Preparation method for halogen-free flame retardant polyester labeled paper

A flame-retardant polyester and label paper technology, applied in chemical instruments and methods, papermaking, paper, etc., can solve the problems of reducing the initial viscosity and stickiness of pressure-sensitive adhesives, difficult to ensure pressure-sensitivity, and affecting product appearance, etc. Achieve the effect of enhancing pressure-sensitive adhesive performance, excellent pressure-sensitive adhesive pressure-sensitive adhesive performance, eliminating environmental pollution and harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

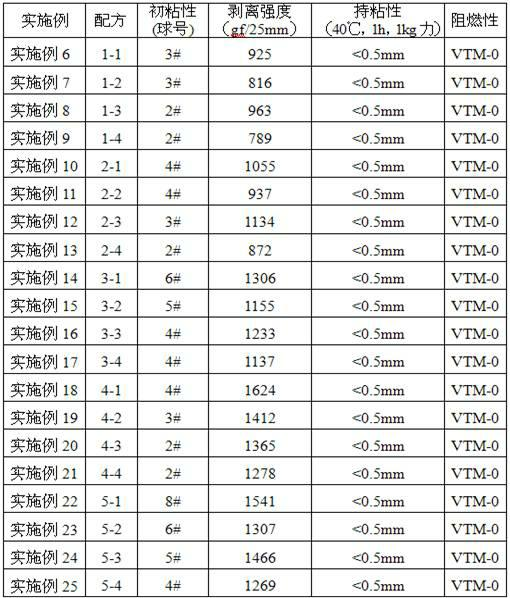

Examples

Embodiment 1

[0035] 1. Preparation of phosphorus-containing flame retardant acrylic prepolymer resin:

[0036] At room temperature, 20Kg of butyl acrylate, 45Kg of isooctyl acrylate, 3Kg of acrylic acid, 2Kg of hydroxyethyl acrylate, 10Kg of ethyl methacrylate, 20Kg of phosphorus-containing flame retardant monomer (2-allylphenoxy) pentaphenoxy Base ring triphosphazene, 100Kg of solvent (ethyl acetate:toluene=19:1), and 0.5Kg of benzoyl peroxide were added to the reaction kettle with condensation reflux device, so that the temperature of the condenser was controlled below 15 ℃, and the number of revolutions Stir at 200 rpm and mix evenly; gradually heat up to 80° C. under nitrogen protection, carry out solution copolymerization reaction for 4 hours, stop heating, and the reaction ends.

[0037] Another: add 100Kg of ethyl acetate and mix evenly, cool to room temperature and discharge to prepare phosphorus-containing acrylic prepolymer resin (A), so that the solid content reaches 33% for lat...

Embodiment 2

[0043] 1. Preparation of phosphorus-containing flame retardant acrylic prepolymer resin:

[0044] Mix 50Kg butyl acrylate, 15Kg isooctyl acrylate, 3Kg acrylic acid, 2Kg hydroxyethyl acrylate, 10Kg ethyl methacrylate, 20Kg phosphorus-containing flame retardant monomer allyl diethyl phosphate, 100Kg solvent (ethyl acetate) at room temperature Ester:toluene=19:1), 0.5Kg of benzoyl peroxide were added to the reaction kettle with condensation reflux device, so that the temperature of the condenser was controlled below 15 ℃, stirred at 200 rpm, and mixed uniformly; gradually under nitrogen protection The temperature was raised to 80° C., the solution copolymerization reaction was carried out for 4 h, the heating was stopped, and the reaction was completed.

[0045] Another: Add 100Kg of ethyl acetate and mix evenly, cool to room temperature and discharge to prepare phosphorus-containing acrylic prepolymer resin (B), so that the solid content reaches 33% for later use.

[0046] 2. P...

Embodiment 3

[0051] 1. Preparation of phosphorus-containing flame retardant acrylic prepolymer resin:

[0052] At room temperature, 30Kg of butyl acrylate, 40Kg of isooctyl acrylate, 6Kg of acrylic acid, 4Kg of hydroxyethyl acrylate, 10Kg of ethyl methacrylate, 10Kg of phosphorus-containing flame retardant monomer (2-allylphenoxy) pentaphenoxy Cyclotriphosphazene, 100Kg of solvent (ethyl acetate:toluene=19:1), and 1.0Kg of azobisisobutyl cyanide were added to the reaction kettle with a condensation reflux device, so that the temperature of the condenser was controlled below 15 ℃, so that the Stir at 200 rpm and mix evenly; gradually heat up to 80° C. under nitrogen protection, carry out solution copolymerization reaction for 4 h, stop heating, and the reaction ends.

[0053] Another: add 100Kg of ethyl acetate to mix evenly, cool to room temperature and discharge to prepare phosphorus-containing acrylic prepolymer resin (C), so that the solid content reaches 33% for later use.

[0054] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com