Second-active-center-containing catalyst hydrogenation apparatus startup method

A technology of active center and hydrogenation unit, which is applied in the fields of hydroprocessing process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problem of increased operational risk, damage to catalyst activity, difficulty in ensuring oxidation state, and cracking activity and activity of elemental metal catalysts. Stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

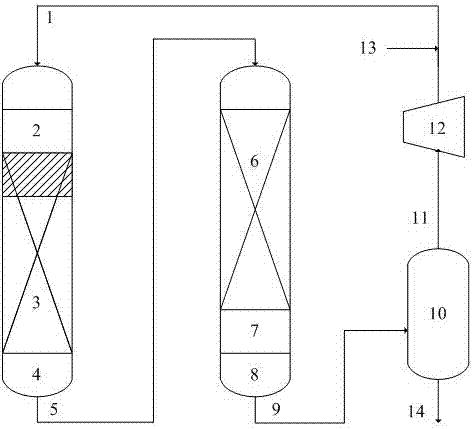

[0044] Such as figure 1 As shown, an embodiment of the hydrogenation catalyst start-up method of the present invention is as follows:

[0045] According to the direction of gas circulation, the circulating hydrogen 1 passes through the hydrotreating reactor 4 containing the hydrogenation protection catalyst 2 and the second-type active center treatment agent 3 (the upper part has been pre-sulfurized outside the device), and the effluent 5 is obtained, and then passed through Hydrocracking reactor 8 containing hydrocracking agent 6 and hydrocracking aftertreatment agent 7, effluent 9 enters high-pressure separator 10, and gas phase 11 discharged from the top passes through circulating hydrogen compressor 12 and mixes with make-up hydrogen 13 , to obtain cycle hydrogen 1. After opening the process according to the above steps, increase the inlet temperature of the hydrofinishing reactor 4 to 160°C, wait for the hydrogen sulfide concentration at the outlet of the hydrofinishing ...

Embodiment 1

[0047] The properties of the protective agent and catalyst used in Example 1 and Comparative Examples 1 and 2 are listed in Table 1. Both are commercial protective agents and catalysts developed and produced by Fushun Petrochemical Research Institute. Embodiment 1 is the start-up method of the present invention. Using the above-mentioned implementation mode, when formulating the plan, the loading and loading capacity of the pre-vulcanized treatment agent outside the device should be adjusted. Sulfur content, so that the excess sulfur content reaches more than 25% of the theoretical sulfur demand of the lower oxidation state type II active center catalyst. Comparative Example 1 is a conventional dry start-up process, and Comparative Example 2 is a conventional wet start-up process.

[0048] project FZC-100 FZC-102B FZC-103 FF-46 FC-24 chemical components, — Mo-Ni Mo-Ni Mo-Ni Mo-Ni Metal content, wt% — 6.8 9.0 29.0 22.7 Sulfur cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com