Dry hanging structure assembly and method for mounting stone veneer

A veneer and stone technology, applied in the processing of building materials, building structure, covering/lining, etc., can solve the problems of hidden dangers, difficult to repair, stuck T-shaped pendants, etc., to achieve rapid installation and reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

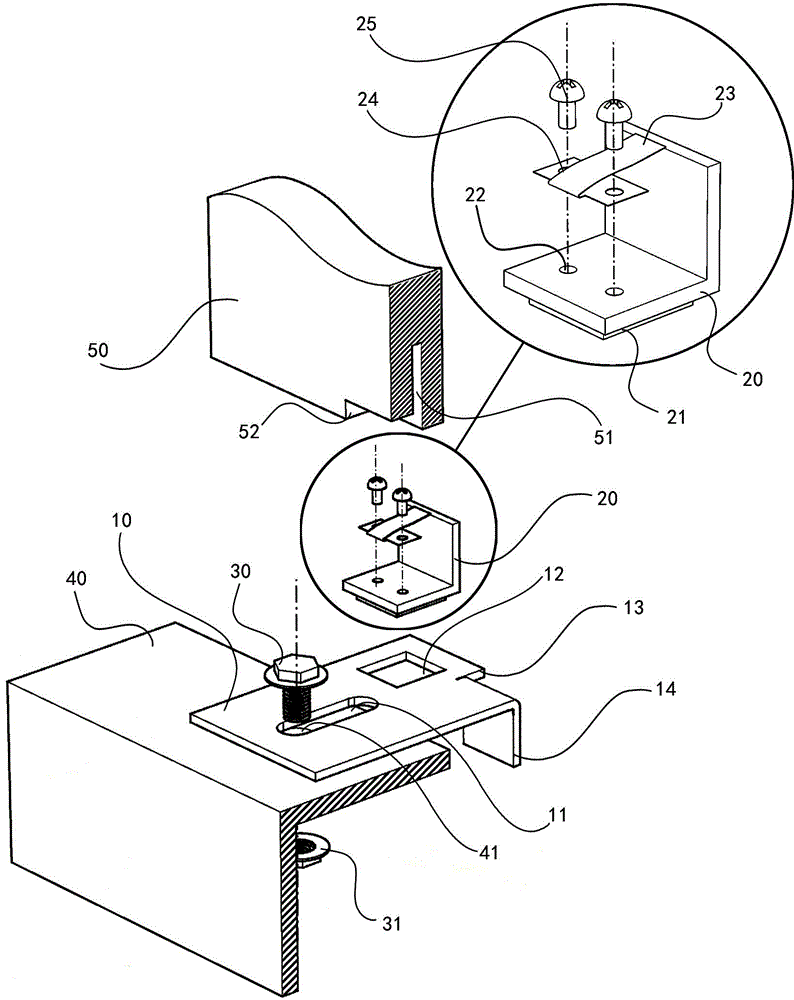

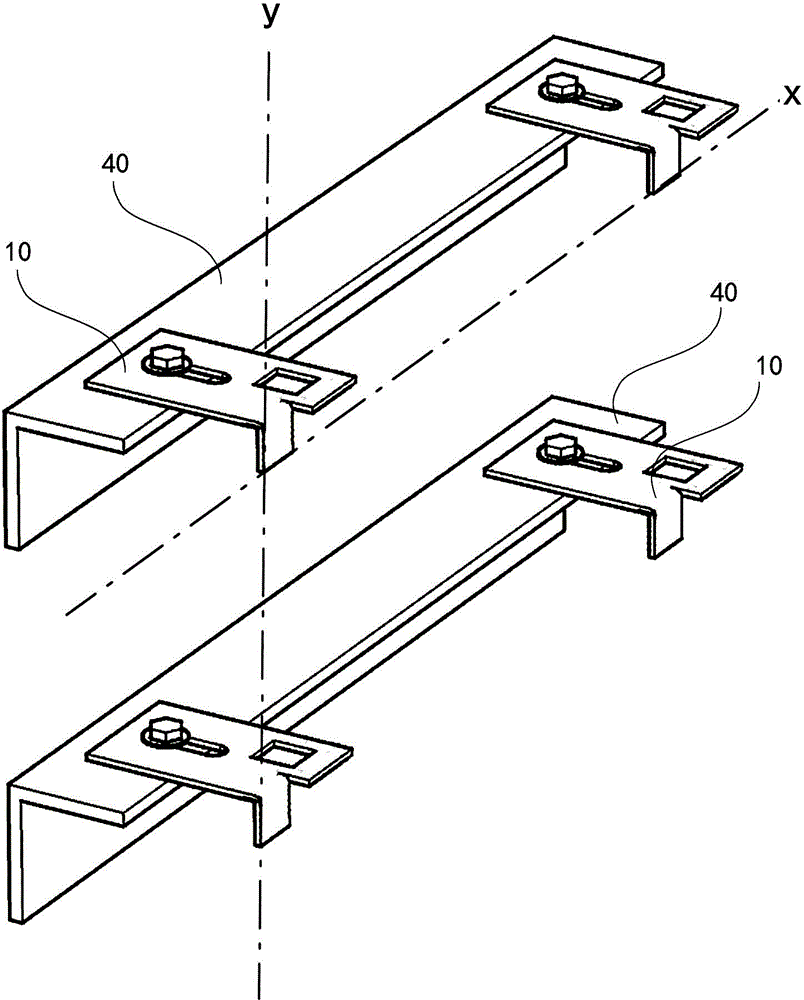

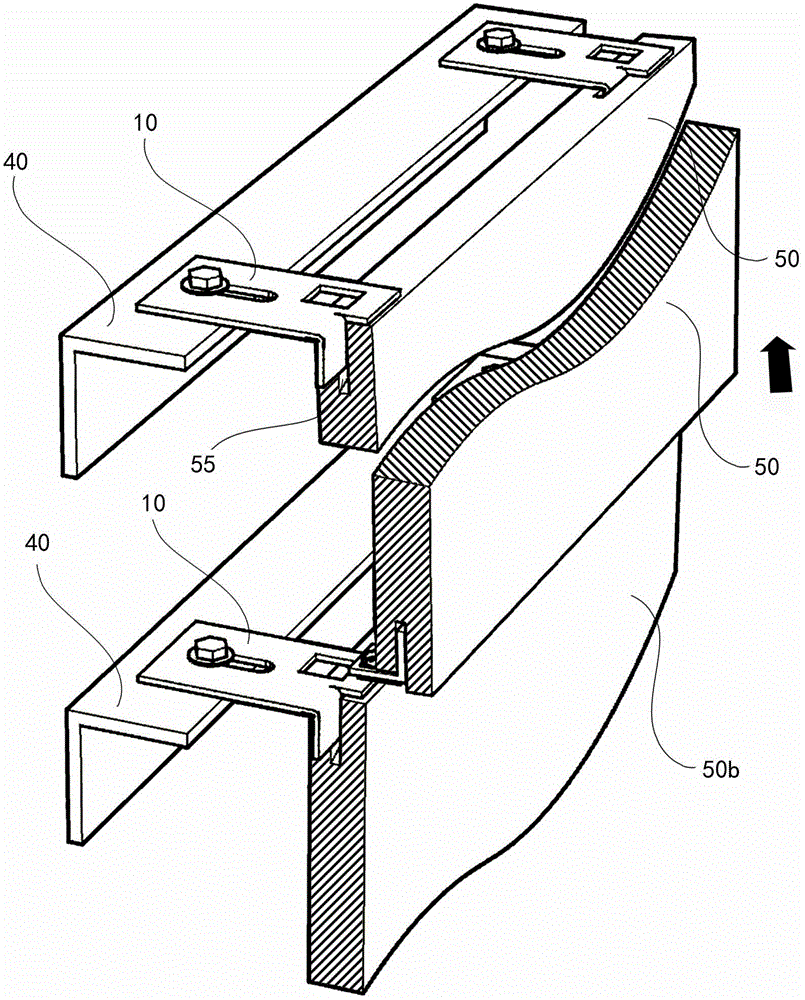

[0016] figure 1 — Figure 5 It is an embodiment of the present invention. As shown in the figure, a dry-hanging structure combination for installing stone veneer panels is composed of angle steel bars 40 , pendant main body 10 , corner blocks 20 , and bolts 30 installed on steel structures or walls. 1. Composed of stone veneer 50, it is characterized in that: the main body 10 of the pendant and the angle steel bar 40 are connected in a vertical state through bolts 30, and the lower hook bar 14 and the corner block 20 at the front part are respectively connected with the corresponding ones set on the stone veneer. The corresponding upper hanging groove 55 and the lower hanging groove 51 are fixed in cooperation; the limiting groove 52 is arranged below the non-viewing surface of the stone veneer 50; the limiting groove 52 intersects with the lower hang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com