Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Solve the appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse cereal instant rice and preparation method thereof

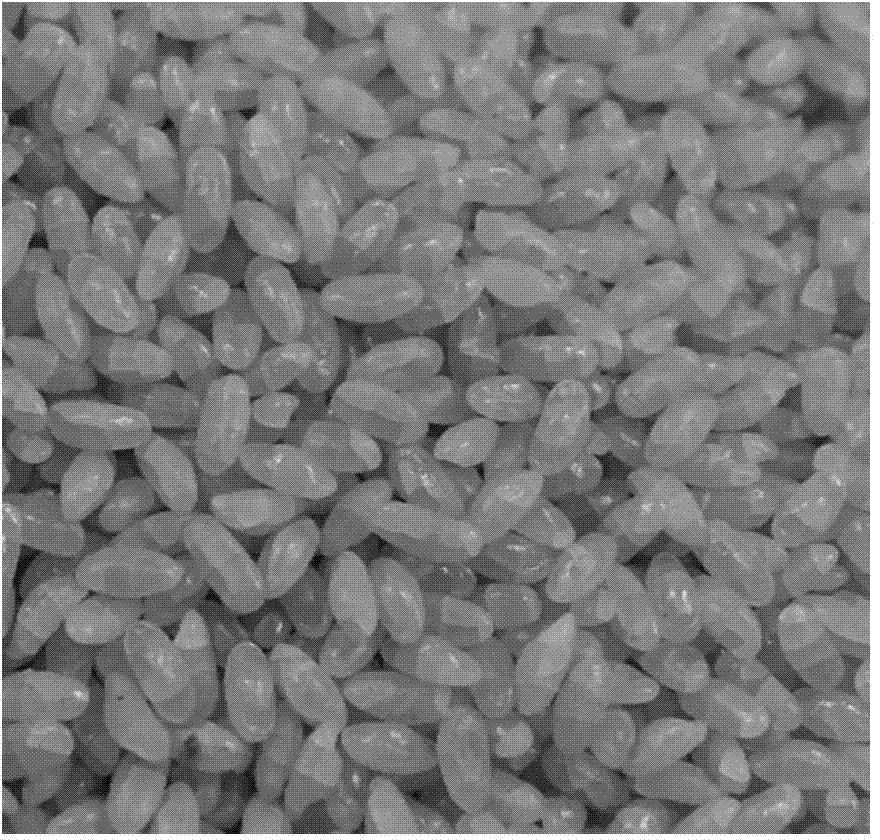

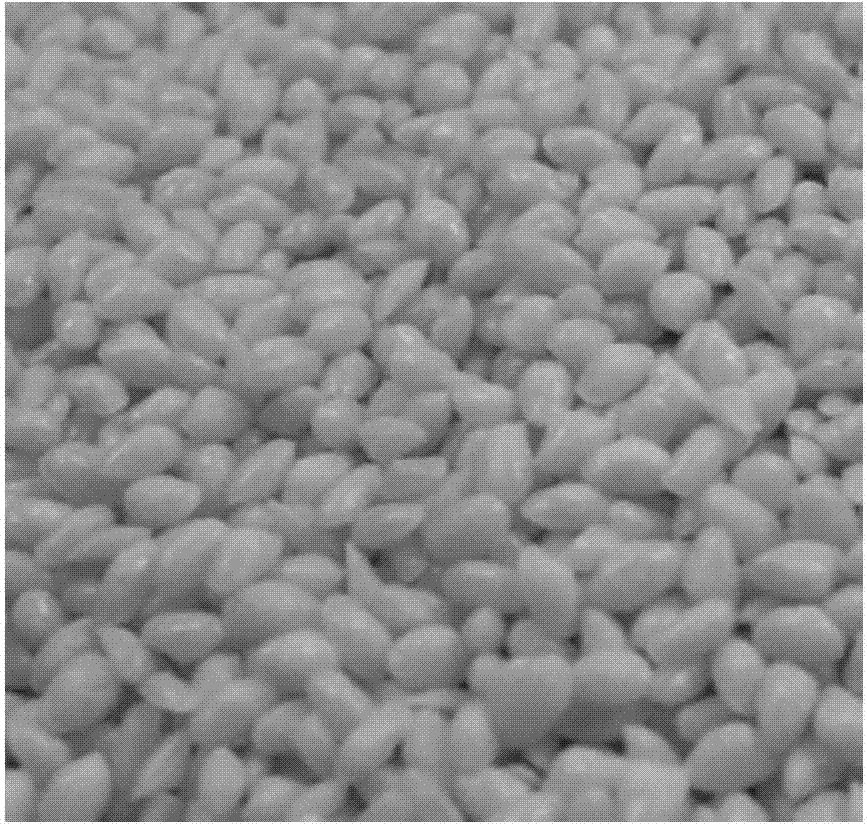

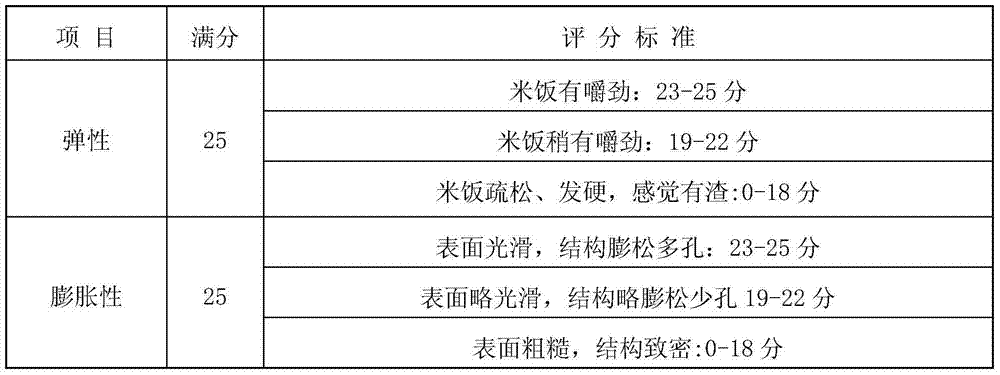

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Aluminum alloy and preparation method thereof

The invention discloses aluminum alloy and a preparation method thereof. The aluminum alloy comprises, by weight, 4.0%-11.0% of Zn, 2.0%-3.0% of Mg, 0-0.3% of Si, 0-0.4% of Ti, 0-0.2% of Cu, 0-0.01% of Zr, 0-0.01% of Cr, 0-0.01% of Mn, less than 0.1% of Fe and the balance Al and accessory impurities. The weight ratio of Zn to Mg is 2-6. According to the aluminum alloy, the surface appearance defects such as fibrous structure stripes and surface yellowing in the anodic oxidation treatment process of commercial 7xxx-series (such as 7075, 7050 and 7055) high-strength aluminum alloy are overcome, high strength and good anodic oxidation treatment surface appearance of the aluminum alloy are integrated, the strength of the aluminum alloy for existing electronic equipment body shells is further improved, and the requirement of electronic equipment lighting and thinning development for aluminum alloy materials for the equipment body shells is effectively met; meanwhile, the application field of the 7xxx-series high-strength aluminum alloy also can be expanded.

Owner:AAC MICROTECH CHANGZHOU

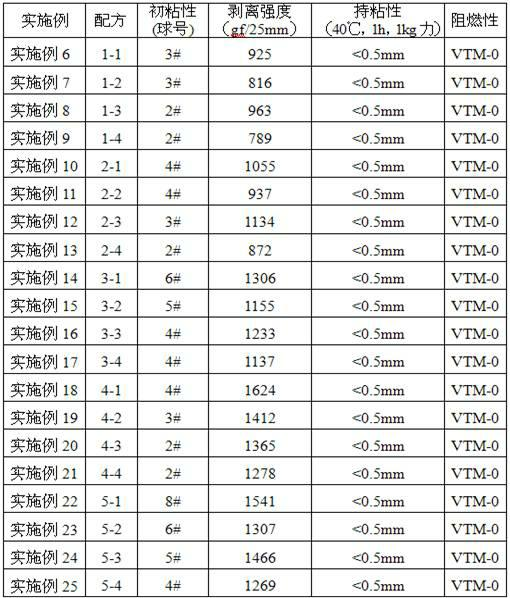

Preparation method for halogen-free flame retardant polyester labeled paper

ActiveCN102518003AImprove flame retardant performanceImprove stabilityStampsNon-fibrous pulp additionMethacrylatePolyester

The invention discloses a preparation method for halogen-free flame retardant polyester labeled paper. The method is characterized in that the method comprises the following steps: adopting butyl acrylate, ethylhexyl acrylate, acrylic acid, hydroxyethyl acrylate, ethyl methacrylate, a phosphorus-containing flame retardant monomer, a solvent, an initiator, and the like as raw materials to prepare a phosphorus-containing flame retardant acrylic acid pre-polymerization resin; preparing a phosphorus-containing flame retardant acrylic acid pressure sensitive adhesive; uniformly coating the phosphorus-containing flame retardant acrylic acid pressure sensitive adhesive on a halogen-free flame retardant polyester thin film; compounding the polyacrylate pressure sensitive adhesive-coated halogen-free flame retardant polyester thin film and a polyester release film; and carrying out ripening to prepare the halogen-free flame retardant polyester label product. With the present invention, the flame retardant and pressure sensitive adhesion property, the appearance and the environmental protection quality of the whole label product can be effectively improved, and the halogen-free flame retardant polyester labeled paper can meet the performance requirement of VTM-0 grade flame retardation.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

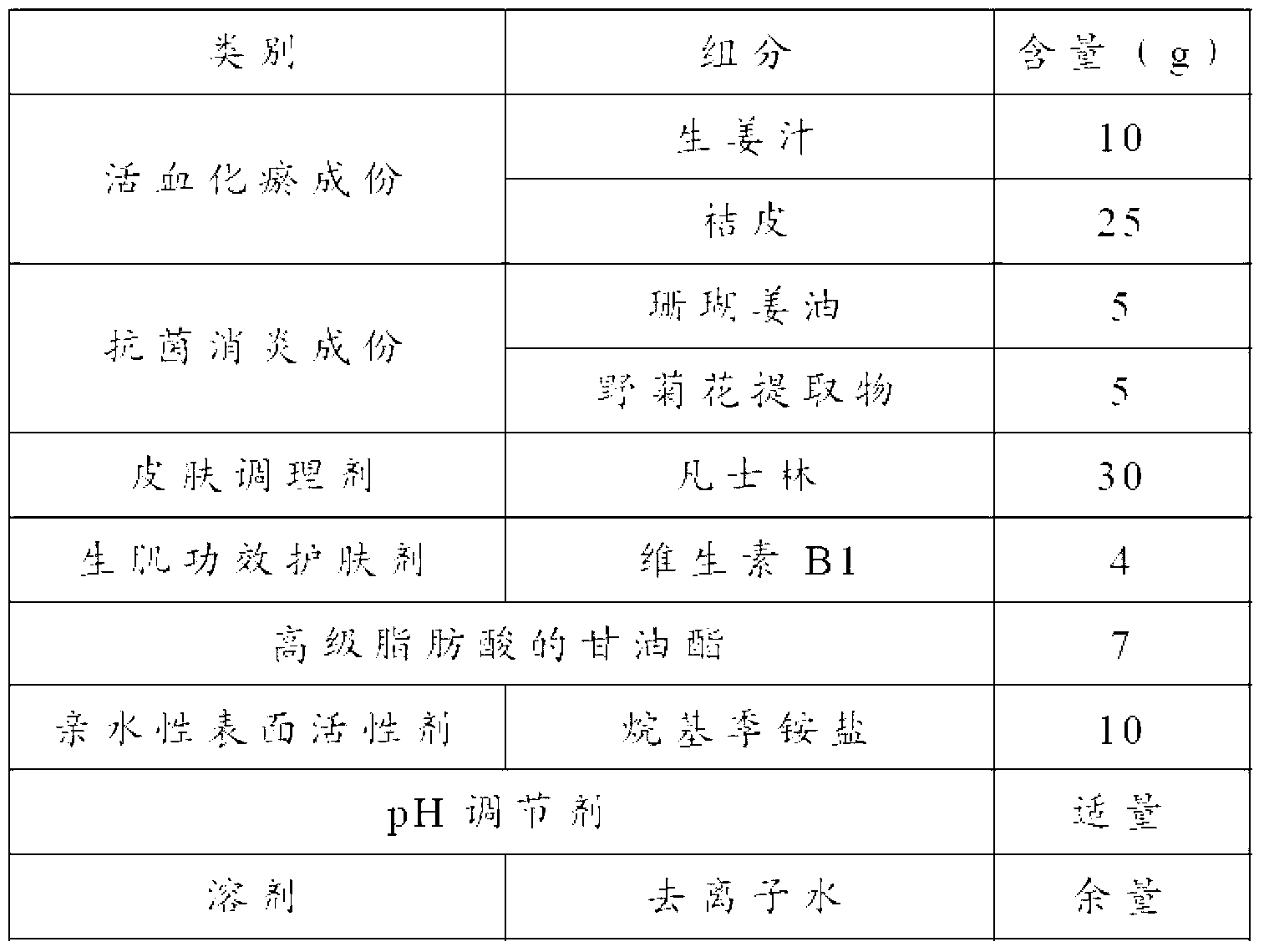

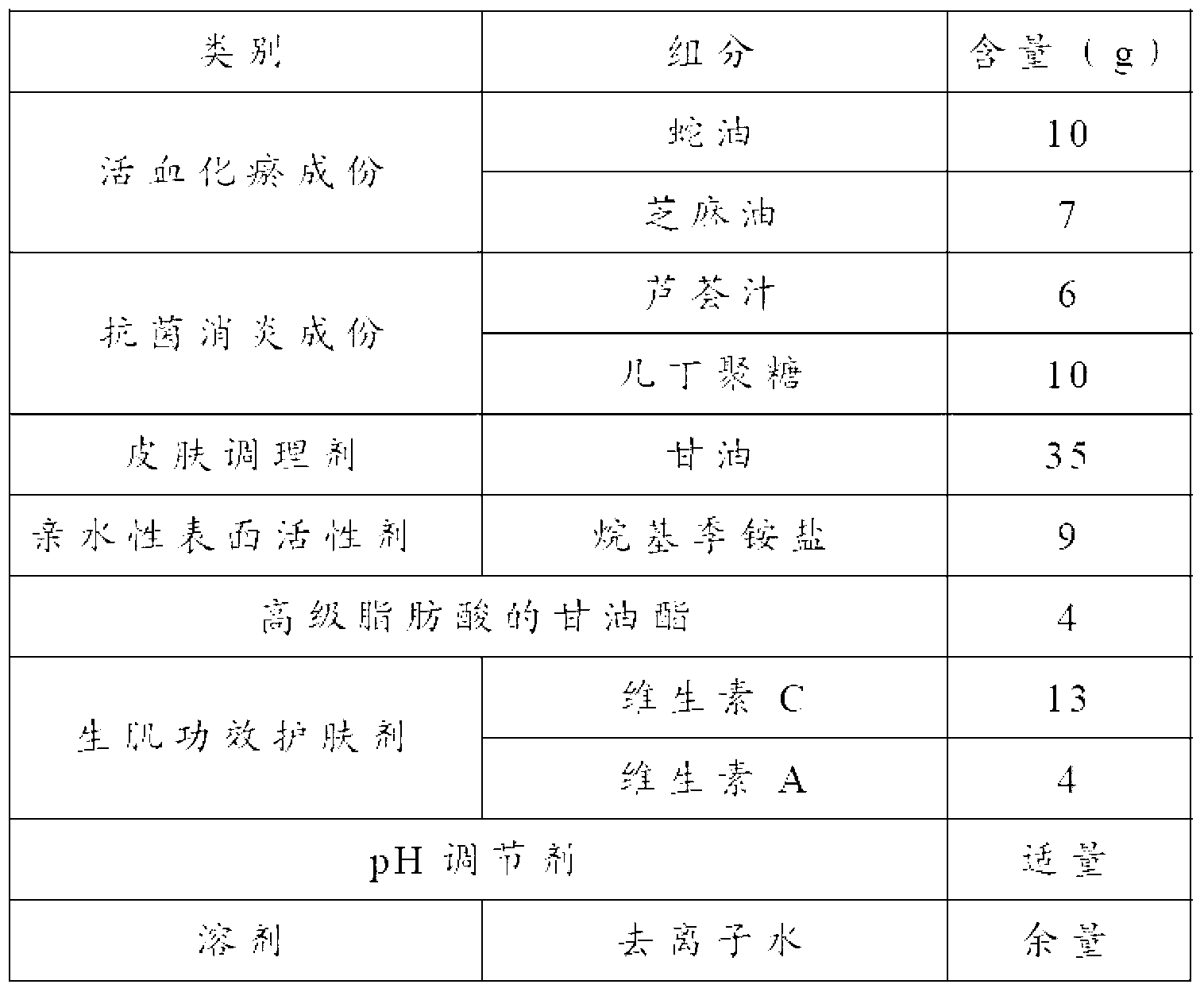

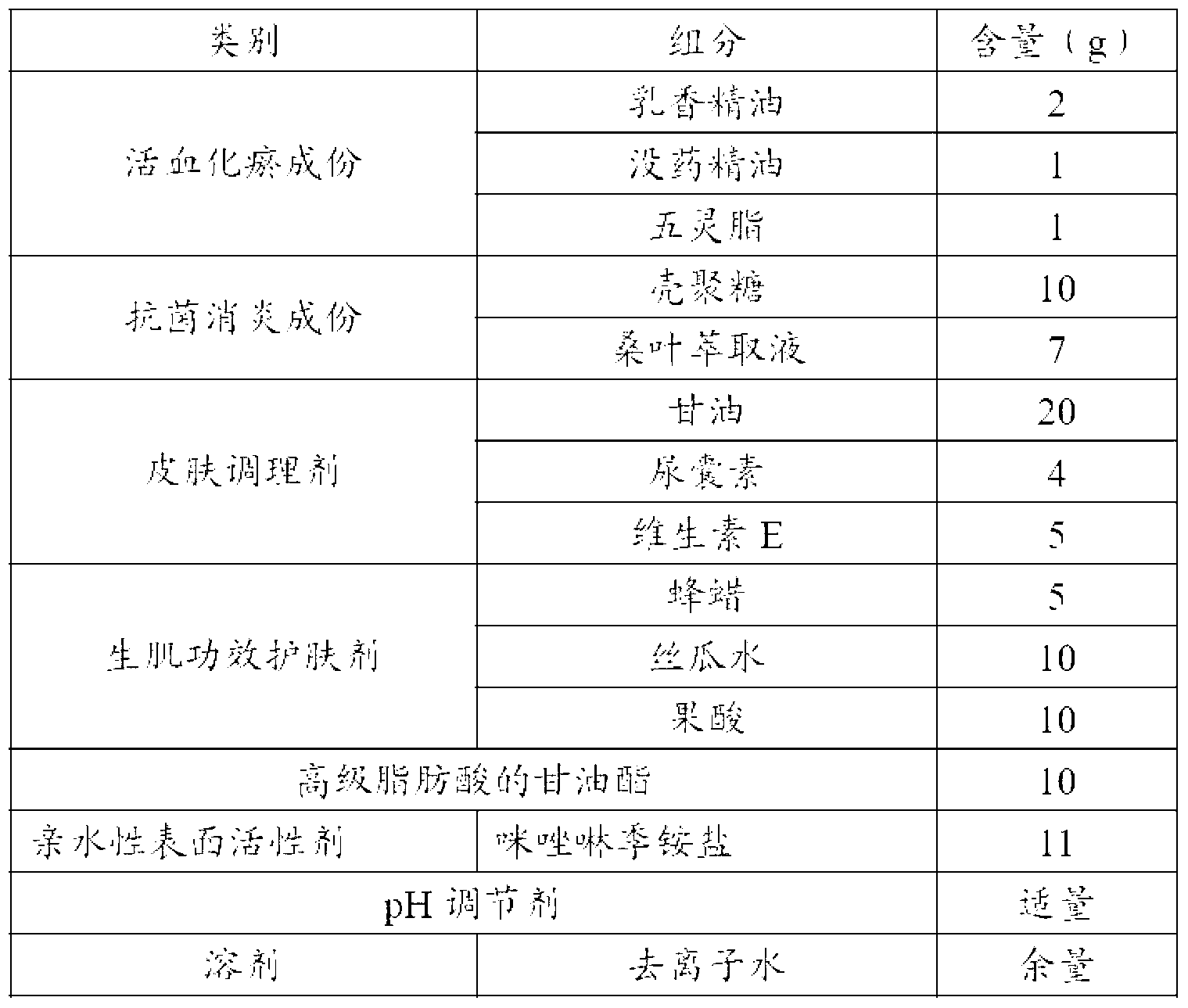

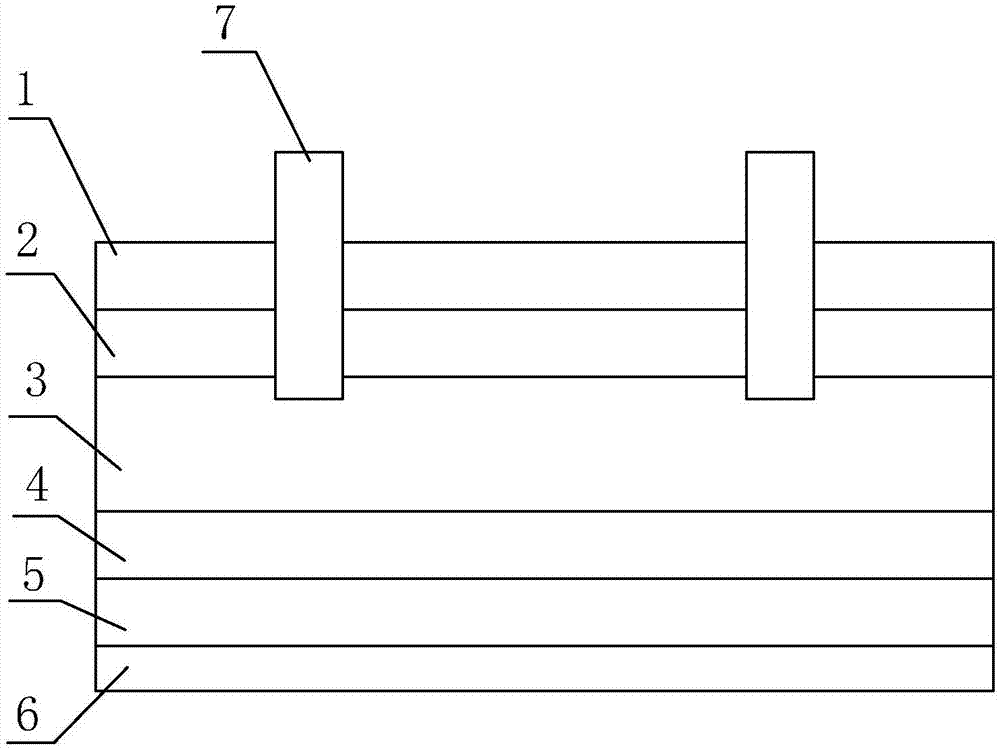

Skin care composition and facial tissue with same

ActiveCN103263669AEasy to useSignificant improvementDermatological disorderSheet deliveryFacial tissueAngelica sinensis extract

The invention discloses a skin care composition which comprises at least one component for promoting blood circulation to remove blood stasis, at least one antisepsis and anti-inflammation component, at least one skin conditioner and at least one muscle generation skin care agent according to the mass ratio of (0.1-50):(0.1-30):(0.1-80):(0.1-30), wherein the component for promoting blood circulation to remove blood stasis is one or a combination of several of ginger juice, snake oil, a radix angelicae extract, a nux vomica extract, a natural copper extract, a sangusis draconis extract, a caulis spatholobi extract, frankincense essential oil, myrrh essential oil, sesame oil, sheep suet, salviae miltiorrhizae, radix notoginseng, a red peony root extract, trogopterus dung, safflower oil, lithospermum essential oil, an angelica sinensis extract, puffball powder, plant soot, orange peel and lavender essential oil. The invention also provides a facial tissue with the skin care composition. The facial tissue can be carried by a user and is used for nursing and improving a chilblain affected part, and the skin improving effect at the affected part is obvious.

Owner:海南金红叶纸业有限公司 +1

Reworking technology of finished crystalline silicon solar cell

ActiveCN102629644AEasy to recycleReduce manufacturing costFinal product manufactureSemiconductor devicesEngineeringSilicon solar cell

The invention discloses a reworking technology of a finished crystalline silicon solar cell to solve an existing problem of resource wasting caused by not reclaiming low-efficiency and appearance-scrapped cells. The technology comprises following steps: 1) carrying out selection and classification on finished cells which need to be reworked; 2) restoring the classified finished cells into original silicon chips; and 3) manufacturing qualified cells from the original silicon chips by using a conventional technology. With the reworking technology of the invention, precious metal electrodes of the cells are reclaimed, qualified products are manufactured after the cells are restored into silicon chips, a yield rate exceeds 90%, and production cost is saved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Double-faced alumina P-type PERC solar cell and making method

ActiveCN107887453ASolve the appearanceSolve the problem of blackening of EL edgeFinal product manufacturePhotovoltaic energy generationScreen printingSolar cell

The invention relates to the field of solar cells, and discloses a double-faced alumina P-type PERC solar cell and a making method. The cell comprises a silicon wafer and two positive electrodes; thefront surface of the silicon wafer is sequentially provided with a front silicon nitride film and a front alumina film; and the back surface of the silicon wafer is sequentially provided with a back alumina film, a back silicon nitride film and a back electrode / field. The making method comprises steps of 1) cleaning and etching, 2) PN junction making through diffusion, 3) etching, 4) front siliconnitride film coating, 5) double-faced alumina film coating, 6) back silicon nitride film coating, 7) laser slotting, and 8) screen printing and sintering. The back surface and the front surface of the silicon wafer are coated with the alumina films, the problems of frontal appearance color difference and blackening of an EL edge caused by coil coating when the back alumina is made in the conventional P-type PERC cell can be solved, the alumina film layer can be uniformly deposited on the front surface, the reflectivity is reduced, and the conversion efficiency is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Low-temperature-hot-stamped gold-stamped type tipping paper for cigarettes and preparation method of tipping paper

ActiveCN105200863AImprove efficiencyImproving hot stamping inaccuracySpecial paperInksAdhesive glueProcess engineering

The invention provides low-temperature-hot-stamped gold-stamped type tipping paper for cigarettes and a preparation method of the tipping paper. The low-temperature-hot-stamped gold-stamped type tipping paper for the cigarettes and the preparation method of the tipping paper are used for overcoming the disadvantages in existing high-temperature hot-stamping that the energy consumption is high, and that the rate of finished products is low and the cold hot-stamping effect is poor. The gold-stamped type tipping paper for the cigarettes, provided by the invention, is prepared through firstly printing environment-friendly alcohol-soluble white ink and printing ink on a base paper layer, then, additionally printing a layer of an adhesion-assisting glue material on the environment-friendly alcohol-soluble ink layer, then, carrying out low-temperature hot-stamping at the temperature of 85-100 DEG C, and carrying out laser boring, slitting and rewinding. According to the low-temperature-hot-stamped gold-stamped type tipping paper for the cigarettes, provided by the invention, an adhesion-assisting layer is additionally printed on the ink layer and has the functions of protecting the ink layer, enhancing the hydrophobicity of the ink layer and improving the adherence with a gold-stamped layer and the fastness of adhering of winding-adhesive glue, and special electrochemical aluminum hot-stamping foil for low-temperature hot-stamping is used in a matched manner, so that a low-temperature hot-stamping procedure can be completed at the temperature of 85-100 DEG C, and the energy consumption of a gold-stamping process is greatly lowered, and the service efficiency of a gold-stamping plate is increased, and thus the cost of gold-stamping is reduced.

Owner:玉溪接装纸制造有限公司

Method for performing high-moisture organization by using wheat vital wheat gluten plasmogen

PendingCN105410329ASolve the difficulty of extrusion aloneGood formabilityVegetable proteins working-upWheat glutenMoisture

The invention discloses a method for preparing high-moisture organized protein by using wheat vital wheat gluten plasmogen. According to the method, extrusion treatment is performed on the wheat vital wheat gluten plasmogen by using a twin-screw extruder with a cooling die head, and high-moisture wheat vital wheat gluten organized protein products are prepared. The high-moisture organized protein which is prepared by using the wheat vital wheat gluten plasmogen in the method presents texture similar to that of meat and better fibrous structure characteristics; besides, the vital wheat gluten plasmogen is used as a raw material, drying the raw material is not needed, and water is not needed to be added for mixing, so that the original activity of vital wheat gluten can be maintained, energy resources are saved, pollution is reduced, products have better appearance and texture, comprehensive and balanced nutrition, low fat and low cholesterol, the products are suitable for public consumption, and the products have broad development and application prospects in the respect of replacing meat products or being used as meat simulants.

Owner:河南省邓肯生物科技有限公司 +1

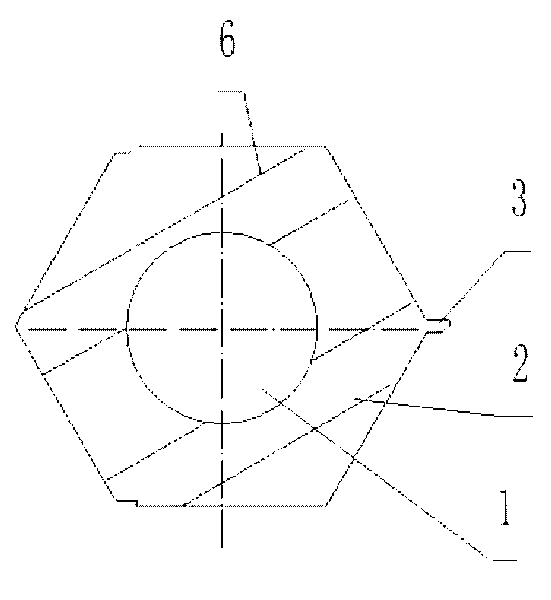

Directional punching shear and processing method for iron core pieces of stator and rotor of rotary motor

ActiveCN101719705ASolve the misalignment of inner and outer edgesSolve the appearanceManufacturing stator/rotor bodiesPunch pressDislocation

The invention discloses a directional punching shear and processing method for the iron core pieces of a stator and a rotor of a rotary motor, which is characterized in that the annular blank pieces of the iron cores of the stator, the middle part of which is provided with an installation through hole of the rotor are firstly punched and are provided with a positioning mark of a rotating orientation, the positioning mark of the rotating orientation is used for forming the annular blank pieces and a punch mould according to a preset rotating orientation during forming, and a mark which is used for correctly overlapping the iron core pieces of the same stator is manufactured on the formed iron core pieces of the stator after the iron core pieces of the stator are formed.The invention aims to provide the directional punching shear and processing method for the iron core pieces of the stator and the rotor of the rotating motor. The method effectively solves the problem of size deviation of the iron core pieces caused by different cutting edges of the mould and the problem of dislocation of the inner edges and the outer edges of the iron cores caused by the size deviation of the iron core pieces caused by different orientations of the rolling traces of materials and improves the appearance of the iron cores greatly.

Owner:陈石云

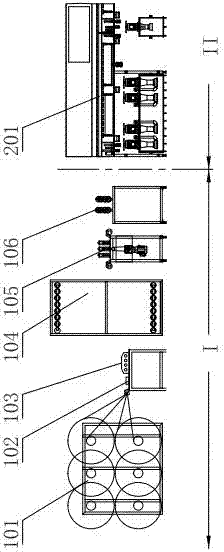

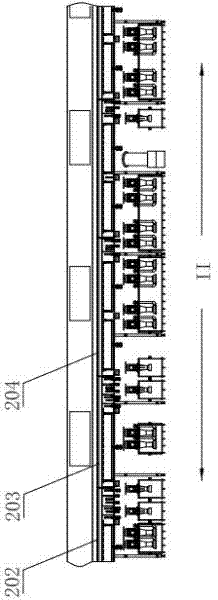

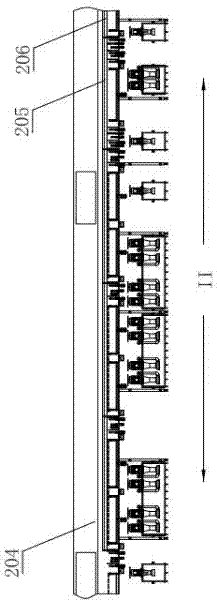

Electroplating process and production line of solar cell sheet solder strip

ActiveCN102443831AReduce energy consumptionOvercome yieldSemiconductor devicesElectrolysisHigh energy

The invention discloses an electroplating process and electroplating production line of a solar cell sheet solder strip. The electroplating process comprises the following serial steps of: feeding, straightening and flattening, copper strip polishing and softening, electrolyzing for deoiling, copper ion regenerating, high-speed electroplating pretreatment, high-speed electrotinning, neutralizing, cleaning with pure water, tin layer repairing, ultrasonic cleaning, drying, solder strip destressing, fault detection, servo material collection and the like in turn. The electroplating production line is composed of a feeding part, electroplating and pretreatment and post-treatment parts, and a material collection part, which are sequentially connected. According to the invention, a high-performance weldable coating is obtained by adopting a high-grade electrochemical method, thus the defects of a tin hot-dipping process, such as high energy consumption, low yield and the like, are overcome, and efficient production is realized; multiple channels share an identical process, which is environmentally-friendly and energy-saving; the solder strip tin layer produced by adopting the electroplating process has adjustable thickness, very good uniformity and smooth and clean appearance without defects; and by adopting the electroplating process, the defects of tradition hot-dipping tin coating in the appearance and performance are avoided, and the high-quality solder strip can be produced.

Owner:SHANGHAI WELNEW MICRO ELECTRONICS

High-strength rubber track for excavating machines and manufacturing method thereof

The invention belongs to the technical field of rubber tracks and preparation thereof, specifically relating to a high-strength rubber track for excavating machines and a manufacturing method thereof. The high-strength rubber track contains the following raw materials by weight part: 100 parts of natural rubber, 3-6 parts of zinc oxide, 1.5-2.5 parts of stearic acid, 1-2 parts of an anti-aging agent 4010 NA, 1-2 parts of an anti-aging agent RD, 40-60 parts of carbon black N330, 8-12 parts of white carbon black, 2-6 parts of Si-69, 3-6 parts of aromatic oil, 2-2.8 parts of S, 1.2-1.8 parts of accelerant Cz 1.2-1.8, and 0.5-0.8 part of scorch retarder Pvi. The high-strength rubber track prolongs service life thereof, and has the advantages of excellent appearance, low hardness, high tear resistance, high tensile strength, excellent ageing resistance and ozone resistance. The high-strength rubber track has lower dynamic heating performance, so the high-strength rubber track can keep excellent performance and appearance under the more bad service environment; the technology is simple; and raw material ratio is reasonable.

Owner:QINGDAO TKS SEALING IND

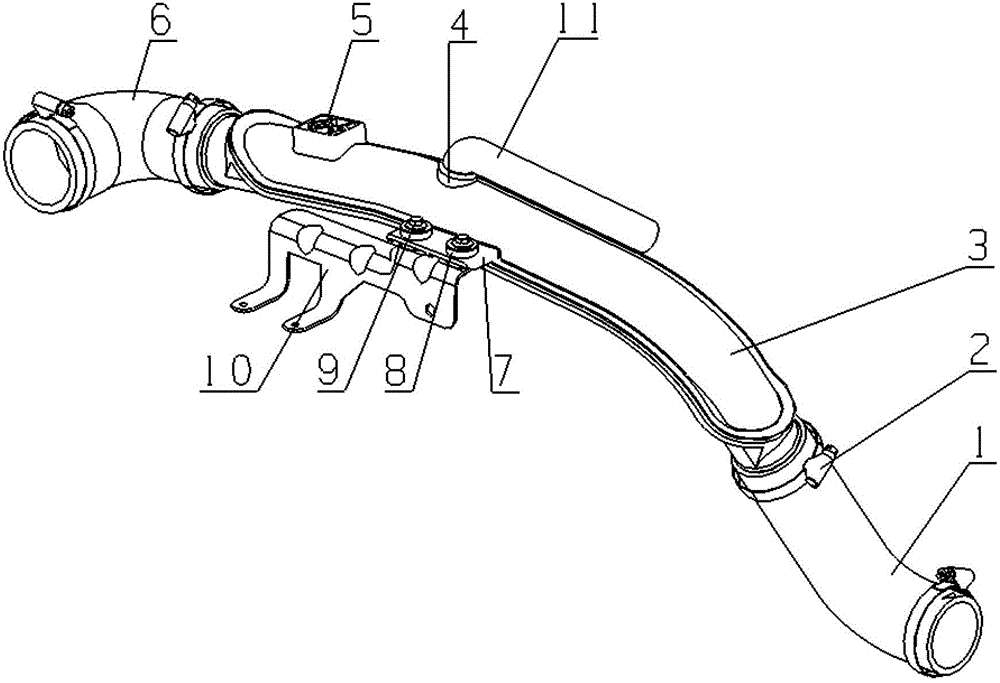

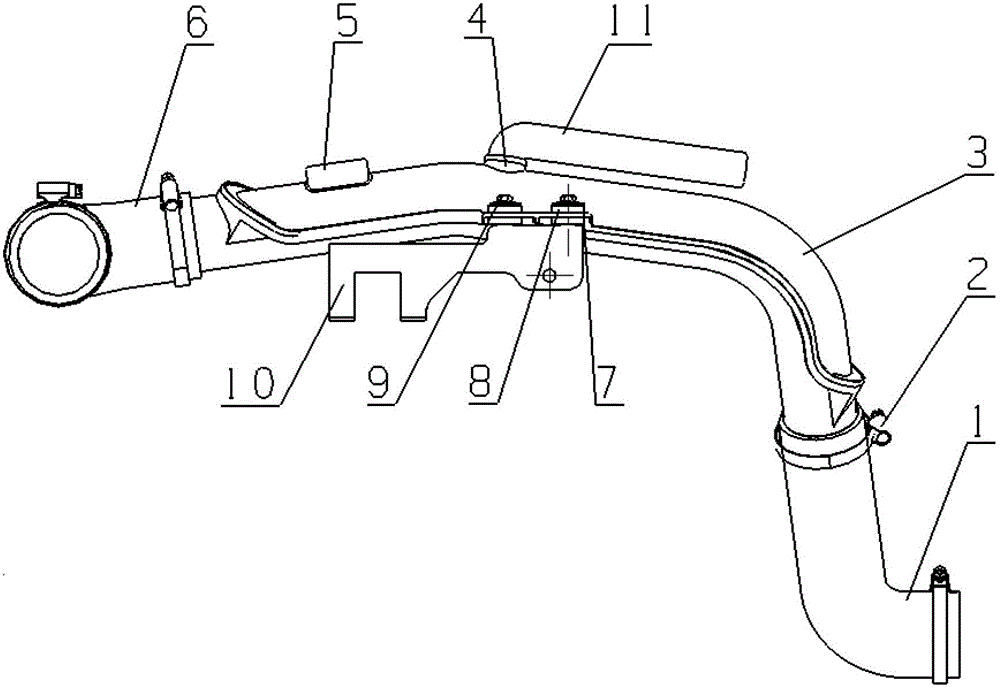

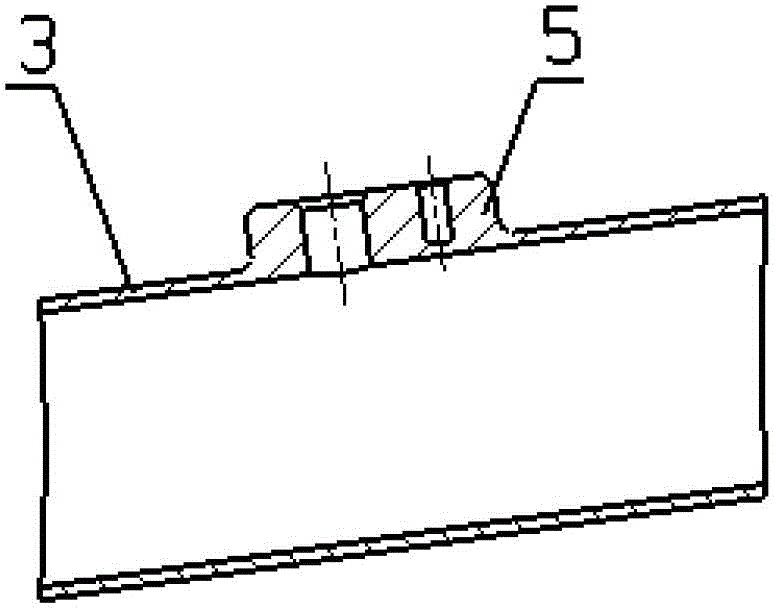

Gas outlet pipe for intercooler

ActiveCN103147841AImprove NVH performanceEliminate Noise PeaksPipe supportsInternal combustion piston enginesEngineeringIntercooler

The invention discloses a gas outlet pipe for an intercooler, which comprises a hard gas outlet pipe, flexible gas outlet pipes used for connecting a intercooler and connected with the two ends of the hard gas outlet pipe respectively, and a flexible gas outlet pipe b connected with a throttle valve of an engine, wherein a sensor interface is formed in the hard gas outlet pipe, and the hard gas outlet pipe and the sensor interface are subjected to integral injection moulding. The gas outlet pipe for the intercooler is in a flexible gas outlet pipe plus hard gas outlet pipe plus flexible gas outlet pipe structure, the hard gas outlet pipe is in an injection moulding structure, and multiple required parts can be integrated, so that the problems that the quality of welding joints at the sensor interface and a fixed bracket welded on the traditional aluminum pipe cannot be controlled easily, gas can leak, and an appearance is not attractive are solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

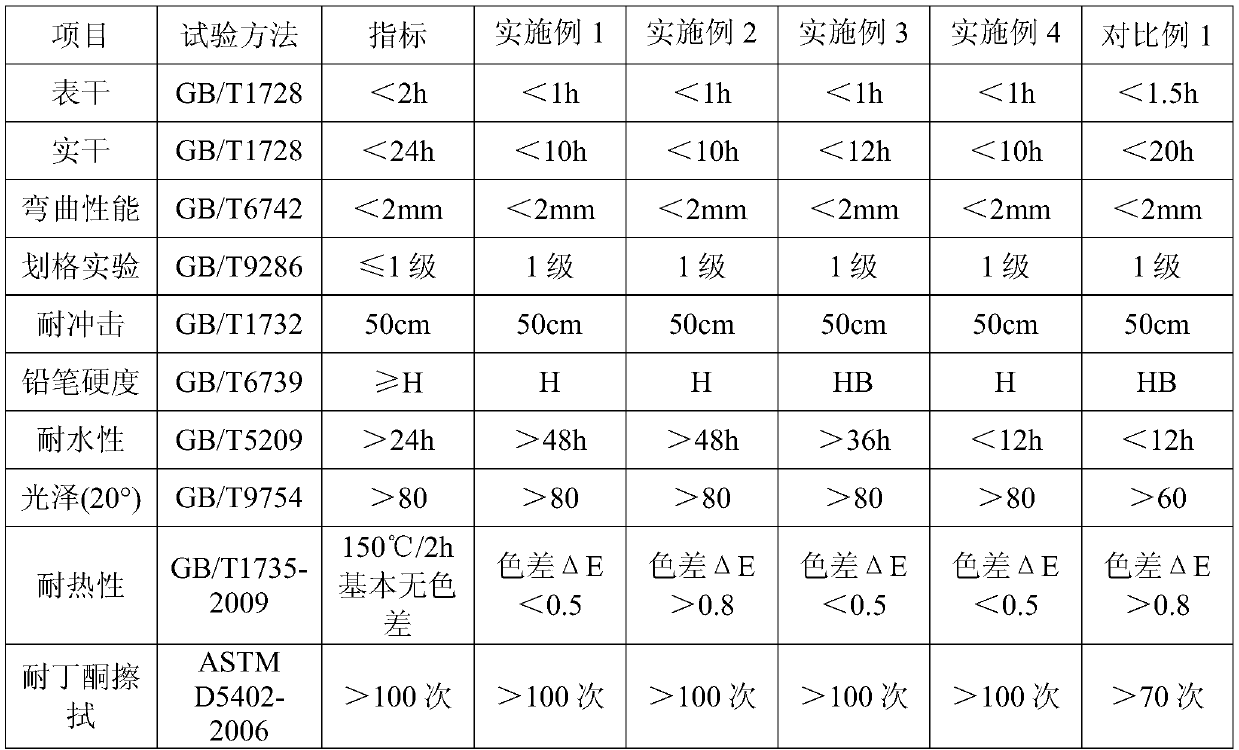

Water-based highlight two-component acrylic polyurethane coating and preparation method thereof

InactiveCN110922878AImprove patienceGood construction performancePolyurea/polyurethane coatingsPolymer sciencePolyurethane coating

The invention relates to a water-based highlight two-component acrylic polyurethane coating and a preparation method thereof, and belongs to the technical field of coatings. The coating comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 20-40 parts of a water-based hydroxy acrylic acid dispersion I; 20-40 parts of a water-basedhydroxy acrylic acid dispersion II, 0-0.5 part of a pH regulator, 1-5 parts of a conventional auxiliary agent, 1-6 parts of a coalescing agent, 1-25 parts of a pigment filler, 0-1.5 parts of a special auxiliary agent, 0.1-0.5 part of bentonite, 5-20 parts of deionized water, 0-1 part of a flash rust inhibitor and 0-1 part of a thickening agent. And the component B comprises the following components in parts by weight: 20-70 parts of an isocyanate curing agent I, 20-70 parts of an isocyanate curing agent II and 0-30 parts of a cosolvent. The two-component coating disclosed by the invention hasthe advantages of high gloss, high fullness and small fog shadow, and the problems of low performance and poor appearance of a water-based coating are solved.

Owner:山东七维新材料有限公司

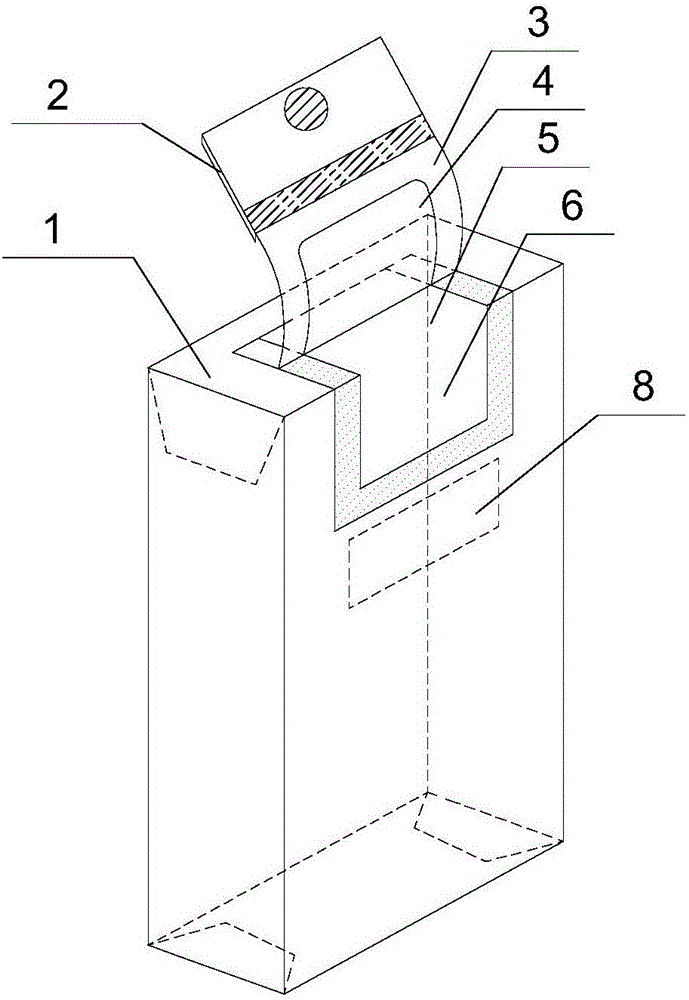

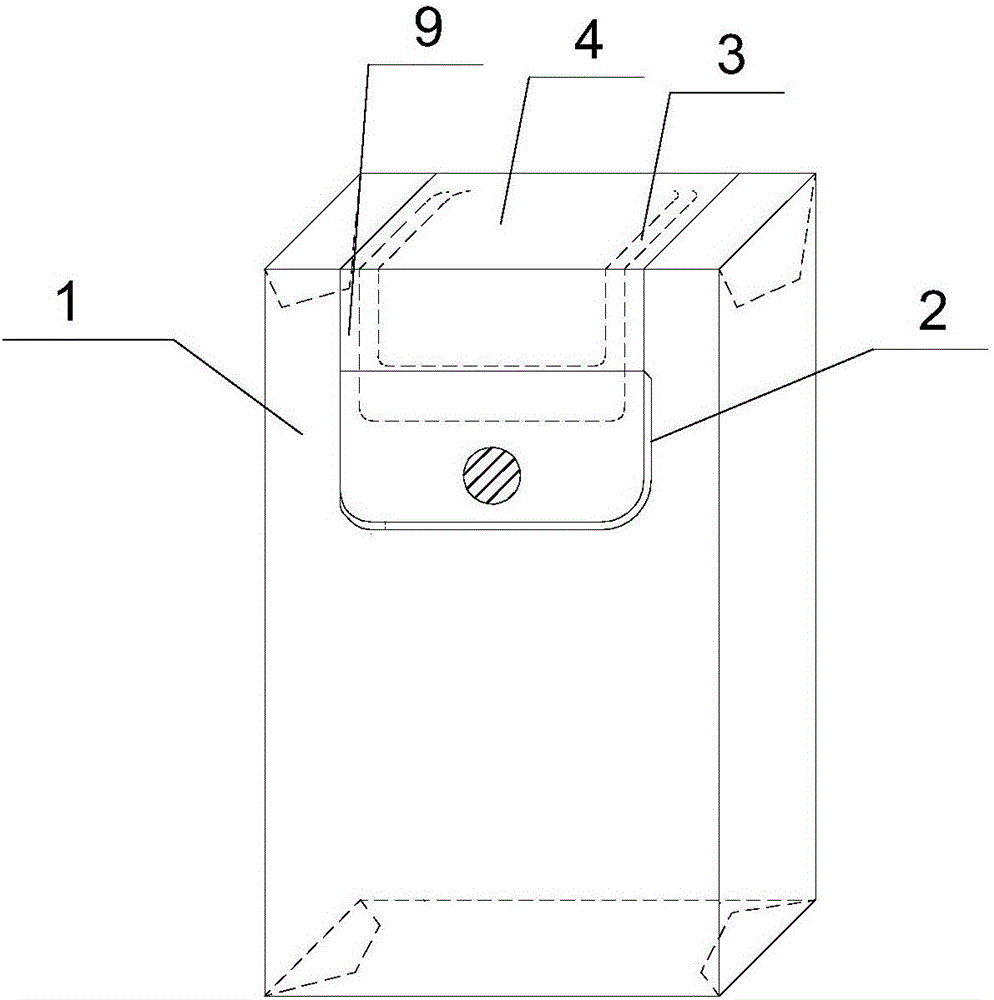

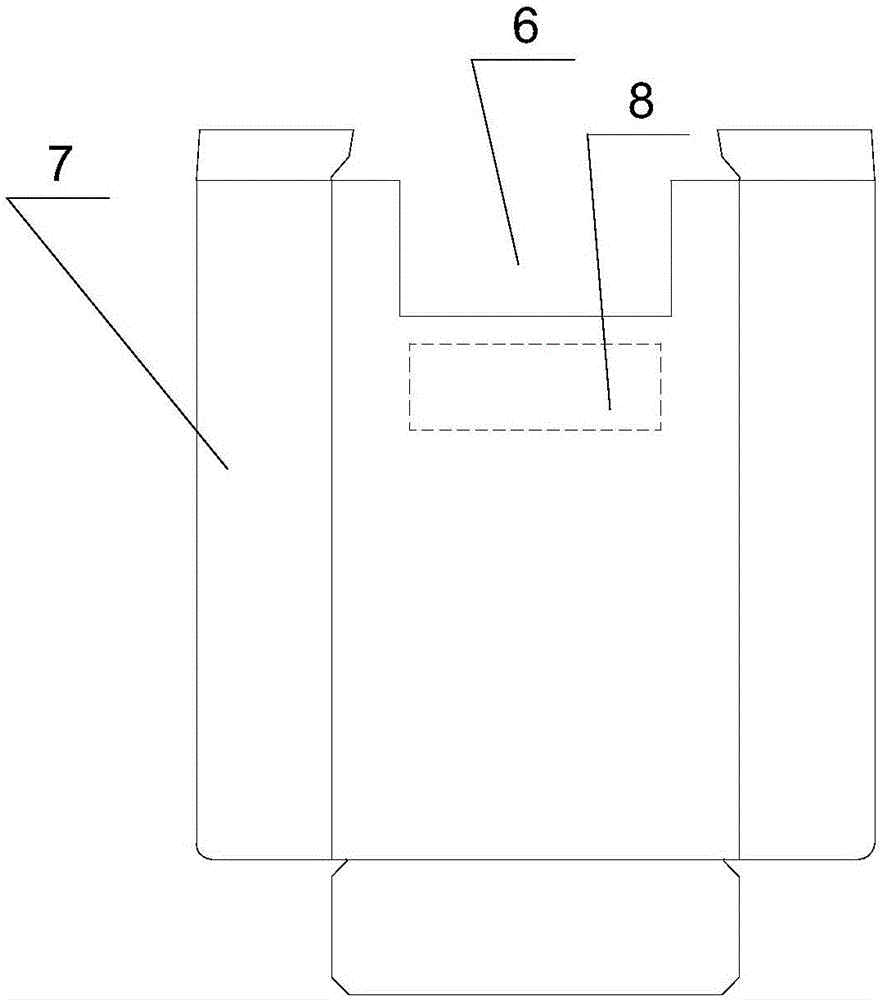

Packaging box with gluing and absorbing combined sealing function

InactiveCN106240987ASolve the problem of open edge warpingRealize the closed functionRigid containersLocking devicesEngineeringSheet material

The invention discloses a packaging box with a gluing and absorbing combined sealing function. The packaging box is formed by a supporting frame and a wrapping sheet. The supporting frame is of a box-shaped support structure and is provided with a frame opening used for enabling packaged articles in the supporting frame to be taken out. The wrapping sheet wraps the supporting frame, and the wrapping sheet and the supporting frame form the packaging box together. An article taking opening is formed in the wrapping sheet and provided with a sealing sheet, the position of the sealing sheet corresponds to that of the article taking opening, and the size of the sealing sheet is identical to that of the article taking opening. The sealing sheet is covered with a sticky cover sheet. The packaging box is simple in structural design, and machine packaging can be achieved simply by modifying existing packaging machine equipment to a certain degree. Meanwhile, due to the fact that a start label is adopted in the packaging box, the problems that a sealed package is covered with an adhesive sticker cover sheet at present, the appearance is simple and crude, and use is inconvenient are solved, and meanwhile the package sense of beauty is improved.

Owner:SHANTOU DONGFENG PRINTING CO LTD

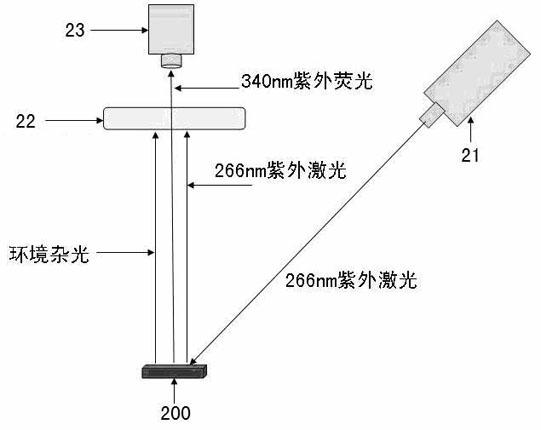

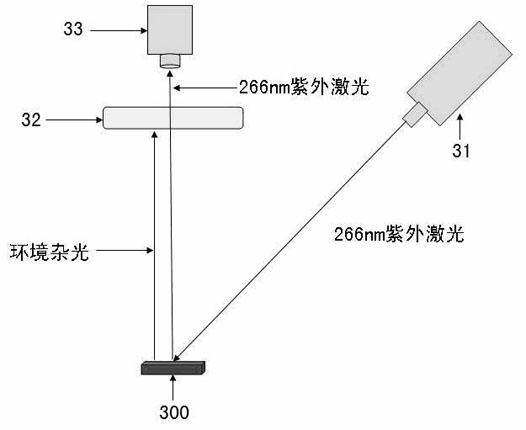

Method and device for revealing and extracting scene potential fingerprint

InactiveCN102184394AGood technical effectDirectionalCharacter and pattern recognitionPhotographyLength waveUltraviolet laser light

The invention discloses a method for revealing and extracting a scene potential fingerprint. The method is characterized by comprising the following steps of: 1, irradiating a short-wave ultraviolet laser light which has a wavelength of 266 nm and is output by a neodymium doped yttrium aluminium garnet (ND-YAG) ultraviolet laser serving as a light source to a detection material on which the potential fingerprint is reserved; 2, filtering environmental parasitic lights by using a band-pass glass filter with the central wavelength of 266 nm, and transmitting a laser image of 266 nm reflected onthe detection material to an ultraviolet camera; and 3, receiving and recording the laser image with the wavelength of 266 nm transmitted by the band-pass glass filter by the ultraviolet camera. The invention also discloses a device for revealing and extracting the scene potential fingerprint. The invention can solve the problems of difficult revealing and extraction of invisible or indistinguishable traces and physical evidences in a criminal case scene, is particularly applicable to the revealing and extraction of the potential fingerprint on a surface of a smooth non-permeable detection material such as glass and smooth paper, and has the advantages of low background interference, high contrast and high revealing rate.

Owner:上海市公安局物证鉴定中心

Heat insulating and flame retardant felt

The present invention provides a heat insulating and flame retardant felt, which is mainly prepared from high density polyethylene, added with glass fiber, wollastonite, montmorillonite, potassium titanate, zinc oxide, an ethylene-propylene-diene monomer, butadiene-acrylonitrile rubber, styrene-butadiene-styrene terpolymer, ethane-octylene copolymer, carbon nano-tube, calcium carbonate superfine powder, polypropylene grafting maleic anhydride, 2, 4, 6-tert-butyl phenol, and a colouring agent. Ingredients of the mixed materials for preparing the heat insulating and flame retardant felt are appropriate, which can overcome problems of poor toughness, low heat resistant grade and so on existed in normal polyethylene composite material felts.

Owner:ZHEJIANG NORMAL UNIVERSITY

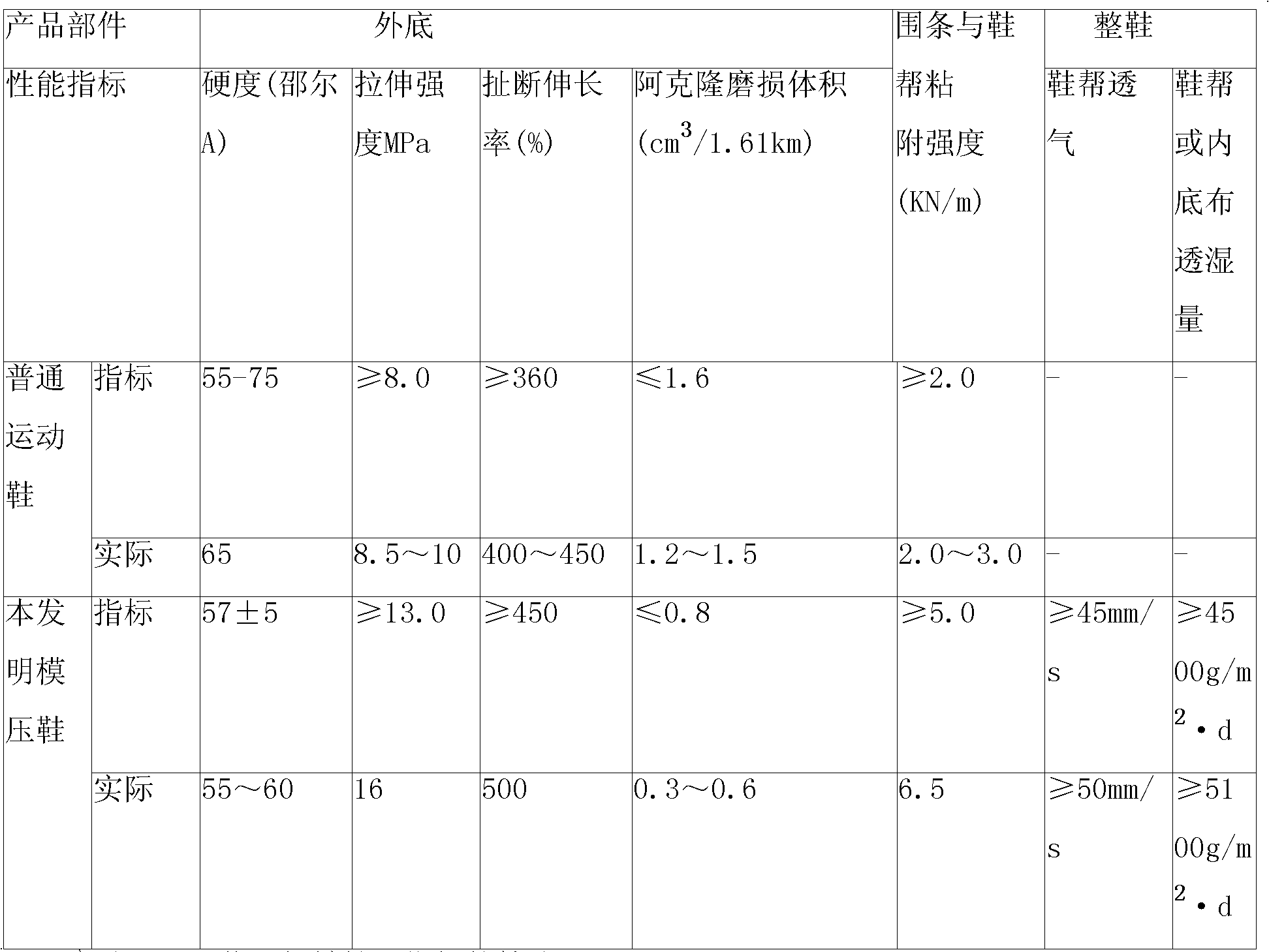

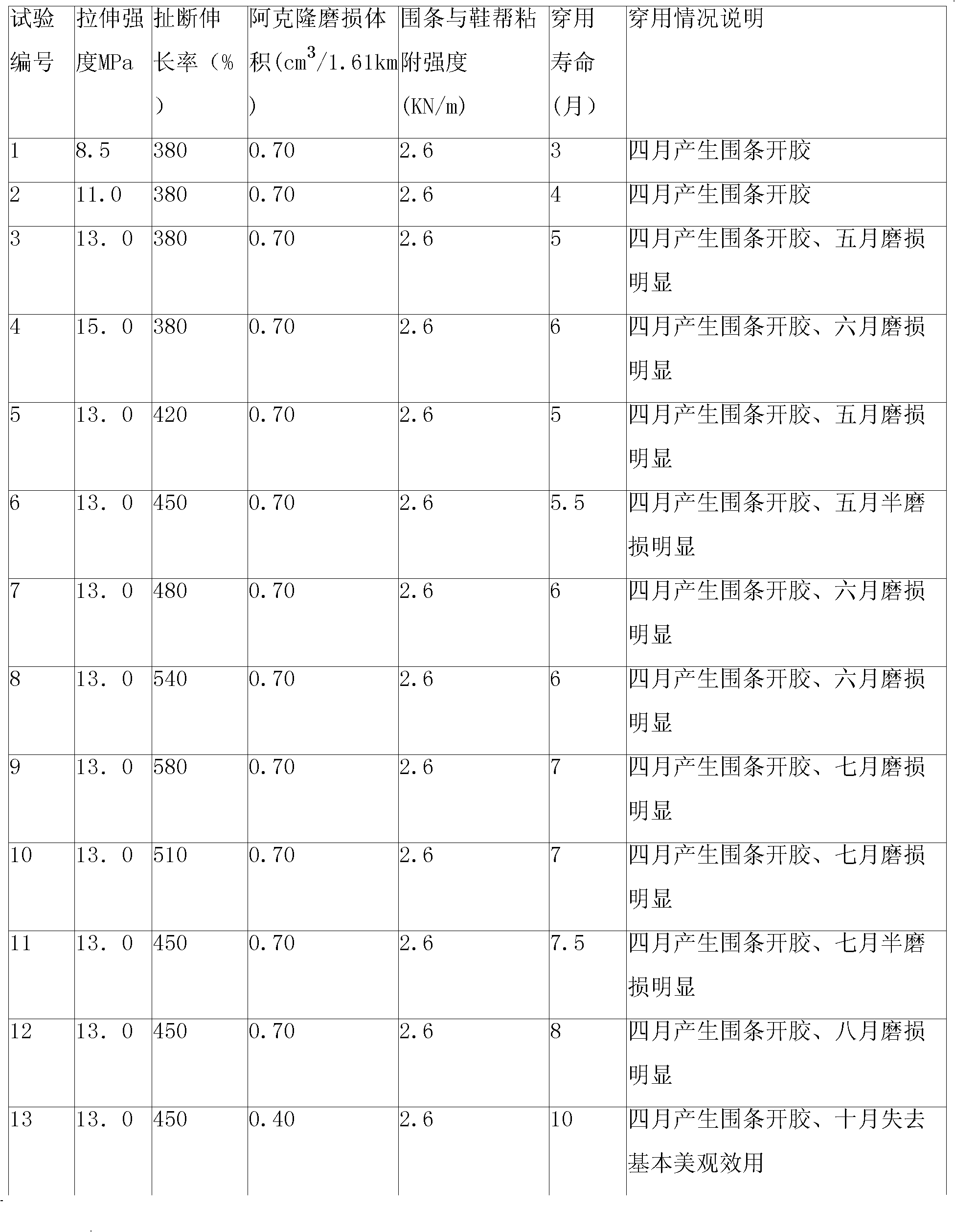

Method for controlling quality of molded shoes with cloth cover

The invention discloses a quality controlling method for a pair of cloth cover moulded shoes. The method consists of the control to raw materials, appearance and physical and mechanical properties, wherein, the raw materials comprise standard natural ruuber, carbon soot with high wear resistance, zinc oxide, stearic acid, accelerant DM, accelerant M, sulfur, space-variant terylene filament canvas and terylene filament flat hair plush; the appearance comprises the appearance of an upper semifinished product and the appearance of a finished shoe; the physical and mechanical properties comprise the bond strength of the upper with a foxing, the wear-resisting performance of external bottom, the strength and elongation performance of the external bottom, the hardness of a glue component, aging performance of glue stuff and the air permeability and the moisture permeability of the upper. The invention establishes a novel quality controlling method for a pair of cloth cover moulded shoes, improves the quality control standard of moulded shoes and ensures the performances of the moulded shoes better, such as the comfortableness for wearing, the wearing resistance, etc.

Owner:JIHUA 3537 SHOE MAKING

Medicine composition with skin whitening and tendering functions and preparing method thereof

InactiveCN105497537ASolve the appearanceOvercome the deep colorOrganic active ingredientsAerosol deliveryWrinkle skinALPHA-ARBUTIN

The invention discloses a medicine composition with skin whitening and tendering functions and a preparing method thereof. The medicine composition is mainly prepared from, by mass, 0.5-5.0 parts of rhizoma bletillae polysaccharide, 4.0-12.0 parts of sea buckthron oil, 0.2-4.0 parts of alpha-arbutin, 0.5-4.0 parts of centella asiatica total glycosides, 0.2-2.0 parts of radix angelica oil, 0.2-1.0 part of jasmine oil and 0.05-0.15 part of vitamin E. Active portions or components of natural medicine are adopted as the skin whitening and tendering medicine composition, hydrogel type emulsion is adopted as a medicine delivery carrier, and the medicine composition is externally used for treating pigmented spots, has the targeted medicine delivery function that the medicine active components reach a nidus directly and has the functions of whitening skin, fading spots, resisting wrinkle, improving elasticity, resisting ageing and preventing rhagades on skin.

Owner:XIAN MEDICAL UNIV

Negative ion plastic and preparation method thereof

The invention discloses a negative ion plastic and a preparation method thereof, wherein the negative ion plastic is prepared from raw material resin, a coupling agent, a composite negative ion material, an antioxidant, a weather resistant agent and a lubricant; by mechanical dispersion, granulation processing and extrusion molding of various household electrical appliance commonly used parts, such as internal and external plastic parts on an air conditioner, refrigerator internal plastic parts, all kinds of automotive internal plastic parts and the like, the surface of the parts can continuously emit negative ions to air; the negative ion plastic comprises the raw materials by ratio: 83-88 parts of a plastic raw material, 4-8 parts of the composite negative ion material, 6-10 parts of the coupling agent, 0.2-0.6 part of the antioxidant, 0.2-0.6 part of the weather resistant agent and 0.5-1.0 part of the lubricant. The negative ion plastic is prone to large-scale industrial production, and the product has extremely high cost-effective ratio; the coupling agent with better use effect is used, and bad appearance, poor performance and other non-ideal results of plastic parts caused by agglomeration and other badness of a negative ion powder in a matrix are solved; the negative ion plastic makes the surface of decorative materials release negative ions, and overcomes the defects of conventional plastics.

Owner:ORINKO NEW MATERIAL CO LTD

Remedy method for serious EL grid breakage of finished crystalline silicon solar cells

ActiveCN104617182ANormal efficiencySolve the backlog of a large number of inefficient tabletsFinal product manufacturePhotovoltaic energy generationNormal appearanceEngineering

The invention discloses a remedy method for serious EL grid breakage of finished crystalline silicon solar cells. The method is characterized by comprising the following steps: putting a cell suffering from serious grid breakage at a positive electrode printing feeding position of a screen printing machine; adjusting the printing offset (X, Y, T) to make a positive electrode printed at the first time and a positive electrode printed at the second time overlap completely; and making the positive electrodes printed at the first time and at the second time normally flow into a sintering furnace for sintering, and carrying out sorting test or EL test to detect grid breakage. The remedy method of the invention has the beneficial effect that by adopting the technical scheme, inefficient cells and cells with bad appearance caused by serious EL grid breakage are made into cells with normal appearance and normal efficiency, the knotty problem that cell manufacturers backlog a large number of inefficient cells and cells with bad appearance is solved, the quality rate is improved, and the economic efficiency of enterprises is increased.

Owner:ZHEJIANG FORTUNE ENERGY

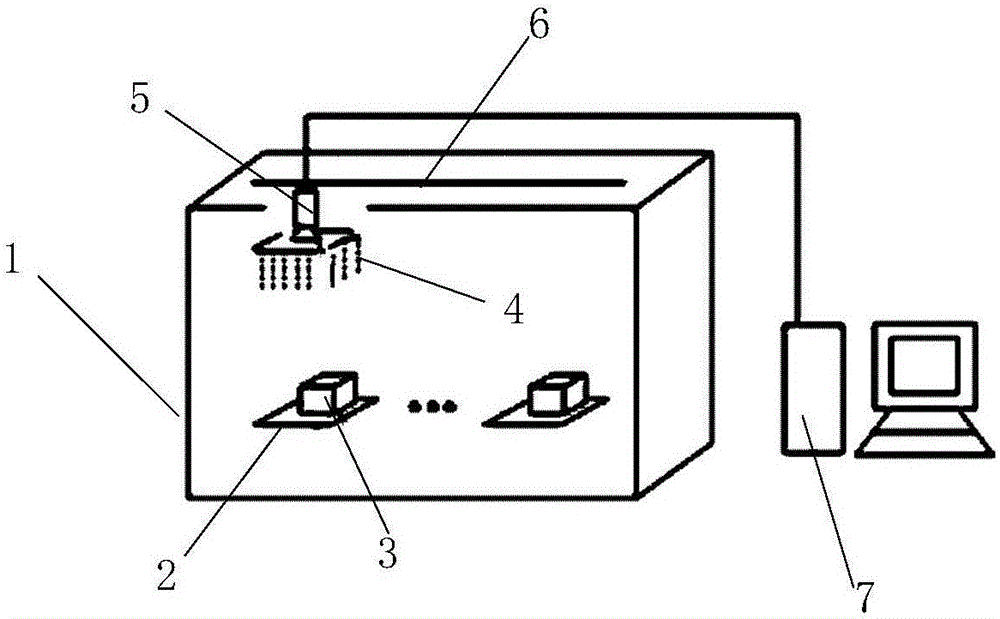

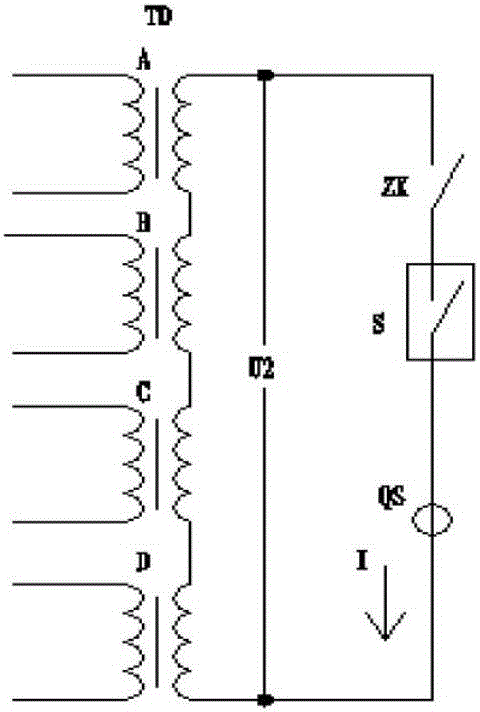

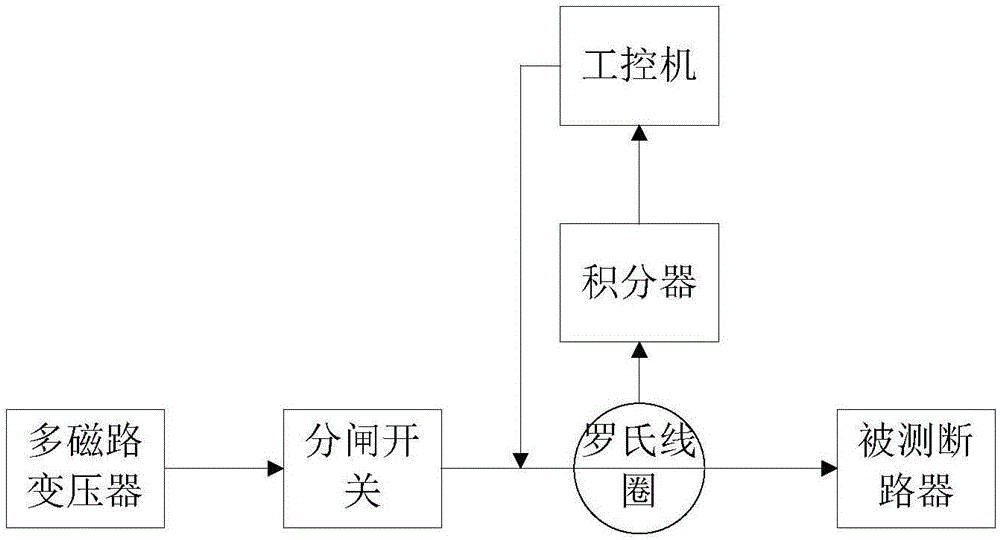

System and method for recognizing external load switches of electric energy meter

ActiveCN106019145ACompatible with tripping characteristic test functionSolve the appearanceOptically investigating flaws/contaminationCircuit interrupters testingData signalTest platform

The invention discloses a system for recognizing external load switches of an electric energy meter. The system comprises a machine case, testing platforms, strip-shaped light sources, a camera, a straight-line sliding table and a processor; the straight-line sliding table is arranged on the upper portion of the machine case, the camera is arranged on the inner side of the upper portion of the machine case and arranged on the straight-line sliding table, and the camera is used for collecting images of the external load switches of the electric energy meter and connected with the processor and transmits the shot images to the processor; the strip-shaped light sources are arranged in the machine case and used for providing illuminating rays when the camera shoots the images of the external load switches of the electric energy meter, and the external load switches of the electric energy meter are arranged on the testing platforms. According to the system for recognizing the external load switches of the electric energy meter, appearance images are automatically shot through the camera, the images are analyzed and processed, and therefore a corresponding characteristic data signal is formed; the system has the function of conducting automatic appearance shooting on the external load switches of the electric energy meter and has the tripping characteristic testing function on the external load switches of the electric energy meter.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +2

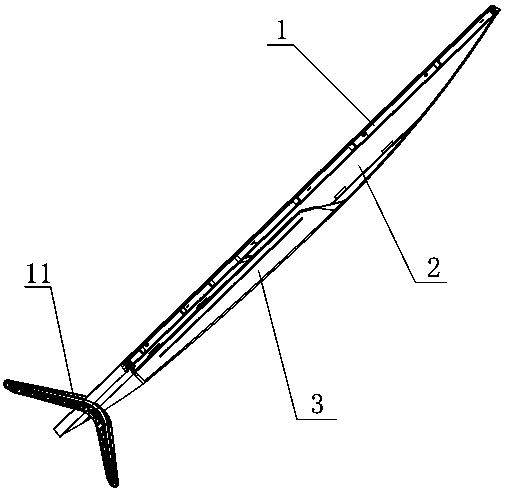

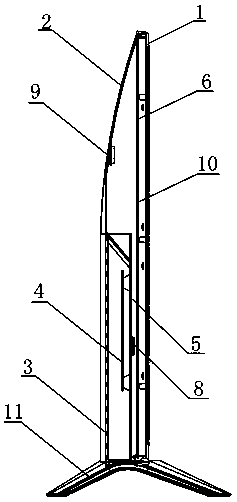

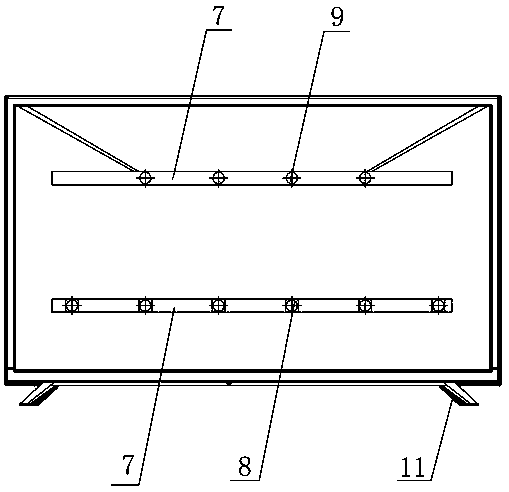

Direct type liquid crystal TV with variable light-mixing distance

InactiveCN108696707AChangeable appearanceSolve thick and abrupt shapeTelevision system detailsColor television detailsEngineeringLED lamp

The invention discloses a direct type liquid crystal TV with variable light-mixing distance. The direct type liquid crystal TV with variable light-mixing distance comprises a front shell for mountinga liquid crystal display; a middle shell arranged behind the front shell and connected with the front shell; a back shell arranged below the middle shell and connected with the middle shell; a mainboard and a power panel which are arranged between the middle shell and the back shell and fixed at the back of the middle shell; and a backlight source arranged in the middle shell and used for emittinglight effect, wherein the backlight source comprises a light bar arranged in the middle shell, LED lamps fixed on the light bar, lenses covered on the LED lamp, a diffusion plate arranged in the middle shell, and an optical film arranged on the diffusion plate; the lenses and the LED lamps in different shapes are arranged according to a certain regular scheme so as to form the backlight source ofthe liquid crystal TV in the mixed way, the shape structures of the middle shell and the back shell of the liquid crystal TV are synchronously adjusted according to the arrangement way of the LED lamps and the lenses, and the problem that the conventional direct liquid crystal TV is thick in complete machine, abrupt in modelling, heavy in appearance, and bad in transition section is solved.

Owner:KONKA GROUP

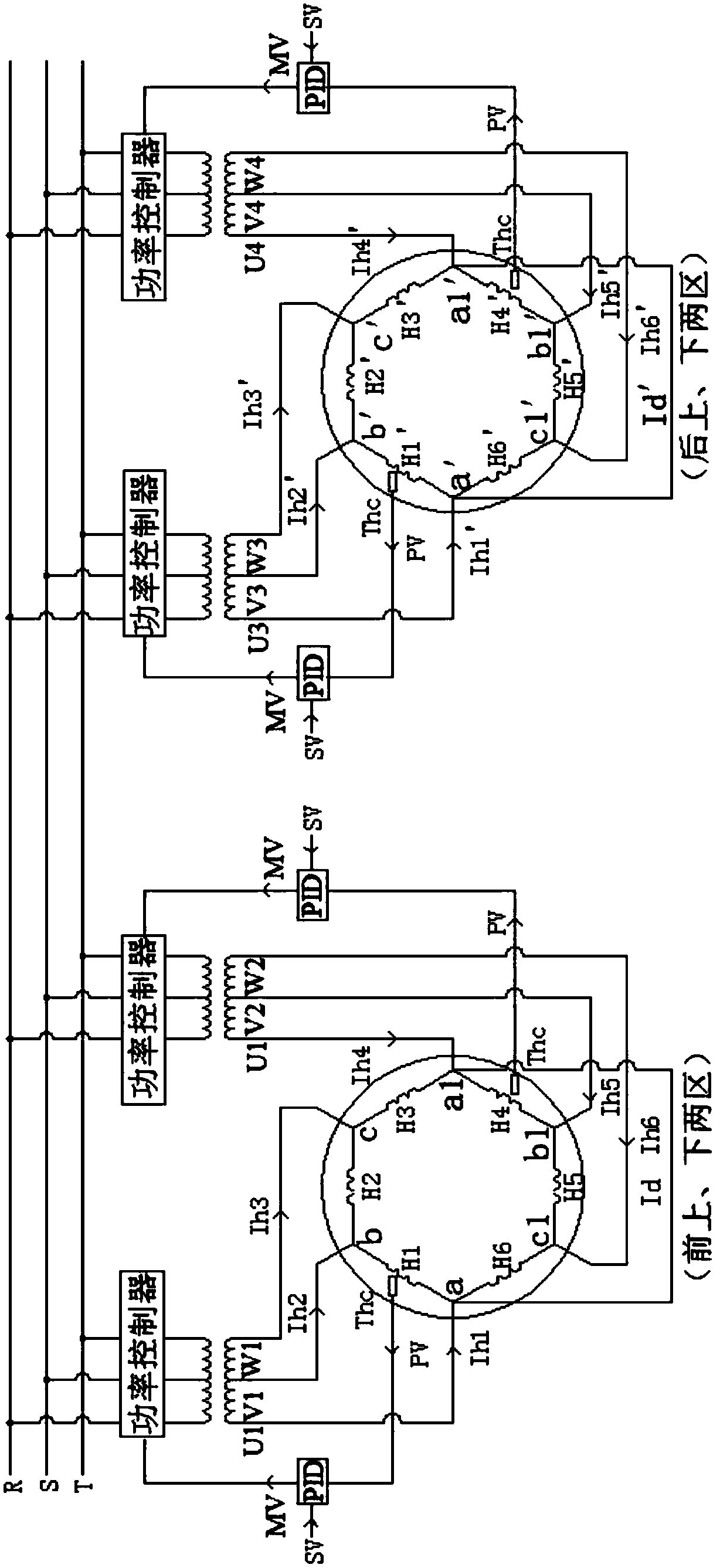

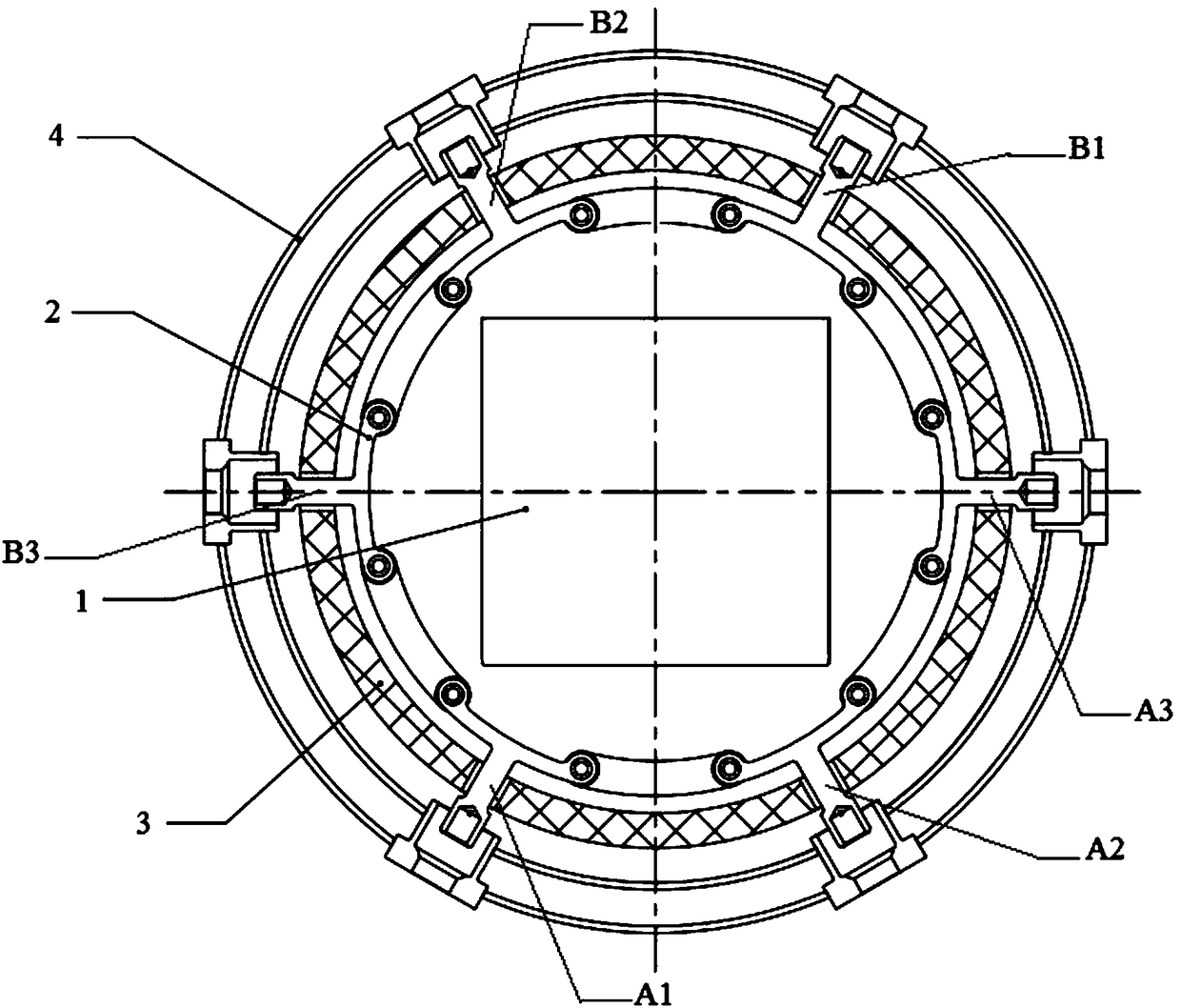

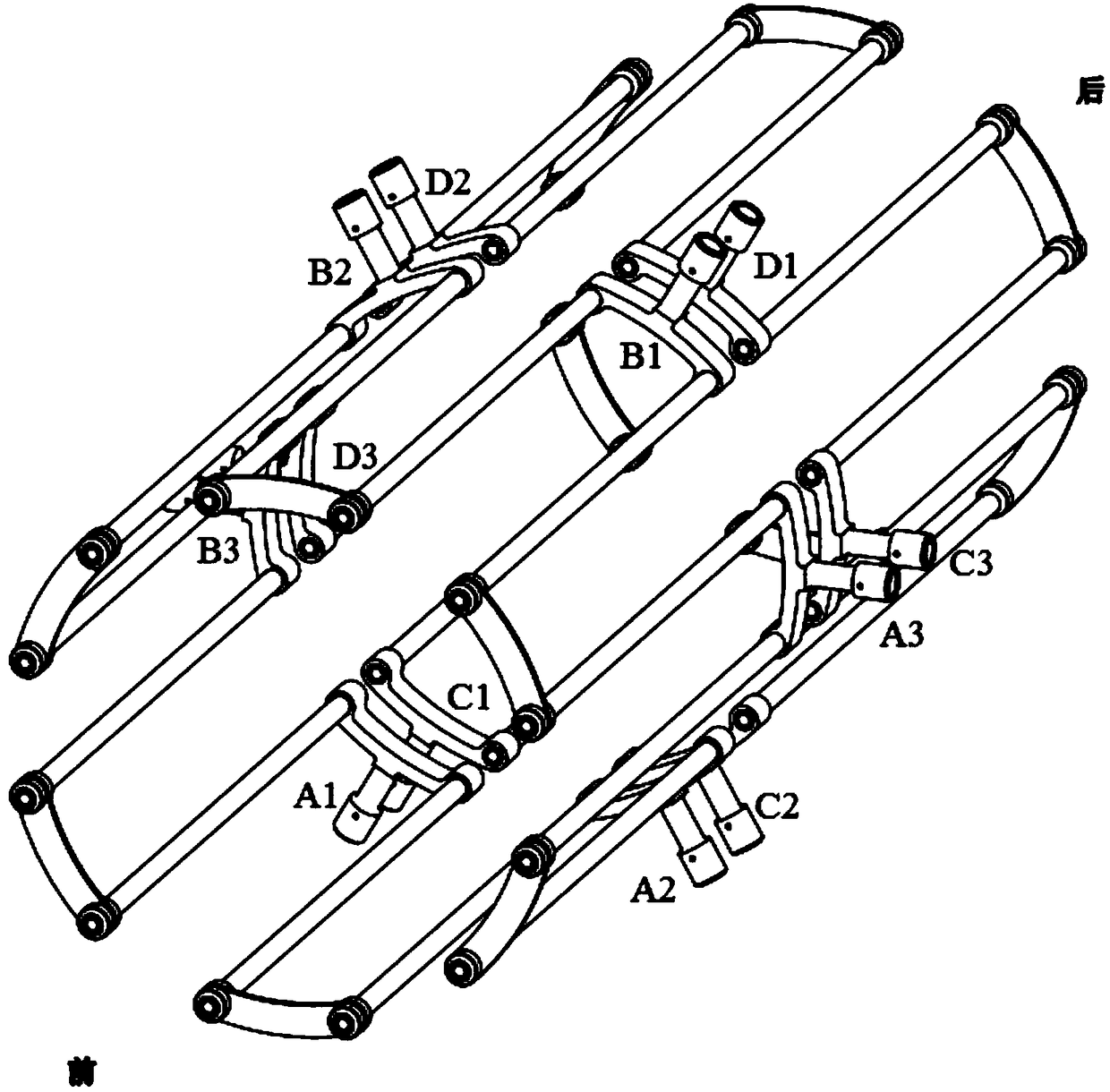

Vacuum sintering furnace achieving four-area temperature control

PendingCN108253780AImprove yieldMake up for the defect of temperature deviationMuffle furnacesCharge treatment typeTemperature controlMetallurgy

The invention discloses a vacuum sintering furnace achieving four-area temperature control. The vacuum sintering furnace comprises a sealing box, a heating device and a heat insulating layer; the heating device is arranged between the heat insulating layer and the sealing box; the heating device comprises two heating body units, and the heating body units surround the front portion and the rear portion of the side face of the sealing box in the axis direction respectively; the heating body units are of the same structure, and each heating body unit comprises a heating rod, an electrode rod anda connecting sheet, is connected with two three-phase transformers and is used for heating an area to be heated of the sealing box corresponding to each heating body unit. By means of the vacuum sintering furnace, the heating uniformity of the whole heating device can be improved, then the deviation of temperatures in all areas in the furnace is reduced, and the cost for balancing the temperatureuniformity in the furnace is lowered.

Owner:NINGBO HIPER VACUUM TECH CO LTD

Construction method for steel-concrete joint section of bridge

InactiveCN105735138AResolve connectivitySolve the appearanceBridge erection/assemblyEngineeringTower

The invention discloses a construction method for a steel-concrete joint section of a bridge. The construction method comprises the following steps: embedding the lower part of an inner support frame at the top end of a concrete section of a bridge tower; fixing a plurality of limiting blocks outside the inner support frame; arranging a plurality of three-way lifting jacks at the top end of the concrete section; mounting a steel tower on the inner support frame after being positioned by the limiting blocks, and allowing the top of each three-way lifting jack to pop up the bottom of the steel tower; adjusting the three-way lifting jacks, and adjusting the position of the steel tower; welding a plurality of inner limiting supporting parts between the steel tower and the inner support frame; removing the limiting blocks and the three-way lifting jacks; fixing a post-cast section wooden template between the top end of the concrete section and the steel tower. The method disclosed by the invention can realize adjustment of six degrees of freedom of the steel tower and is convenient and precise to adjust; according to the method, inner space occupancy of the steel tower is relatively small, the steel tower can be stabilized in the concrete pouring period, and linear smooth transition between the steel tower and a concrete tower is realized.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD +1

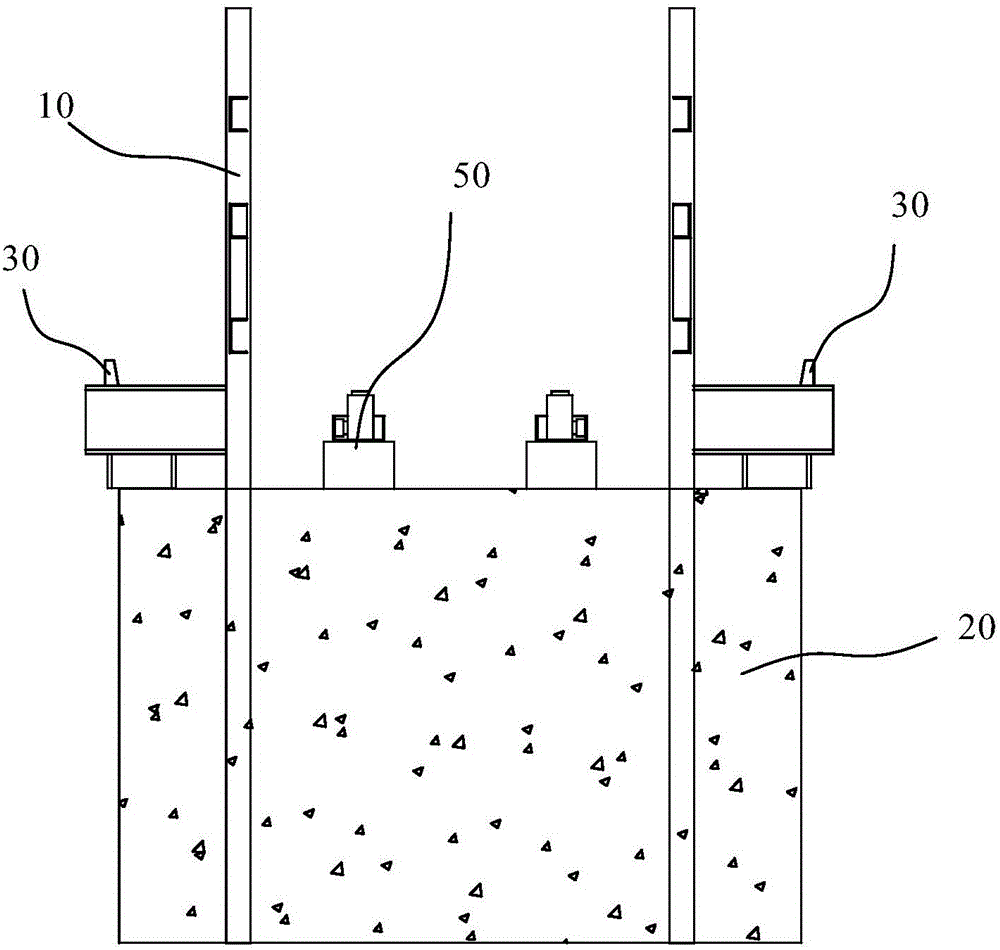

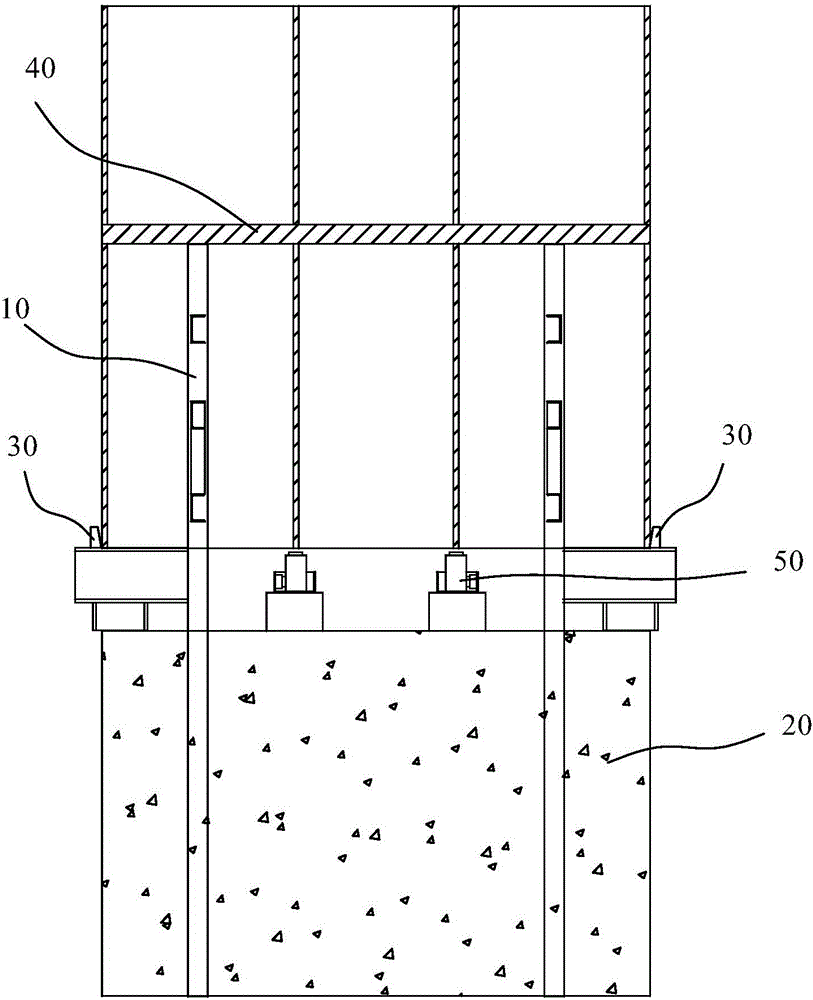

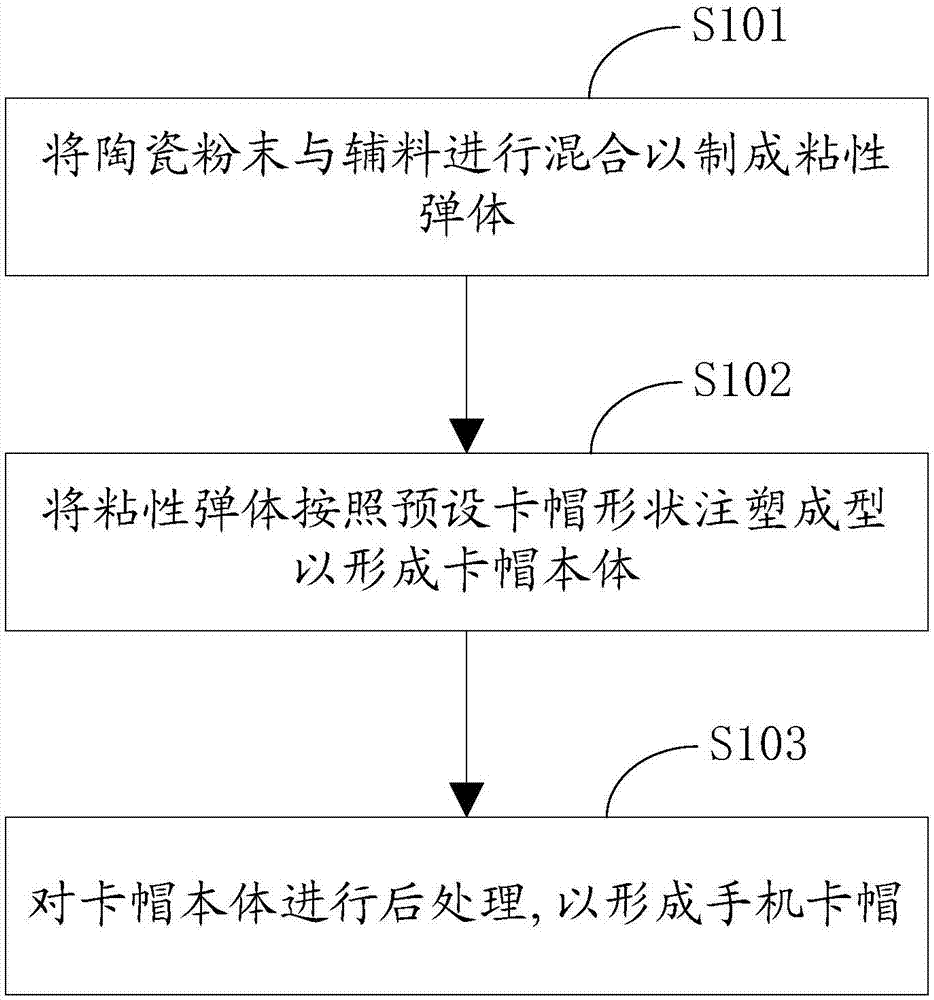

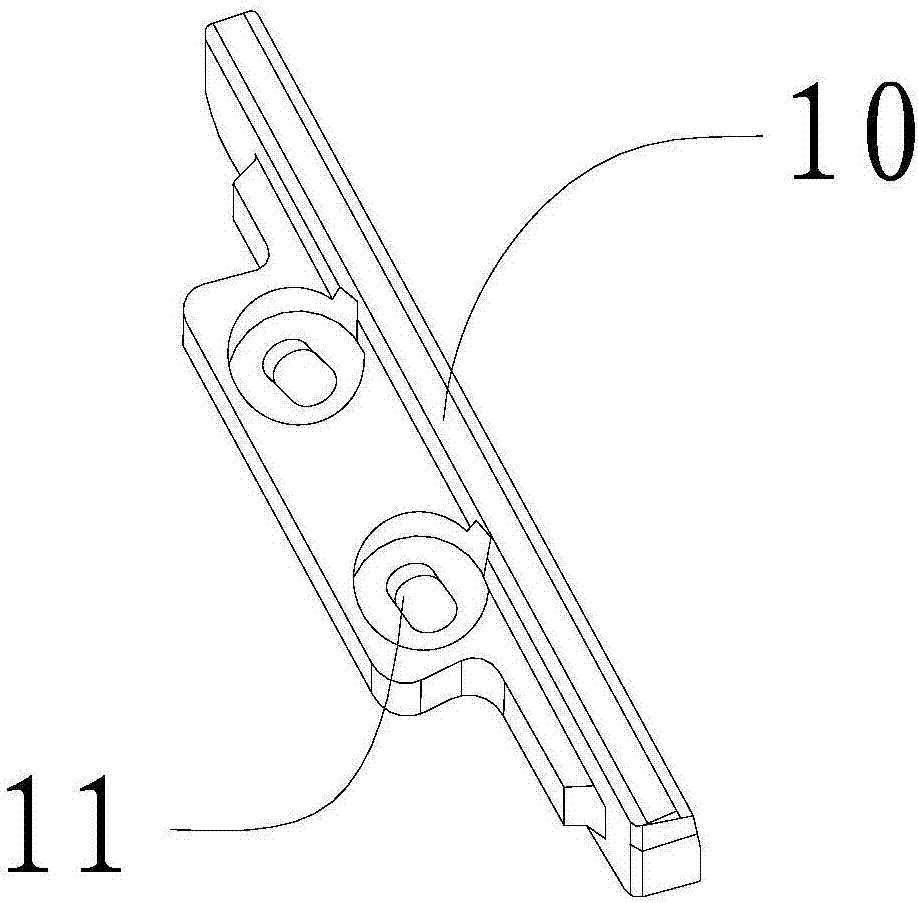

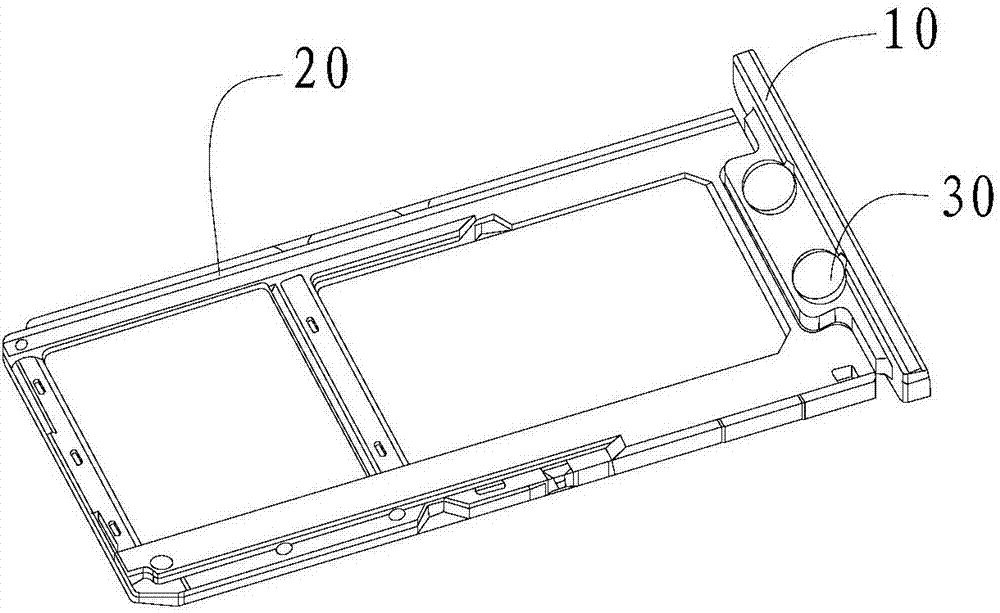

Combined mobile phone clamping support, mobile phone clamping cap and manufacturing method thereof

InactiveCN107317594ASolve the problem of scratch resistanceSolve the intoleranceTransmissionTelephone set constructionsEngineeringInjection moulding

The invention discloses a combined mobile phone clamping support, a mobile phone clamping cap and a manufacturing method thereof. The manufacturing method of the mobile phone clamping cap comprises the steps of mixing ceramic powder with accessories to produce elastic projectile body; performing injection module on the elastic projectile body according to the preset clamping cap shape to form the clamping cap body; and postprocessing the clamping cap body to form the mobile phone clamping cap. The manufacturing method of the mobile phone clamping cap is simple and easy to implement and few in operation step; the mobile phone clamping cap and the combined mobile phone clamping support provided by the invention has good hand feel like jade and gentle sense of touch, has better appearance effect than metal or plastic, and has the effect of being resistant to scrub, firm and resistant to drop.

Owner:SHENZHEN TINNO WIRELESS TECH

Method for compounding arabinose with sucrose

InactiveCN104543676ASolve the appearanceSolve the disadvantage of taste changeFood ingredientsFood preparationPeristaltic pumpSucrose

The invention belongs to the field of food processing, and relates to a method for evenly attaching an arabinose solution on the surface of sucrose. The method for compounding arabinose with sucrose comprises the following steps: firstly, turning on hot air preheating equipment, then adding the sucrose raw material to compound equipment, turning off the equipment, and starting hot air to preheat the sucrose into a fluidized state; lastingly adding the prepared arabinose solution into the compound equipment by virtue of a peristaltic pump; atomizing the arabinose solution fed to the equipment by virtue of atomizer and then mixing with the sucrose in the fluidized state; drying and attaching on the sucrose surface under the action of hot air; and completely adding the arabinose solution, further introducing hot air for a period of time, completely drying and emptying to obtain the required product. According to the method for compounding the arabinose with the sucrose, the arabinose and the sucrose are evenly mixed together in an atomizing manner, and are dried and mixed evenly in the atomizing process; and the appearance and the taste of the sucrose are kept invariable.

Owner:SHANDONG FUTASTE

Preparing method of Shiwuwei Longdanhua pill

InactiveCN106728424AShorten drying timeThe solution is not easy to disintegratePill deliveryRespiratory disorderMedicineDrying time

The invention relates to a preparing method of Shiwuwei Longdanhua pills. The method is characterized by comprising the steps of firstly evenly wetting prepared Shiwuwei Longdanhua pill pellets with purified water, adding Shiwuwei Longdanhua pill raw powder and performing round rolling, then putting the Shiwuwei Longdanhua pill pellets into a boiling drying granulator to conduct primary drying, afterwards performing screening, supplementing powder with the Shiwuwei Longdanhua pill raw powder, conduct secondary drying in the boiling drying granulator, finally capping the pellets after secondary drying with the purified water, and only conducting tertiary drying in the boiling drying granulator. According to the preparing method of the Shiwuwei Longdanhua pills, a method of boiling drying is adopted to replace heat-wind circulating drying, accordingly the problems that the pellet drying time is long, the pellets are not easy to disintegrate and the appearance shape is not good are effectively solved, the pellet drying time can be reduced to about 20 h, meanwhile stability of Shiwuwei Longdanhua pill product is effectively improved, and further the product quality is improved; the produced pills are easy to disintegrate and thus convenient to take, the color and luster of the pellets are consistent, and the appearance shape is uniform.

Owner:NINGXIA DUOWEI PHARMA

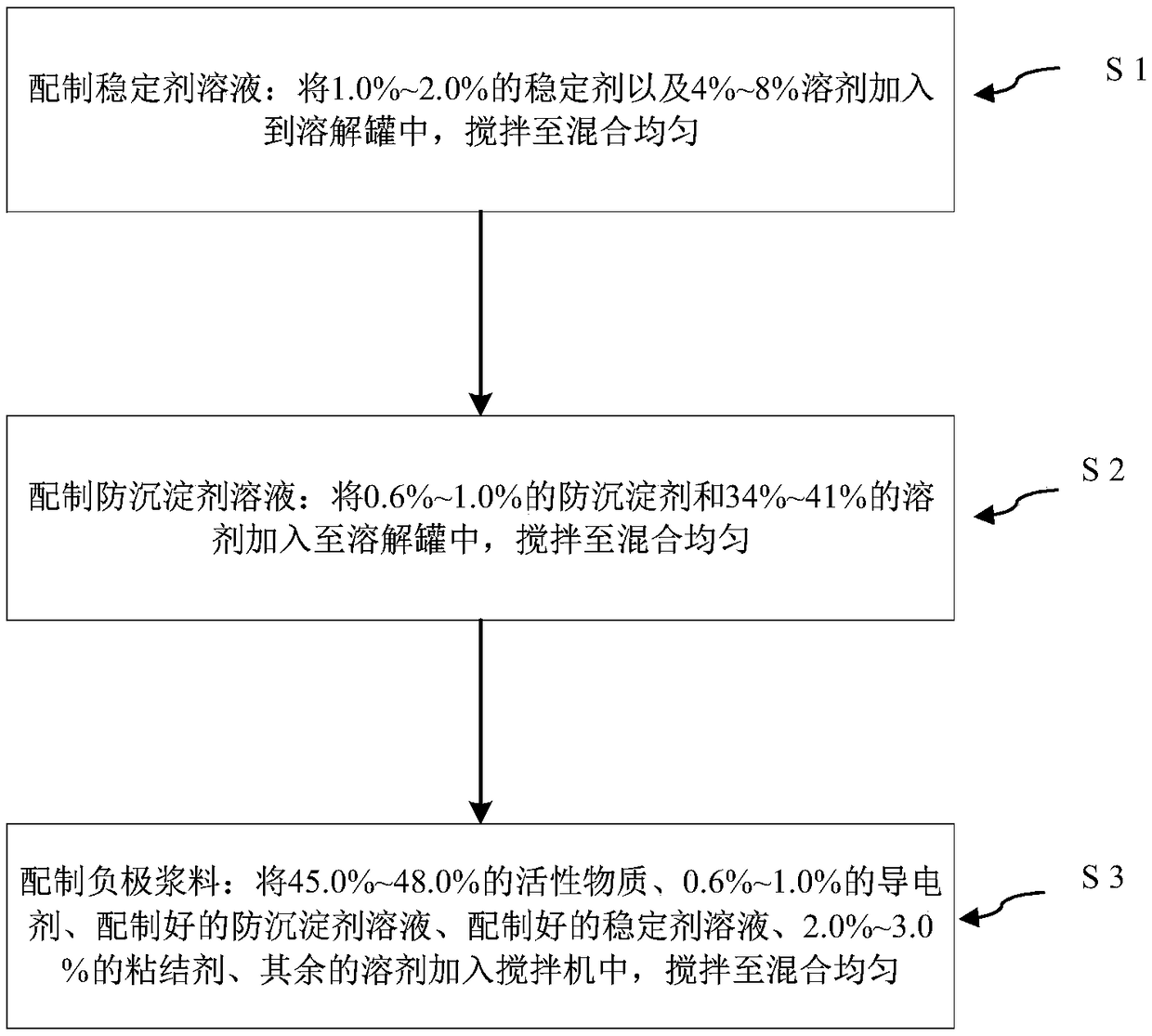

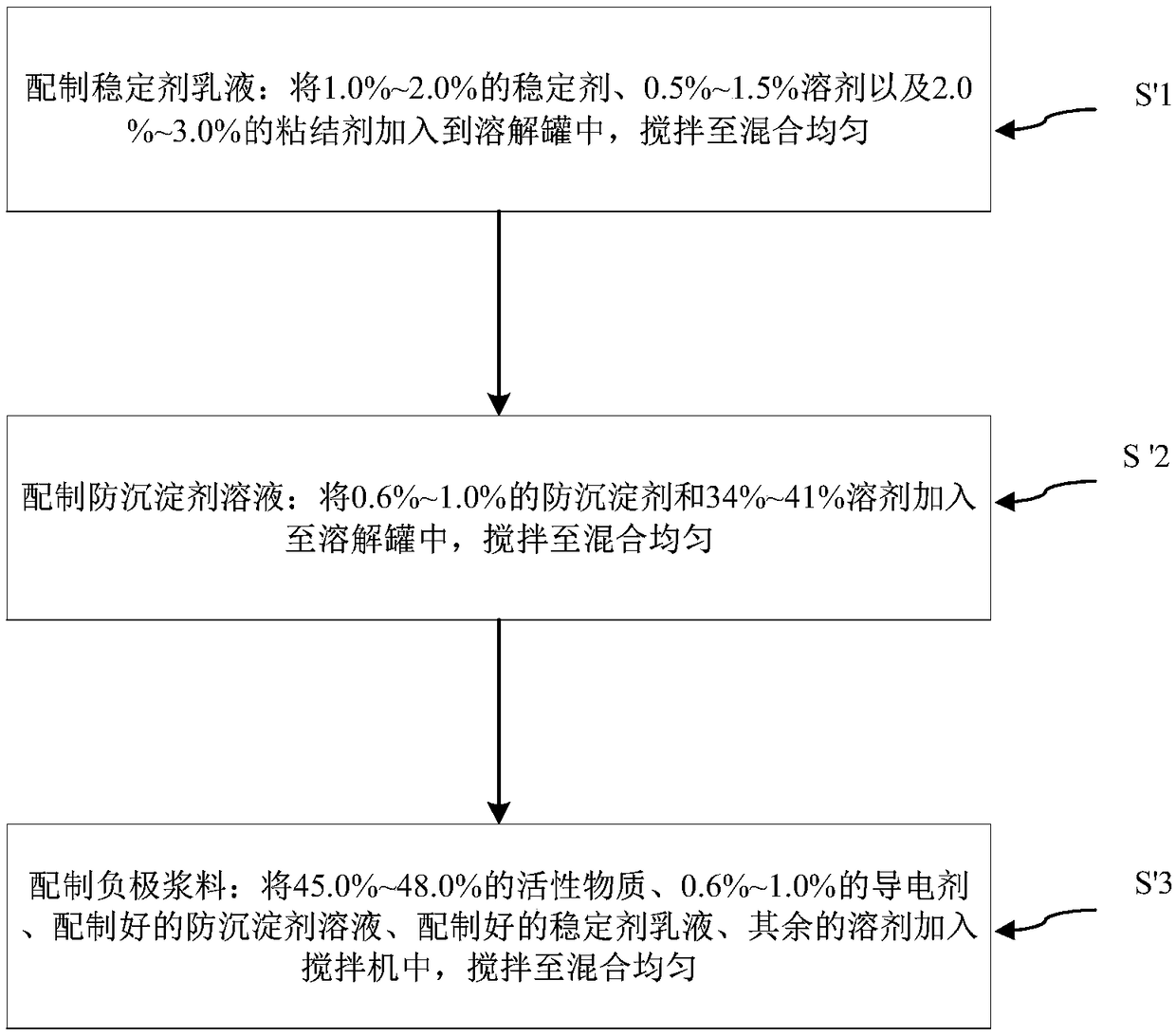

A lithium ion battery negative electrode slurry and a preparation method thereof

InactiveCN109148825AStable battery performanceReduce manufacturing costSecondary cellsElectrode collector coatingBlack spotSlurry

The invention relates to a lithium ion battery negative electrode slurry and a preparation method thereof. The lithium ion battery negative electrode slurry comprises the following raw material components in percentage by mass: 45.0 to 48.0 percent of active substance; 0.6 to 1.0 percent of conductive agent, 0.6 to 1.0 percent of anti-precipitation agent, 2.0 to 3.0 percent of binder, 1.0 to 2.0 percent of stabilizer, solvent: balance; the lithium-ion battery negative electrode slurry can greatly solve the problems of bubbles, black spots, pits and other poor appearance, especially the pittingproblem. The negative electrode paste of the lithium ion battery has the advantages of low manufacturing cost and wide application range, and the battery prepared from the negative electrode paste ofthe lithium ion battery has stable cell performance. The preparation method of the negative electrode slurry of the lithium ion battery has the advantages of simple operation, low equipment requirement and convenient popularization and application.

Owner:HUIZHOU TOPBAND ELECTRICAL TECH CO LTD

Self-service sandwich ice cream and production method thereof

InactiveCN103907743AWill not absorb moisture and deformCrispy tasteFrozen sweetsBakery product preservationEngineeringMoisture

The invention relates to a self-service sandwich ice cream and a production method thereof. The self-service sandwich ice cream comprises an ice cream semi-finished product placed in a supporting box and two biscuits placed in a biscuit packing bag, and the supporting box and the biscuit packing bag are stored separately. The invention also provides a production method of the self-service sandwich ice cream. The biscuits and the ice cream semi-finished product are separately independently packaged, and then packaged in one same packing bag according to the method, and the problems that biscuits of sandwich ice cream products in the prior art are easy to absorb moisture to deform, bad in taste and irregular in appearance and the like are solved; a design and color line can be used for production due to use of the packaging manner, so that the problem that traditional sandwich ice cream can only be produced by use of a tunnel line, and the product yield and yield of primary product can be greatly improved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

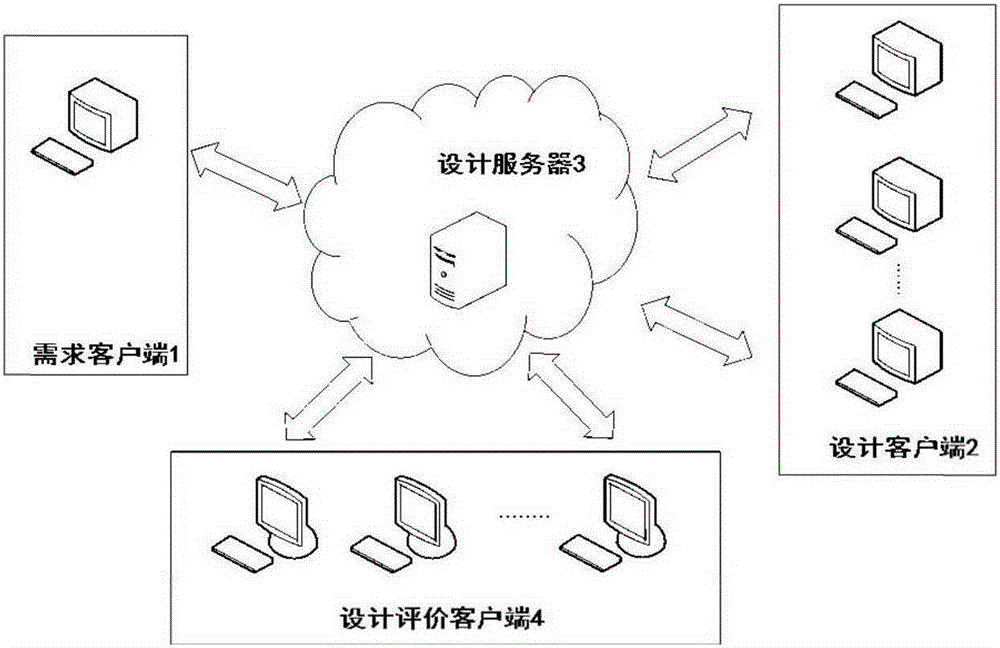

Product appearance design system

InactiveCN105243199ASolve the appearanceSolve the speed problemSpecial data processing applicationsUser needsDesign evaluation

The present invention belongs to the field of product appearance design, and particularly relates to a product appearance design system. The system comprises a demand client, a design client, a design server and a design evaluation client. The design evaluation client comprises at least one eye tracker and an electroencephalograph. An evaluator uses the design evaluation client to perform a satisfaction test on the product appearance design, and determines whether to modify the design according to a test result. The system can effectively solve the problems of poor capability, low speed and difficulty for meeting a user demand in product appearance development.

Owner:邓俊生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com