Stone veneer positive angle splicing structure and its construction method

A construction method and finishing technology, which is applied in the direction of building structure, building material processing, covering/lining, etc., can solve the problems of uneven stone joints, affecting the quality of appearance, and explosive edges, etc., and achieve good appearance effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

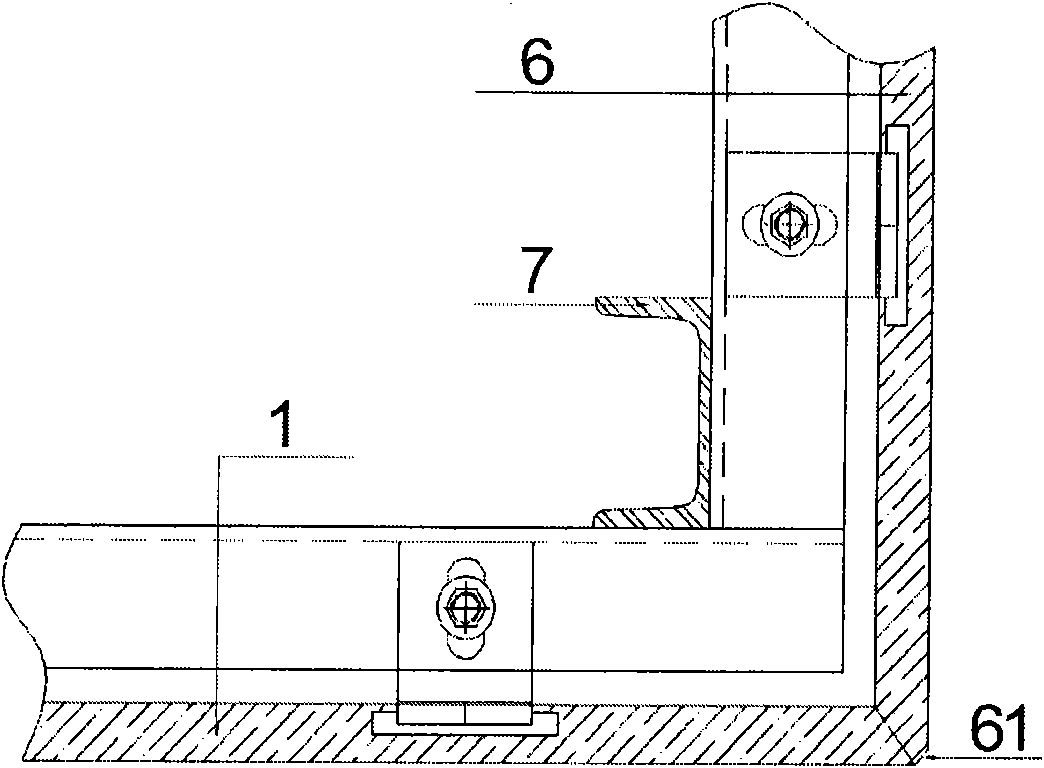

[0024] like figure 1 , Figure 7 As shown, a stone facing external corner splicing structure, which includes a stone facing 1, a stone facing 2 6, an angle grinding surface 61 is provided at the joint of the external corners of the stone facing 1 and the stone facing 2 6, The seam 10 between the first stone veneer 1 and the second stone veneer 6 is not in the middle of the grinding angle surface 61 . The patchwork 10 is located at the water chestnut line of the grinding angle surface 61 .

Embodiment 2

[0026] like Figure 8 As shown, a construction method for splicing external corners of stone veneer, including the following construction steps,

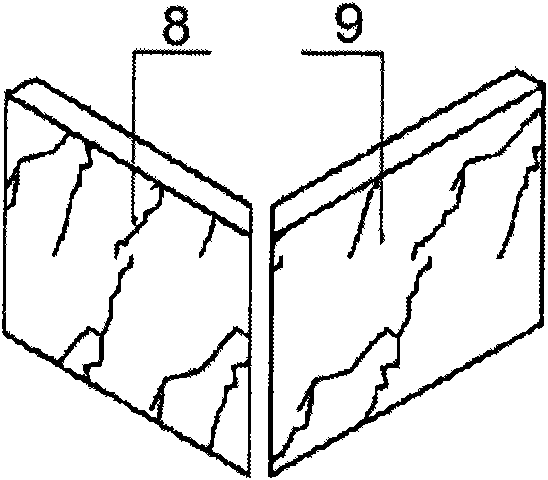

[0027] a. Stone veneer 1 and stone veneer 2 6 are both edged with sharp corners;

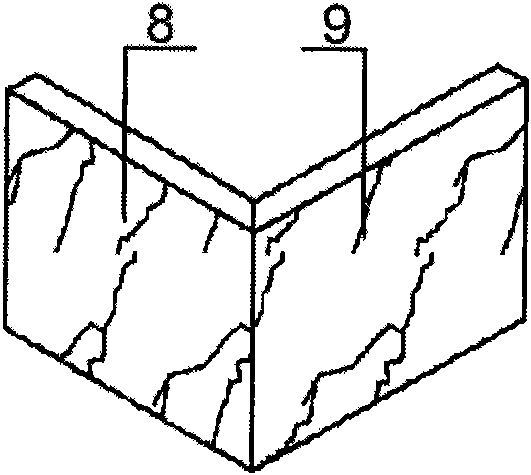

[0028] b. Stone veneer 1 and stone veneer 2 6 are bonded to form an assembly through sharp corners. When bonding, the sharp corners of the plate end of stone veneer 2 6 protrude from the surface of stone veneer 1 for a certain distance to form a protruding part ;

[0029] c. After the splicing of stone veneer 1 and stone veneer 2 6 is completed, after the adhesive is cured, grind off the protruding part, so that the joints of stone veneer 1 and stone veneer 2 6 form a ground angle surface 61 .

[0030] The protruding amount of the protruding part in the step b is determined according to the grinding angle after splicing.

[0031] According to the angle grinding amount of the protruding part in the step c, after the angle grinding is completed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com