Rare earth composite corundum reinforced fiber ultrathin resin cutting blade and production method thereof

A rare-earth composite and reinforced fiber technology, which is applied in the direction of abrasives, metal processing equipment, grinding devices, etc., can solve the problems that affect the cutting effect, shorten the service life of the cutting blade, affect the cutting quality, etc., and achieve fast and efficient cutting Speed, material loss reduction, and material saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

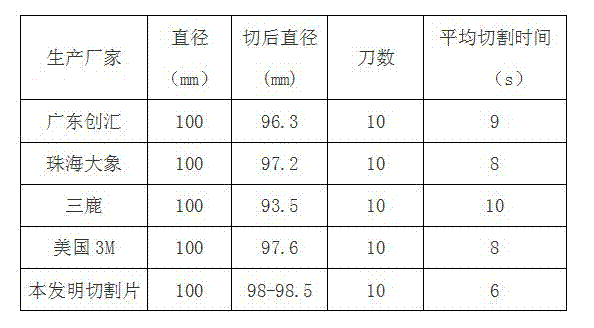

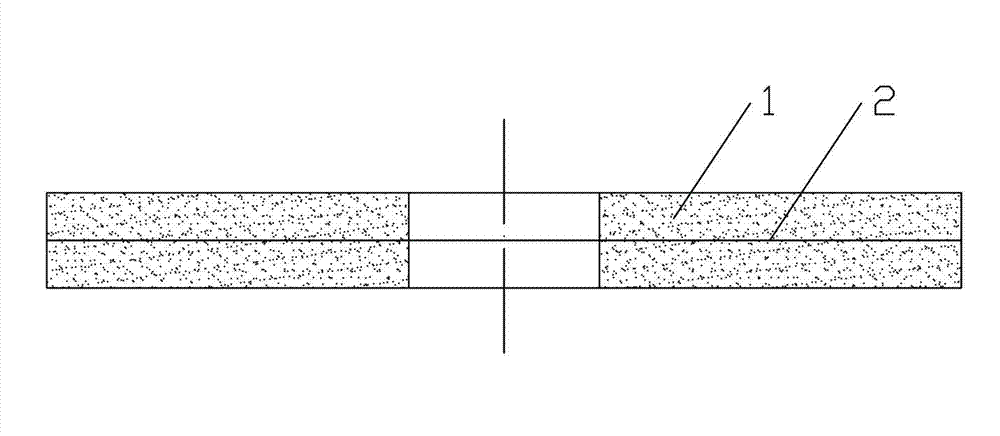

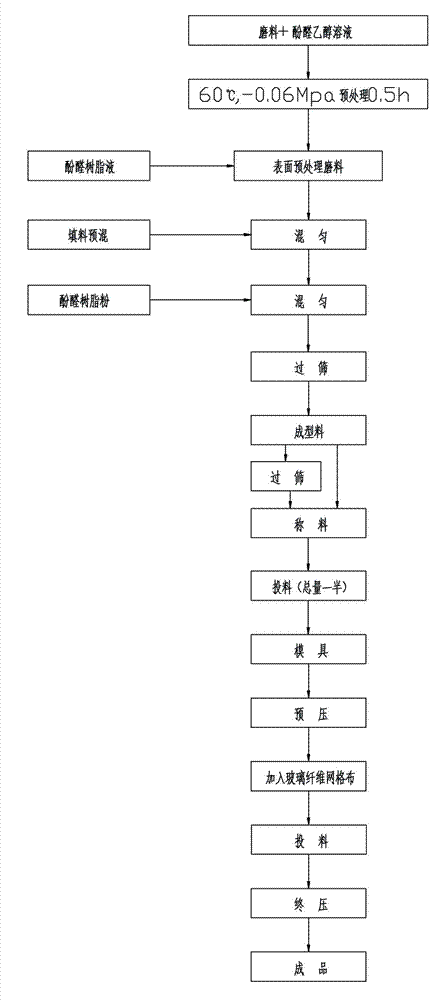

[0016] Example 1: see figure 2 , a rare earth composite corundum reinforced fiber ultra-thin resin cutting sheet, which has an abrasive sheet 1, a layer of glass fiber mesh cloth layer 2 is arranged at the center of the abrasive sheet 1, and the abrasive sheet 1 is composed of the following raw materials in parts by weight : Rare earth composite corundum 100kg (using self-produced rare earth zirconium yttrium titanium composite corundum, of which 46# material 60kg, 60# material 40kg), phenolic ethanol solution 100kg, phenolic resin powder 10kg, phenolic resin liquid 16kg, cryolite 6kg, iron black 1kg, gypsum 3kg, ferrous sulfide 3kg.

[0017] The phenolic resin powder described in this example has a melting point of 82-90° C., measured by the Thilele method, and the free phenol content is ≤3.5%.

[0018] The phenolic resin solution described in this example has a viscosity of 120 s, measured by the 4-cup method, the content of urotropine: 5%, and the solid content: 75%.

[...

example 2

[0022] Example 2: a rare earth composite corundum reinforced fiber ultra-thin resin cutting sheet, it has an abrasive sheet 1, the center of the abrasive sheet 1 is arranged with a layer of glass fiber mesh cloth layer 2, and the abrasive sheet 1 consists of the following parts by weight Raw material composition: 100kg of rare earth composite corundum (using self-produced rare earth zirconium yttrium titanium composite corundum, of which 46# material 50kg, 60# material 25kg, 80# material 25kg), phenolic ethanol solution 100kg, phenolic resin powder 11kg, phenolic resin liquid 19kg , cryolite 7kg, iron black 2kg, gypsum 4kg, ferrous sulfide 4kg.

[0023] The phenolic resin powder described in this example has a melting point of 82-90° C., measured by the Thilele method, and the free phenol content is ≤3.5%.

[0024] The phenolic resin solution described in this example has a viscosity of 120 s, measured by the 4-cup method, the content of urotropine: 6%, and the solid content: ...

example 3

[0026] Example 3: A rare earth composite corundum reinforced fiber ultra-thin resin cutting sheet, which has an abrasive sheet 1, and the center of the abrasive sheet 1 is arranged with a layer of glass fiber mesh cloth layer 2, and the abrasive sheet 1 consists of the following parts by weight Raw material composition: 100kg of rare earth composite corundum (using self-produced rare earth zirconium yttrium titanium composite corundum, of which 30# material is 45kg, 36# material is 55kg), phenolic ethanol solution 100kg, phenolic resin powder 12kg, phenolic resin liquid 22kg, cryolite 8kg, Iron black 3kg, gypsum 5kg, ferrous sulfide 5kg.

[0027] The phenolic resin powder described in this example has a melting point of 82-90° C., measured by the Thilele method, and the free phenol content is ≤3.5%.

[0028] The phenolic resin solution described in this example has a viscosity of 120 s, measured by the 4-cup method, the content of urotropine: 7%, and the solid content: 80%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com