Fast forming method of fusion of metal powder of three beams of laser compound scanning

A technology of metal powder and composite scanning, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of non-negligible heat conduction of machine parts, hinder the normal operation of the machine, and damage machine parts, so as to ease the stress field and reduce the Small cracks and warping, slowing down the effect of drastic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

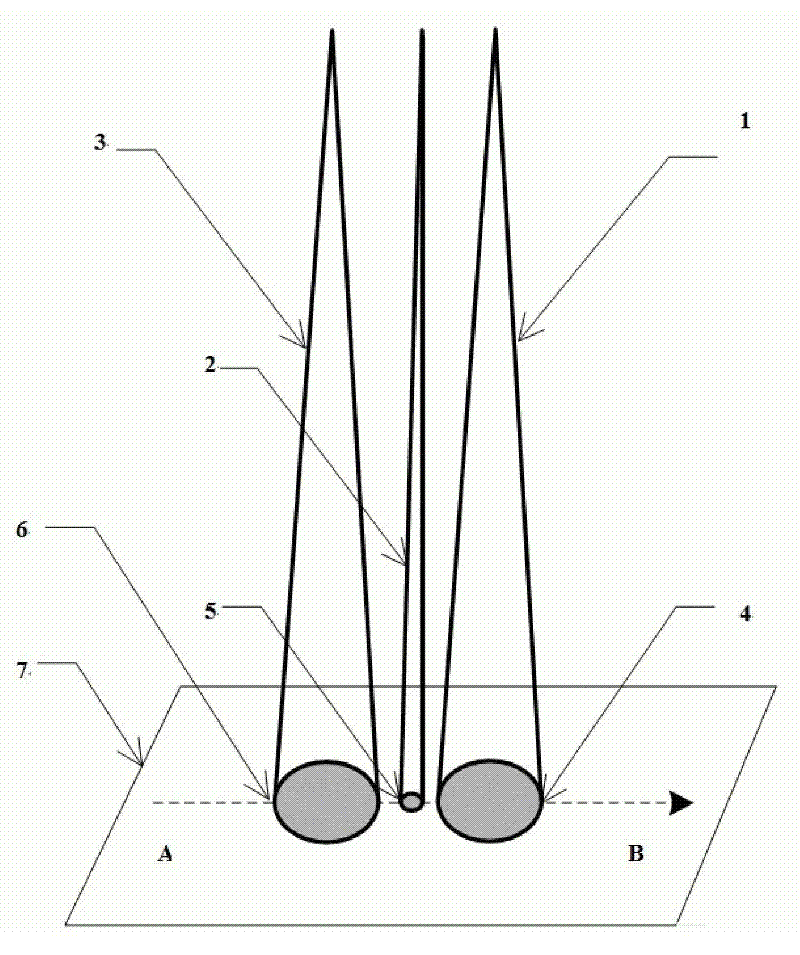

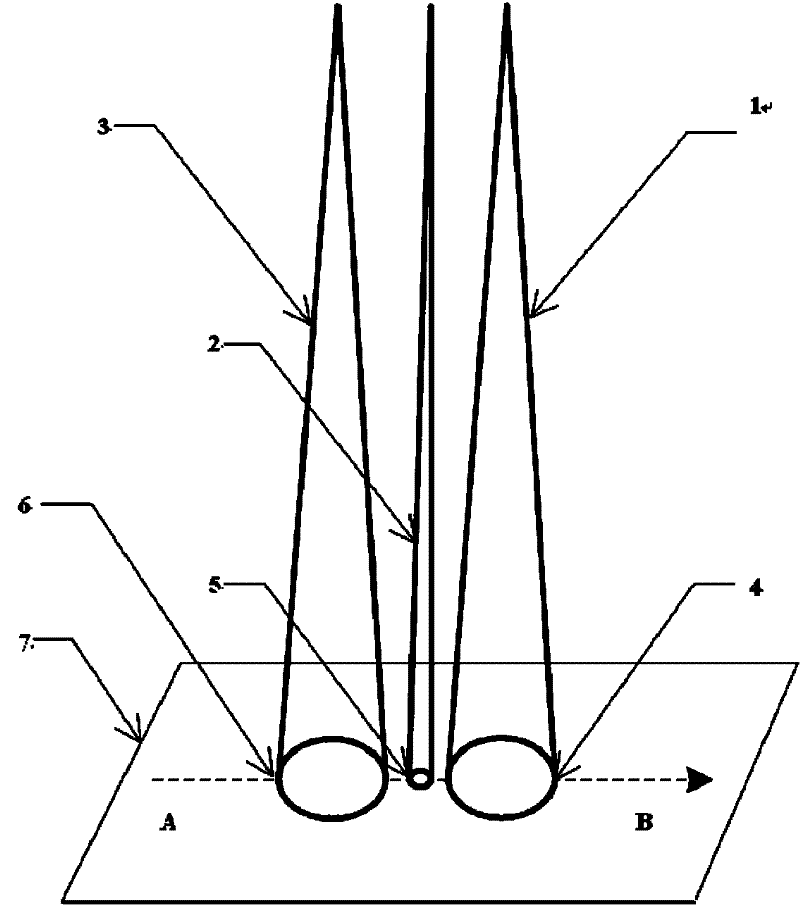

[0028] The spherical 316L stainless steel powder with a particle size of 20 microns is selected for SLM forming, and three-beam laser composite scanning is used to prepare metal parts with low stress, no warping, and uniform structure. The part graphics are designed by CAD software, processed by slicing software and path software, saved as STL, and input into SLM equipment for SLM forming. The specific scanning method of each layer is as follows:

[0029] Use CO 2 The laser is used as the first laser beam, the laser power is set to 50W, the scanning speed is 200mm / s, and the 316L stainless steel powder bed is scanned and preheated along the set scanning path;

[0030] Use the fiber laser as the second laser beam, set the laser power to 200W, and the scanning speed to 200mm / s, scan and melt along the scanning path, and make the position of the second laser spot be behind the scanning direction of the first laser spot with a distance of 0.1 mm;

[0031] Use CO 2 The laser is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com