Stone blank door with novel rotating shaft mechanisms and installation method of stone blank door

A stone and shaft technology, which is applied in the arrangement of doors and wings, fire rescue and other directions, can solve the problems of inability to complete the free disassembly and assembly of the secret door, affecting the service life of the stone secret door, and colliding and damaging the edge of the stone veneer. Or turn on the effects of flexibility, firm support, and increased structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below through the embodiments and in conjunction with the accompanying drawings.

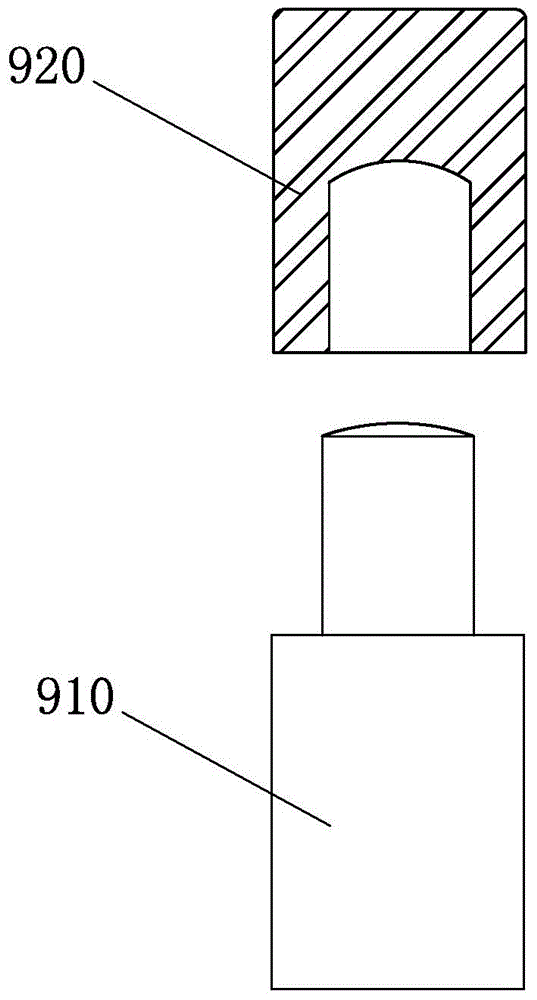

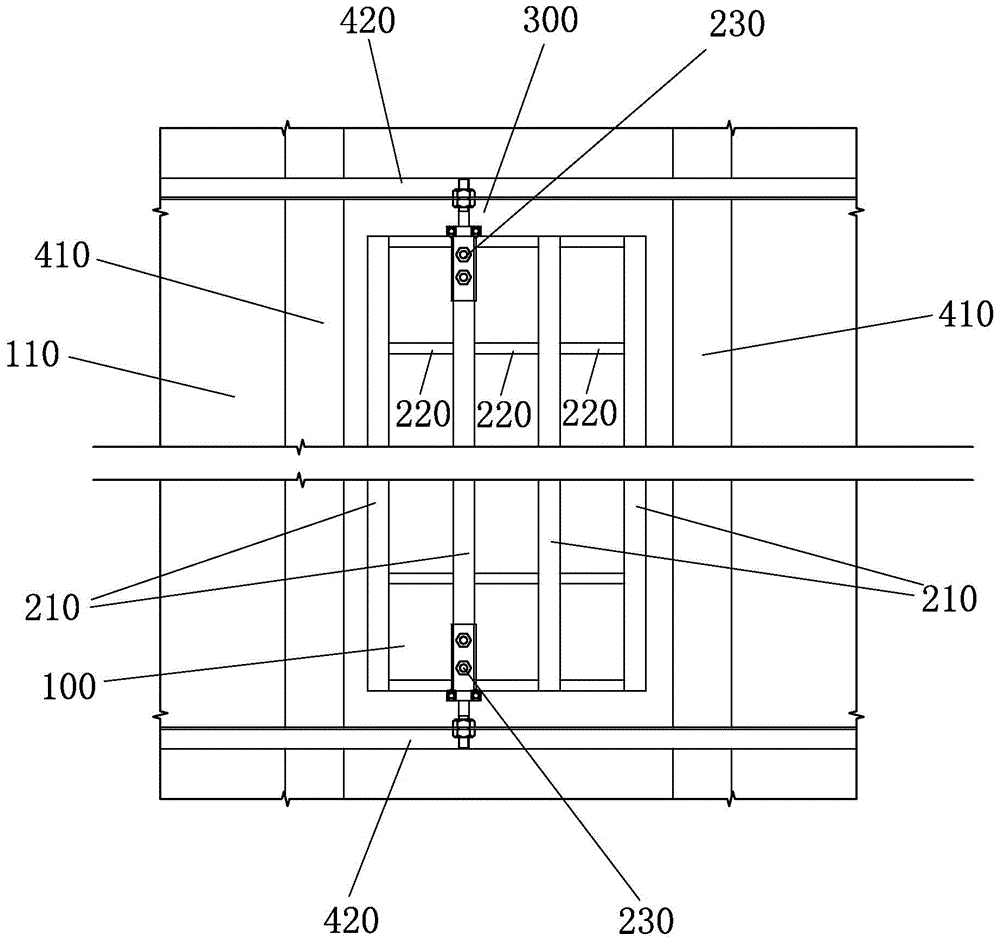

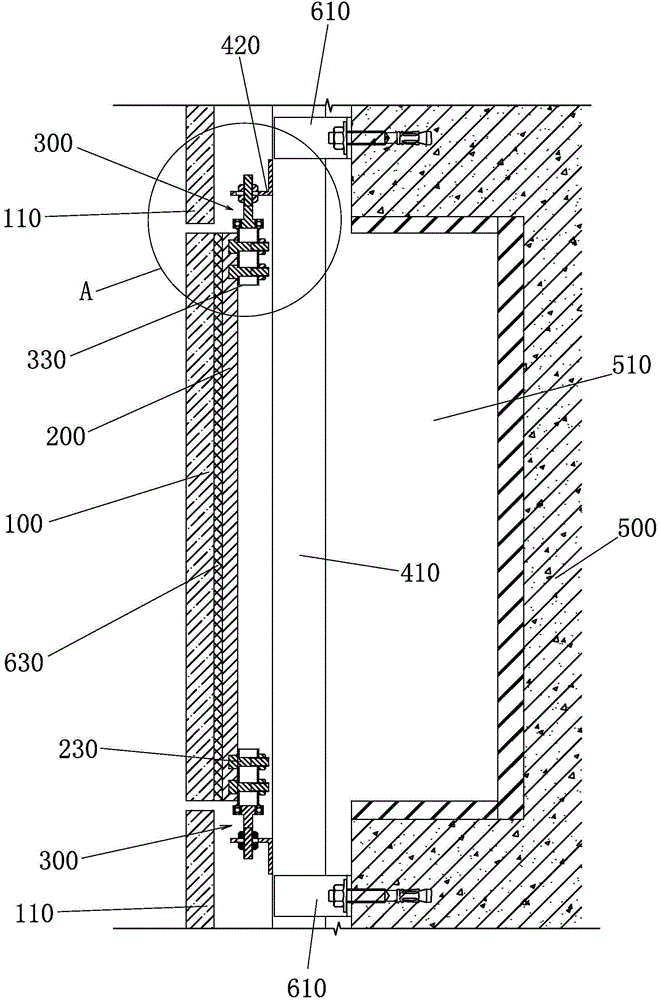

[0036] Such as figure 2 , image 3 and Figure 5 As shown, the stone secret door with a novel rotating shaft mechanism of the present invention includes a stone door leaf 100 adapted to the installation position of the stone veneer 110 secret door, a stone door steel frame 200, a stone veneer steel frame and two stone door leaves 100 connected to each other. The back and the rotating shaft mechanism 300 of the steel skeleton with stone material finish. The stone door steel frame 200 is composed of several door steel columns 210 and angle steel beams 220 transversely welded between adjacent door steel columns 210, and the stone door steel frame 200 is bonded and fixed on the back of the stone door leaf 100 by structural glue 630. Embedded bolts 230 are fixed at corresponding positions at the upper and lower ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com