Steel bar fixing and placing frame convenient to for storage and taking

A technology for placing racks and steel bars, applied in the field of placing racks, can solve the problems of not paying attention to the construction efficiency of materials, taking time and effort of steel bars, hidden dangers to the safety of staff, etc., so as to improve the practicability and flexibility, the flexible use, and the improvement of efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

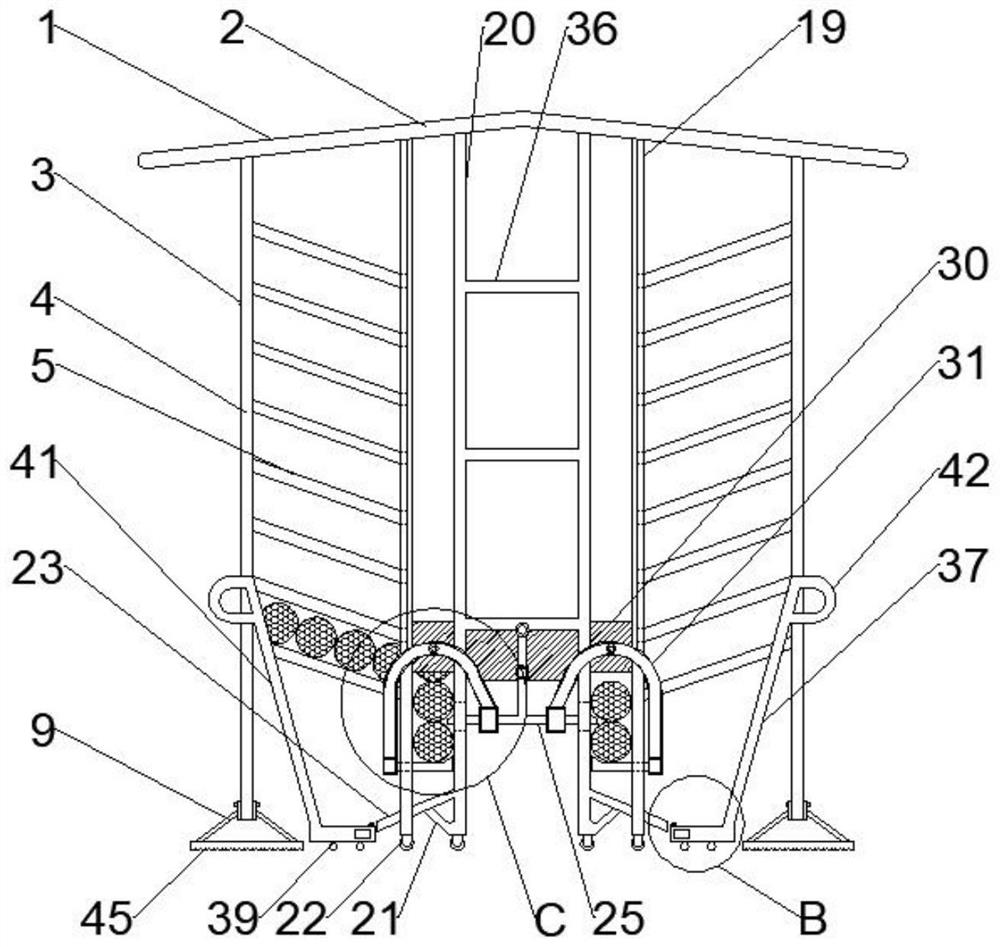

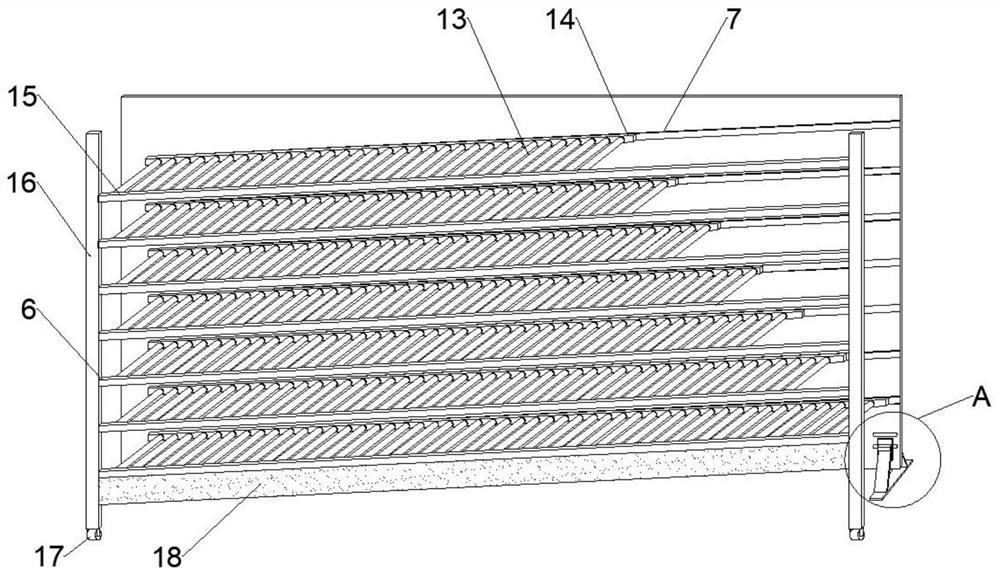

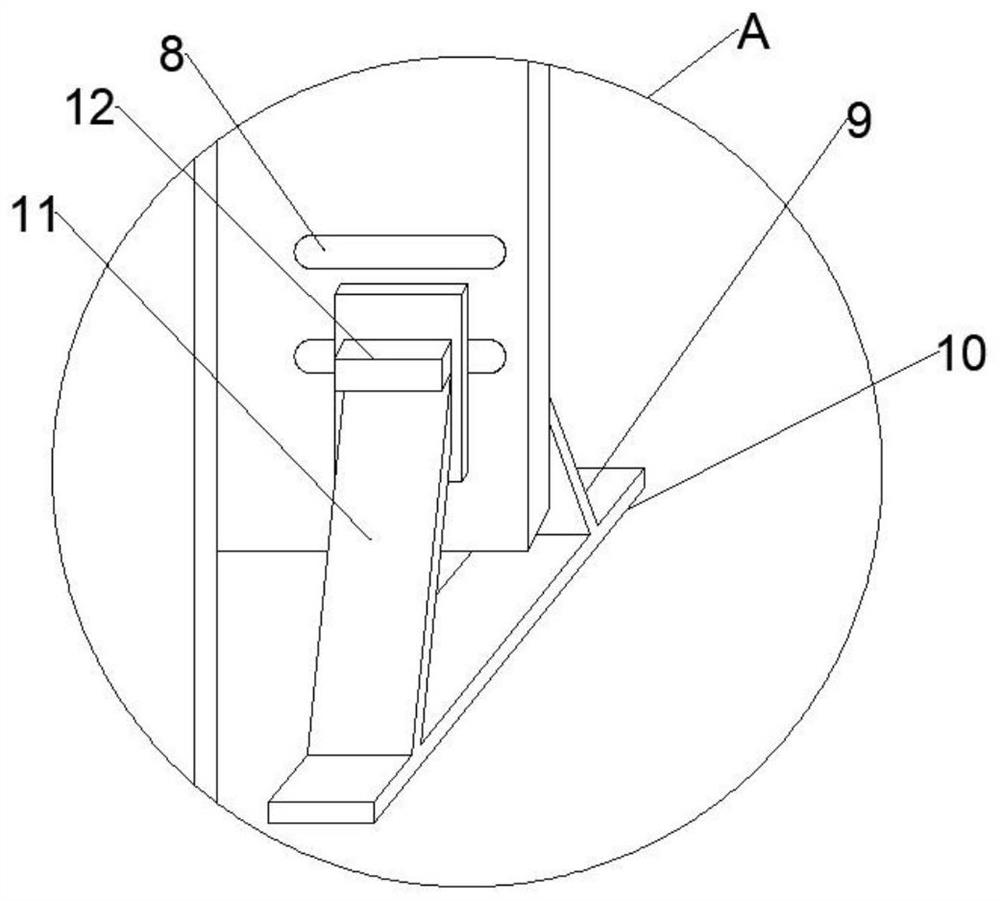

[0025] In order to further illustrate the various embodiments, the present invention provides accompanying drawings, which are part of the disclosure of the present invention, and are mainly used to illustrate the embodiments, and can be used in conjunction with the relevant descriptions in the specification to explain the operating principles of the embodiments, for reference Those of ordinary skill in the art should be able to understand other possible implementations and advantages of the present invention. The components in the figures are not drawn to scale, and similar component symbols are generally used to represent similar components.

[0026] like Figure 1-7 As shown, according to an easy-to-access steel bar fixing shelf according to an embodiment of the present invention, the top of the main body 1 is provided with a rainproof roof 2, and the bottom of the rainproof roof 2 is provided with the frame 20 and the The groove corresponding to the top of the placement fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com