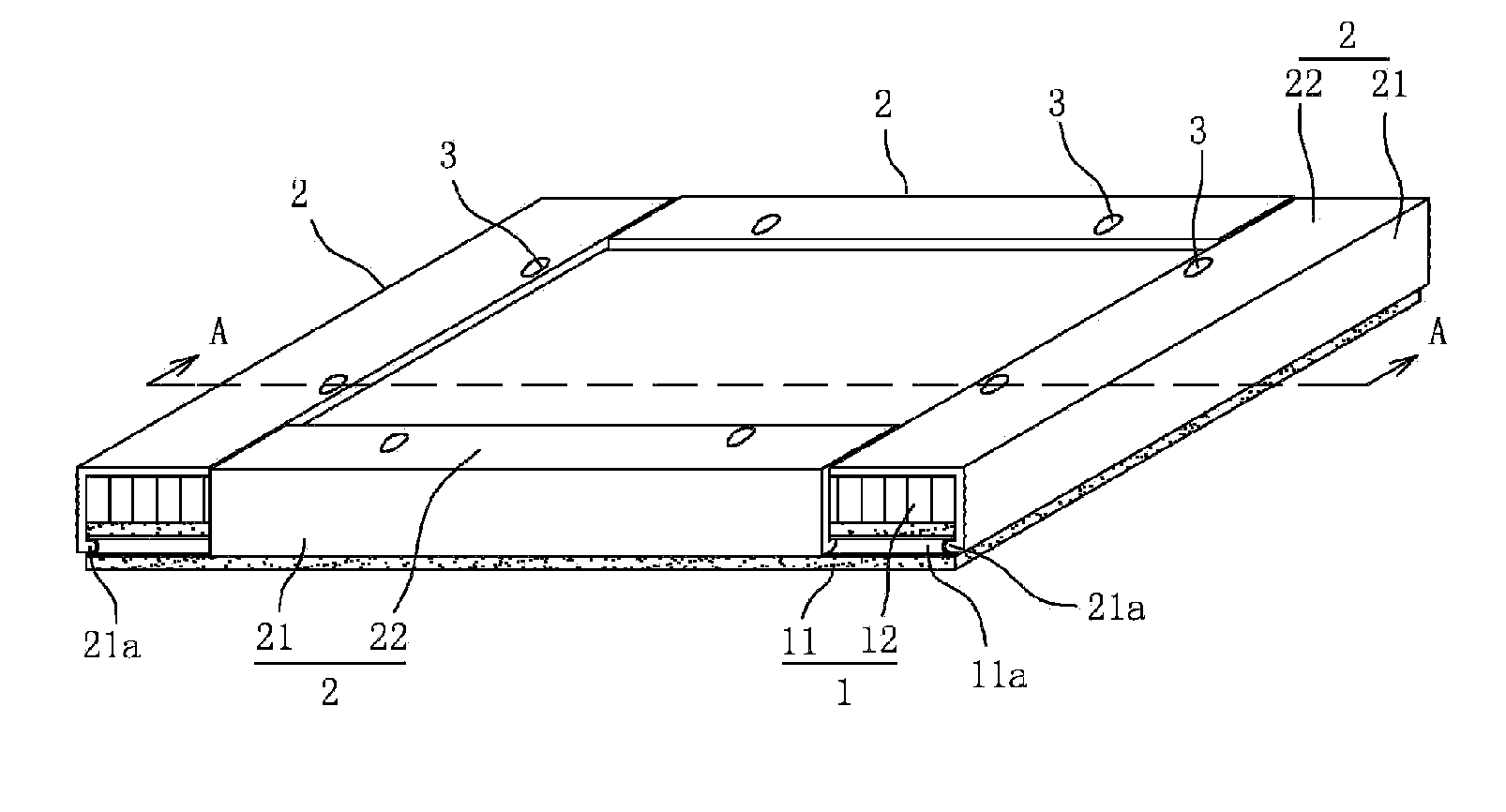

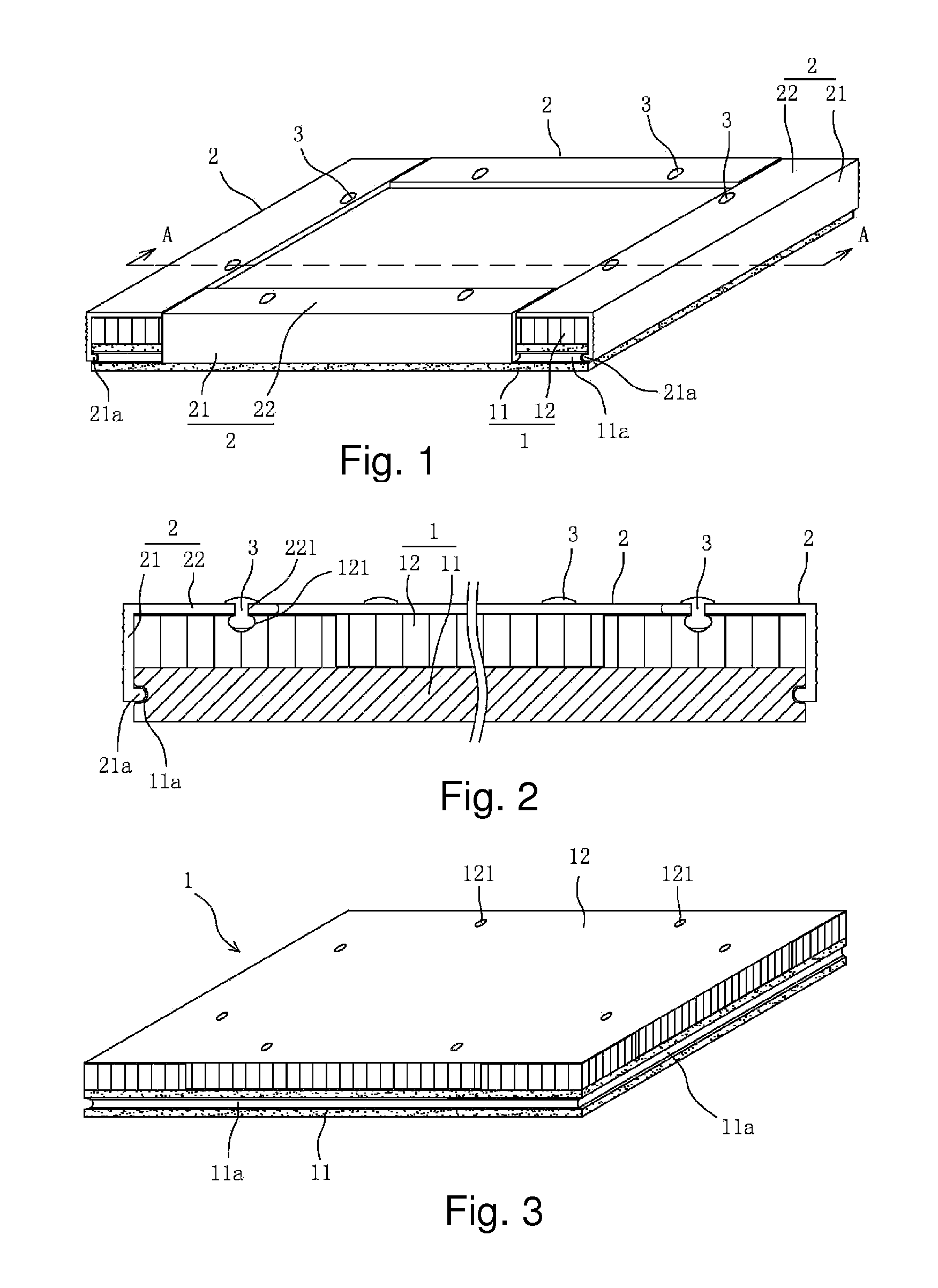

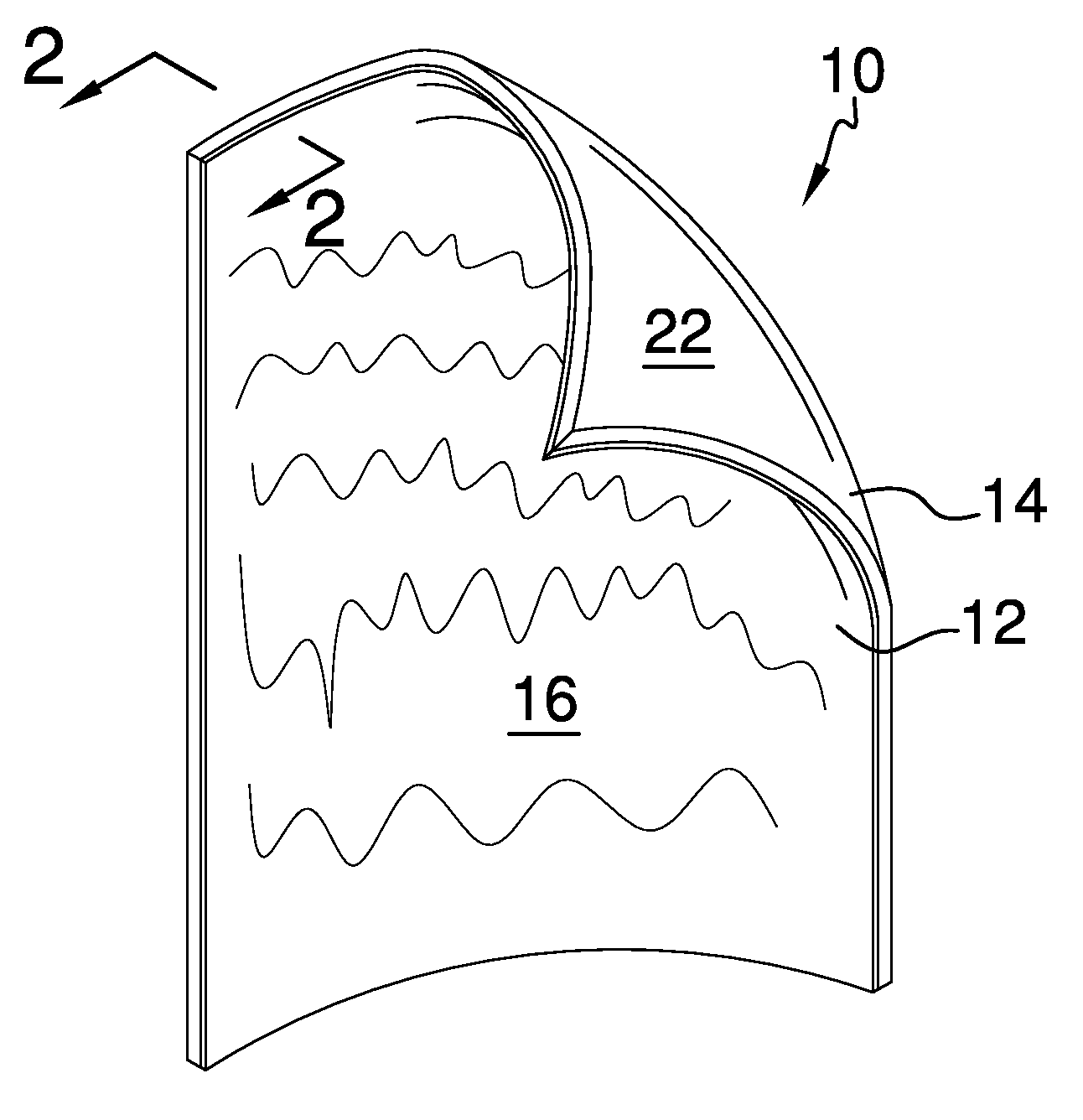

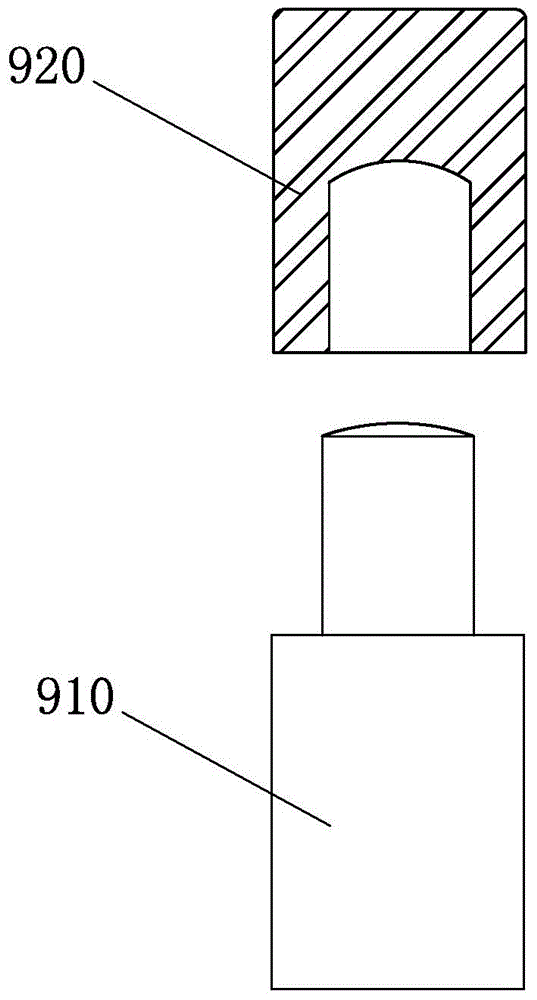

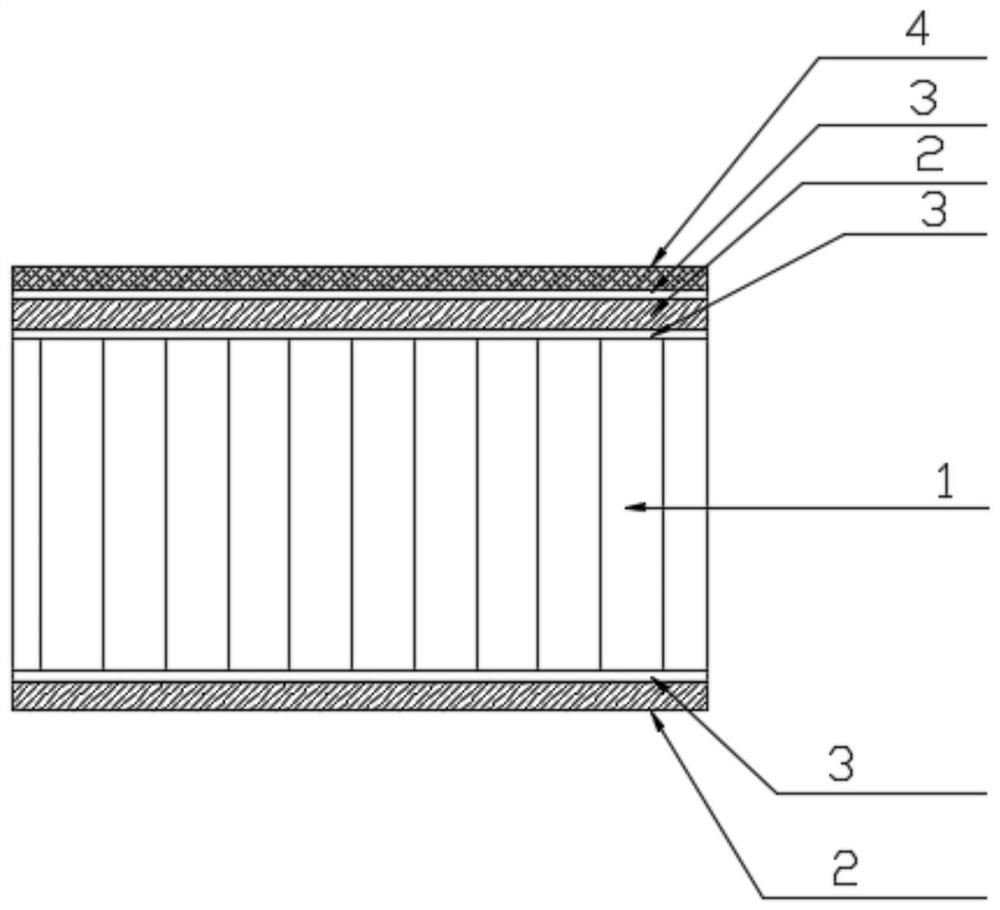

Falling-prevention ultra thin stone composite board

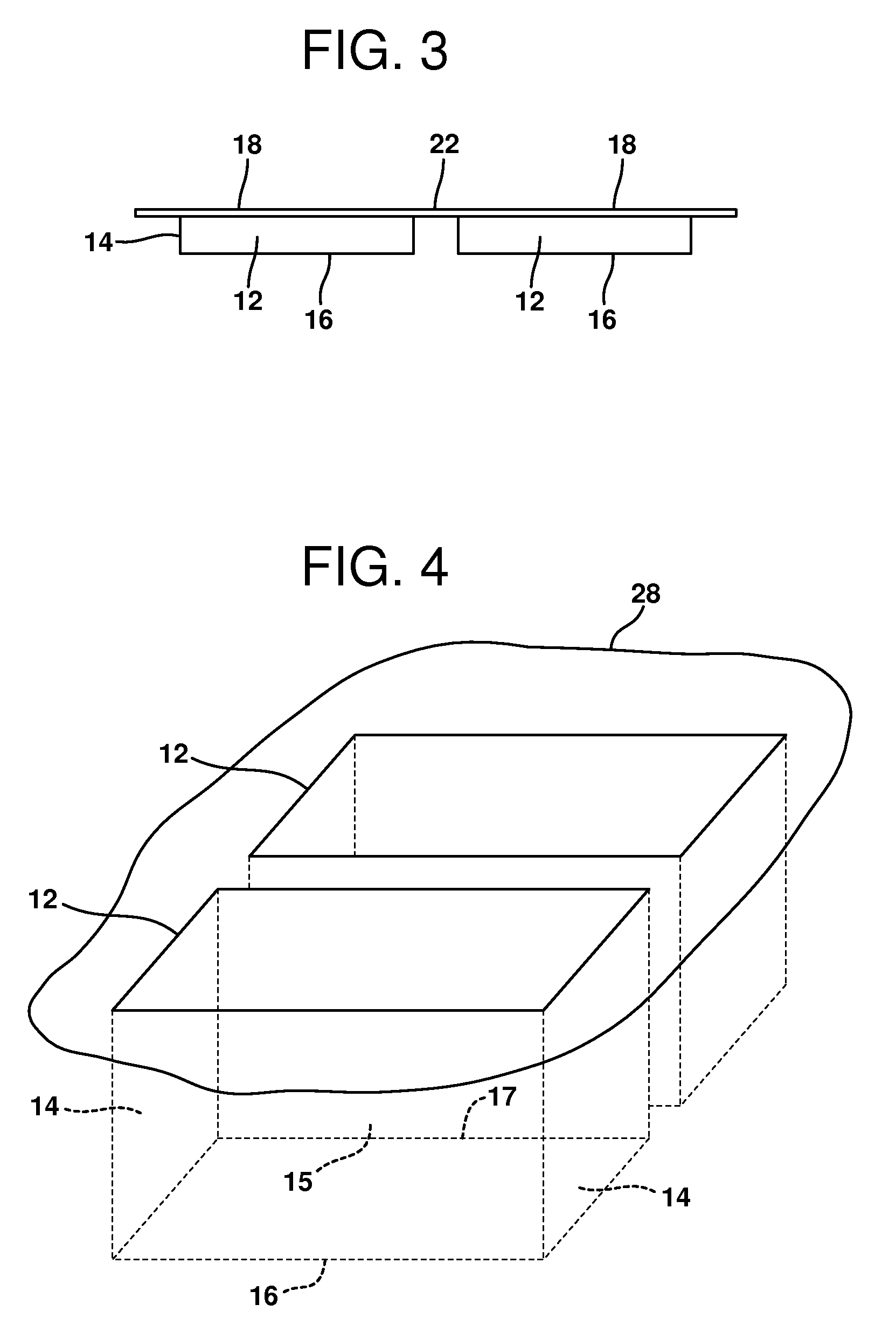

InactiveUS20110113716A1Solve the real problemImprove securityConstruction materialCovering/liningsSingle plateEngineering

A falling-prevention ultra thin stone composite board is provided with a composite board body 1 composed of ultra thin stone veneer 11 and a light base board 12 sticking to the rear surface of the stone veneer. At least a pair of opposite bottom edges of the composite board body is separately fixed with connecting battens 2 which fasten the stone veneer 11 and the light base board 12 together. The cross section of the connecting batten 2 is general L-shape. And the connecting batten 2 is integrally formed by front plate and rear plate. The rear plate is fastened to the rear surface of the light base board 12 and the front plate is laid against the side surface of the composite board body 1, then the front plate of the connecting batten and the side surface of the stone veneer 1 are fixed together by a fasten device.

Owner:GUO ZHENYI

Hard polyurethane foamed wall-sticking stone material veneering construction method

InactiveCN1460760AWaterproofWith insulationCovering/liningsPolyureas/polyurethane adhesivesSurface cleaningSlurry

Firstly, cleaning base surface of building and stone veneer, prepositioning on the wall body, preparing working slurry liquor in-situ, and using the hard polyurethane foamed working slurry liquor to making veneering construction of stone veneer along the prepositioned position, then pointing and cleaning surface.

Owner:江苏久久节能科技工程有限公司

Flexible slate veneer architectural panel

InactiveUS20120276366A1Adds to insulation valueEasy to manufactureLayered productsThin material handlingAdhesiveArchitectural engineering

A flexible slate veneer architectural panel includes a slate veneer and a flexible closed cell foam backing The panel exhibits high flexibility permitting the panel to be attached to curved building structures with an adhesive or with mechanical fasteners if desired. The panel further provides an interface between the building surface to which it is attached and the slate veneer that is capable of absorbing different thermal expansions and contractions of the slate veneer and the building surface thereby preventing delamination of the panel from the building surface and preventing cracking of the slate veneer.

Owner:TOUPIN ERIC +1

Structural combination and installation method of installing stone veneer with push-in positioning pendant

Owner:CHONGQING UNIV +1

Composite coating for architectural pieces

InactiveUS20070289224A1The implementation process is simpleEasy to peelArtificial islandsOrnamental structuresBrickGranolithic

The present invention relates to a composite coating for architectural pieces used in building and remodeling of existing buildings. The architectural pieces include plastics, polyurethanes, wood and glass decorative items, granite and all manners of stone, wood inlays, wood flooring products, full size brick and pavers as well as thin veneer varieties such as brick or stone veneer. In addition, the invention relates to a method for grouting the architectural pieces.

Owner:PARMLEY RONALD L

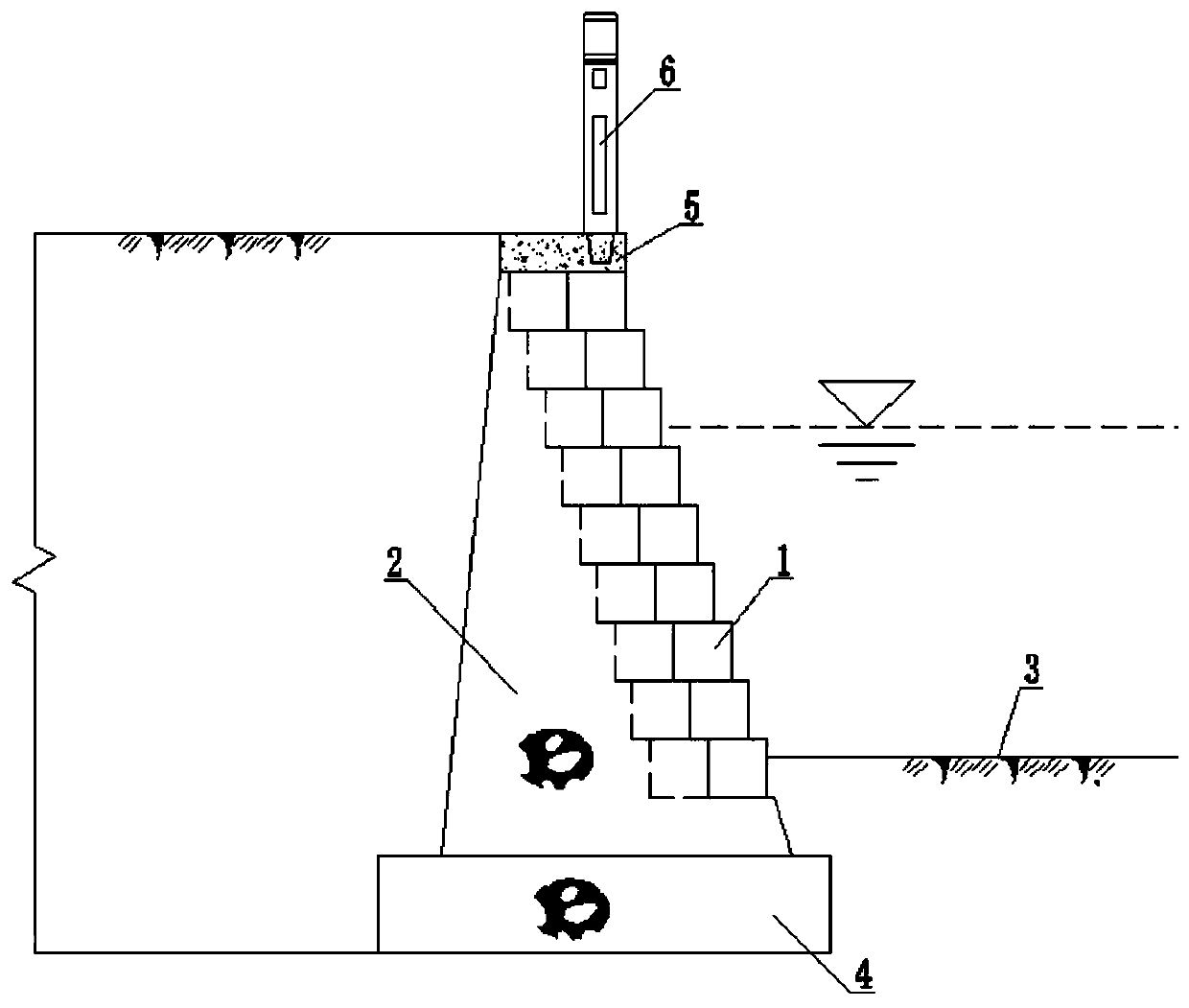

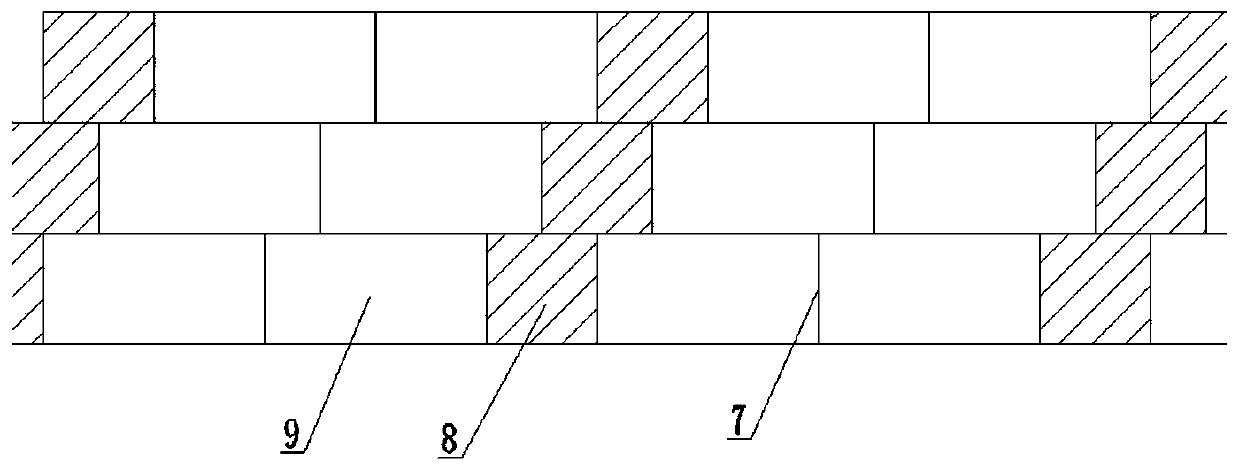

Structure and method suitable for flood control wall stone veneer of landscape river

The invention belongs to the technical field of hydraulic engineering in water conservancy engineering, and particularly relates to a structure and a method suitable for a flood control wall stone veneer of a landscape river. The invention adopts the structural method of Flemish double-stretcher bond or Flemish garden wall bond through the combination of a veneer stone and a flood control wall body, namely, laying two stretchers and one stone, or three stretchers and one stone. Then, and so on, the stone is anchored to the flood control wall to increase the impact strength of the veneer stone,and the upper and lower layers are staggered to meet the stability of the wall in a high-speed water channel, the wall of the flood control wall is prevented from being washed away and damaged effectively so as to meet the flood control requirements of the river and enhance the landscape of a dike effectively.

Owner:POWERCHINA XIBEI ENG

Artificial marble exterior facing plate and installation method thereof

The invention relates to an artificial marble exterior panel and an installation method thereof, belonging to the technical field of construction. The artificial marble exterior panel is made of artificial marble slab and outer metal finish layer through hot pressing technology. Four holes are punched at the four corners of the artificial marble slab. The four holes are respectively connected with the decorative panel bolts. It is fixed by a fixative to make it a whole; the fixed component is installed, and the fixed component is connected with the components embedded in the wall by bolts, and the artificial marble exterior panel is connected with the bolts of the fixed component and the decorative panel by dry hanging outside the building. The invention increases the corrosion resistance and aesthetics of the stone veneer, has fast installation and construction speed, good economic effect and good seismic performance, removes the dragon skeleton required by the dry hanging method, reduces the load bearing of the building, reduces the working hours and reduces the cost .

Owner:SHENYANG JIANZHU UNIVERSITY

Wall surface design structure with dry-hanging type quartz stone veneer and mounting method of wall surface design structure

The invention provides a wall surface design structure with a dry-hanging type quartz stone veneer. The wall surface design structure comprises a keel frame, a first hanging piece, a second hanging piece and a veneer. A plurality of vertical keels arranged in parallel are fixedly mounted on a wall surface base layer, first transverse keels and second transverse keels arranged in parallel are arranged on the vertical keels, the second transverse keels are provided with obliquely-arranged bent edges, the veneer is provided with the first hanging piece corresponding to the first transverse keelsin position, a connecting plate of the first hanging piece is fixedly mounted on the first transverse keels through a first fastening piece, the veneer is further provided with the second hanging piece corresponding to the second transverse keels in position, and an inclined hanging plate on the second hanging piece is hung on the bent edges. The invention further provides a mounting method of thewall surface design structure with the dry-hanging type quartz stone veneer. Compared with the prior art, the veneer can be stably hung on the wall surface base layer, the hanging structure is not prone to deforming, and the wall surface integrity is good.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

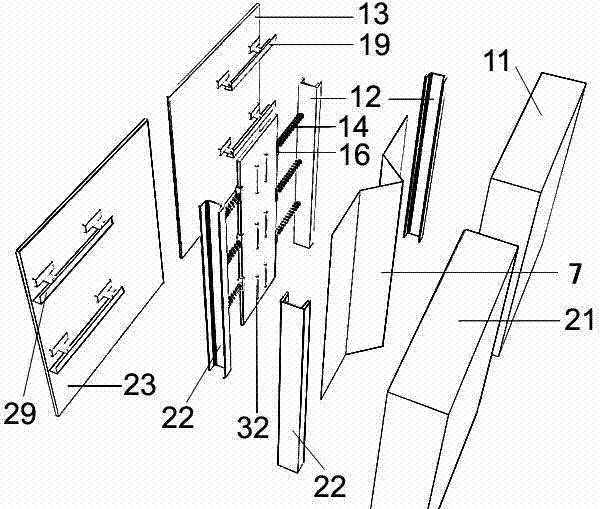

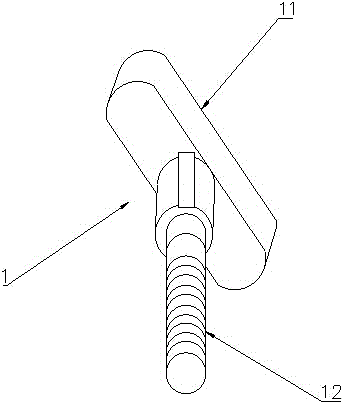

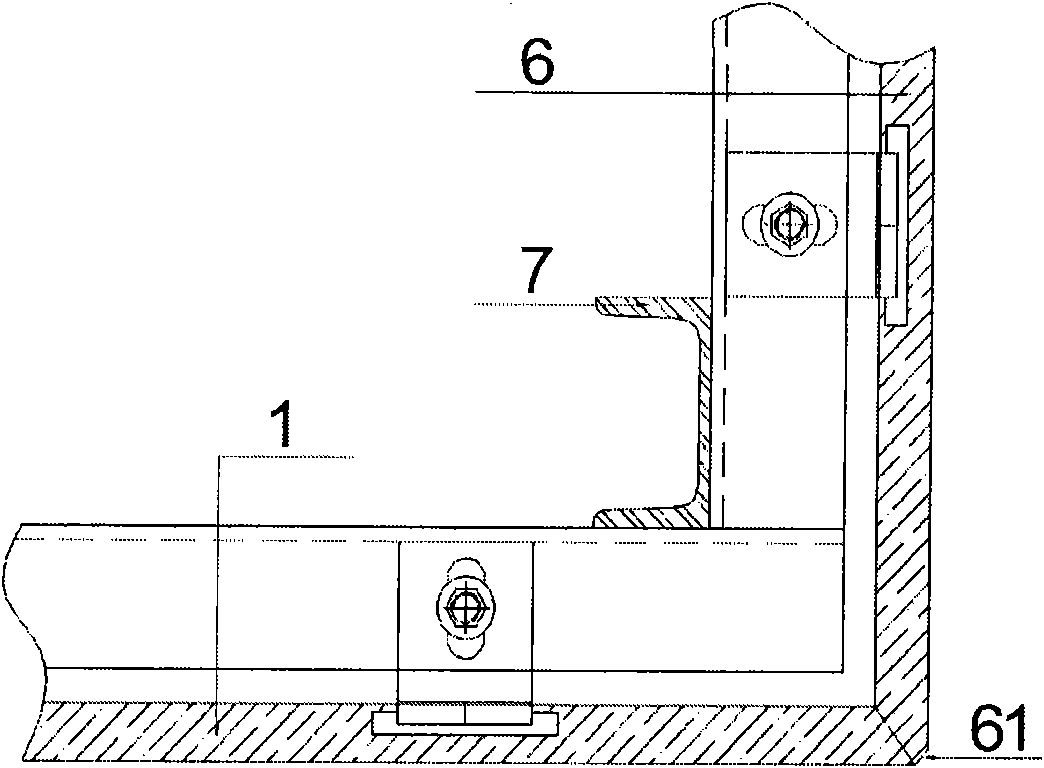

Stone blank door with novel rotating shaft mechanisms and installation method of stone blank door

ActiveCN104481359ARealize free disassemblyClose flexibleFire rescueWing arrangementsEngineeringVertical axis

The invention discloses a stone blank door with novel rotating shaft mechanisms and an installation method of the stone blank door. The stone blank door comprises a stone door leaf, a stone door steel skeleton, a stone veneer steel skeleton and the two rotating shaft mechanisms, wherein the stone door leaf is matched with the installation position of a stone veneer blank door; the two rotating shaft mechanisms are connected with the back surface of the stone door leaf and the stone veneer steel skeleton; the stone door steel skeleton is fixed on the back surface of the stone door leaf; a steel upright post and an inner wall behind a stone veneer are fixed at an interval through a corner connector; a screw rod of each embedded bolt respectively passes through a mounting hole of a square tube of the corresponding rotating shaft mechanism, and then is locked and fixed with a connecting nut; a screw rod on the bolt of each rotating shaft mechanism passes through a mounting groove in the corresponding steel angle beam, and is locked through an upper positioning nut and a lower positioning nut; the rotating shaft mechanisms at the upper end and the lower end of the stone door leaf are positioned on the same vertical axis. According to the stone blank door disclosed by the invention, the space between the stone veneer and the stone veneer steel skeleton is cleverly and fully utilized, so that the stone blank door is relatively flexible, smooth and free of a sound when the stone door leaf is closed or opened; the support on the stone door leaf is relatively stable; the service life is prolonged.

Owner:SDCIC CONSTR GRP CO LTD

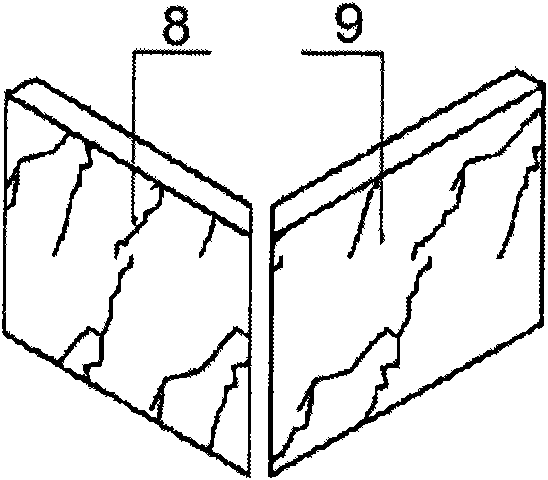

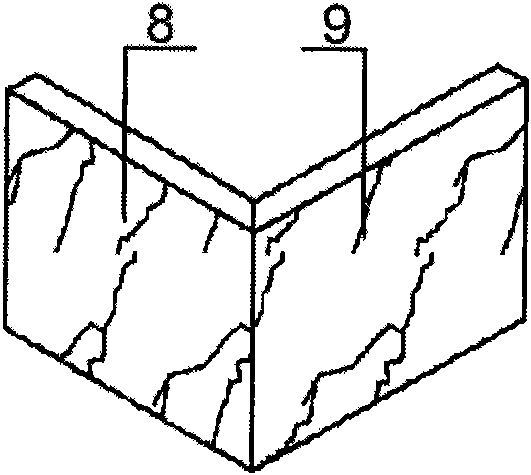

Stone veneer positive angle splicing structure and its construction method

The invention discloses a splicing structure of an external corner of a stone veneer, which comprises a stone veneer one (1), a stone veneer two (6), and an external corner of the stone veneer one (1) and the stone veneer two (6) An angled surface (61) is provided at the joint, and the seam (10) between the first stone veneer (1) and the second stone veneer (6) is not in the middle of the angled surface (61). The patchwork (10) is positioned at the water chestnut line position of the grinding angle surface (61). The invention also discloses a construction method of the outside corner splicing structure of the stone veneer. The invention can overcome the disadvantages of obvious color difference of the seam glue and uneven seam after corner grinding of the conventional seam, and has good appearance effect at the external corner and high quality of perception.

Owner:GOLD MANTIS CONSTR DECORATION

System for designing, previewing, and cutting natural stone veneer to deliver ready for installation

InactiveUS20070197131A1Save effortShorten the timeGrinding feed controlAbrasive feedersDesign planEngineering

The present invention relates to a method of designing, previewing a stone veneer project in its entirety before a single stone is cut; cutting and finishing the edges of a stone to form interconnecting natural stone veneer components, each having a perimeter of a pre-determined contour and a finished edge, the method comprising: drawing or otherwise importing a design plan comprising overall dimensions and shape of a finished stone veneer project; drawing or otherwise importing a pattern of shape and placement of the stone veneer components within the design plan; programming, scanning or otherwise inputting a plurality of cutting patterns, wherein the cutting patterns are the same or different, each cutting pattern designed to form the stone veneer component having a perimeter of a pre-determined contour; converting the pattern into a machine-readable program to produce a cutting path on an abrasive waterjet machine; loading a cutting path file for the stone veneer component into the abrasive water jet machine; positioning a cutting head of the waterjet machine over the natural stone at a distance of from about 0.3 inch to about 4 inches from a contact surface of the stone; running the cutting path program and cutting through the stone by contacting the contact surface of the stone with a waterjet from the waterjet machine.

Owner:NEW WORLD STONEWORKS

Method of manufacturing stone veneers

InactiveUS20070028549A1Output maximizationQuantity maximizationConstruction materialCovering/liningsEngineeringStone veneer

An efficient method of manufacturing stone corner veneers, veneers, floor tiles and pavers, as well as a method of applying the veneers, is disclosed. The method consists of manufacturing veneer corners from a substantially parallelepiped stone, comprising the steps of: a) making a cut from a split face side of the stone into the stone a distance equal to the dimension of the stone from the surface being cut into to the opposite surface of the stone, less a thickness equal to a desired thickness of the veneer corner; and b) splitting the stone, from the side of the stone parallel to the cut and furthest from it, along a grain to the internal end of the cut whereby the veneer corner is created having an ashler side and a split face side and the remaining stone has only one cut face on an ashler side.

Owner:MUSKOKA GRANITE & STONE

Dry hanging structure of overhead stone and construction method thereof

ActiveCN106351416AImprove flexural strengthReduce bending deformationCovering/liningsUltimate tensile strengthStone veneer

The invention discloses a dry hanging structure of an overhead stone and a construction method thereof. The dry handing structure comprises a structural beam, an angle steel, a stone veneer and a connection mechanism, wherein the stone veneer is formed by assembling multiple stone plates; the angle steel and the connection mechanism are arranged between the structural beam and the stone veneer; the angle steel and the structural beam are in chemical anchoring or welding connection; the angle steel is connected with the stone veneer by the connection mechanism; the connection mechanism comprises an angle steel angle code and a dry hanging piece; one end of the angle steel angle code is fixed on the angle steel by a bolt and the other end is fixedly connected with the dry hanging piece by the bolt; the dry hanging piece is inserted into the assembled stone crack slot to hang the stone; and the structural glue is filled in the crack. The dry hanging structure can reduce the lower bending deformation of the stone, increase the strength of the stone at the slot and ensure the using safety of the stone.

Owner:JIANGSU JIAYANGHUALIAN BUILDING & DECORATION CO LTD

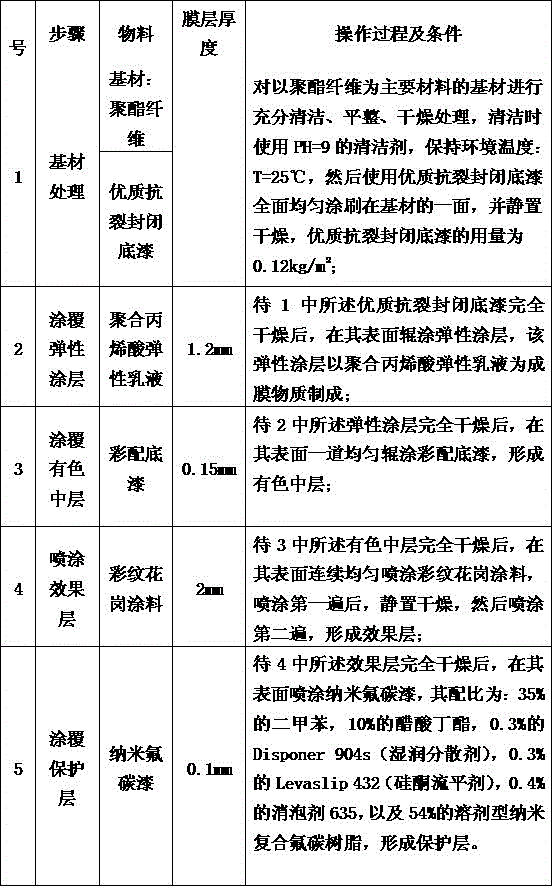

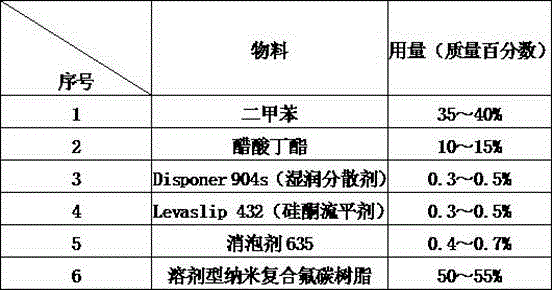

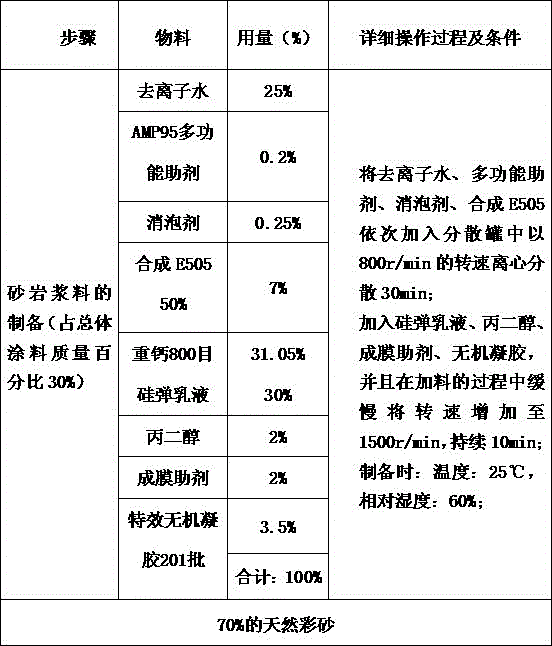

Sandstone veneer stone and manufacturing method thereof

The invention discloses a sandstone veneer stone, which comprises a base material, an elastic coating coated on the base material, a colored middle layer coated on the elastic coating by a roller, an effect layer formed by spraying sandstone paint on the colored middle layer, And the protective layer coated on the effect layer, the protective layer is nano fluorocarbon paint; the sandstone paint includes 30% sandstone slurry and 70% natural colored sand; the sandstone slurry consists of a mass fraction of 25%- 30% deionized water, 0.2% multifunctional additive, 0.25% defoamer, 7% synthetic E505, 22%-35% 800 mesh heavy calcium, 30% silicon bomb emulsion, 2% propylene glycol , 2%-3% coalescent, 3.5% inorganic gel composition. The invention has the characteristics of convenient transportation and construction, stable pattern, smooth hand feeling, delicate and smooth.

Owner:浙江泰基涂料有限公司

Ultra-thin stone veneer hyperboloid metal composite plate

InactiveCN111959051AImprove securityHigh yieldCovering/liningsMetal layered productsComposite plateNatural stone

The invention discloses an ultra-thin stone veneer hyperboloid metal composite plate which is characterized by comprising an aluminum alloy honeycomb core material, the upper portion and the lower portion of the aluminum alloy honeycomb core material are connected with aluminum alloy boards respectively, and an ultra-thin natural stone veneer is laid on the aluminum alloy board located on the aluminum alloy honeycomb core material. The ultra-thin natural stone veneer adopted by the invention is ultrathin and only 0.5-2.0 mm in thickness, is light in weight, energy-saving, environment-friendly,high in plasticity, high in safety and quick and convenient to install, and is lower in cost and resource-saving compared with the traditional process.

Owner:上海西蒙铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com