Fireplace surround system and method of making same

a technology of surround system and manufactured stone veneer, which is applied in the direction of domestic stoves or ranges, construction, water heaters, etc., can solve the problems of difficult installation, difficult and time-consuming affixing of mantel shelves, legs or other surround components to the support wall, and difficulty in construction, etc., to achieve quick and inexpensive installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

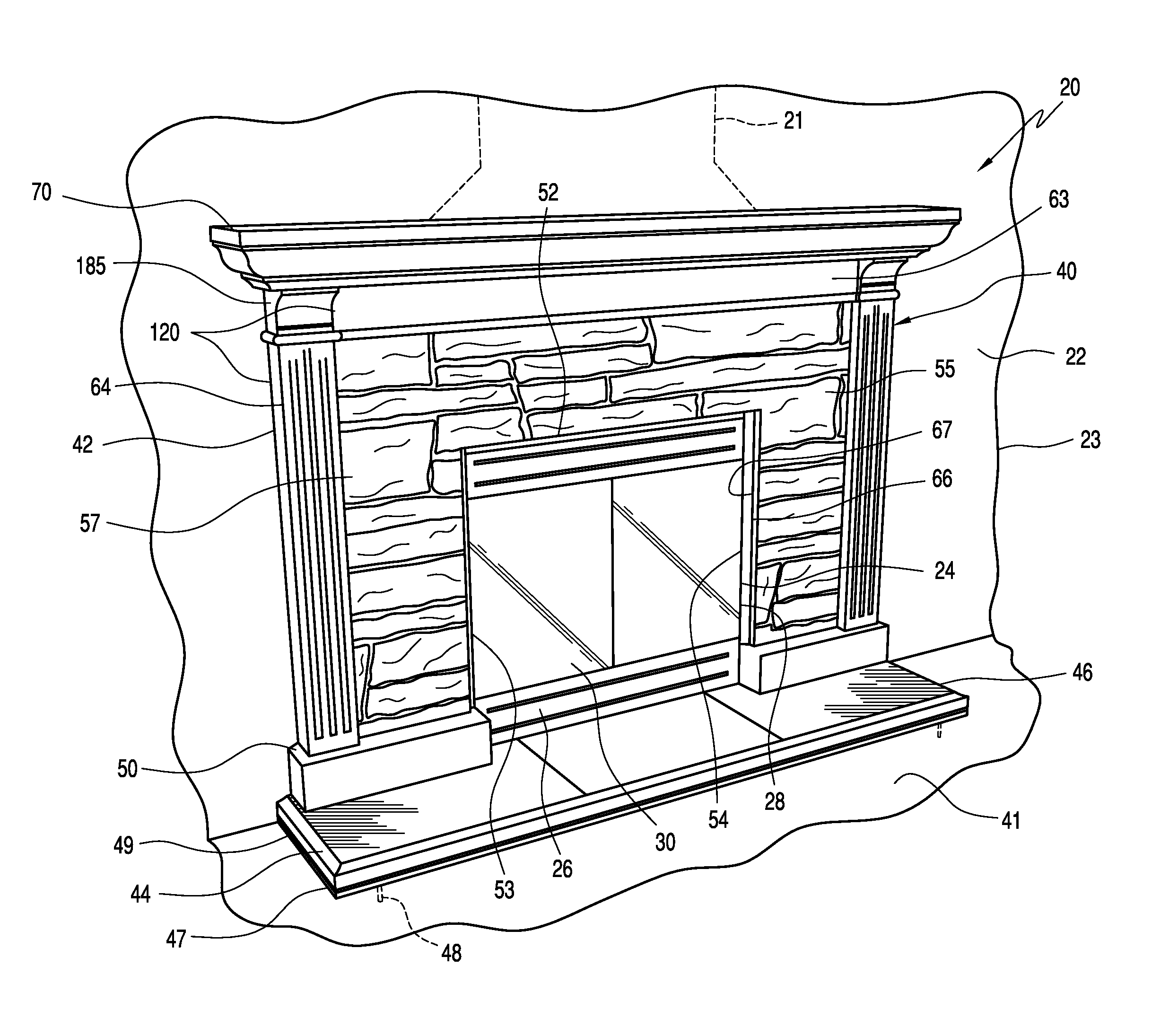

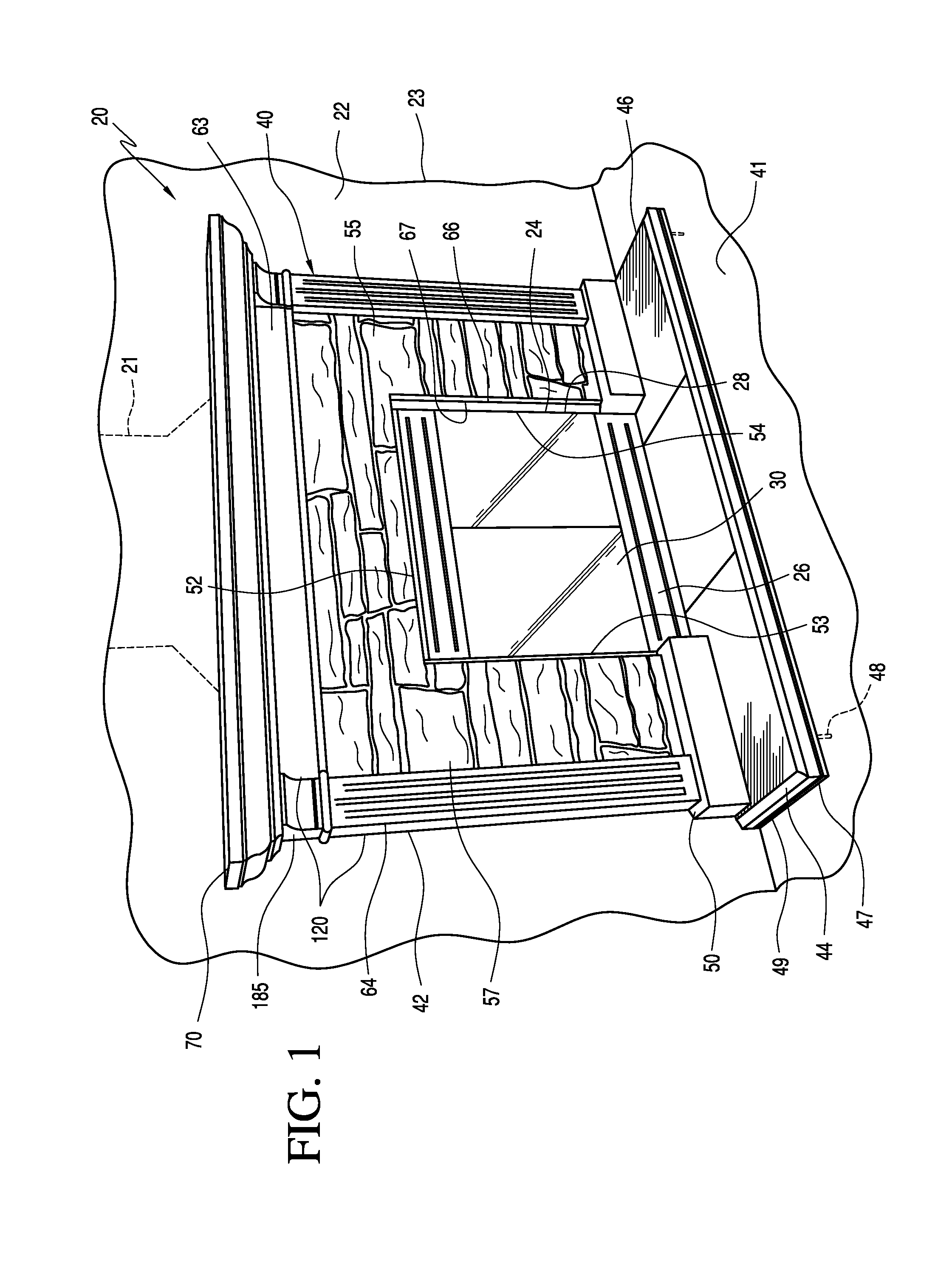

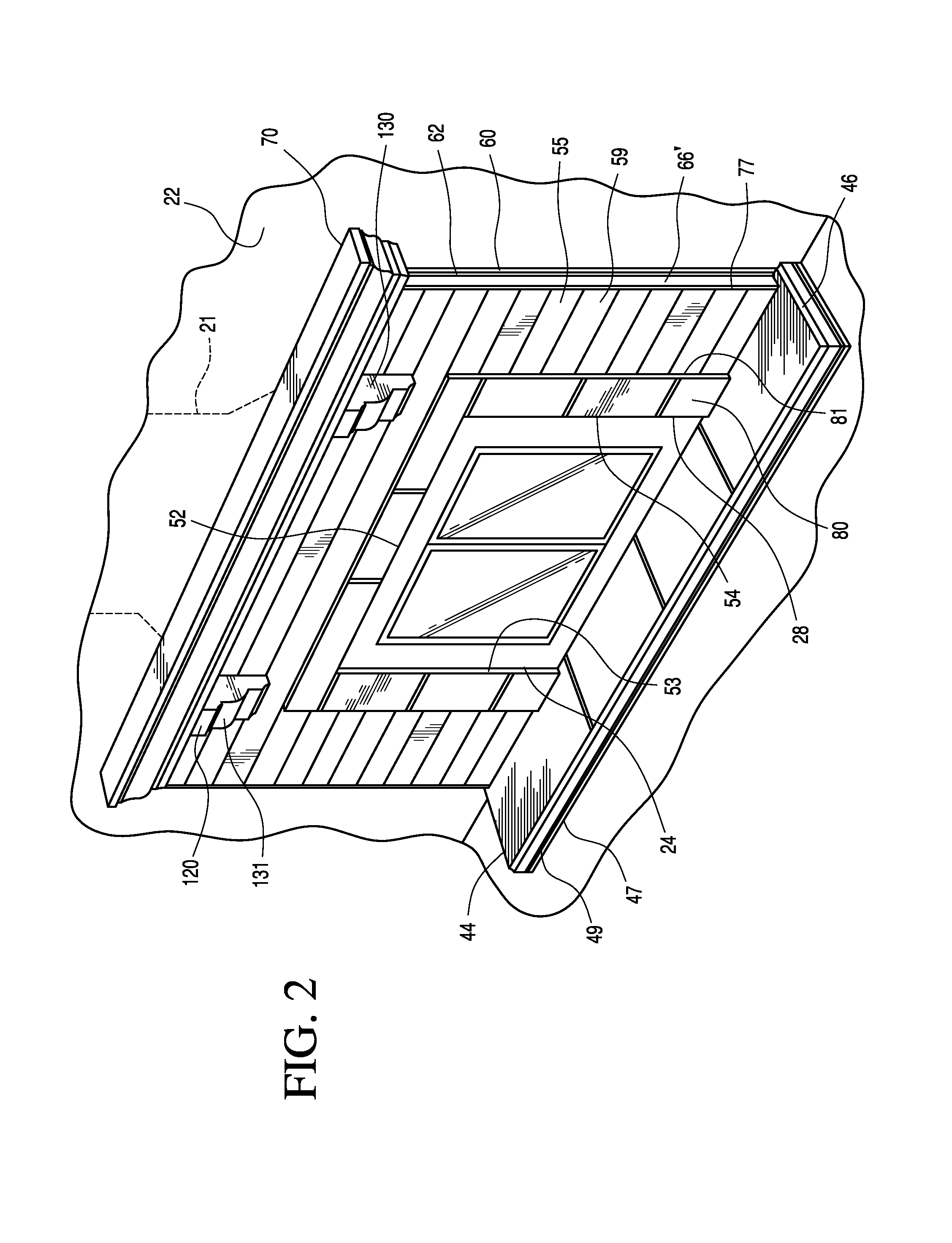

[0027]With initial reference to FIG. 1, there is shown an exemplary fireplace 20, having an associated chimney 21, located in a support wall 22 of a house or other building 23. As shown, the fireplace 20 is a pre-manufactured fireplace having a front opening 24. Vents 26 may be provided above and below a firebox 28 to allow air to circulate and provide better heating efficiency. A pair of glass doors 30 is provided to allow people to tend to the fireplace 20. The doors 30 may be left closed or open as desired. When the fireplace 20 is not is use, the doors 30 are typically left shut in order to prevent air from escaping up the chimney 21. The fireplace 20 may be a conventional wood fireplace or may be fueled by natural gas, propane or other sources.

[0028]A fireplace surround assembly 40 is adapted to be mounted on a support floor 41 and to the support wall 22 around the fireplace 20. The surround assembly 40 is modular and formed from a plurality of surround components 42. A consume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com