Method for plating tungsten on diamond surface

A technology of diamond particles and tungsten plating, which is applied in the field of pre-processing of diamond abrasive tools or other diamond products, can solve the problems of high cost of tungsten plating and poor coating effect, and achieves simple process and required equipment, avoids subsequent processing, The effect of a large amount of plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

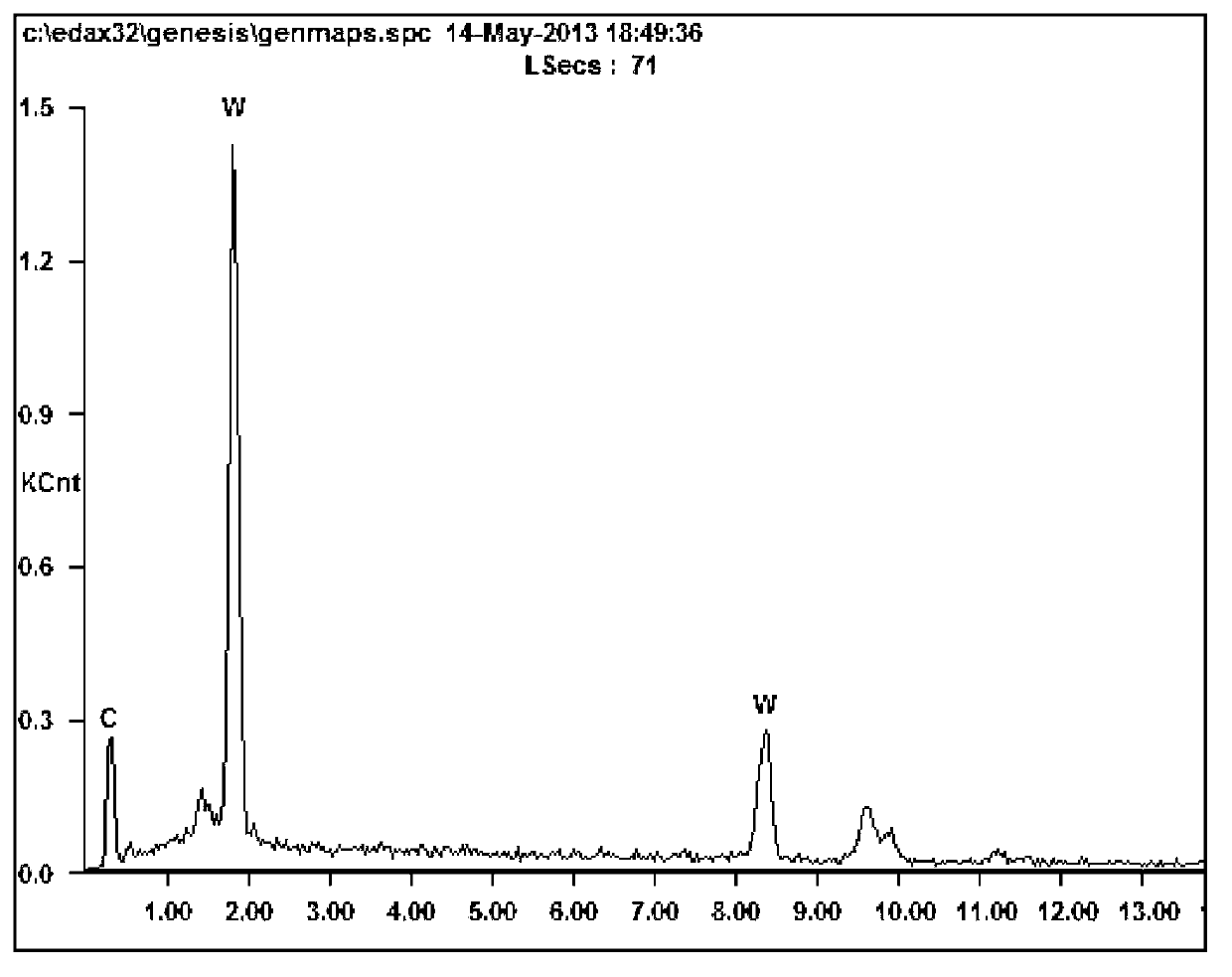

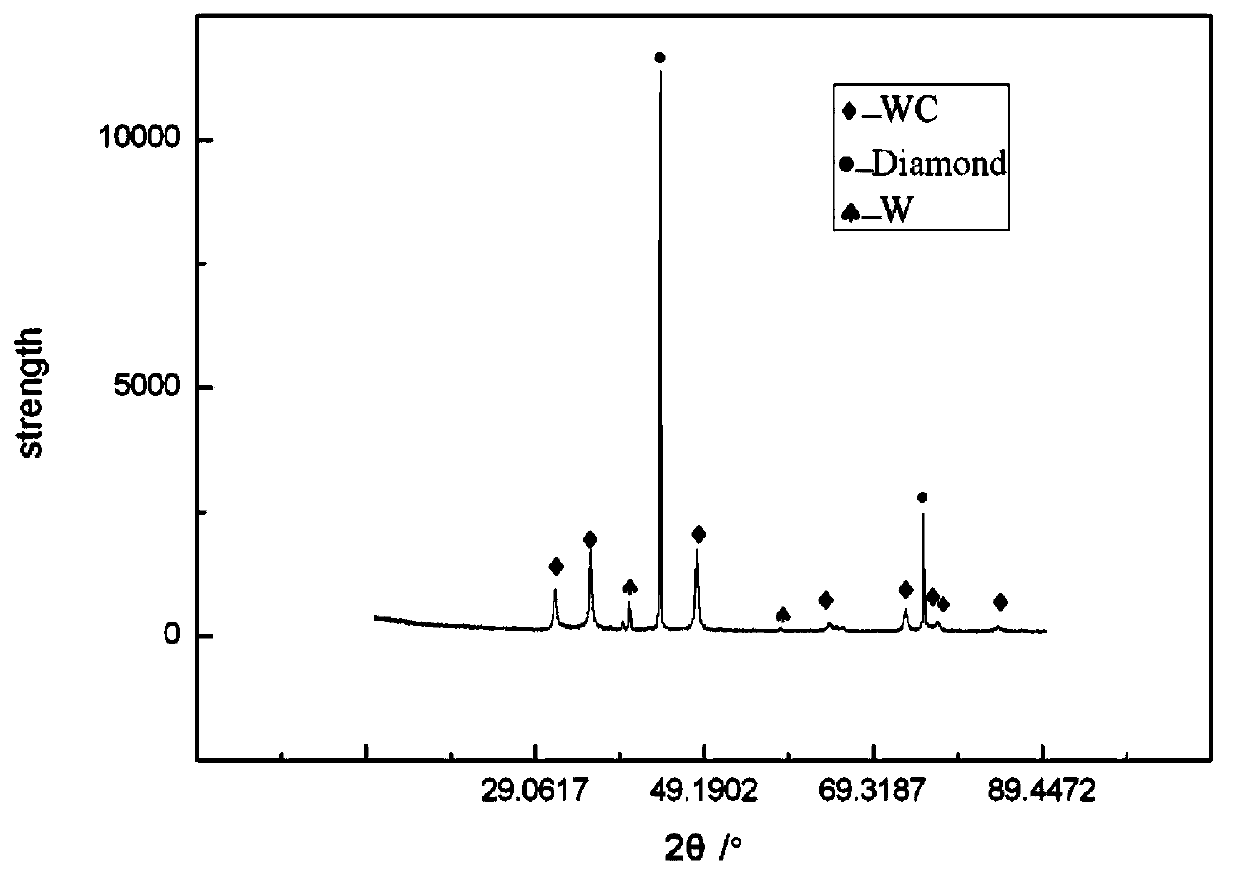

[0045] Weigh 1g of synthetic diamond powder (model MBD4, 120 / 140 mesh) with an analytical balance, first place the diamond particles in a 0.1mol / L NaOH solution, clean them with ultrasonic vibration for 0.5h, and wash them with deionized water until Neutral; then place the diamond particles in 0.1mol / L dilute hydrochloric acid and soak for 0.5h, take it out and wash it with deionized water until it is neutral; add an appropriate amount of 30% nitric acid solution and boil for 5min, carry out roughening treatment, and use Wash with deionized water until neutral; place the roughened diamond particles in a newly prepared colloidal palladium solution, stir rapidly for 5 minutes, and wash with deionized water until neutral; then use 10% dilute hydrochloric acid or 25g / L hypophosphorous acid Restore with sodium hydrogen solution, stir quickly for 3 minutes, then wash with deionized water until neutral; then wash with alcohol or acetone for 10 minutes; finally wash with deionized wate...

Embodiment 2

[0046] Embodiment 2: take by weighing 1g synthetic diamond powder (model is MBD4, 120 / 140 order) with analytical balance, at first diamond particle is placed in the KOH solution of 0.05mol / L, cleans 0.5h with ultrasonic vibration, after taking out, use Wash with deionized water until neutral; then soak the diamond particles in 0.1mol / L dilute hydrochloric acid for 0.5h, take it out and wash with deionized water until neutral; add an appropriate amount of 20% nitric acid solution and boil for 10min for roughening treatment, and washed with deionized water until neutral; the roughened diamond particles were placed in a newly configured colloidal palladium solution, stirred rapidly for 10 minutes, and washed with deionized water until neutral; then use 10% dilute hydrochloric acid or 30g / Restore with L of sodium hydrogen hypophosphite solution, stir rapidly for 3 minutes, then wash with deionized water until neutral; then wash with alcohol or acetone for 5 minutes; finally wash w...

Embodiment 3

[0047] Embodiment 3: take by weighing 1g synthetic diamond powder (model is MBD4, 120 / 140 order) with analytical balance, at first diamond particle is placed in the NaOH solution of 0.2mol / L, cleans 0.5h with ultrasonic vibration, after taking out, use Wash with deionized water until neutral; then soak the diamond particles in 0.1mol / L dilute hydrochloric acid for 0.5h, take it out and wash with deionized water until neutral; add an appropriate amount of 25% nitric acid solution and boil for 7min to coarsen treatment, and washed with deionized water until neutral; the roughened diamond particles were placed in the newly configured colloidal palladium solution, stirred rapidly for 4min, and washed with deionized water until neutral; then use 10% dilute hydrochloric acid or 20g / Restore with L of sodium hydrogen hypophosphite solution, stir rapidly for 3 minutes, then wash with deionized water until neutral; then wash with alcohol or acetone for 10 minutes; finally wash with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com