Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

An auxiliary heat source and rail technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as poor railway branching and repair of damaged rails, and achieve good overall fatigue performance, high processing accuracy, and small residual stress and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

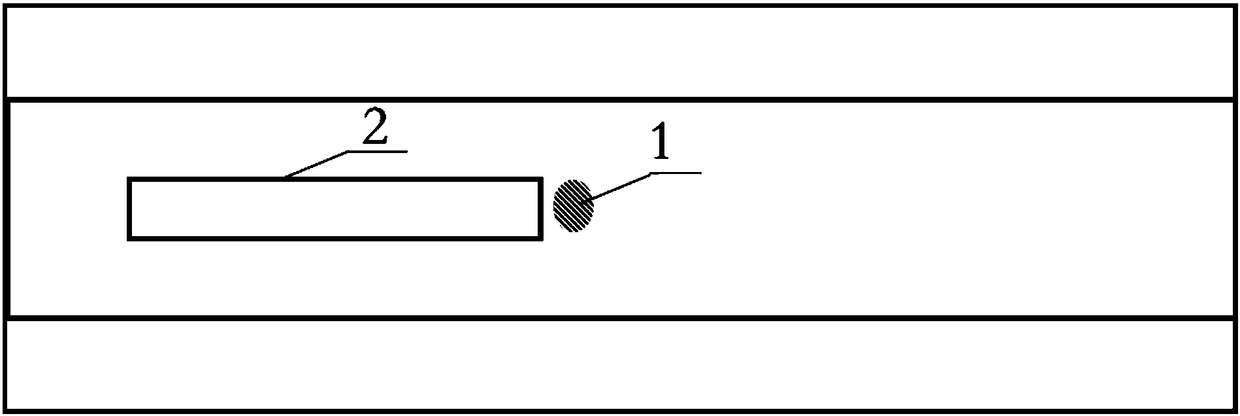

[0048] Example 1: High-efficiency thermal composite cladding after on-line laser-induction of railways

[0049] In this example, the service rails are efficiently strengthened and repaired at the railway site, induction heating is used as an auxiliary heat source, and the processing motion and position control unit adopts industrial manipulators or three-dimensional motion axes. The area to be clad on the surface of the rail is heated by an induction heating component and a temperature control mechanism, and the heating temperature and time are controlled. The induction heating component includes an induction power supply and an induction coil. The temperature control mechanism includes an infrared thermometer and a temperature controller. The induction coil is connected to the induction power supply. The infrared thermometer is connected to the temperature controller. The temperature controller is connected to the induction power supply through a data line. . The detection s...

Embodiment 2

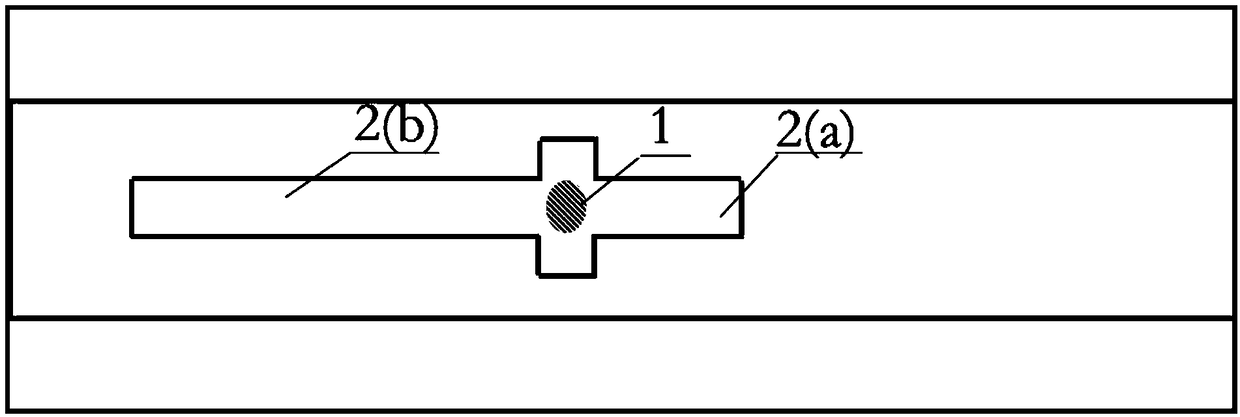

[0059] Example 2: Railway online laser-induction preheating + post-induction heat efficient composite cladding

[0060] In this example, the service rails are efficiently strengthened and repaired at the railway site. Induction heating is used as an auxiliary heat source. The induction heating control mechanism is the same as that of Example 1. The processing motion and position control unit adopts industrial manipulators or three-dimensional motion axes. The laser spot is focused in the middle of the induction coil, such as figure 2 As shown, the metal cladding layer is prepared on the surface of the rail by laser-induction preheating + post-induction thermal composite cladding. The basic implementation steps are as follows:

[0061] (1) Nickel-based alloy powder is selected as the cladding material, the main chemical composition is (Wt.%): (0.01-0.50) C, (20-30) Cr, (5-10) W, (3-5) Si ,(0-3)B,(5-10)Fe,Ni balance;

[0062] (2) Grinding the cladding area on the surface of t...

Embodiment 3

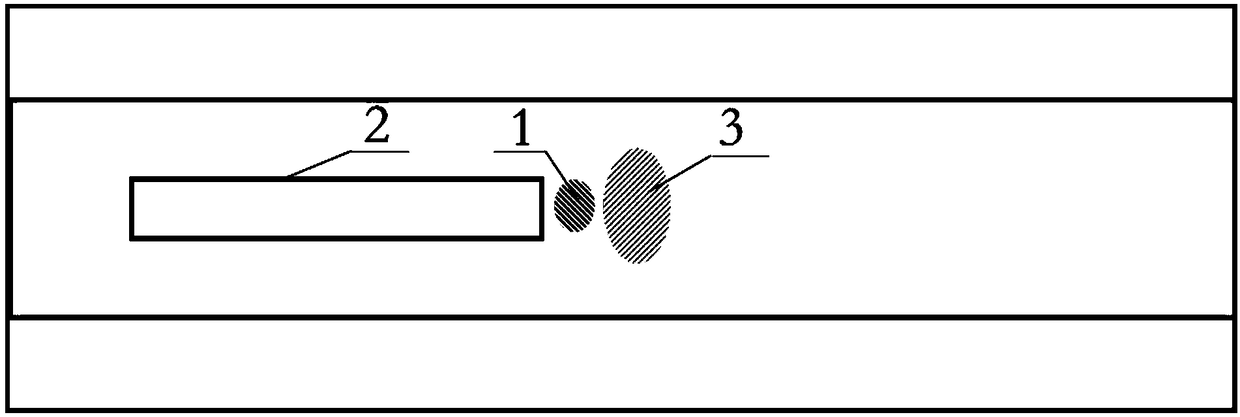

[0070] Example 3: Off-line rail surface laser-induction heating + oxyacetylene flame (propane blowtorch) heating and high-efficiency composite cladding

[0071] In this example, off-line strengthening and repairing of steel rails is carried out, and induction heating and oxyacetylene flame (or propane torch) are used as auxiliary heat sources. The laser spot is focused in front of the induction coil, and the oxyacetylene flame (or propane torch) preheats the surface of the rail to be clad, such as image 3 As shown, the laser and the induction coil move in the same direction and at the same speed, and the induction heating performs synchronous heating on the laser molten pool and the heat-affected zone of the rail. The basic implementation steps are as follows:

[0072] (1) Cobalt-based alloy powder is selected as the cladding material, the main chemical composition is (Wt.%): (0.01-0.5) C, (20-35) Cr, (1-10) Ni, (1-3) Si , (5-15) W, (0-3) B, (0.5-2) Mn, Co balance;

[0073] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com