Simulated stone veneer architectural trim assembly

a technology of architectural trim and simulated stone veneer, which is applied in the direction of electrical equipment, building components, constructions, etc., can solve the problems of difficult installation of architectural trim pieces made from simulated stone veneer materials, difficult mounting of architectural trim pieces over electrical boxes, and accompanied installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

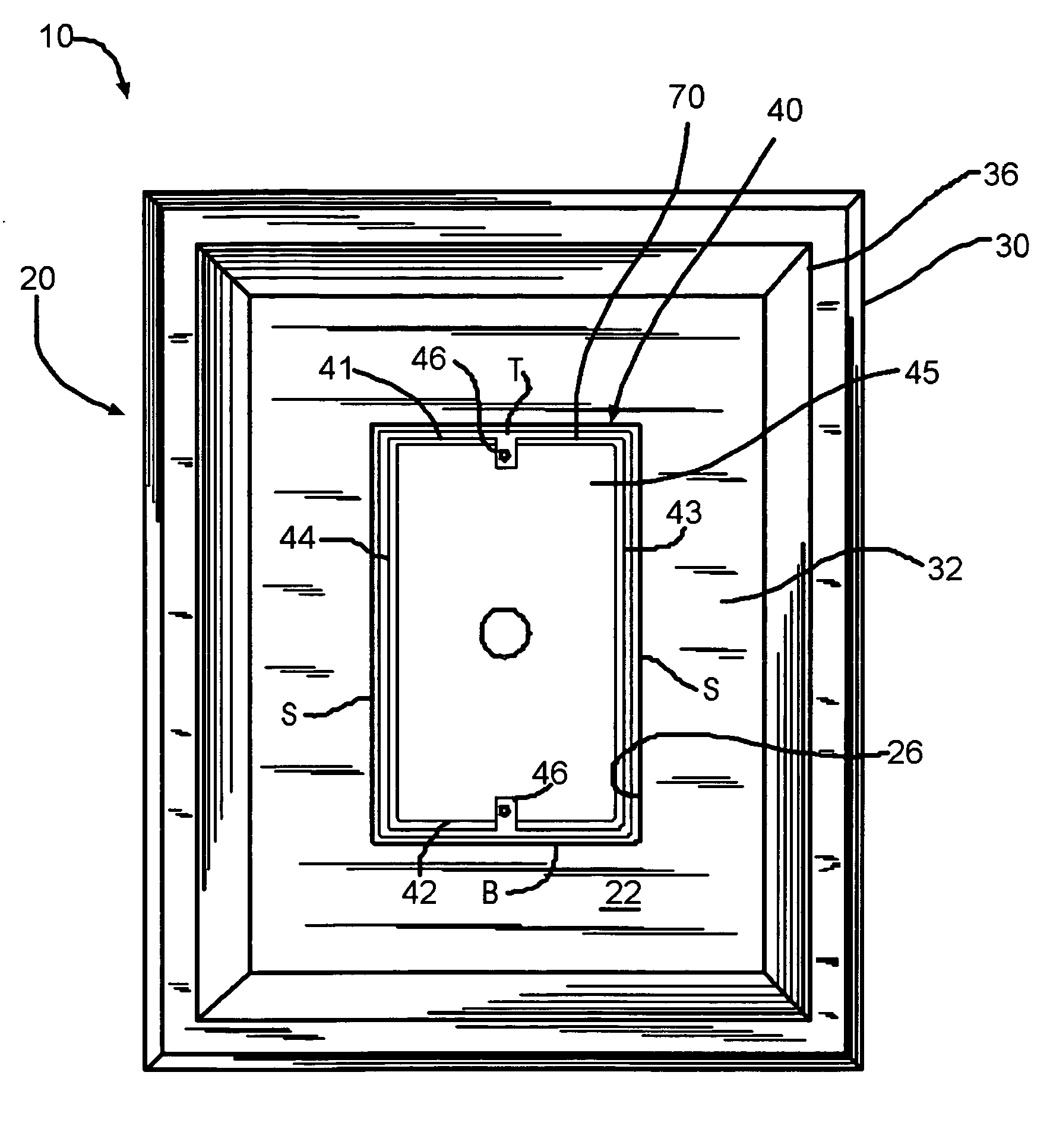

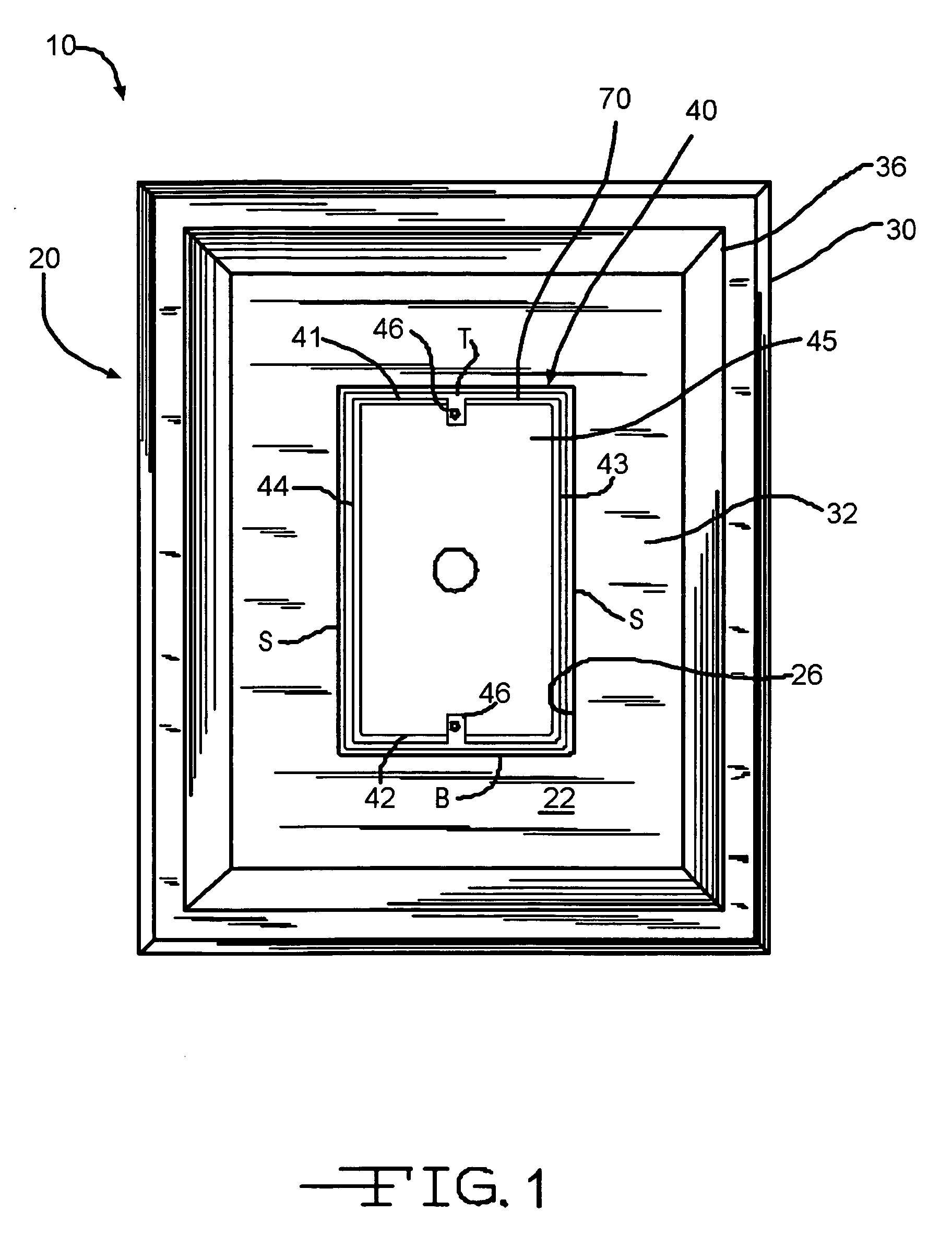

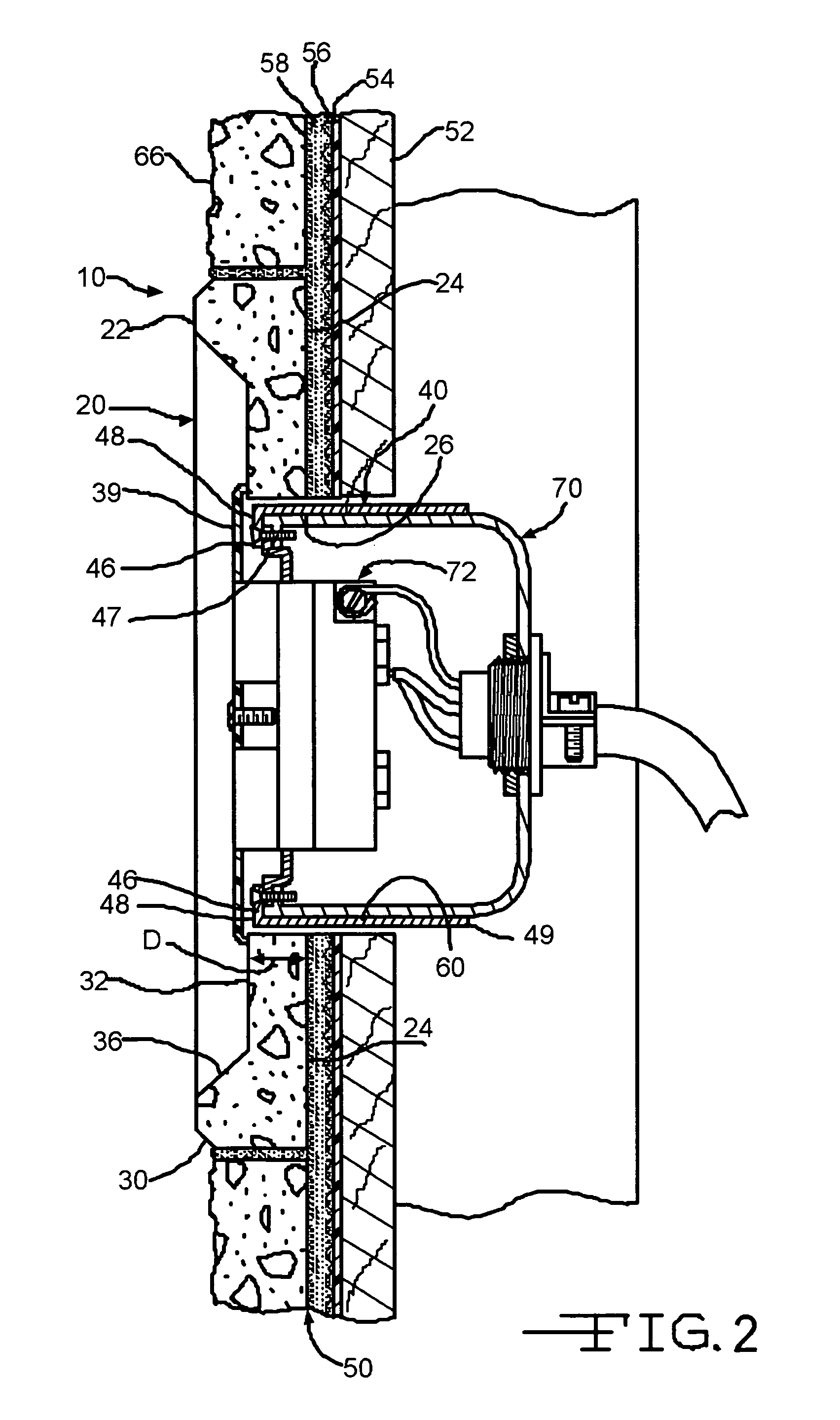

[0037] Light Fixture Trim Assembly

[0038] A rectangular 8″×10″ light fixture stone veneer trim piece features a stone surface texture that is any one of the types of Cultured Stone® wall veneers, stucco, thin brick or other exterior finishes, as described herein. The Light Fixture Trim Assembly has chamfered edges and an inset grooved border design. The Light Fixture Trim Assembly accommodates both standard round fixture bases and rectangular bases up to 8″ height. In one embodiment, an octagon-shaped orifice is centered and accommodates a standard 3½″×1½″ octagon extension box-type receptacle. An extension box-type receptacle is used in aligning and setting the simulated stone veneer trim piece in place.

[0039] Single Outlet Trim Assembly

[0040] A Single Outlet Trim Assembly is a 6″×8″ outlet fixture stone veneer trim piece that features a stone surface texture that is any one of the types of Cultured Stone® wall veneers, stucco, thin brick or other exterior finishes, as described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com