Goods sorting method based on intelligent AGV

A commodity and intelligent technology, applied in the field of warehousing, can solve problems such as high cost, long implementation period, dismantling, transshipment, and difficult expansion, and achieve the effect of less investment in equipment, short implementation period, and convenient expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

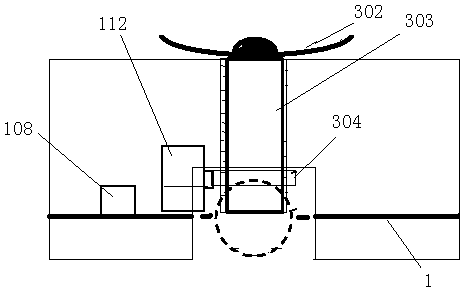

[0023] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

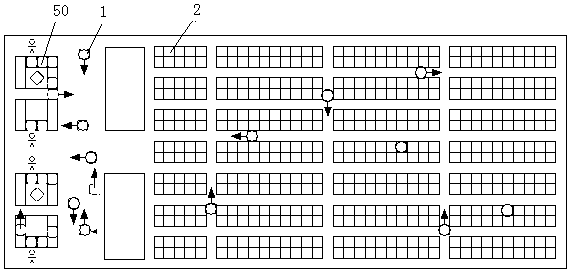

[0024] like figure 1 As shown, an intelligent AGV-based product sorting method provided by the embodiment of the present invention relates to a warehouse sorting system, and the warehouse sorting system includes control terminals (not shown in the figure) respectively arranged in the warehouse, Sorting workstation 50, and multiple automatic guided vehicles 1, multiple movable shelves 2;

[0025] Each automatic guided vehicle 1 is connected to the control terminal and the sorting workstation 50 through a wireless network. A plurality of navigation markers for automatic guided vehicle navigation are arranged in the warehouse, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com