Recycled aggregate artificial artistic stone veneer and preparation method thereof

A recycled aggregate and artificial technology, which is applied in the field of building decoration materials, can solve the problems of difficult to remove fine powder, damaged strength of recycled aggregate, and rough appearance color, etc., to achieve improved strength and compactness, high feasibility, and improved Strength and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

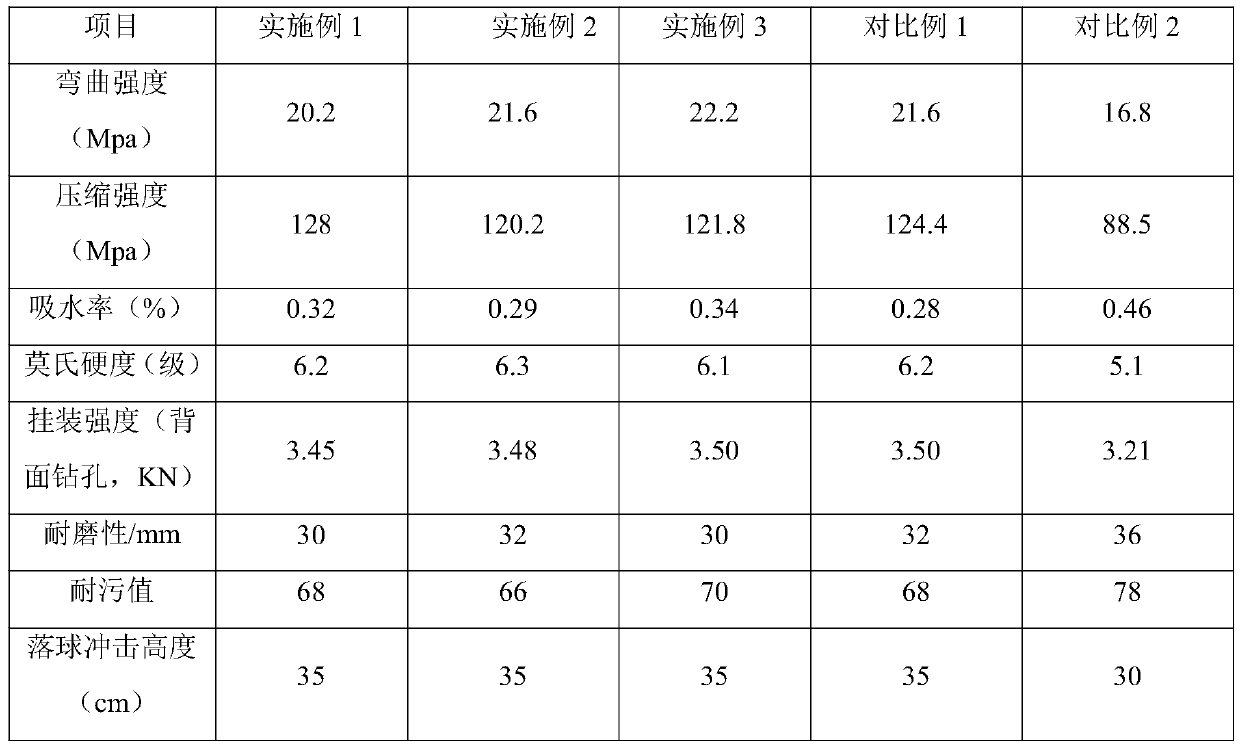

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the recycled aggregate artificial art stone veneer as described above, comprising the following steps:

[0042] S1: Mix the raw materials of the surface layer in the following proportions by weight evenly: 60-70 parts of quartz sand, 6-12 parts of quartz powder, 18-23 parts of cement, 1-4 parts of active additive, 2-4 parts of emulsion, water reducing 0.5-0.8 parts of agent, 0.06-0.12 parts of water retaining agent, 3-5 parts of water;

[0043] Mix the raw materials of the substrate layer in the following parts by weight evenly: 55-65 parts of recycled coarse aggregate, 10-20 parts of recycled fine aggregate, 18-25 parts of cement, 2-4 parts of active additive, concrete sealing and curing agent 0.15-0.30 parts, 0.6-1.0 parts of water reducing agent, 0.06-0.12 parts of water retaining agent, 3-5 parts of water;

[0044] S2: placing the uniformly mixed substrate layer raw materials and surface layer raw materials i...

Embodiment 1

[0059] Prepare the surface layer raw materials (×1kg) of the recycled aggregate artificial art stone veneer according to the following proportions by weight: quartz sand: 60 parts, quartz powder: 6 parts, cement: 18 parts, active additives: 1 part, emulsion: 2 parts , Water reducing agent: 0.5 parts, water retaining agent: 0.06 parts, water: 3 parts.

[0060] Quartz sand is a mixture of 16-120 mesh continuous gradation, quartz powder is 160 mesh, cement is high-grade 52.5 ordinary Portland cement, active additive is microsilica fume, emulsion is styrene-butadiene polymer emulsion, and water reducing agent is polycarboxylate. Acid high-efficiency water reducer, water retention agent is carboxymethyl cellulose, water is tap water.

[0061] Prepare the substrate layer raw material (× 4kg) of recycled aggregate artificial art stone veneer panel according to the following weight ratio: recycled coarse aggregate: 55 parts, recycled fine aggregate: 10 parts, cement: 18 parts, active ...

Embodiment 2

[0065] Prepare the surface layer raw materials (×1kg) of recycled aggregate artificial art stone veneer according to the following proportions by weight: quartz sand: 65 parts, quartz powder: 9 parts, cement: 20.5 parts, active additives: 2.5 parts, emulsion: 3 parts , Water reducing agent: 0.65 parts, water retaining agent: 0.09 parts, water: 4.0 parts.

[0066] The quartz sand is a mixture of 8-120 mesh continuous gradation, the quartz powder is 300 mesh, the cement is high-grade 52.5 white cement, the active additive is slag powder, the emulsion is styrene-acrylic polymer emulsion, and the water-reducing agent is polycarboxylic acid high-efficiency water-reducing agent. agent, the water-retaining agent is hydroxypropyl methylcellulose, and the water is tap water.

[0067] Prepare the substrate layer raw material (× 4kg) of recycled aggregate artificial art stone veneer panel according to the following proportions by weight: recycled coarse aggregate: 60 parts, recycled fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com