Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Large elbow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abnormal increased size of the elbow joint. [] {comment=HPO:probinson}

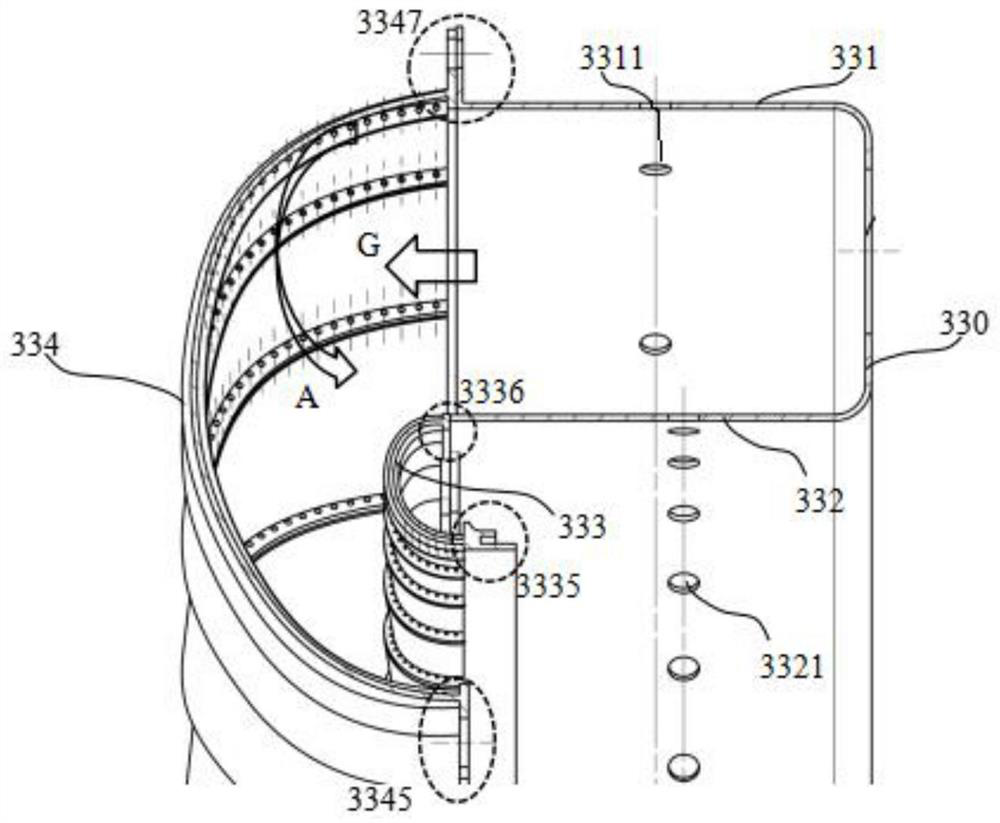

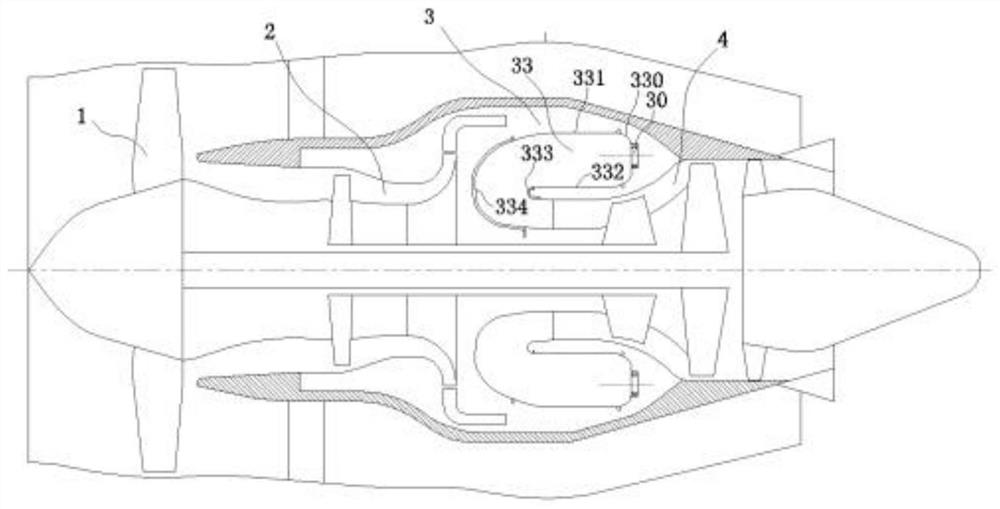

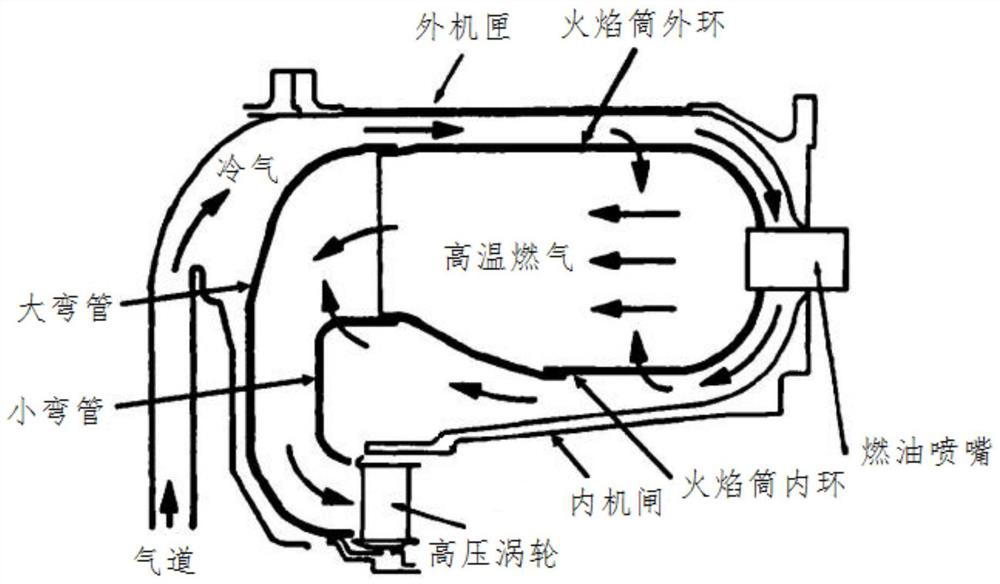

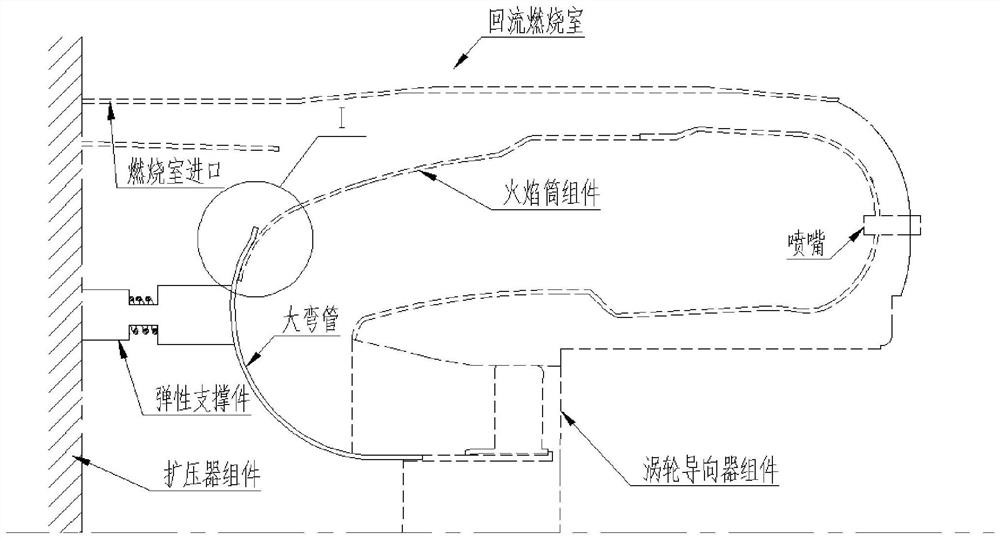

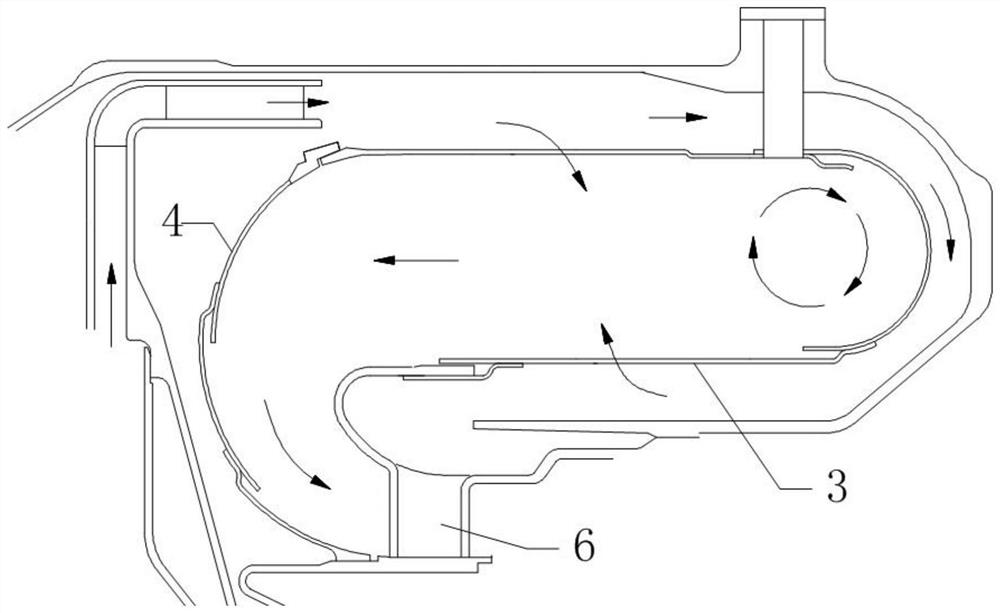

Reverse flow combustor allowing wider range of stable running

ActiveCN104676650AAvoid cokingGuarantee atomization qualityContinuous combustion chamberCombustorCombustion chamber

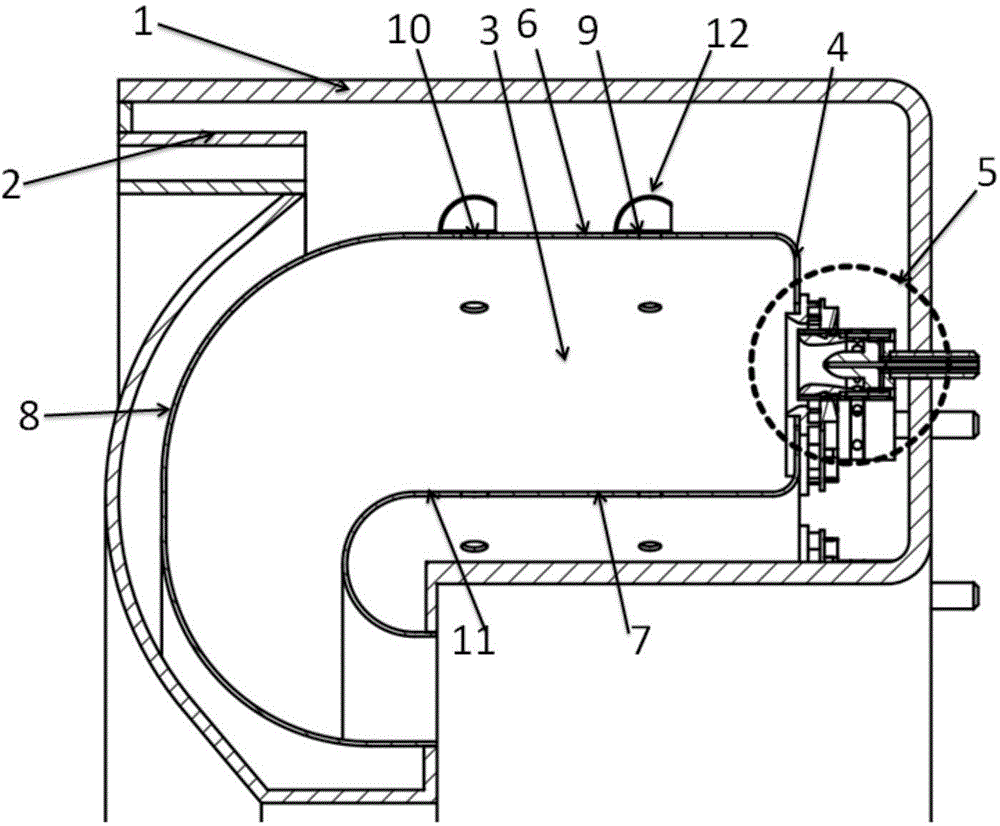

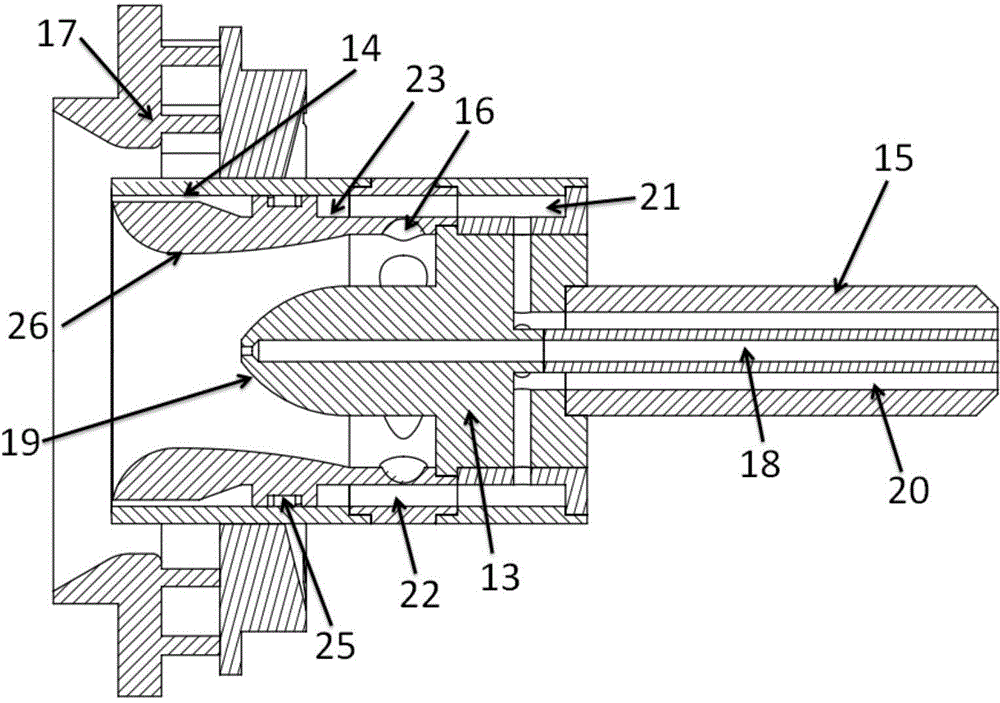

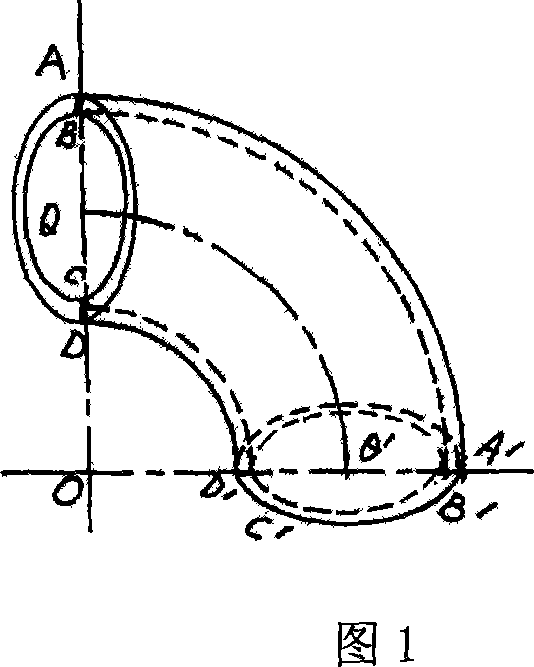

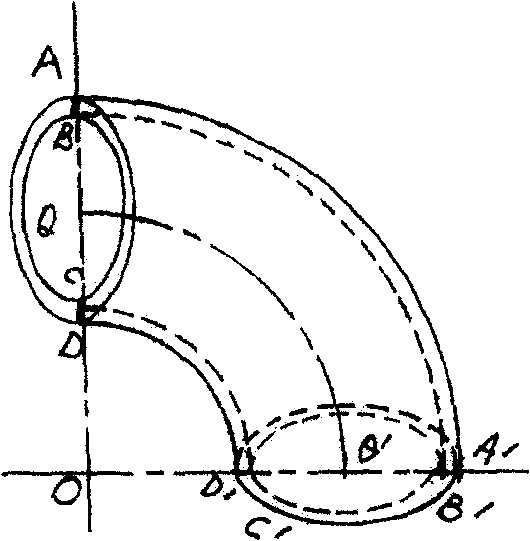

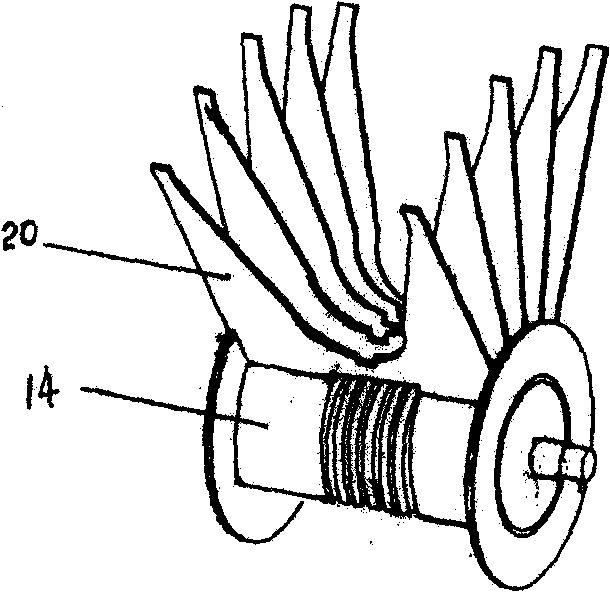

The invention provides a reverse flow combustor allowing a wider range of stable running. The reverse flow combustor comprises a diffuser, a combustor casing, a flame cylinder head end wall, a flame cylinder outer wall, a flame cylinder inner wall, a large elbow and a head atomizer. Air enters the combustor through the diffuser; part of the air enters a flame cylinder through the head atomizer; another part of the air enters through a main combustion hole of the flame cylinder and a mixing hole thereof, the remaining enters from a cooling structure. The air and fuel fully mix and combust in the flame cylinder. After passing by two 180-degree turns, the air leaves the combustor. The head atomizer performs atomizing in a mixed mode of pressure centrifugal atomizing and pre-swirling prior to pre-film air atomizing; the fuel is fed through a main oil circuit and an auxiliary oil circuit; the main combustion hole arranged in the outer wall of the flame cylinder and the mixing hole thereof are provided with a hood, jets are avoided flowing to the head, and inner and outer jets are ensured being symmetrical. The range of stable running of the reverse flow combustor can be expanded, and uniformity of fuel gas temperature of an outlet is guaranteed.

Owner:BEIHANG UNIV

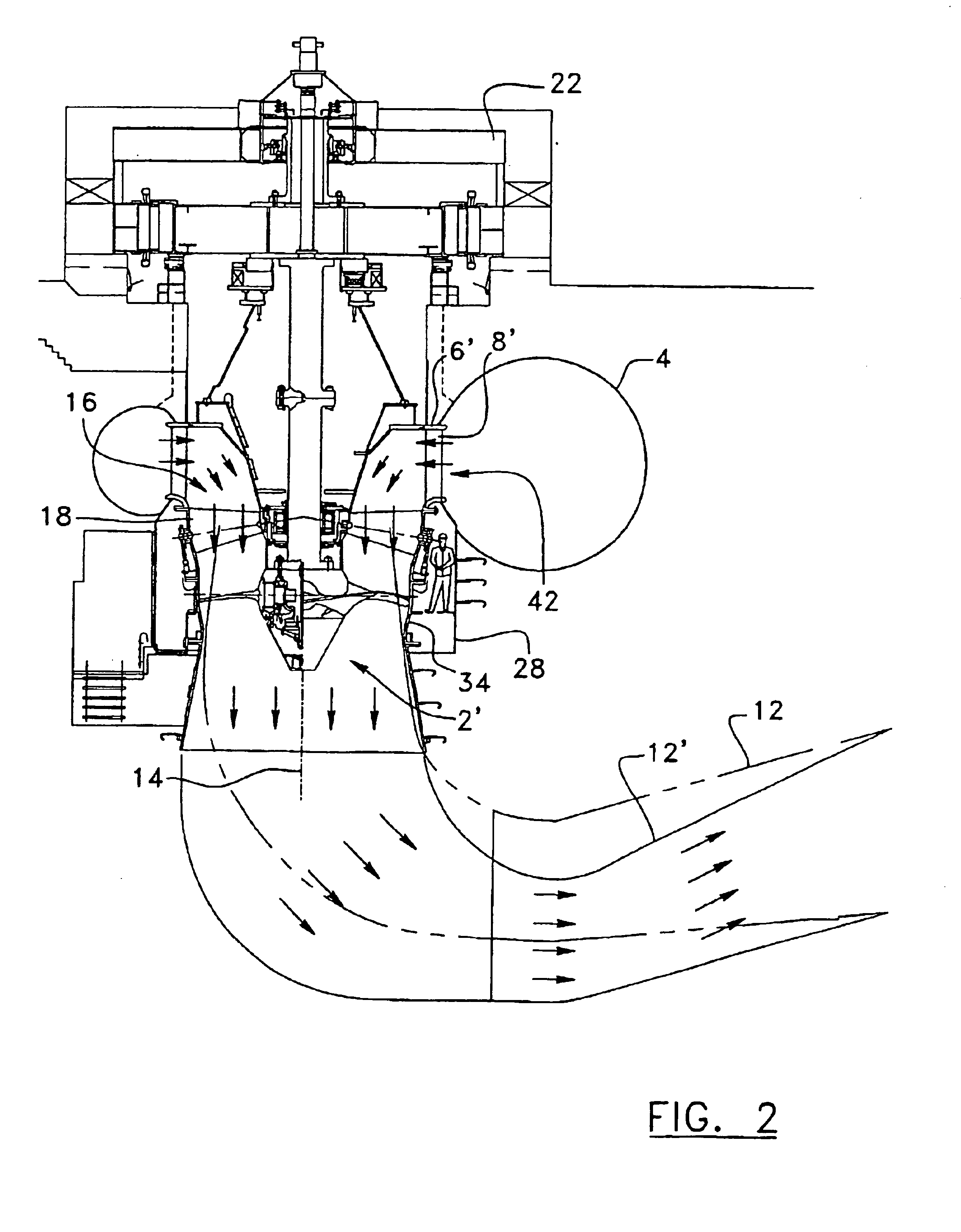

Hydraulic turbine with increased power capacities

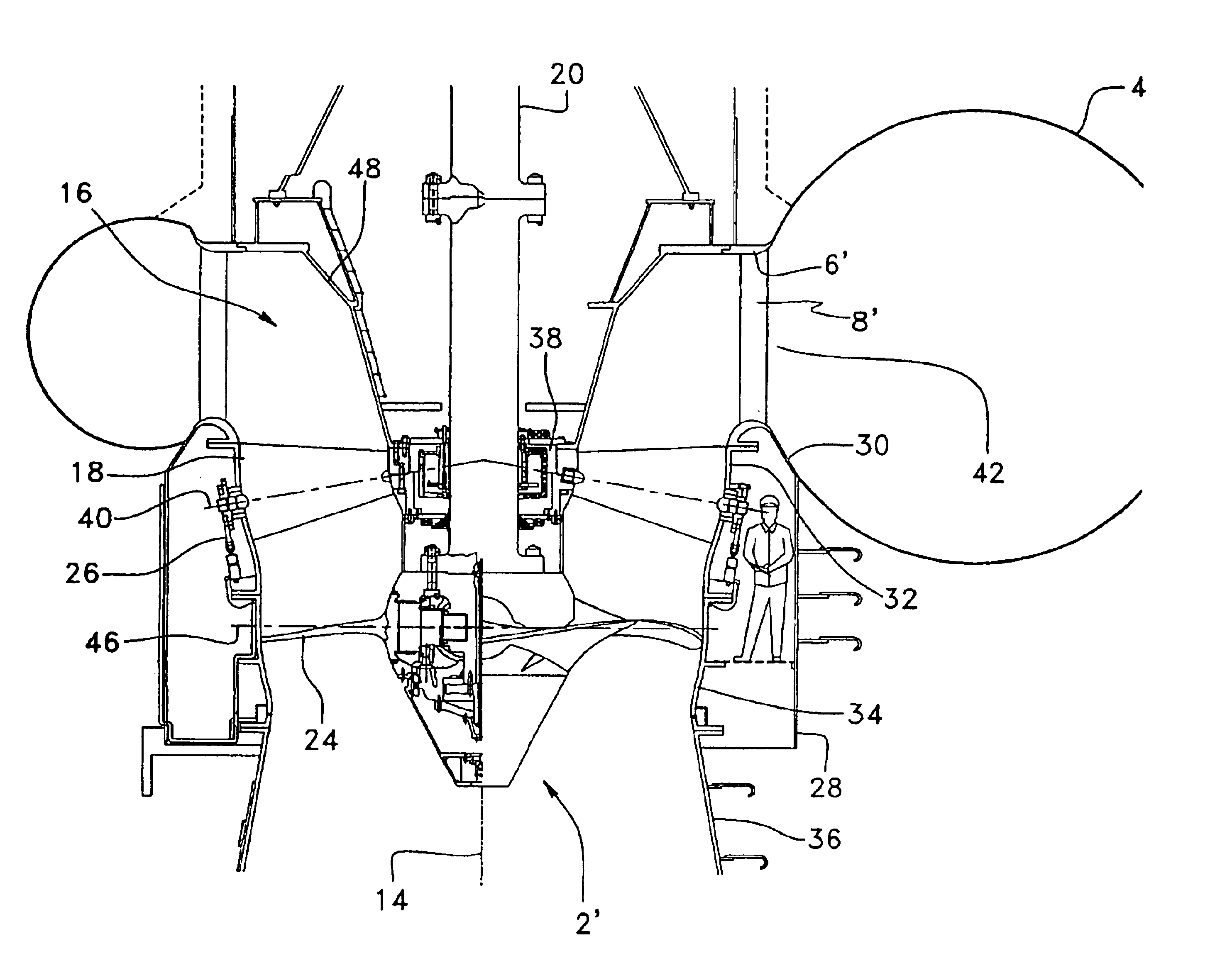

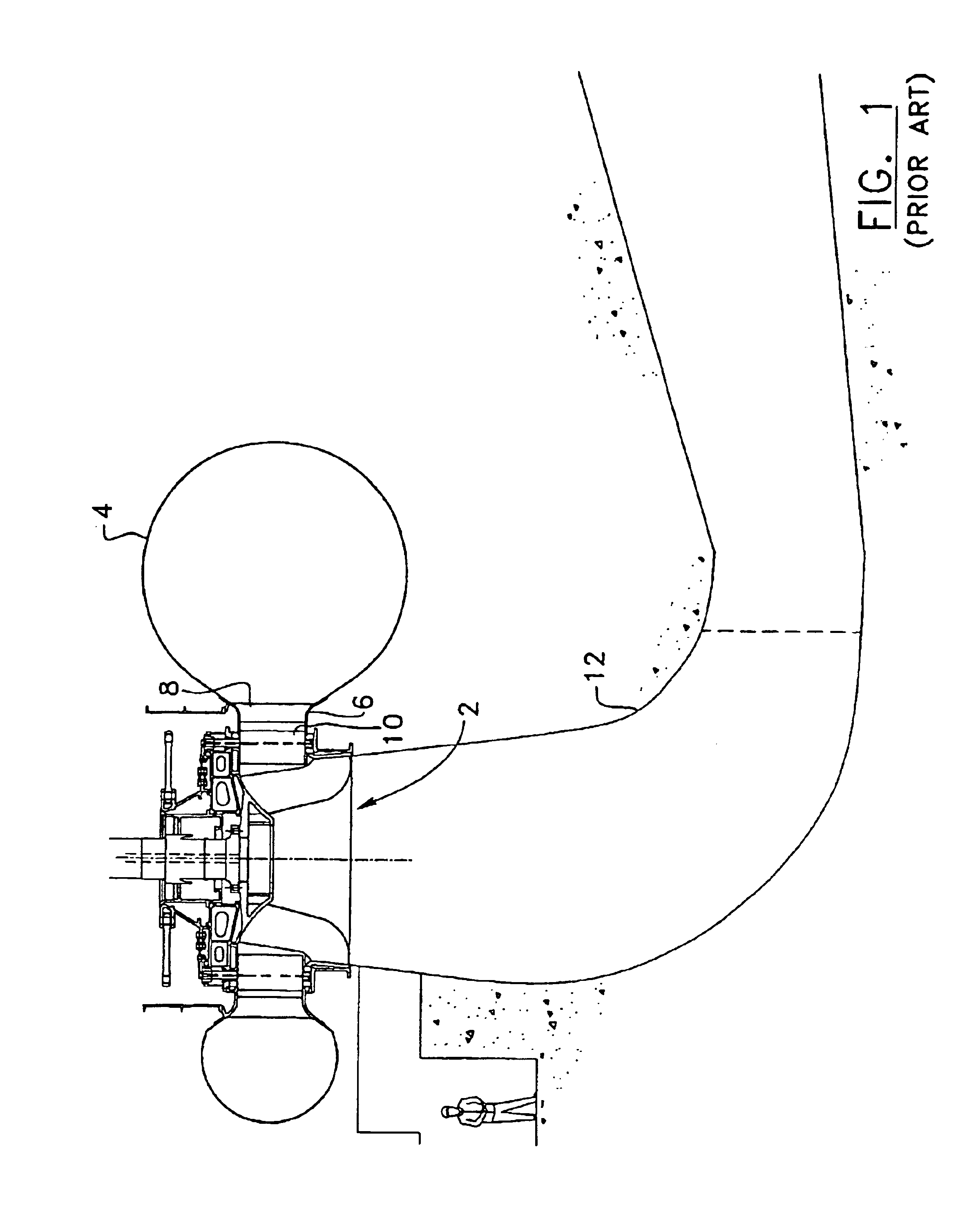

InactiveUS6926494B2Increased power capacityReduce in quantityEngine manufactureWind motor controlWater flowEngineering

Owner:ALSTOM CANADA

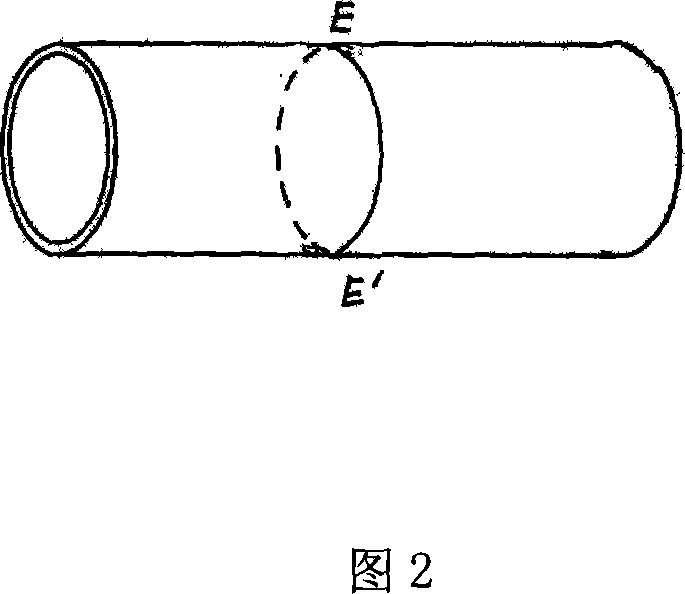

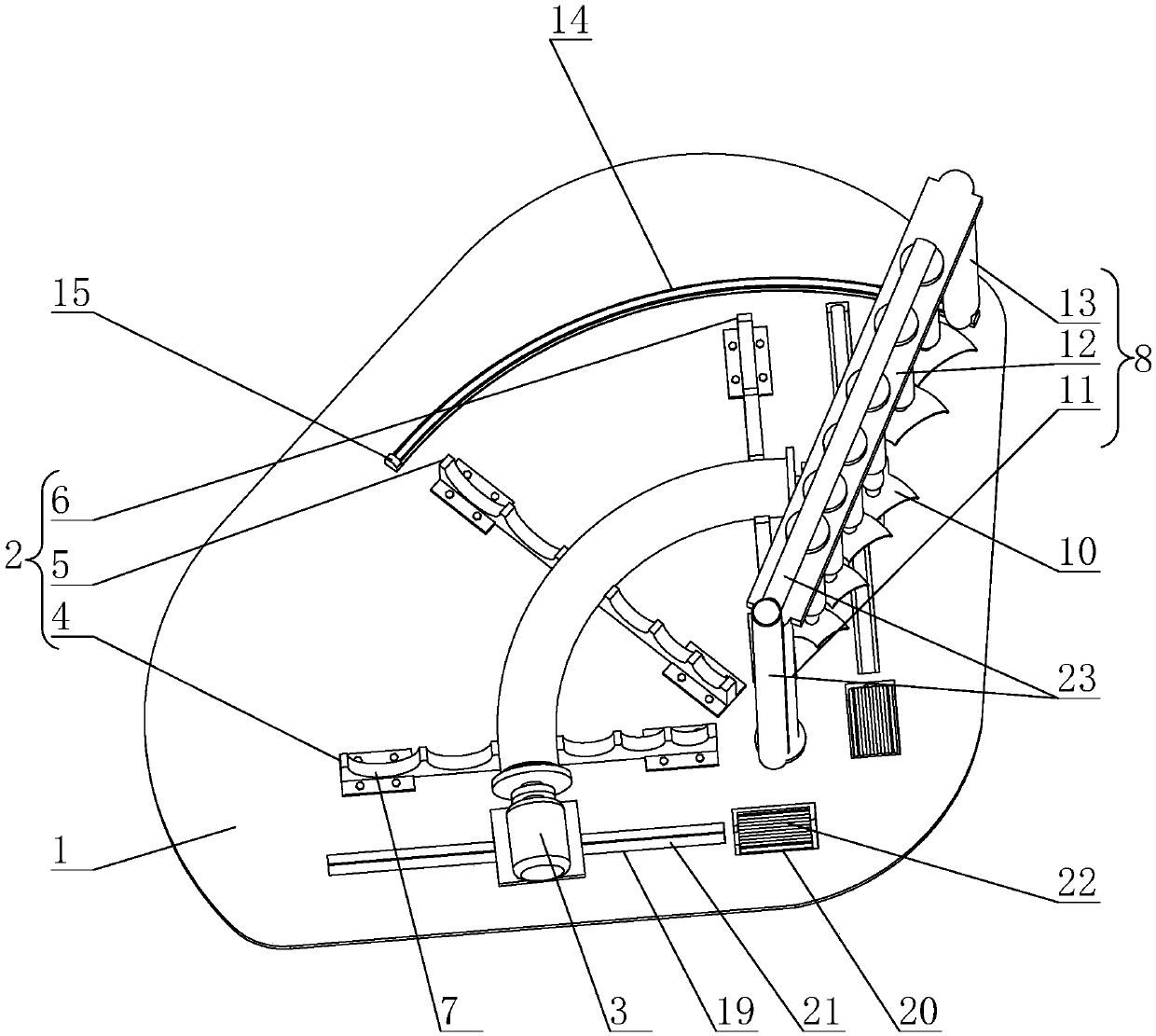

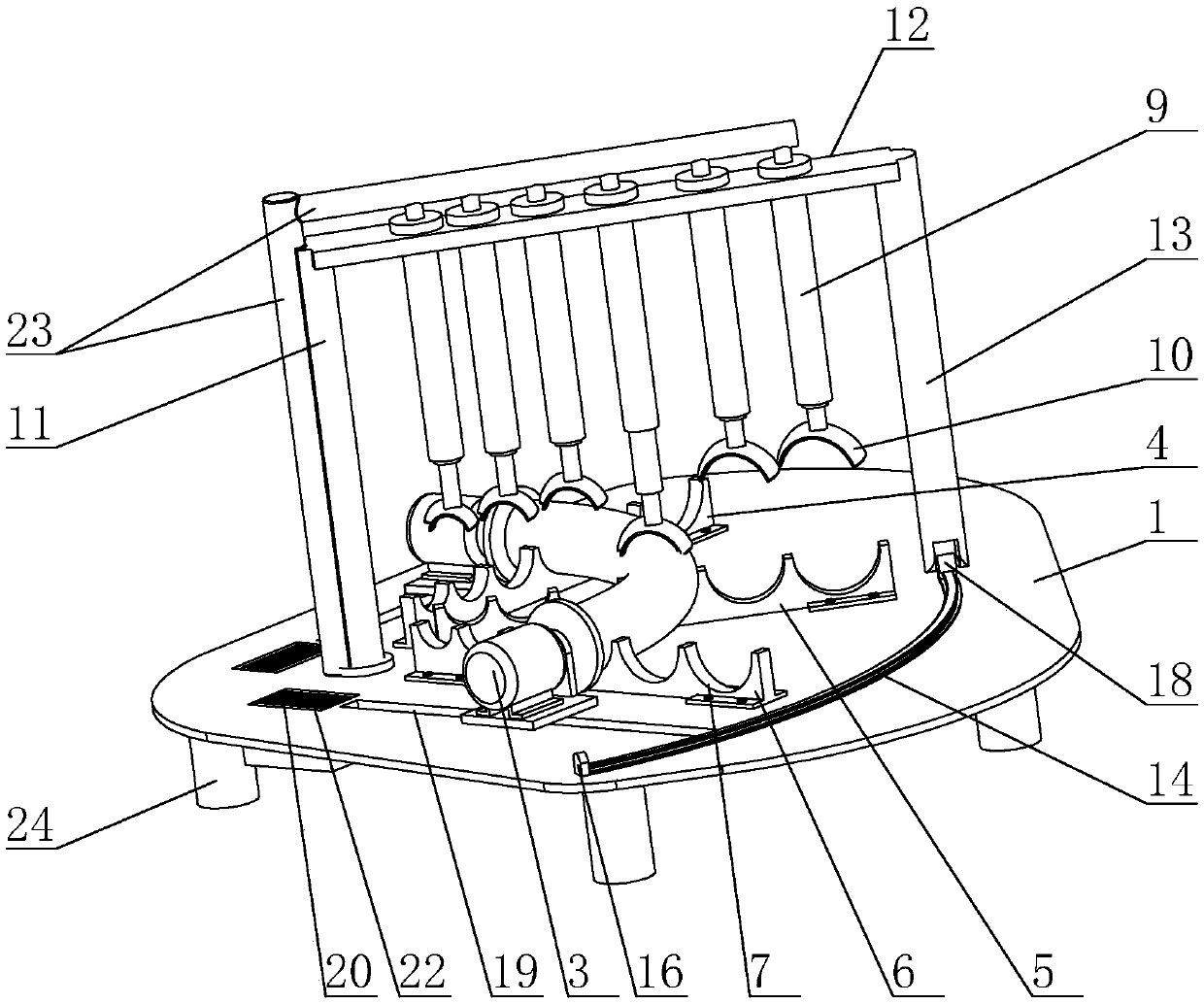

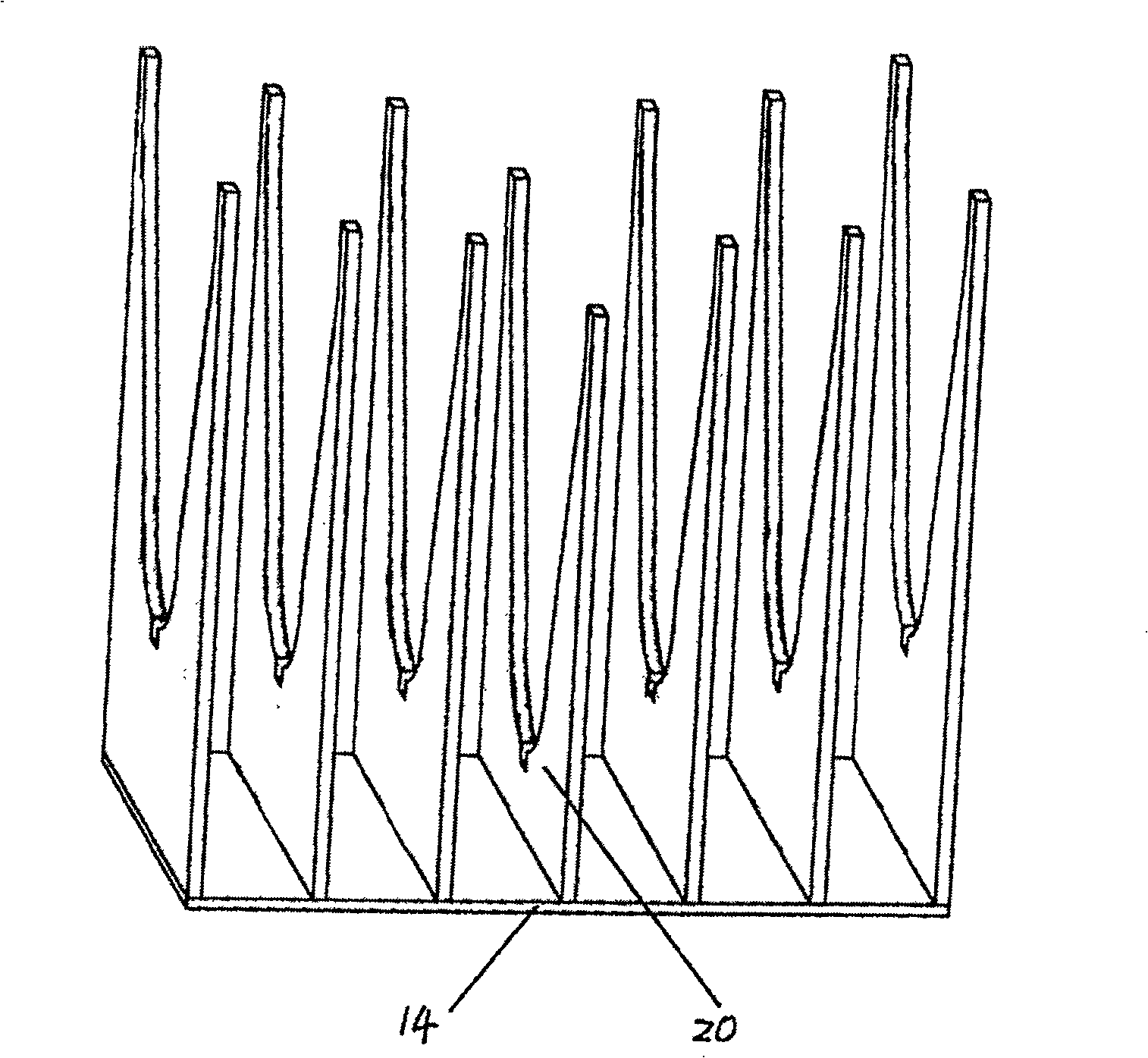

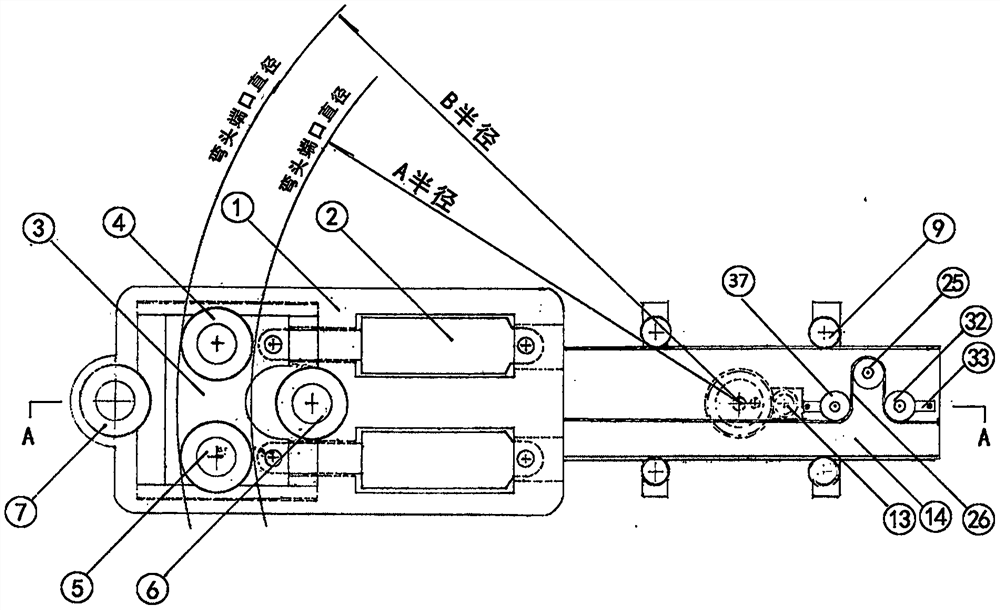

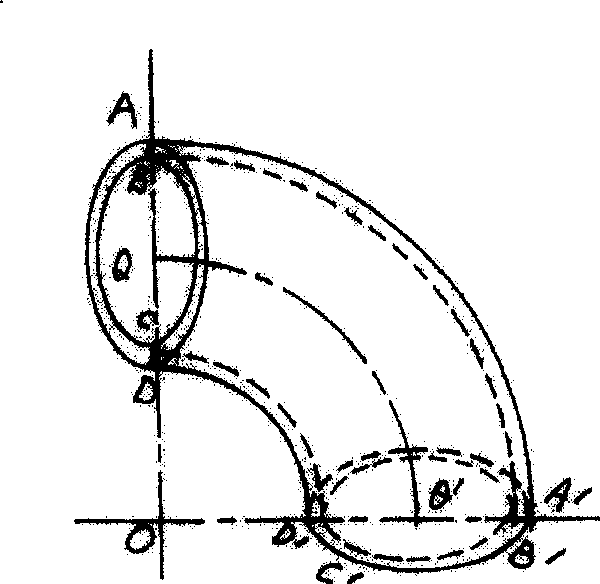

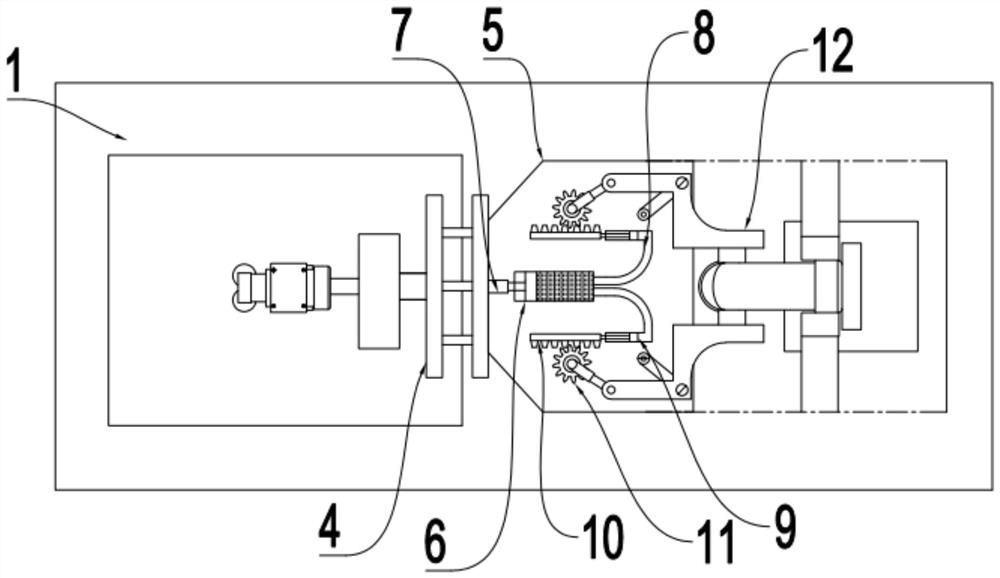

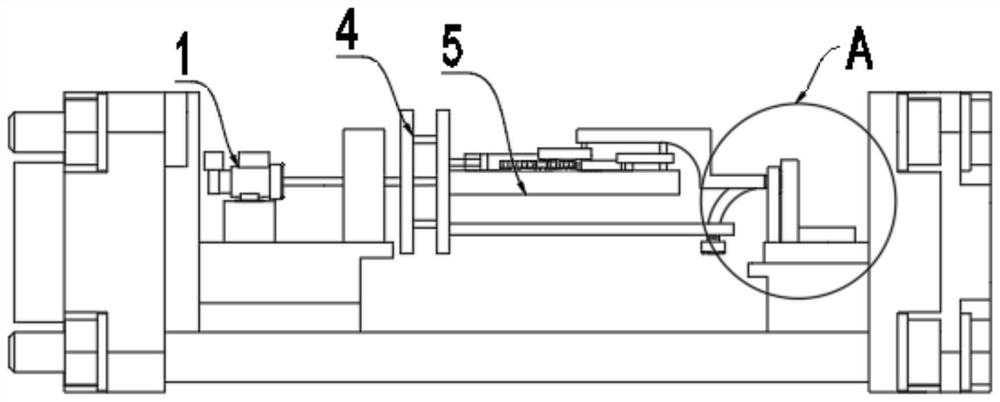

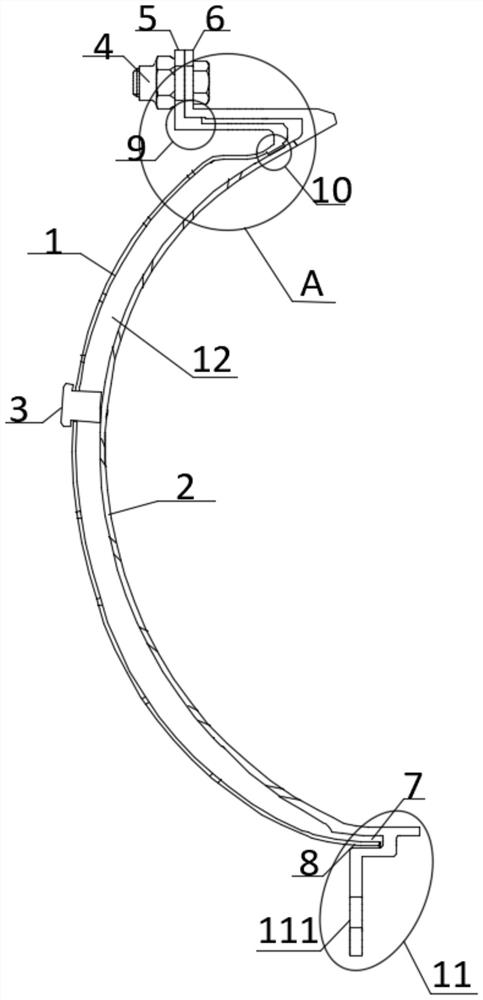

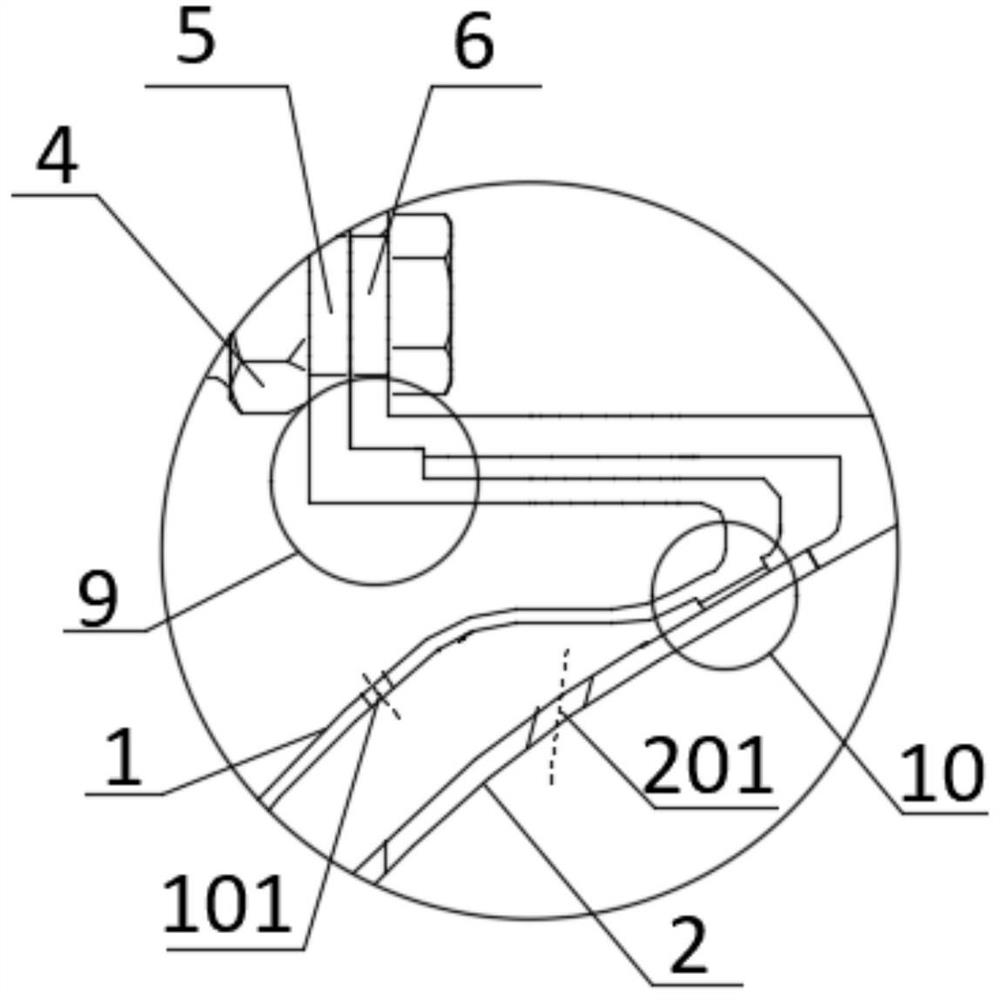

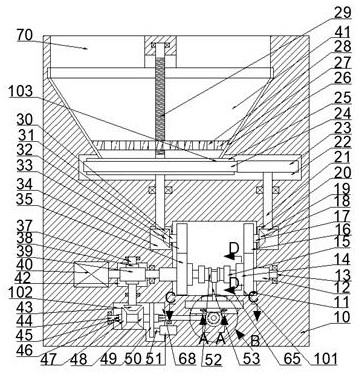

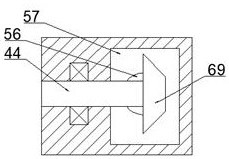

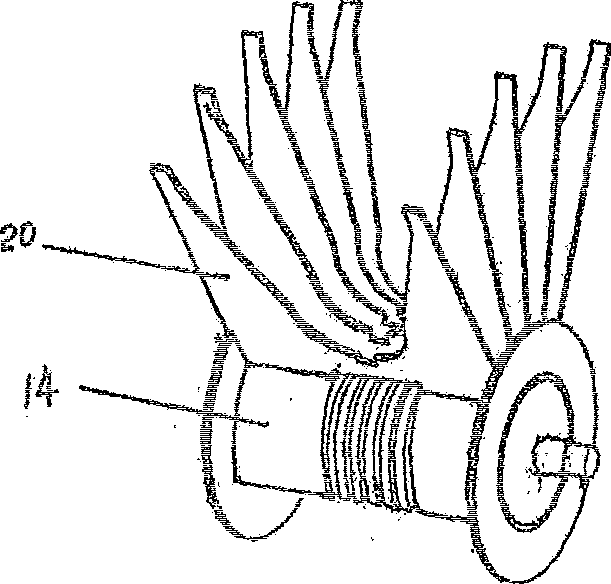

Equipment for automatically welding longitudinal concave seam of large elbow

InactiveCN101045273AImprove welding qualityPrevent fallingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPower unit

An automatic welder for the longitudinal concave seam of a great elbow is composed of a power unit, a great elbow locating unit with several fastening plats fixed on smooth plate and having centering function, a welding head locating unit with synchronizing mechanism and supporting frame, and a brake unit.

Owner:李文秀

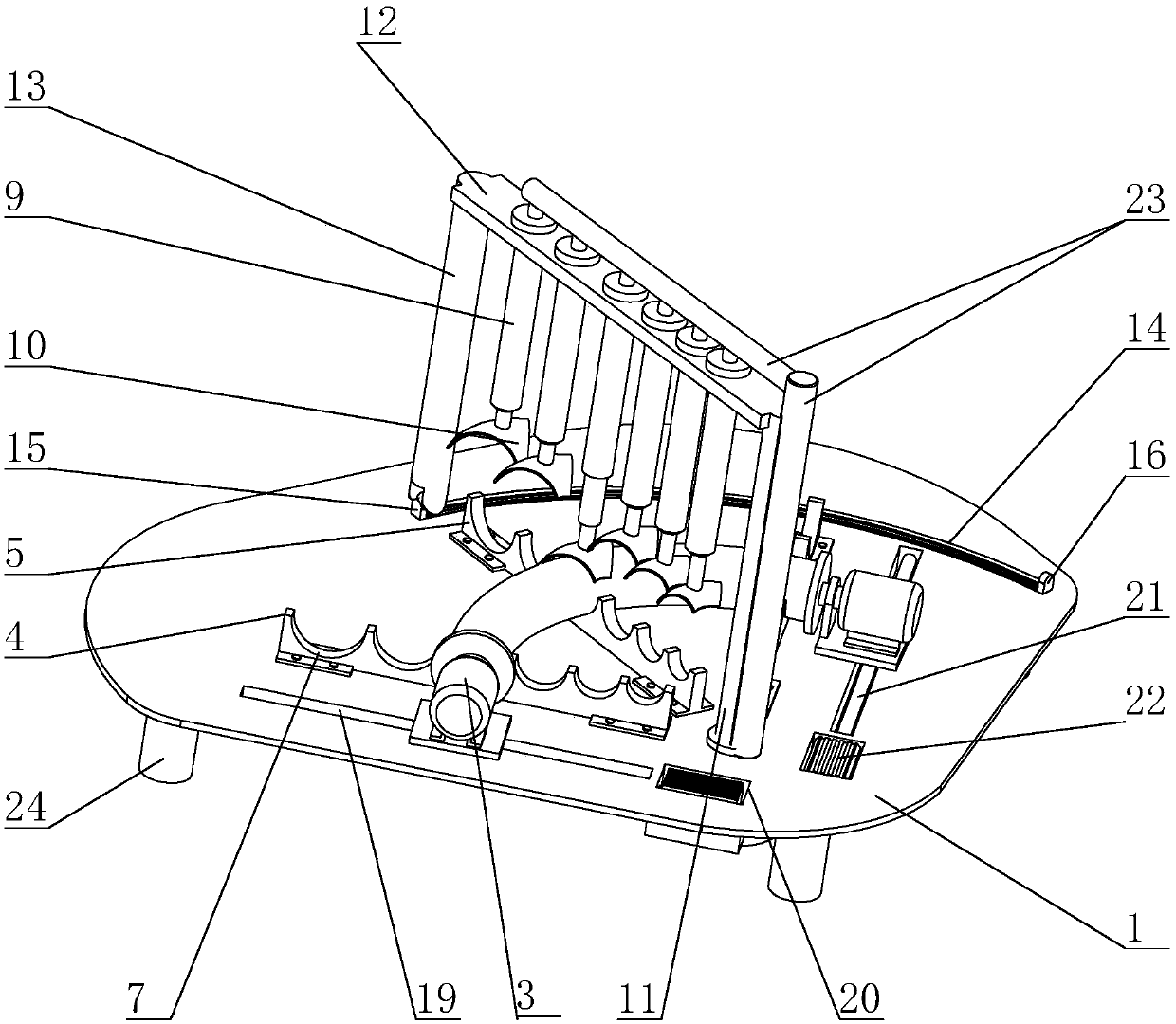

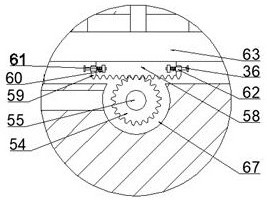

Equipment for automatically welding longitudinal arched seam of large elbow

InactiveCN101045274APrecise positioningImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPower unit

An automatic welder for the longitudinal arch seam of a great elbow is composed of a power unit, a great elbow locating unit with several fastening plats fixed on drum and having centering function, a welding head locating unit with special supporting frame, and a brake unit.

Owner:李文秀

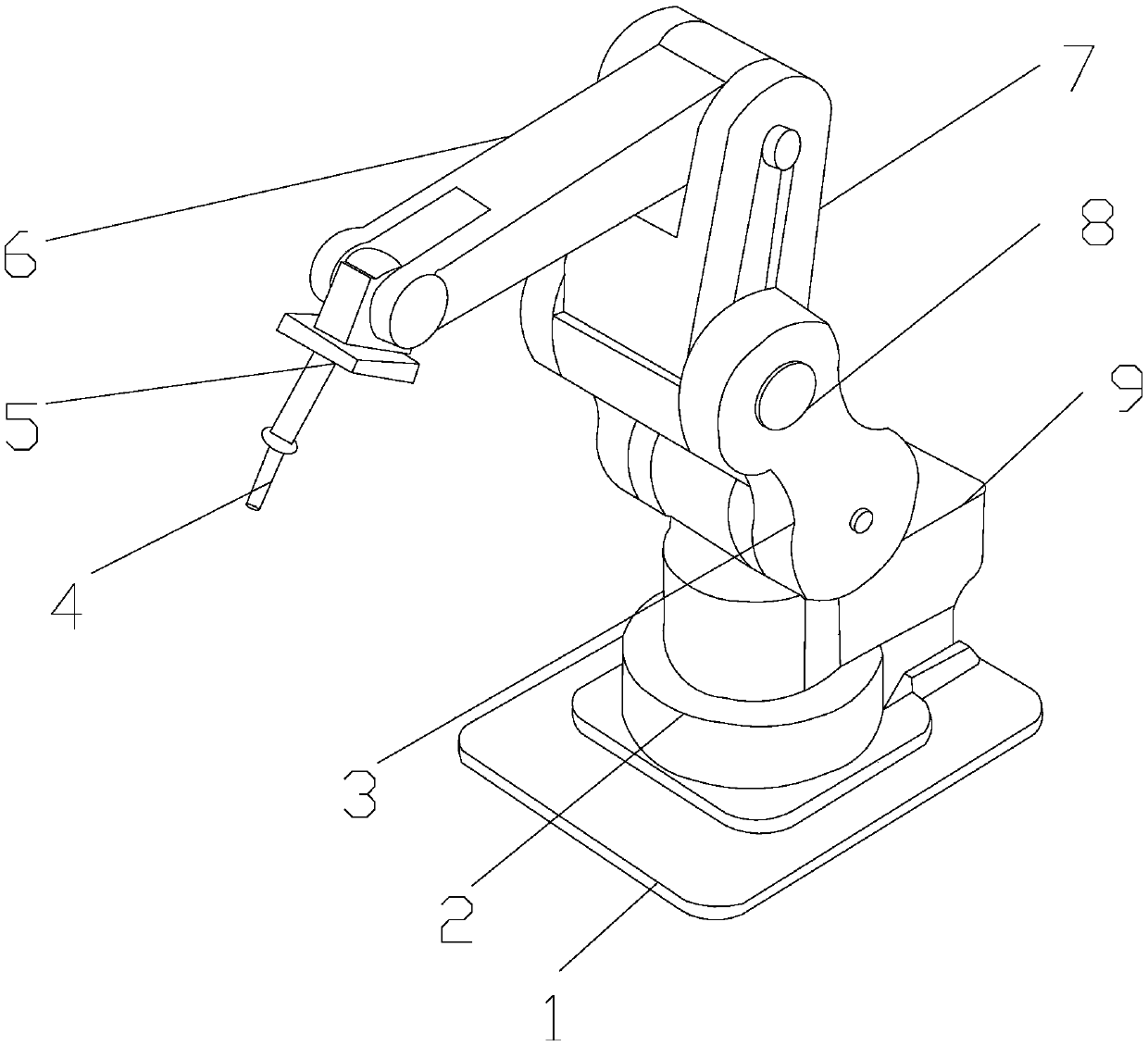

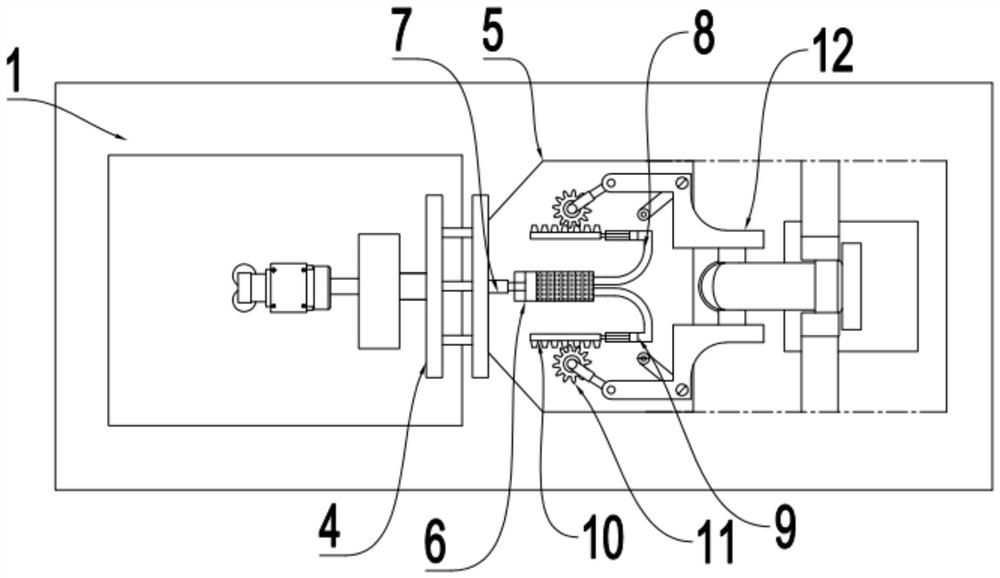

Robot for automobile part welding

InactiveCN107671466AFlexible movementHigh speedProgramme-controlled manipulatorJointsRobotic armGear wheel

The invention discloses a robot for welding auto parts. The structure includes a chassis, a base, a large arm, a welding torch, a connection fixing plate, a small arm, a forearm, an elbow joint, and a junction box. The upper end of the chassis is attached to the lower end of the base. , the upper end of the upper arm is provided with an elbow joint, and the welding torch is installed on the lower end of the connecting and fixing plate. The present invention connects the upper arm to the forearm through the elbow joint, and the staff connects the forearm, the forearm, and the upper arm to make the robot move mechanically in all directions. The elbow joint is embedded and connected in the connecting ring. When the welding robot moves, it drives the sliding gear to rotate. The sliding wheel in the sliding gear will rotate at a high speed so that the robot can move flexibly and the conveyor belt roll, so that the robot can speed up when welding. When personnel use the welding robot to work, the friction during the mechanical movement of the robot can be reduced by rotating the sliding wheel, so that the mechanical arm can move quickly and flexibly, and the work efficiency can be improved.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

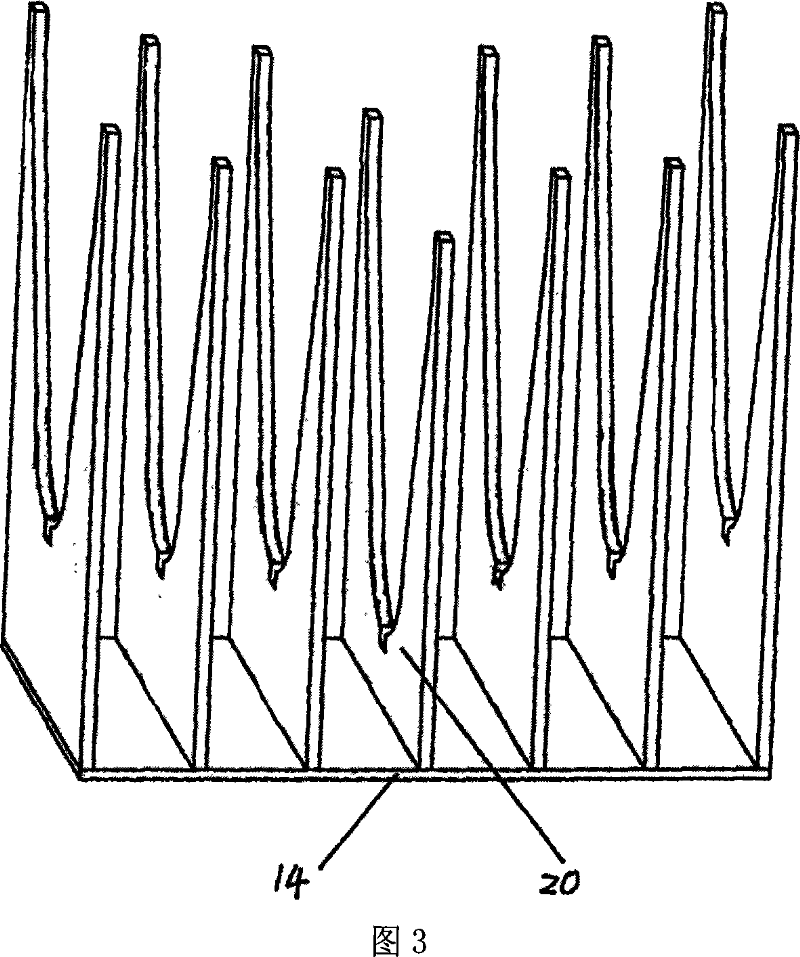

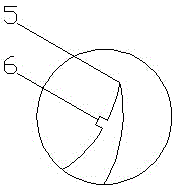

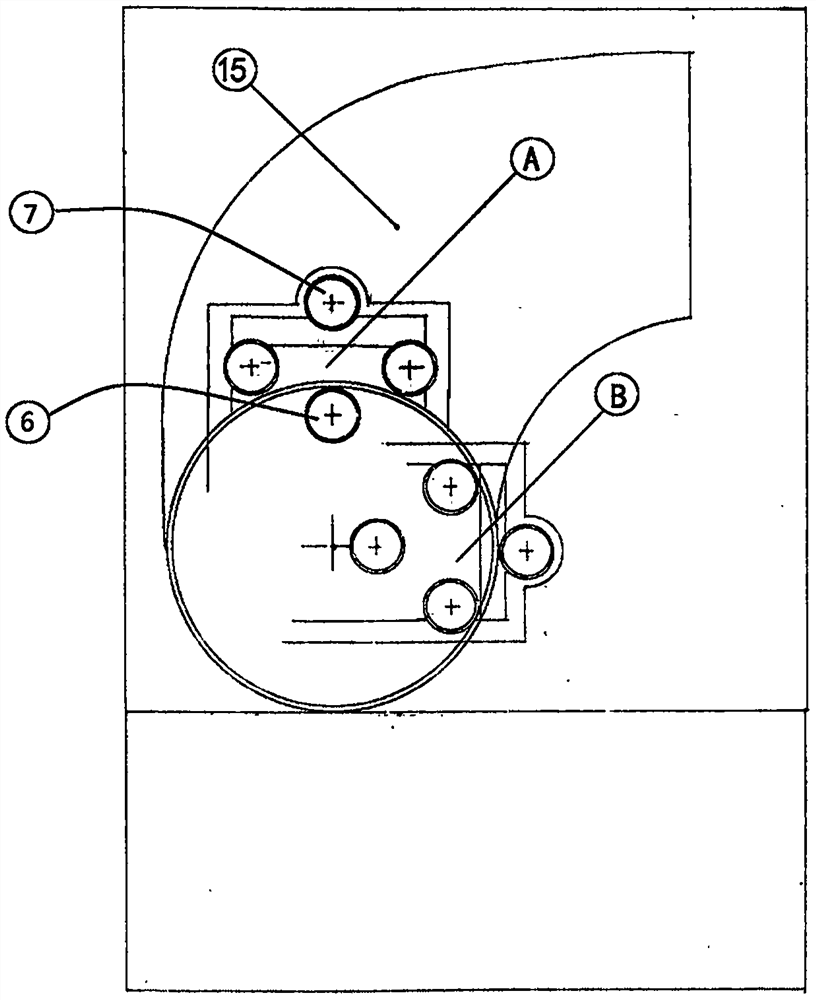

Orientation clamping board of the automatic welding equipment with a big elbow

InactiveCN101041217ASimple structureReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentSheet steel

The invention relates to a location clipboard of automatic welding machine for large elbow, comprising bottom part, left wing and right wing. The whole is in V-shape and the left wing is symmetric to the right wing. Circles set by any symmetric points on inner sides of two wings are coincidence with the cross section of large elbow which is set at two points. It comprises small arc, tangential plane of two circles, big arc and retaining part. There is a concave groove at the lower of small arc. The machining method is that the clapboard is produced by adopting marking and cutting method on steel plate; the clipboard is fixed on the automatic welding machine for large elbow according to certain way to form the clipboard location device. The clipboard produced by the method has performances of automatic centering and automatic aligning welding line and makes arch-shape welding line of workpeice is changed into ring automatic welding line. It solves difficult location problem in automatic welding for large elbow. The method provides a simple and easy production method for producing clipboards. The produced clipboard is provided with simple structure and low producing cost.

Owner:李文秀

Elbow pipe double-end welding groove machining tool

InactiveCN109623042AEasy to placeReduce occupancyPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses an elbow pipe double-end welding groove machining tool and mainly relates to the field of mechanical manufacturing. The elbow pipe double-end welding groove machining tool comprises a workbench, three elbow pipe supports, a pressing device and a beveling machine. The three elbow pipe supports are arranged on the workbench. Each elbow pipe support is provided with a plurality of cambered surface seat openings. The pressing device comprises a portal frame capable of being rotated to open and close, hydraulic cylinders and cambered pressing plates. A fixed rotary column isrotatably connected to the workbench. The hydraulic cylinders are arranged on a cross beam. The beveling machine is arranged on the outer side of the left port support and the outer side of the rightport support. Moreover, the beveling machine is matched with the end faces of the two sides of an elbow pipe when conducting beveling. The elbow pipe double-end welding groove machining tool has thebeneficial effects that the machining tool can be suitable for double-end groove machining of a large elbow pipe of a hoisting upper part of a gantry crane and can conduct machining on double-end grooves of various types of elbow pipe workpieces in one working position, and the occupied workshop area of the working position is greatly reduced.

Owner:泰安隆泰金属制品有限公司

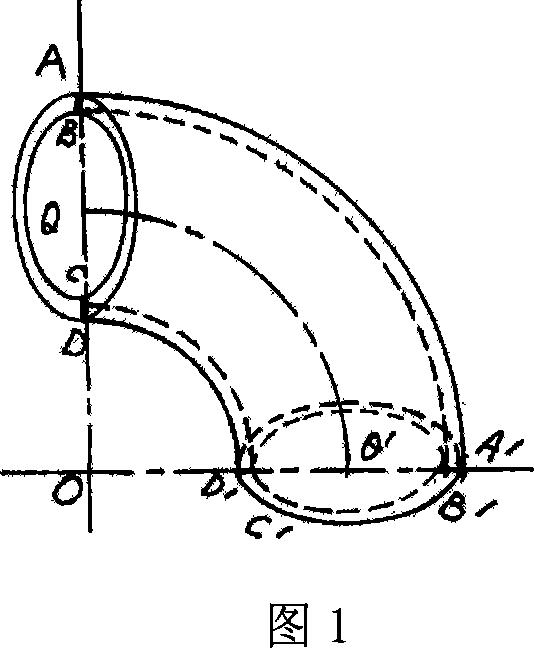

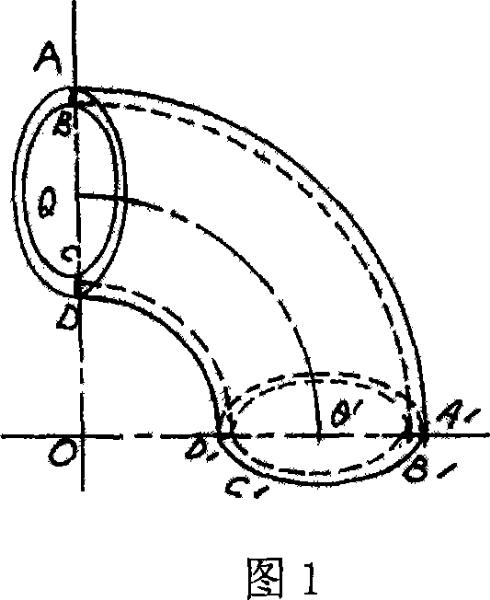

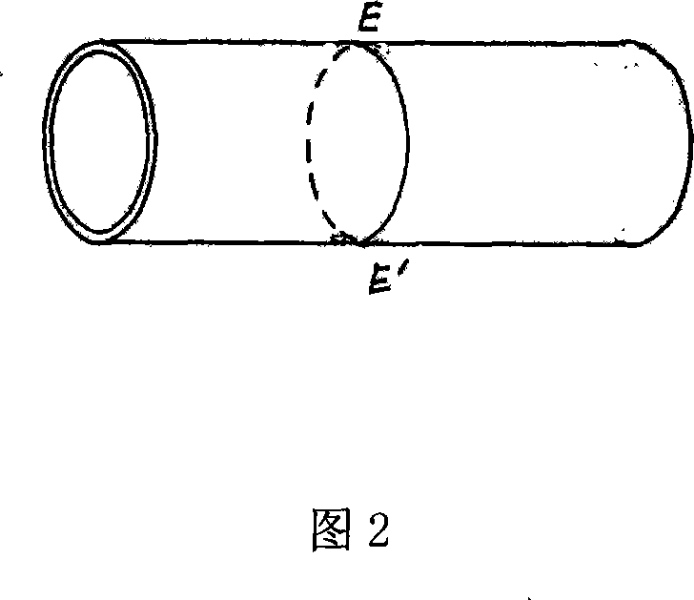

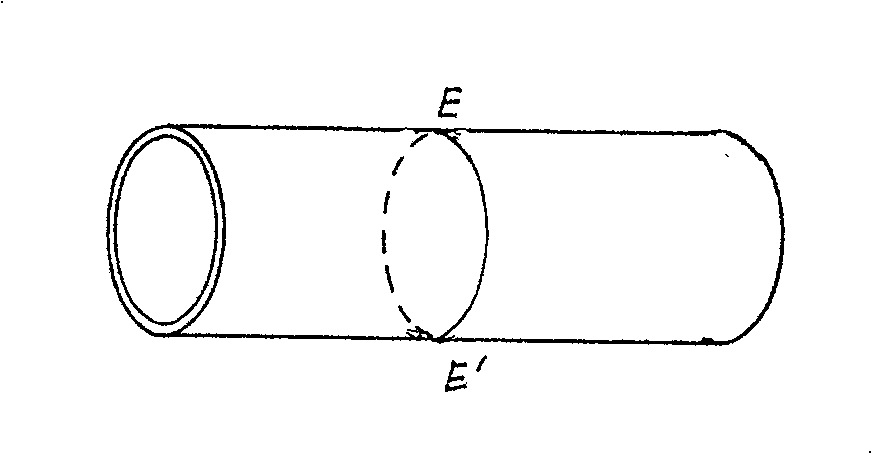

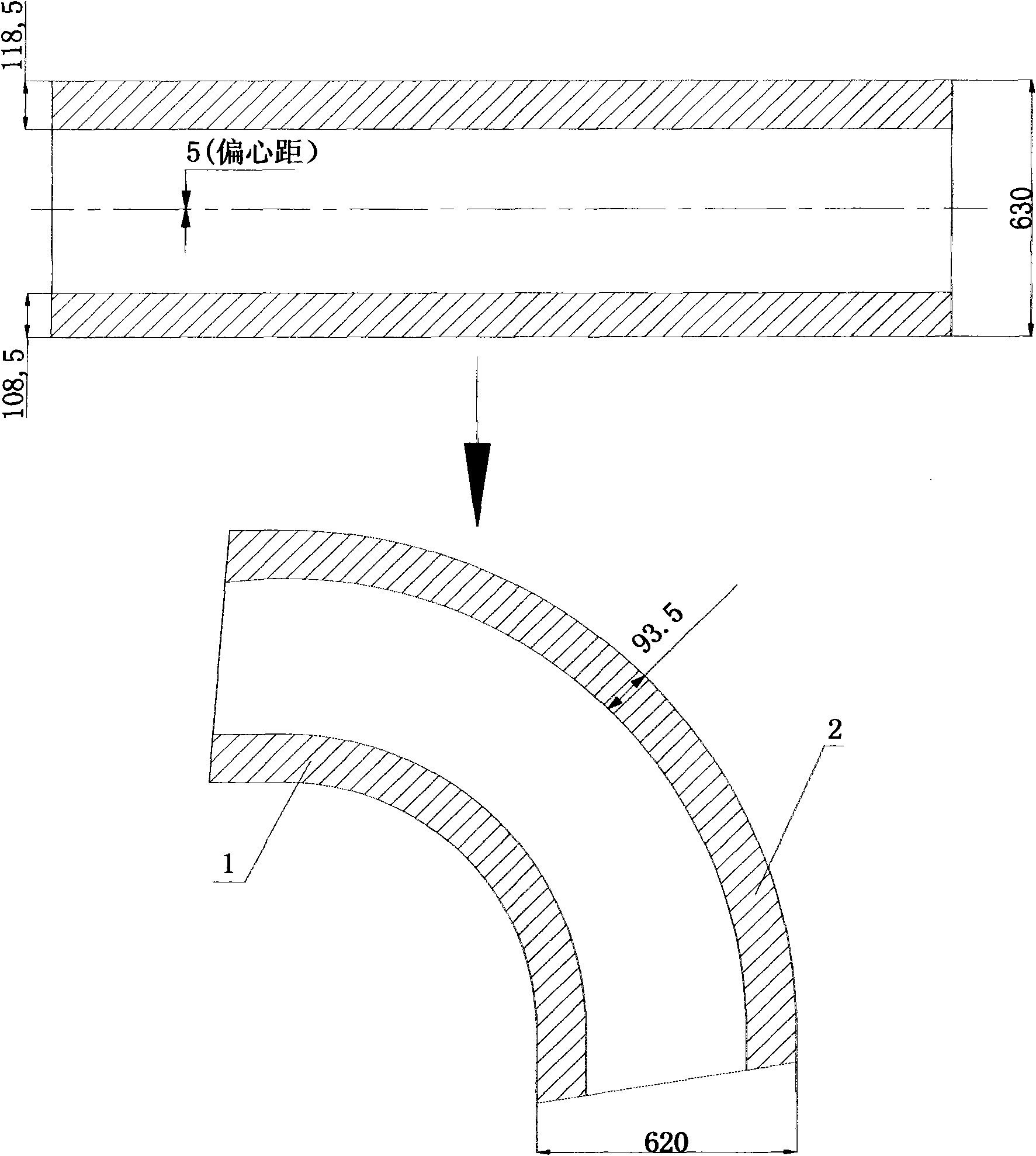

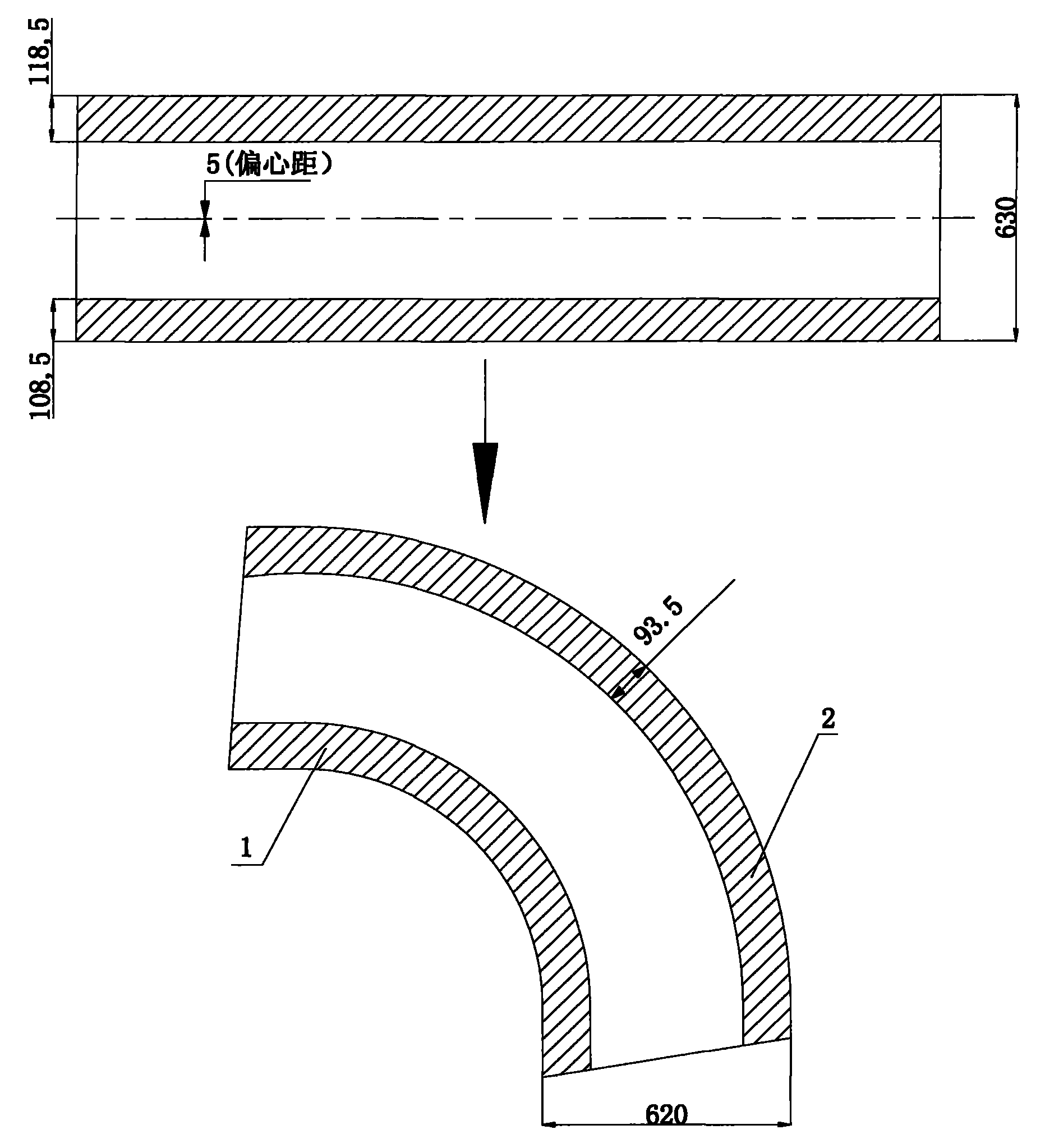

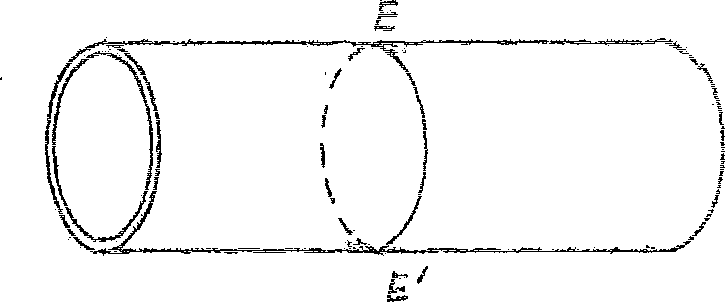

Preparation technology of forging elbow

ActiveCN101603614AUniform wall thicknessSimple processEngine componentsRigid pipesHeat treatedMaterials science

The invention relates to the elbow preparation technical field, in particular to a preparation technology of forging elbow. The technology is characterized in that: (1) forging a pipe, namely a forging rod is fixed and forged into a forging pipe, and the eccentricity of the forging pipe is 4-6% of the wall thickness of a finished elbow; (2) bending, namely half-round thin pipe wall of the forging pipe formed by eccentricity is made into the inner ring of an elbow while the half-round thick pipe wall is made into the outer ring of the elbow after the forging pipe is subject to heat treatment, thus the forging pipe is bent into the elbow. Compared with the prior art, the invention has simple technology, large elbow can be bent by adopting the technology, and the wall thickness of the inner ring and the out ring of the elbow can be ensured to be relatively uniform.

Owner:SHANGHAI CHANGQIANG POWER

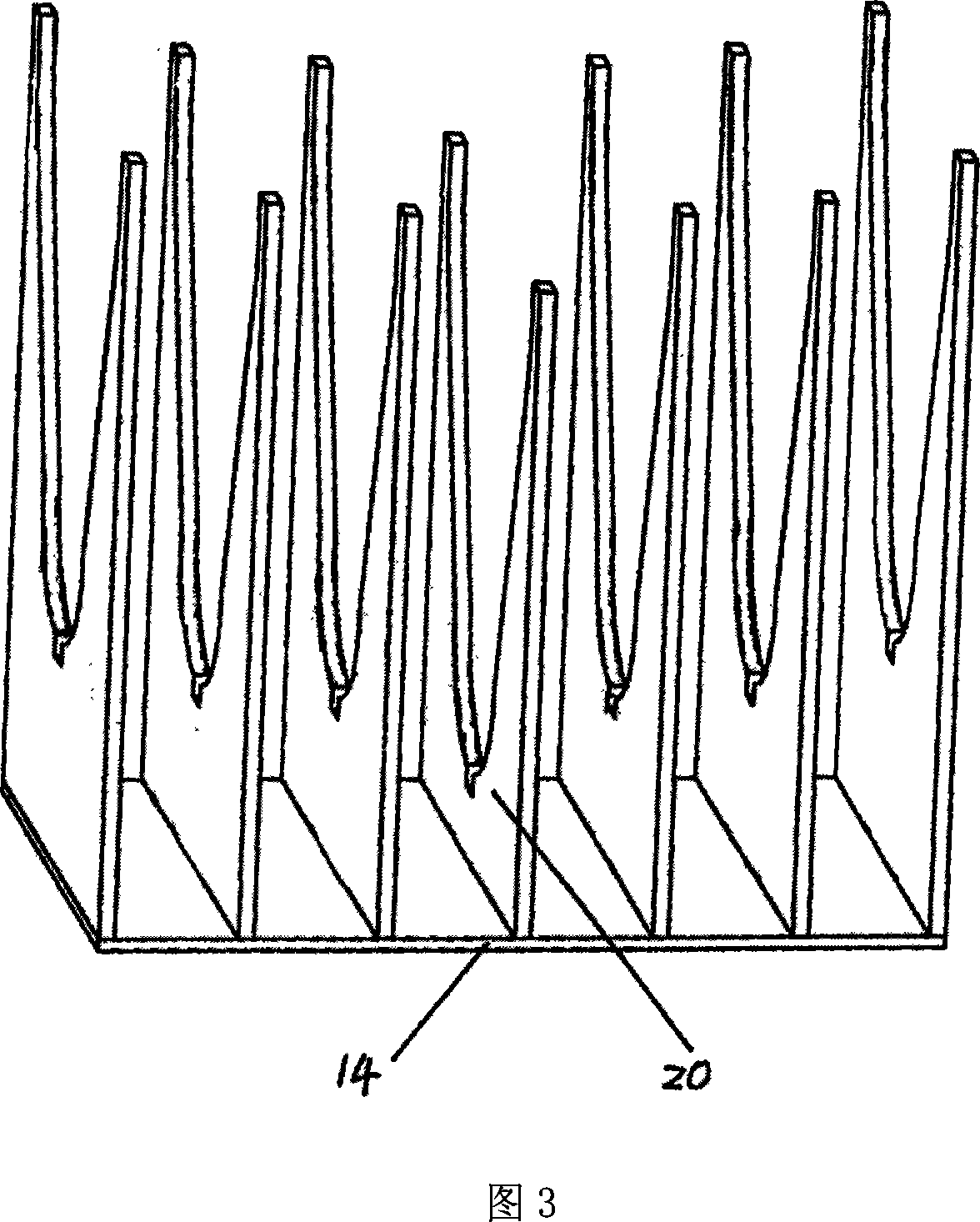

Heat dissipation device automatic elbow installation device

InactiveCN103894821AReduce labor costsSimple structureAssembly machinesProduction lineManufacturing technology

The invention relates to the technical field of heat dissipation device manufacturing, in particular to a heat dissipation device automatic elbow installation device. The heat dissipation device automatic elbow installation device comprises an oil pump, a support, a production line conveyor belt, a first feed box and a second feed box, wherein the first feed box and the second feed box are connected with the support in a sliding mode through slide rails and connected with the oil pump through reversing valves. Guide openings are formed in the bottom of the first feed box and the bottom of the second feed box respectively, and are right opposite to the conveyor belt below the support. An oil cylinder used for supporting a heat dissipation device is arranged below the conveyor belt, and connected with the oil pump. Large elbows and small elbows are installed through the heat dissipation device automatic elbow installation device instead of manual operation, the labor cost is greatly reduced for an enterprise, and work efficiency is greatly improved.

Owner:TIANJIN LONGTAI HEATING & COOLING EQUIP MFG

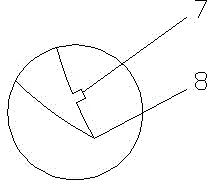

Orientation device with a big elbow and the processing method of the clamping board

InactiveCN101041218ASimple structureReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

The invention relates to a location device for large elbow and the processing method for the clipboard. The location device comprises bottom plate and several clipboards. Clipboards are fixed with the bottom plate. The clipboard comprises bottom part, left wing and right wing. The whole is in V-shape and the left wing is symmetric to the right wing. Circles set by any symmetric points on inner sides of two wings are coincidence with the cross section of large elbow which is set at two points. The machining method is that the clapboard is produced by adopting marking and cutting method on steel plate. The clipboard produced by the method has performances of automatic centering and automatic aligning welding line and makes the motion track of concave welding line of workpeice is changed into circle track. It solves difficult location problem in automatic welding for large elbow. The method provides a simple and easy production method for producing clipboards of location device for large elbow. The produced clipboard is provided with simple structure and low producing cost.

Owner:李文秀

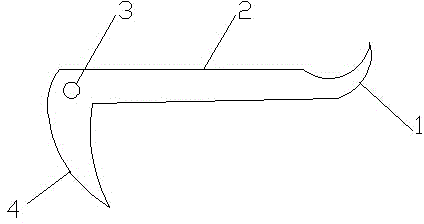

U-shaped pin pull-out device

InactiveCN105773514AImprove lifting abilityAvoid bruisesMetal-working hand toolsSheet steelEngineering

Disclosed is a U-shaped pin pull-out device. The U-shaped pin pull-out device comprises a strip-shaped steel plate. A small elbow which is upwards bent is arranged at one end of the strip-shaped steel plate, and is mainly used for pulling small U-shaped pins out. A large elbow which is downwards bent is arranged at the other end of the strip-shaped steel plate. A protrusion is arranged on the portion, close to the sharp portion, of the left side of the small elbow, and a protrusion is arranged on the portion, close to the sharp portion, of the right side of the large elbow. The steel plate is a stainless steel plate. Due to the facts that existing methods that U-shaped pins are pried by a screwdriver, a vice is matched with the screwdriver to pull the U-shaped pins out, and the U-shaped pins are knocked by a hammer can be changed, and the U-shaped pins can be pulled out by a special tool, the pull-out effect can be effectively improved, and the situation that a worker is bruised or scratched can be avoided.

Owner:朱鹏飞

Orientation device with a big elbow and the processing method of the clamping board

InactiveCN100475428CSimple structureReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld line

The invention relates to a location device for large elbow and the processing method for the clipboard. The location device comprises bottom plate and several clipboards. Clipboards are fixed with the bottom plate. The clipboard comprises bottom part, left wing and right wing. The whole is in V-shape and the left wing is symmetric to the right wing. Circles set by any symmetric points on inner sides of two wings are coincidence with the cross section of large elbow which is set at two points. The machining method is that the clapboard is produced by adopting marking and cutting method on steel plate. The clipboard produced by the method has performances of automatic centering and automatic aligning welding line and makes the motion track of concave welding line of workpeice is changed into circle track. It solves difficult location problem in automatic welding for large elbow. The method provides a simple and easy production method for producing clipboards of location device for large elbow. The produced clipboard is provided with simple structure and low producing cost.

Owner:李文秀

Orientation clamping plate of the automatic welding equipment with a big elbow

InactiveCN100457378CSimple structureReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentSheet steel

The invention relates to a location clipboard of automatic welding machine for large elbow, comprising bottom part, left wing and right wing. The whole is in V-shape and the left wing is symmetric to the right wing. Circles set by any symmetric points on inner sides of two wings are coincidence with the cross section of large elbow which is set at two points. It comprises small arc, tangential plane of two circles, big arc and retaining part. There is a concave groove at the lower of small arc. The machining method is that the clapboard is produced by adopting marking and cutting method on steel plate; the clipboard is fixed on the automatic welding machine for large elbow according to certain way to form the clipboard location device. The clipboard produced by the method has performances of automatic centering and automatic aligning welding line and makes arch-shape welding line of workpeice is changed into ring automatic welding line. It solves difficult location problem in automatic welding for large elbow. The method provides a simple and easy production method for producing clipboards. The produced clipboard is provided with simple structure and low producing cost.

Owner:李文秀

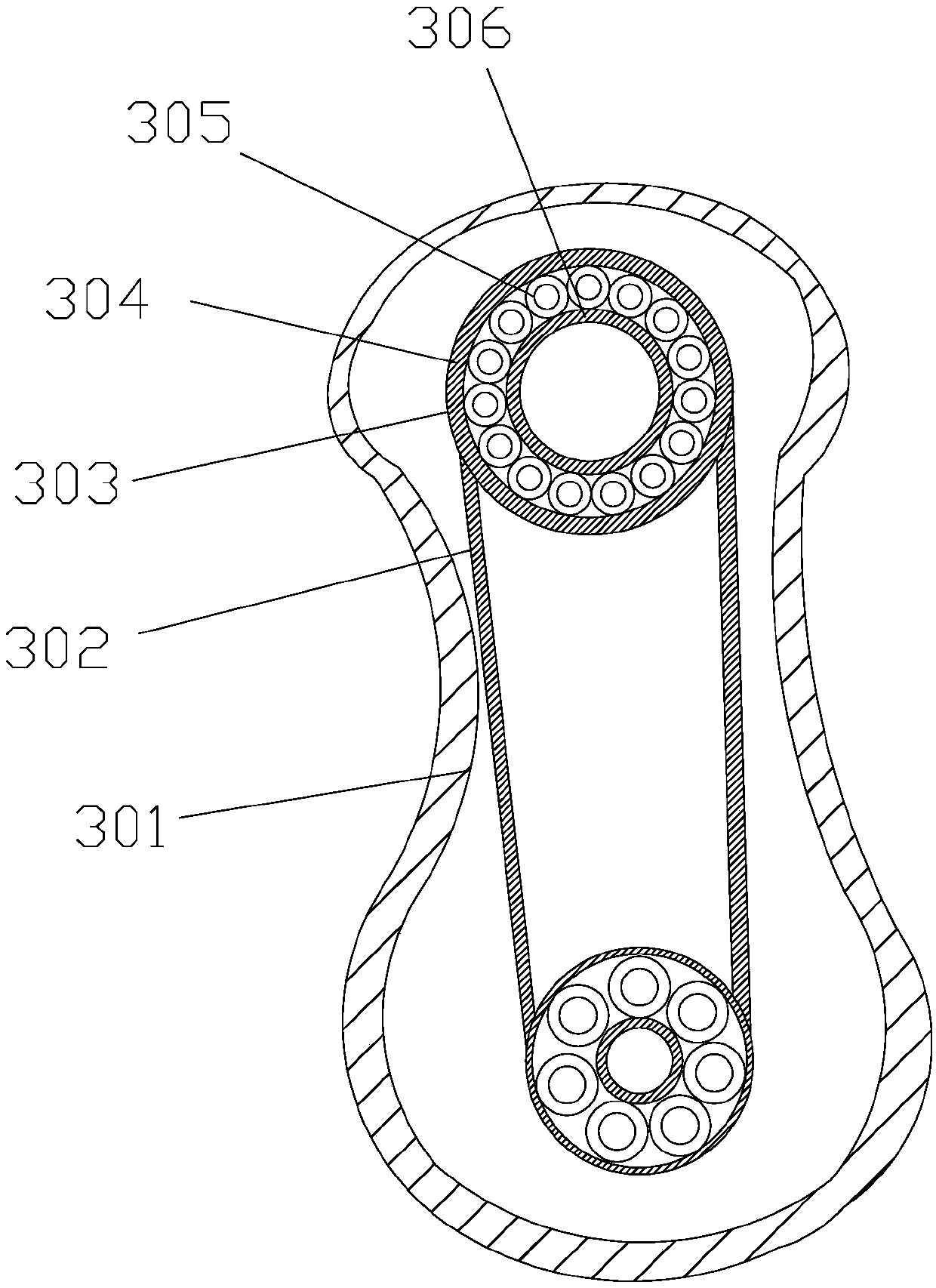

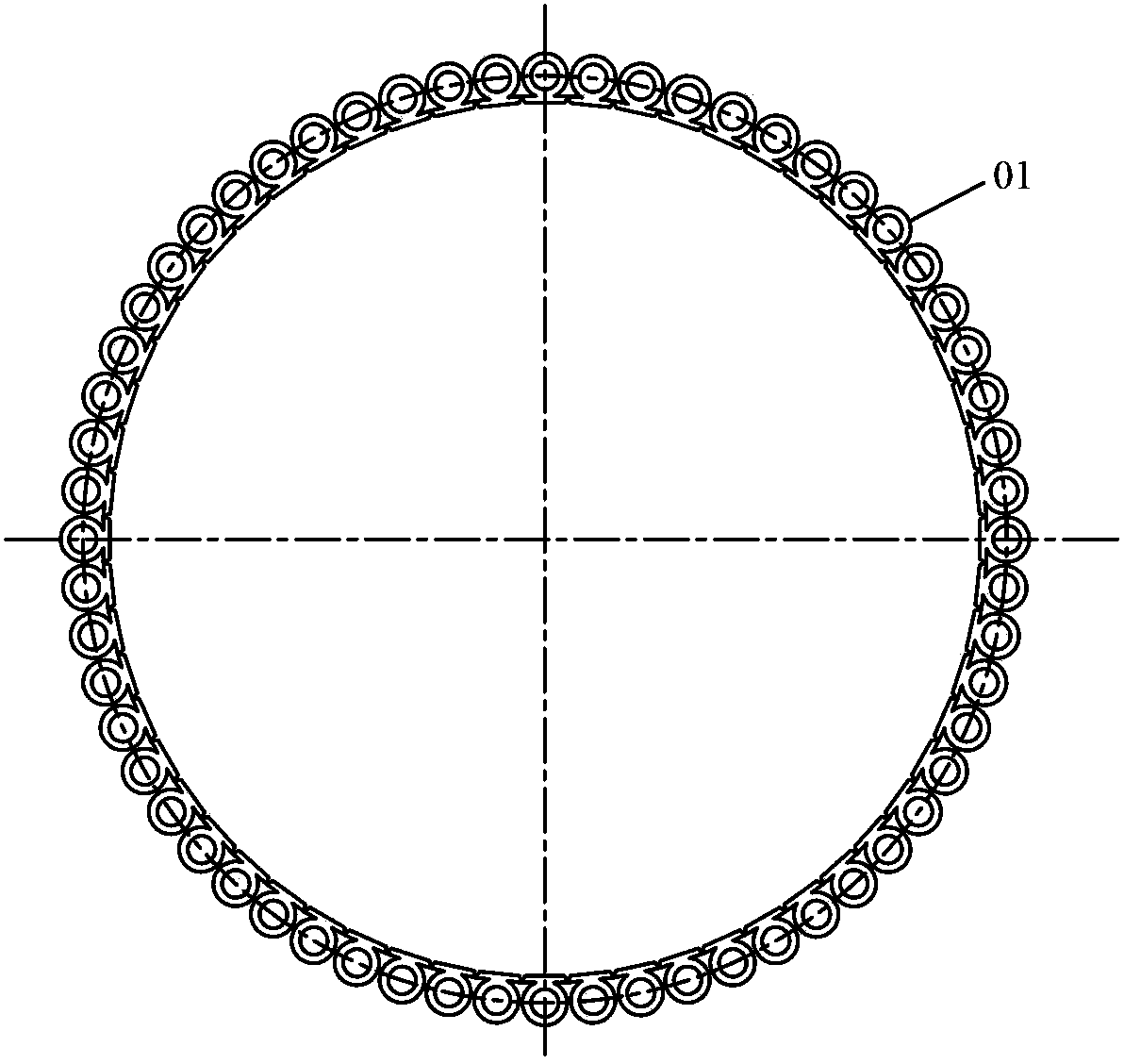

Device for correcting ovality of port of large elbow pipe fitting

The invention relates to a device for correcting the ovality of a port of a large elbow pipe fitting. The device comprises an ovality correcting body used for installing an ovality correcting part andis characterized in that a driving wheel and a driven wheel are arranged on the ovality correcting body, the driving wheel can move left and right relative to the driven wheel, the driving wheel andthe driven wheel can be coordinated with each other to clamp a port of an elbow so as to correct the ovality of the port, and a first driving motor for driving the driving wheel to rotate and a driving wheel translation driving mechanism for driving the driving wheel to move left and right are correspondingly arranged on the ovality correcting body.

Owner:杨喜春

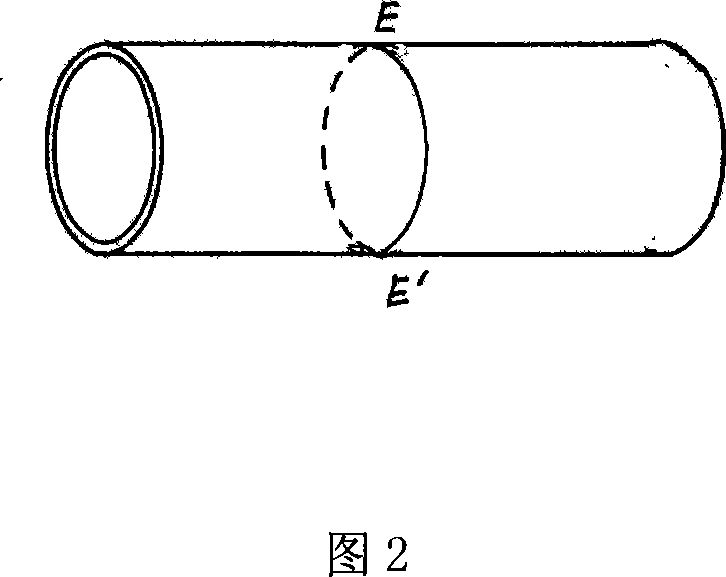

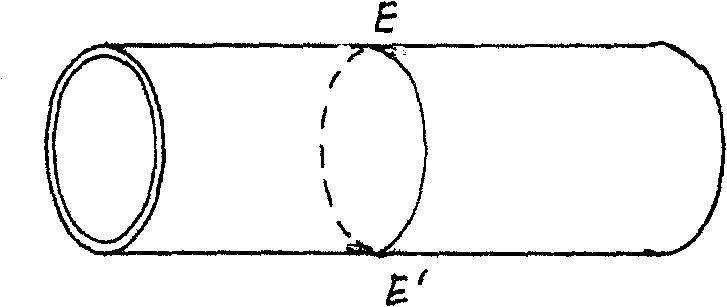

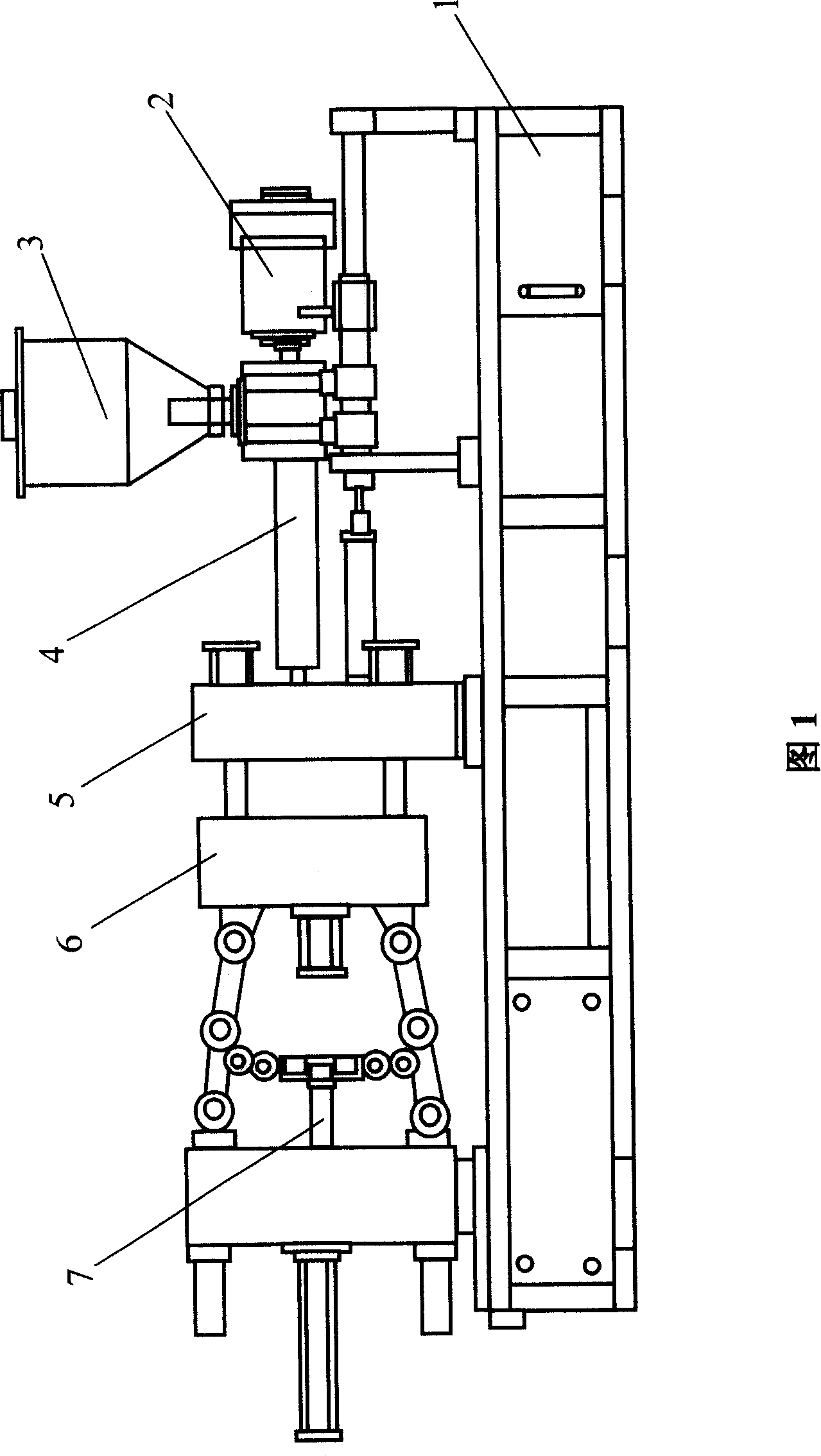

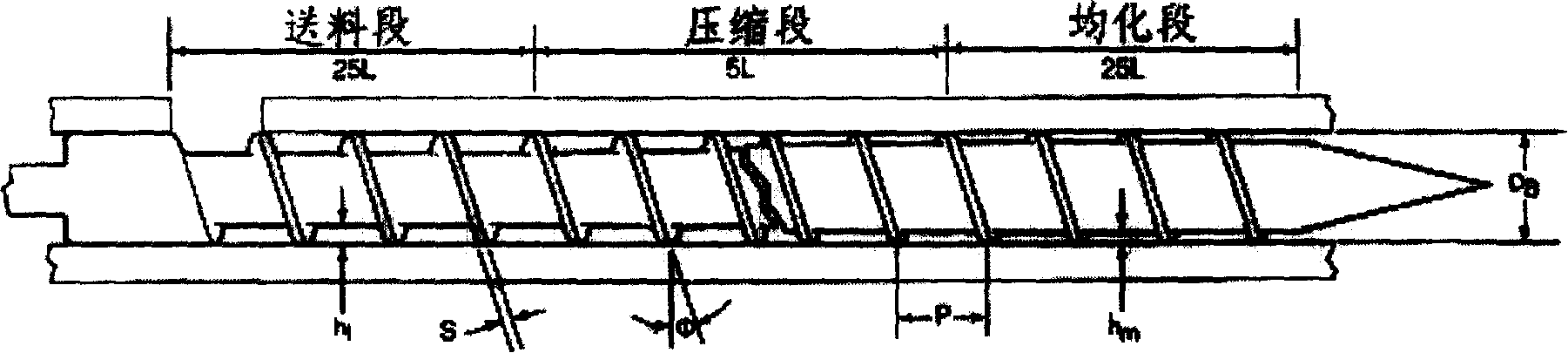

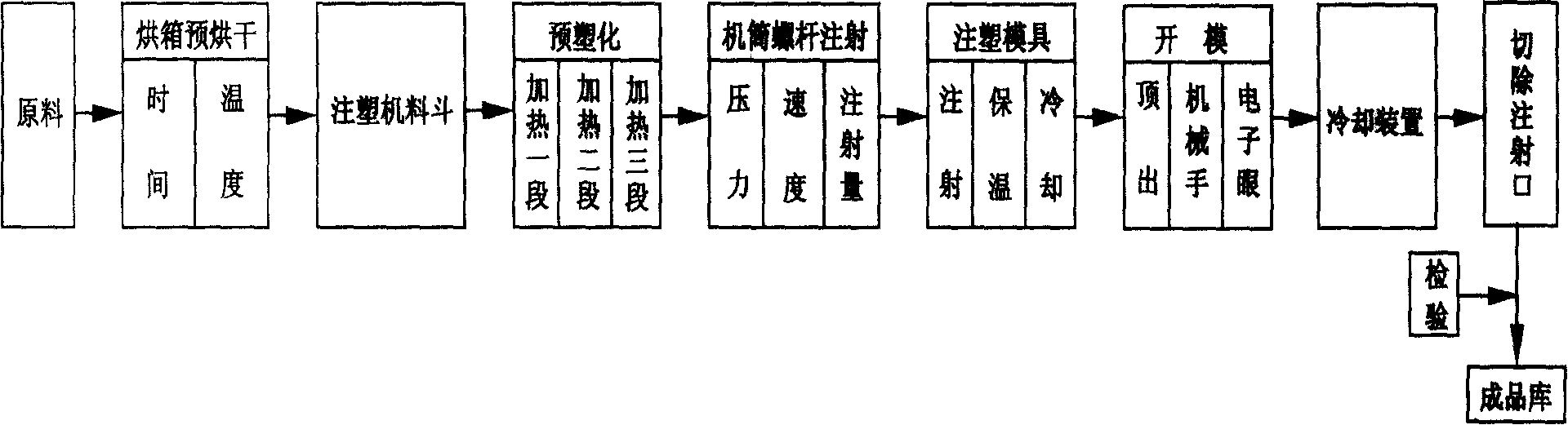

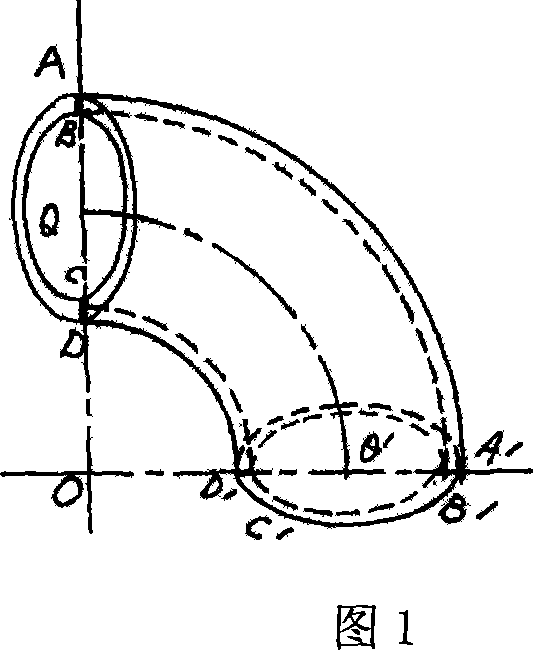

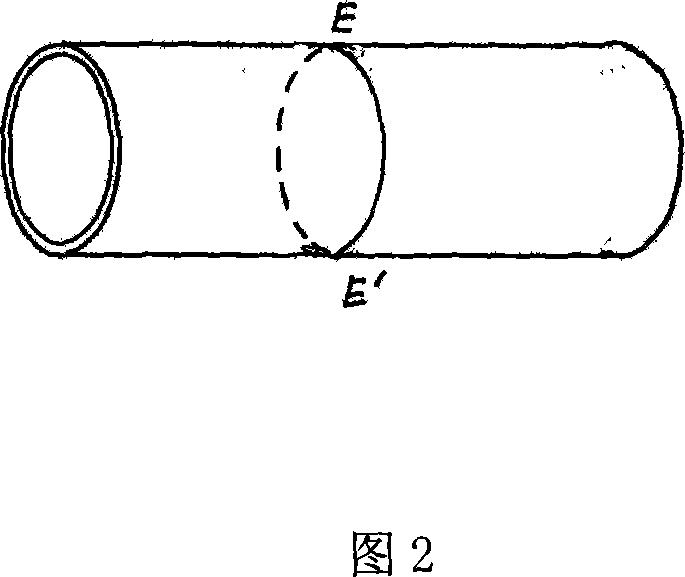

Chlorinated polyvinyl chloride DN400 elbow pipe fitting once injection moulding technique and device thereof

InactiveCN101168286AReduce frictional heatStable speedTubular articlesTemperature controlInjection pressure

The invention relates to a production process of resin pipe fittings, in particular to a one-time injection molding process and equipment for chlorinated polyvinyl chloride elbow pipe fittings. The process includes batching, drying, injection molding, pressure holding, and mold opening process. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the temperature range of each section is 150-155°C and 168-173°C. , 162~167℃, 160~165℃, 155~160℃, 150~155℃, 145~150℃, the mold temperature is controlled between 60~70℃; the injection pressure during injection molding is divided into three sections, respectively 58MPa , 65MPa and 80MPa. The pitch of the injection molding machine screw used in the method is equal to the diameter of the screw, the feeding section accounts for 25% of the total length, the compression section accounts for 50% of the total length, and the homogenization section accounts for 25% of the total length. The invention realizes one-time injection molding of DN400 large elbow pipe fittings through the improvement of process and equipment.

Owner:YOULI HLDG GRP

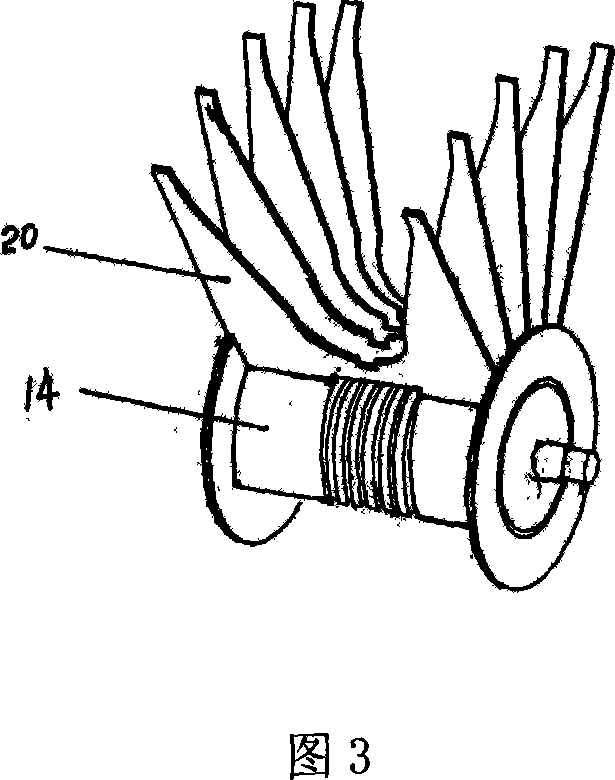

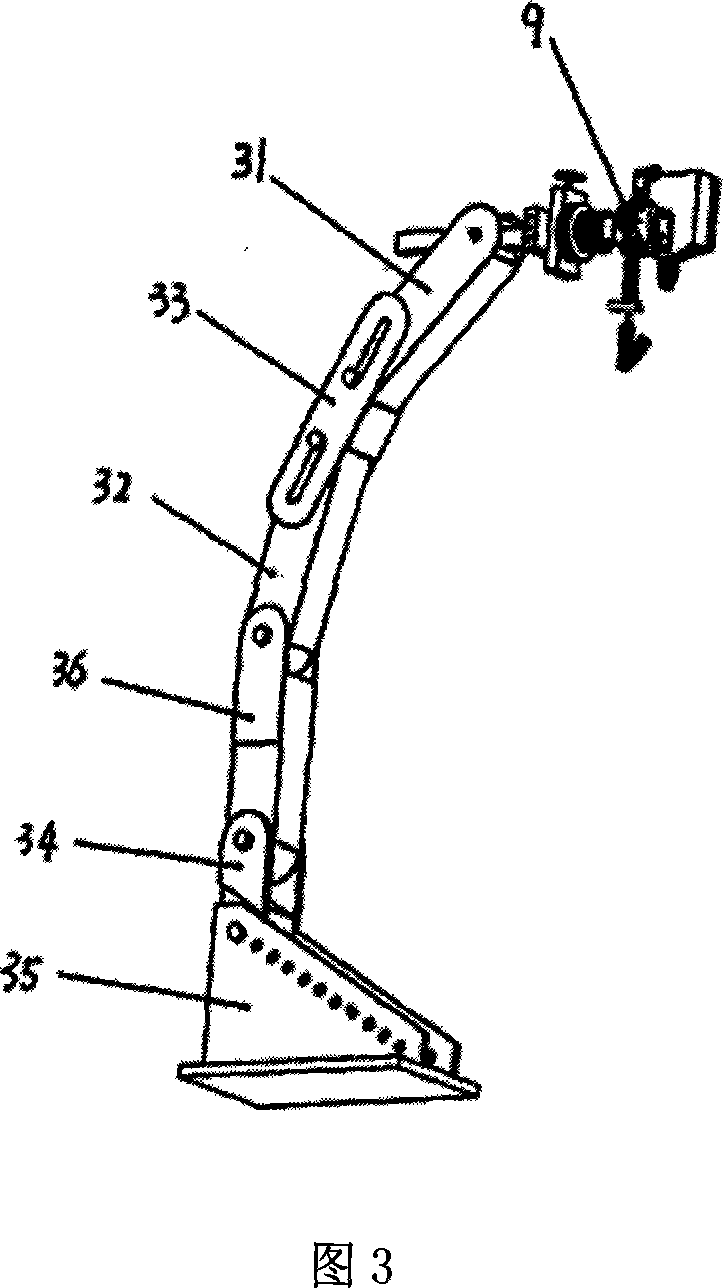

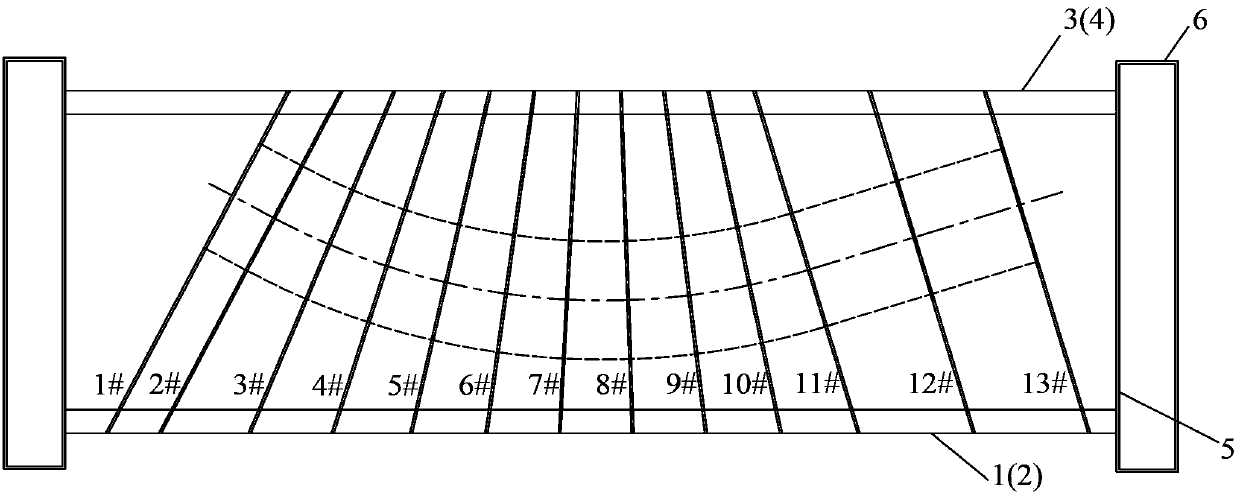

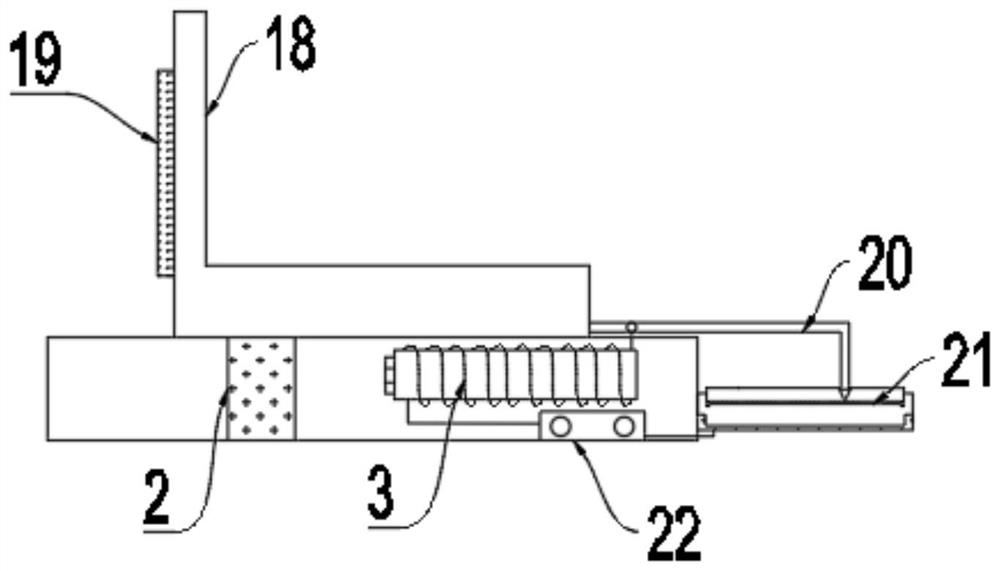

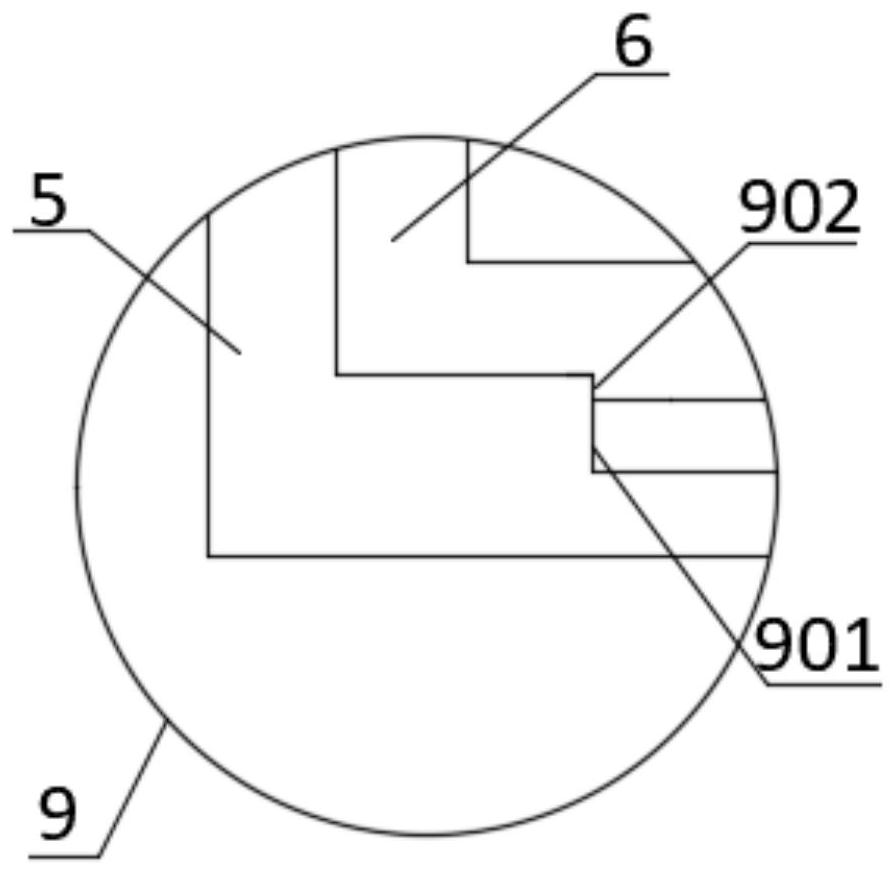

Stand for welding machine head of equipment for automatically welding large elbow

InactiveCN101045275APrecise positioningImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

A weld head supporting frame for the automatic welder of great elbow is composed of a beginning segment, an intermediate segment, a regulating plate, a final segment and a base. It features that said all segments are sequentially linked to become an arc shape whose circular center is coincident with that of great elbow, so ensuring that the welding direction is always perpendicular to welded seam, resulting in high weld quality.

Owner:李文秀

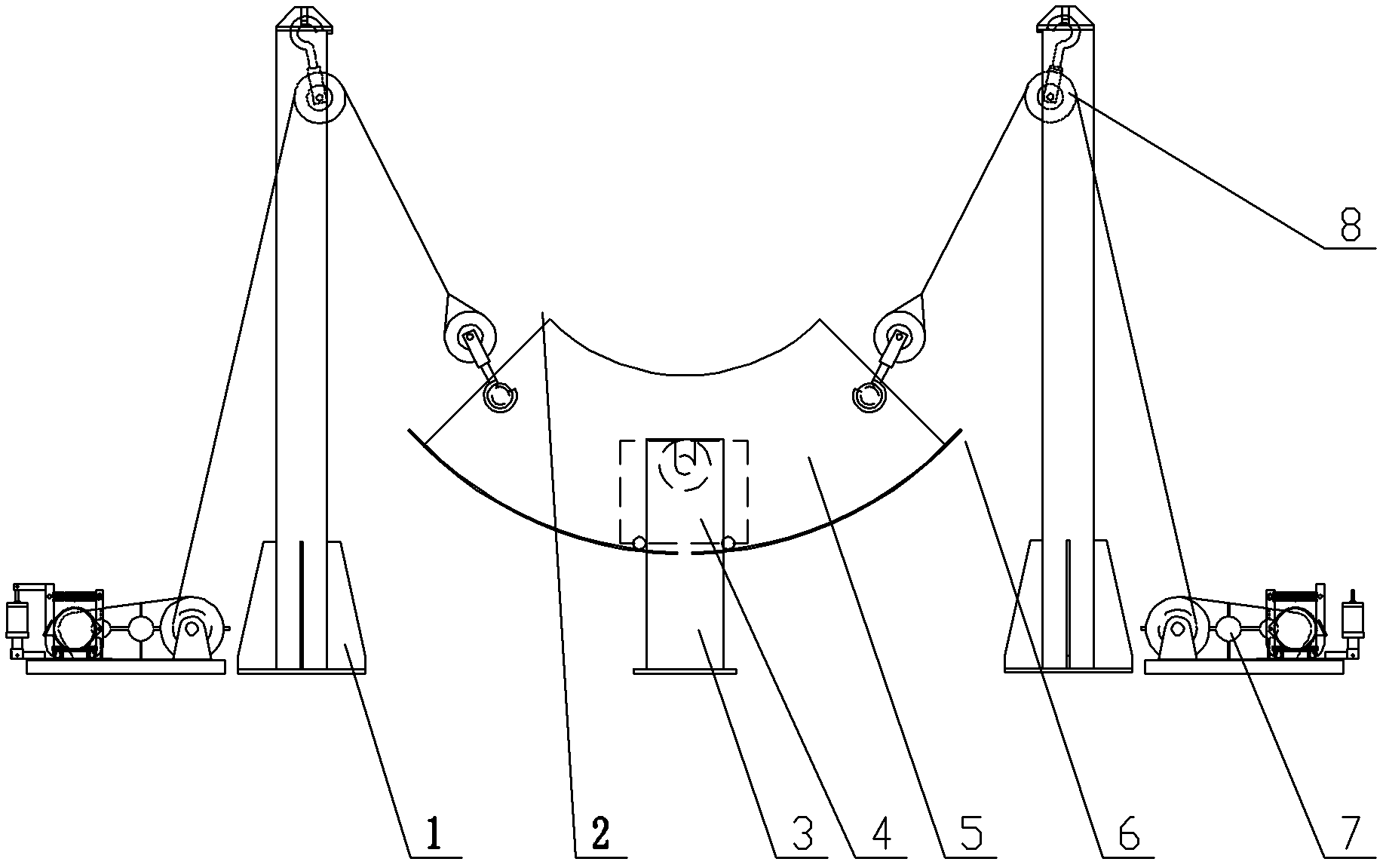

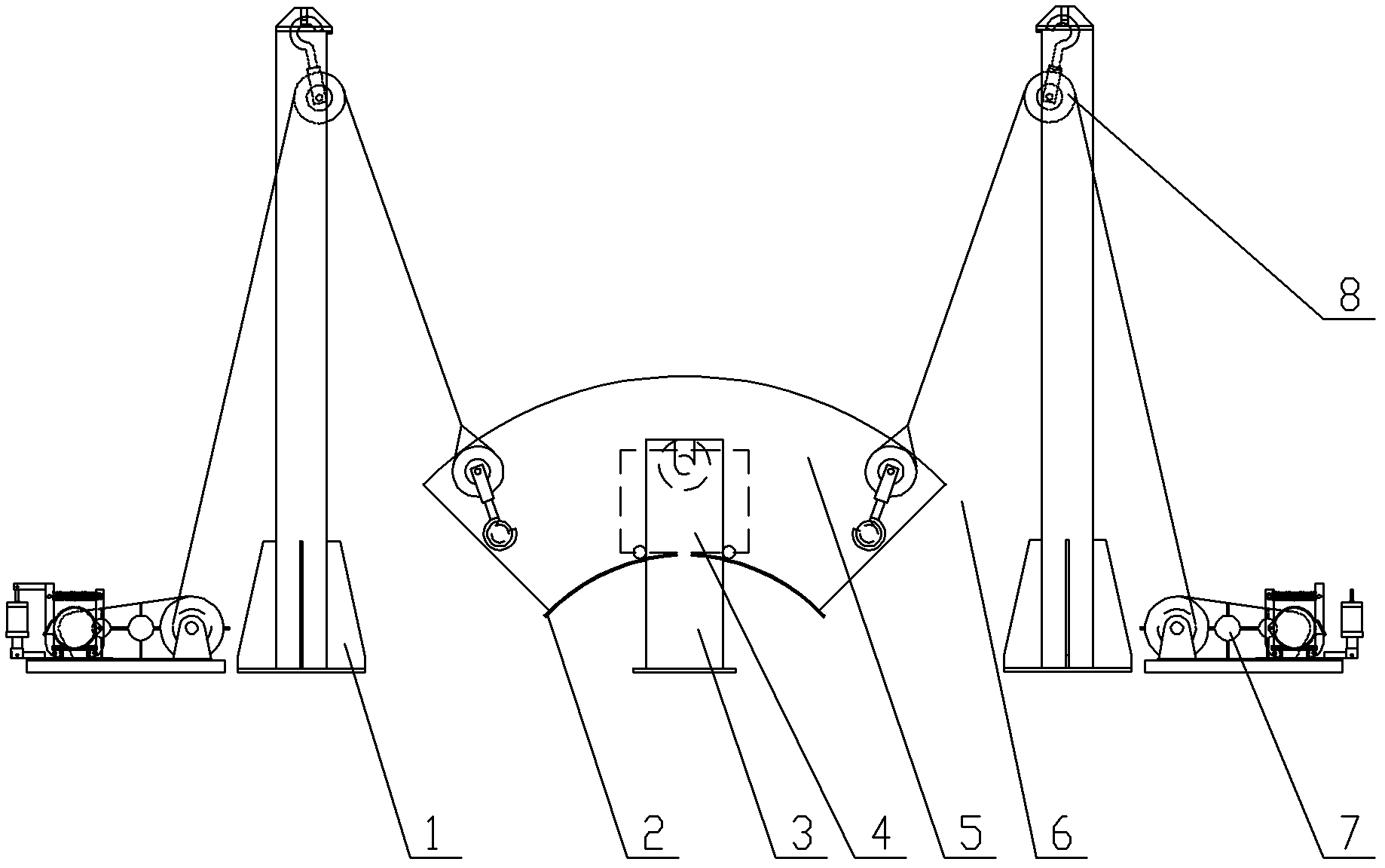

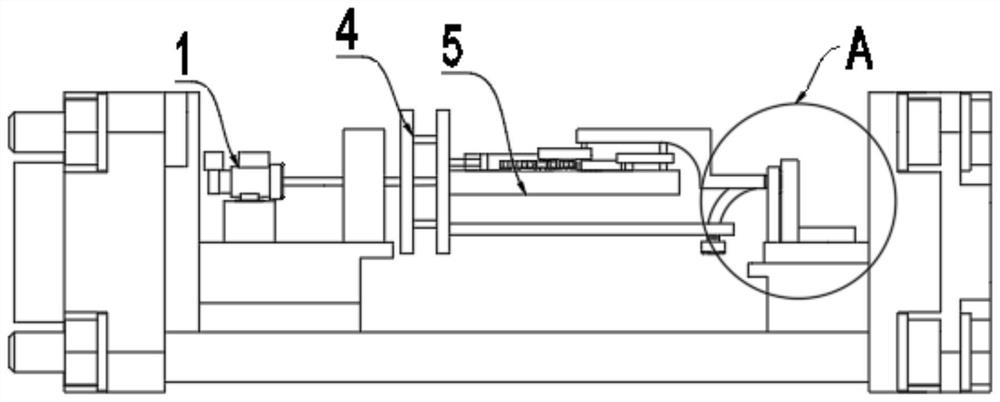

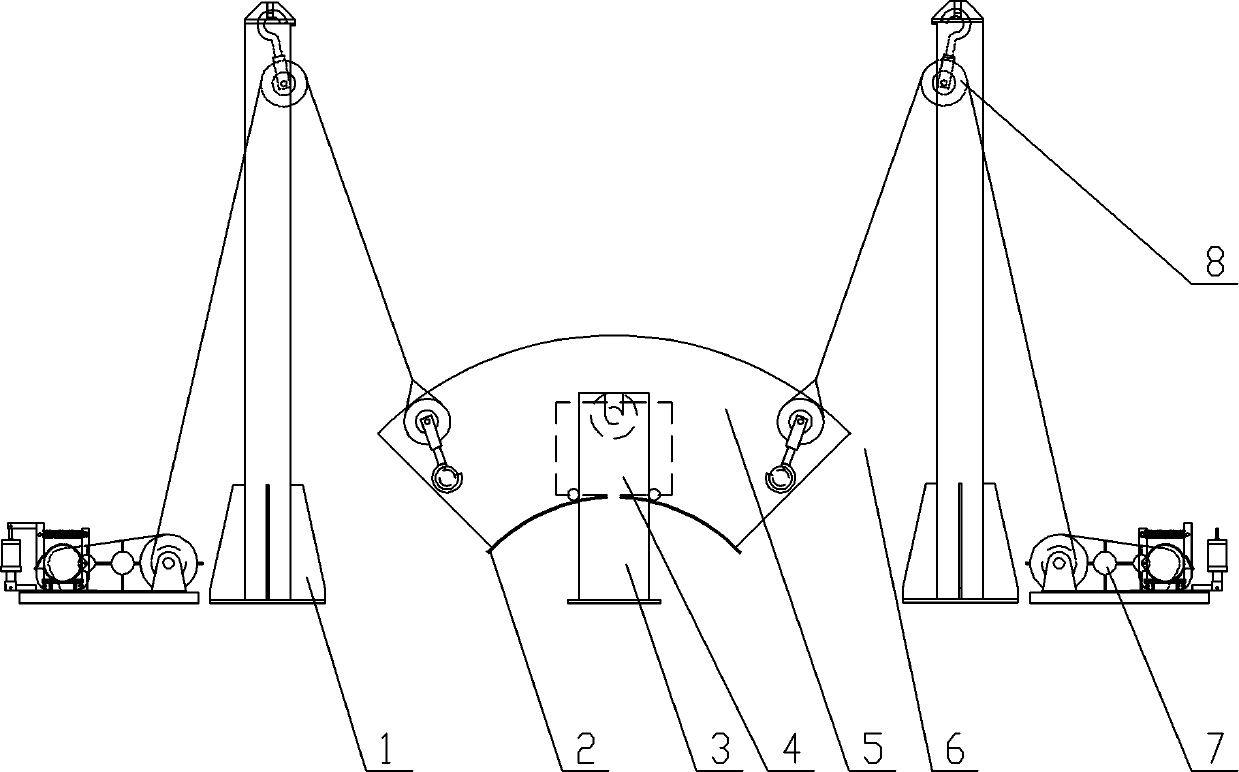

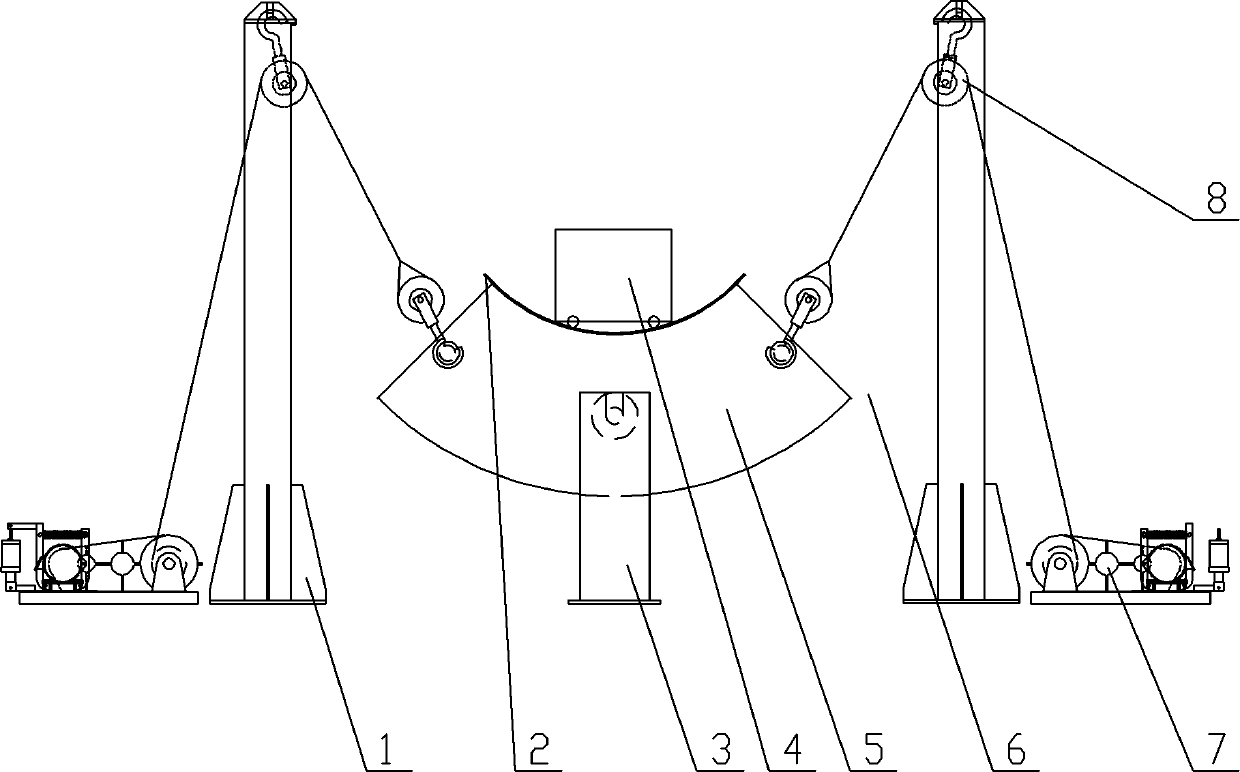

Device for automatically welding 90-degree large elbow

The invention relates to a device for automatically welding a 90-degree large elbow. The device comprises a welding gun, a submerged arc welding trolley and winches and is characterized by also comprising an elbow turning rest, wherein struts are respectively arranged on the two sides of the elbow turning rest; pulleys are arranged at the tops of the struts; one sides of the two struts are respectively provided with one winch; an elbow is fixed on the elbow turning rest; the two ends of the elbow are respectively connected with the winches by virtue of steel wire ropes; one ends of the steel wire ropes are fixed on the winches and the other ends of the steel wire ropes are fixedly connected with the elbow by bypassing the pulleys; a rail is arranged on the welding line of the elbow; and the submerged arc welding trolley is put on the rail and is provided with the welding gun. The device runs stably and is high in welding efficiency; and the welding gun can be always vertical to the welding line so as to avoid reducing the welding line quality because a molten pool is affected by the gravity, thus obtaining the high-quality welding line.

Owner:WUXI HANSHEN ELECTRIC

Equipment for automatically welding longitudinal concave seam of large elbow

InactiveCN100506463CPrevent fallingGuarantee job securityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPower unit

An automatic welder for the longitudinal concave seam of a great elbow is composed of a power unit, a great elbow locating unit with several fastening plats fixed on smooth plate and having centering function, a welding head locating unit with synchronizing mechanism and supporting frame, and a brake unit.

Owner:李文秀

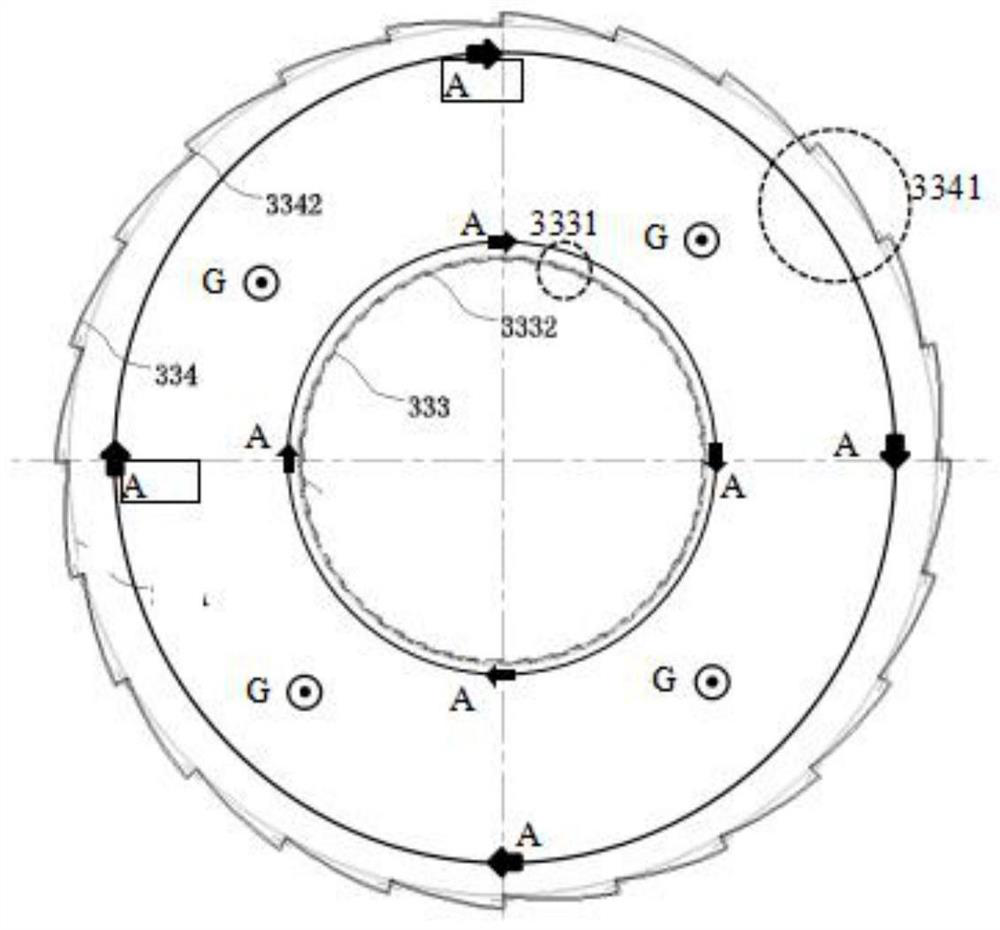

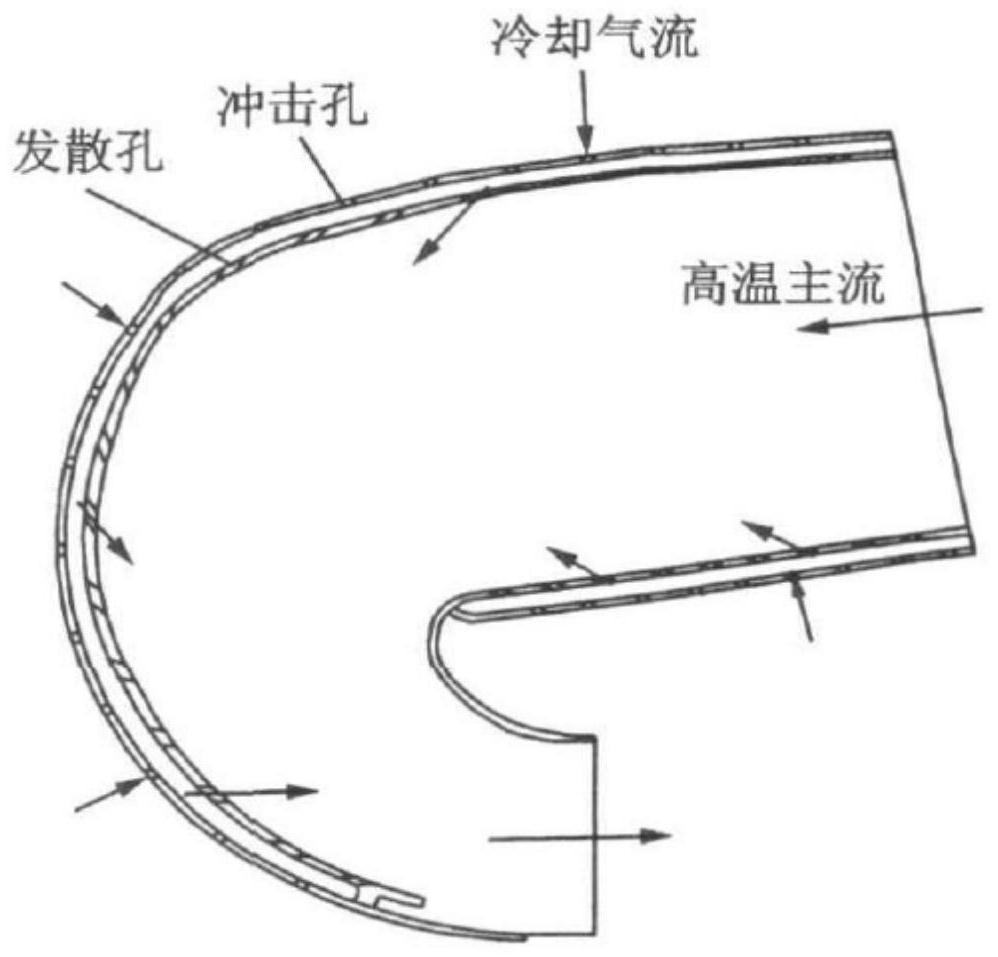

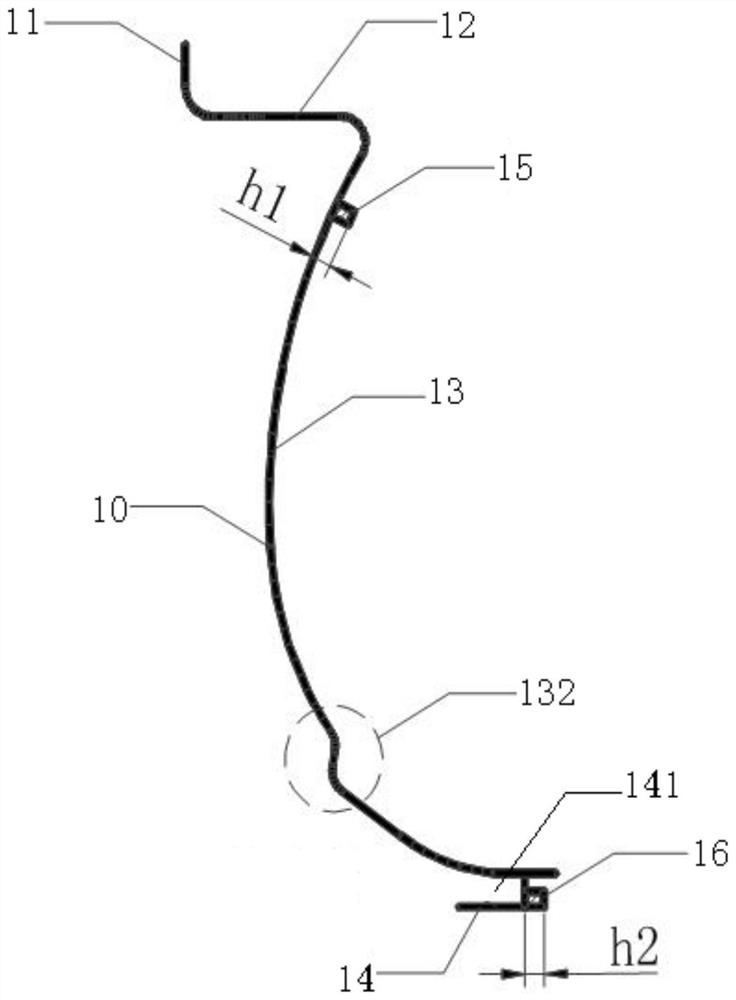

A cooling structure for the flame cylinder and the elbow of the backflow combustor

ActiveCN113154457BReduce heating effectWith gas collection effectContinuous combustion chamberCombustion chamberEngineering

The invention discloses a cooling structure for a recirculation combustion chamber, which comprises a flame tube outer ring, a flame tube inner ring, a large bend, a small bend and a flame tube head. One end of the flame tube outer ring is provided with a large bend, a large bend It is a ring structure, the other end of the flame tube outer ring is provided with a flame tube head, the inside of the flame tube outer ring is provided with a flame tube inner ring, and the end of the flame tube inner ring close to the large bend tube is provided with a small bend; the flame tube outer ring , which is provided with a plurality of outer ring mixing holes, and is divided into a plurality of first L-shaped unit bodies along the circumferential direction; the small elbow is in a ring structure, and is divided into a plurality of second L-shaped unit bodies along the circumferential direction . The invention belongs to the technical field of cooling, and the cooling efficiency of an L-shaped cooling elbow is higher than that of a conventional cooling elbow; the L-shaped cooling elbow is not easy to be ablated; the L-shaped cooling elbow can reduce the cost of sheet metal processing; The assembly of the segmental lap welded structure of the pipe is simple and easy to realize.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

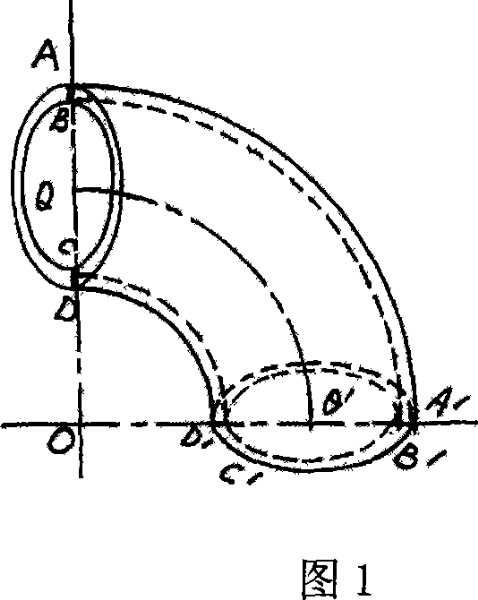

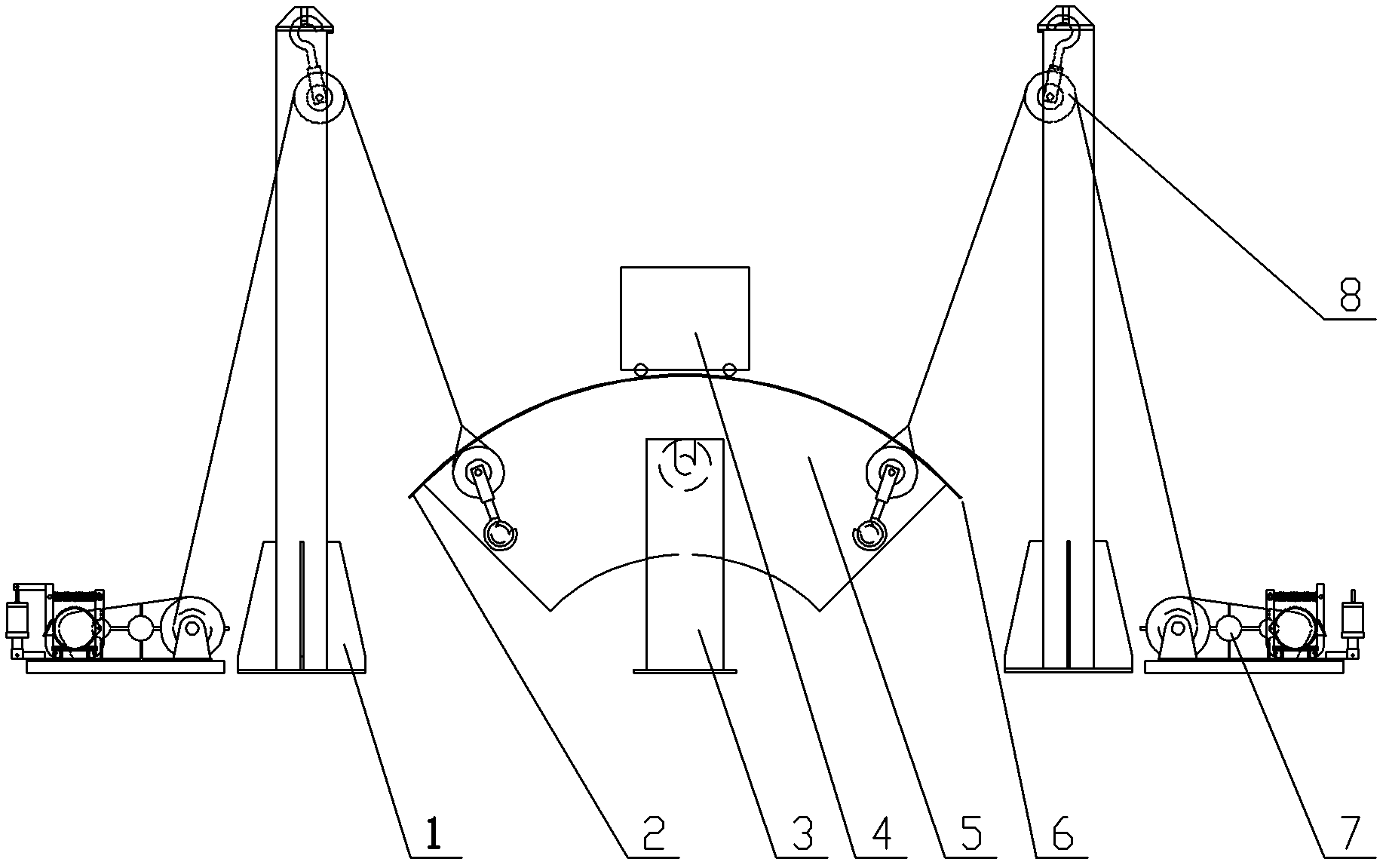

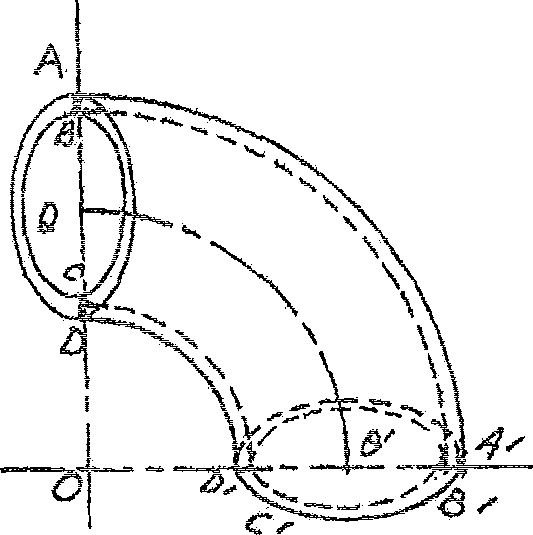

Method for forming large elbow and tool for forming large elbow

InactiveCN103028877BSimple structureEasy to installWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOmega

The invention discloses a specific assembling method of a tool for forming the large elbow. The tool comprises four H-shaped steel, wherein a plurality of steel plates are respectively connected onto each H-shaped steel, the number of the steel plates is determined according to elbow parameters including external diameter, bending angle and linear segment length which are required by elbow forming, a round hole is formed in each steel plate, the diameter of the round hole equals to the external diameter of the elbow to be installed and formed, the two ends of each H-shaped steel are respectively connected with a ring plate, and a backing ring is connected onto the external diameter of each ring plate; and a method for specifically installing the tool for forming the elbow comprises steps of horizontal reference plane determining, H-shaped steel 1 and H-shaped steel 2 installing, steel plate installing, H-shaped steel 3 and H-shaped steel 4 installing and backing ring installing. By the tool, the forming technical problem of large pipelines with cross sections which are formed by installing and welding steel pipes of a plurality round straight pipes, omega-shaped straight pipes, polygonal straight pipes and the like is solved, and the tool for forming the large elbow is simple in structure, is convenient to install, can be repeatedly used, has higher precision and can satisfy design requirements during the practical application.

Owner:SICHUAN BLUSR MACHINERY

A large elbow mouth rounding equipment

ActiveCN113059357BImprove grinding efficiencySave human effortOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention belongs to the technical field of mechanical processing, and in particular relates to a device for rounding the mouth of a large elbow. The device includes: a frame; The rotating shaft is connected to fix the elbow to be rounded; the equipment also includes: a rounding mechanism, which is arranged on both sides of the elbow, and is used to round the two sides of the elbow; a grinding mechanism, perpendicular to the elbow to be rounded A full-circle elbow is set; the first magnetic assembly is installed at the bottom of the grinding mechanism; the second magnetic assembly is connected in a closed circuit, and the second magnetic assembly is opposite to the first magnetic assembly and the two are opposite to each other The magnetism of the surface is the same; the flow blocking part is connected in the closed circuit and connected with the grinding mechanism; the elbow can be fixed by setting the clamping mechanism, and the elbow is driven by the driving part to rotate at the same time. The mechanism is convenient for limiting the travel of the elbow while it is rotating.

Owner:青岛昌辉管业有限公司

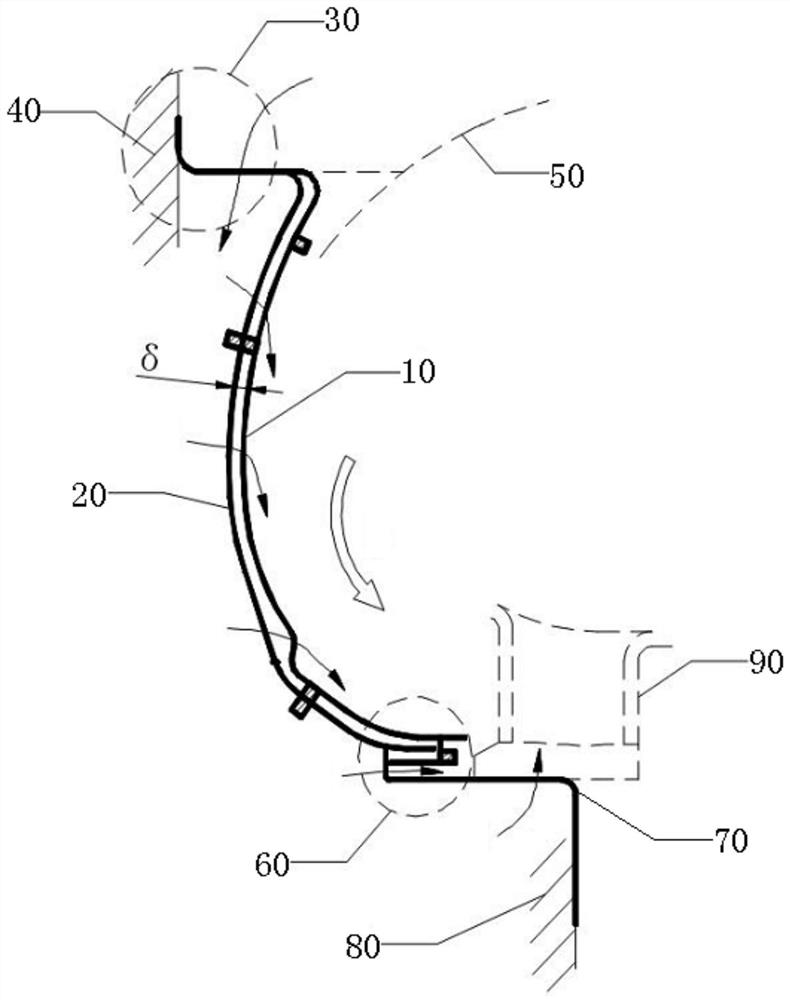

An Axially Floating Backflow Annular Combustion Chamber Large Elbow Structure

ActiveCN112377946BExtended service lifeSelf-adjusting temperatureContinuous combustion chamberCombustion chamberCooling effect

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Large elbow opening rounding equipment

ActiveCN113059357AImprove grinding efficiencySave human effortOther manufacturing equipments/toolsPositioning apparatusMachiningPhysics

The invention belongs to the technical field of machining, and particularly relates to large elbow opening rounding equipment. The equipment comprises a rack, a driving part which is mounted on the rack, and a clamping mechanism which is connected with the rotating shaft and used for fixing a to-be-rounded elbow; the output end of the driving part is connected with a rotating shaft; the equipment further comprises rounding mechanisms which are arranged on the two sides of the elbow and used for rounding the two sides of the elbow, a polishing mechanism which is arranged perpendicular to the to-be-rounded elbow, a first magnetic component which is mounted at the bottom of the polishing mechanism, a second magnetic component which is connected in the closed loop, and a flow choking component which is connected in the closed loop and is connected with the polishing mechanism; the second magnetic component and the first magnetic component are oppositely arranged, and the opposite surfaces of the second magnetic component and the first magnetic component have the same magnetism. The elbow is conveniently fixed through arrangement of the clamping mechanism, meanwhile, the elbow is driven by a driving piece to rotate, and the stroke of the elbow is conveniently limited while the elbow rotates through arrangement of the rounding mechanisms.

Owner:青岛昌辉管业有限公司

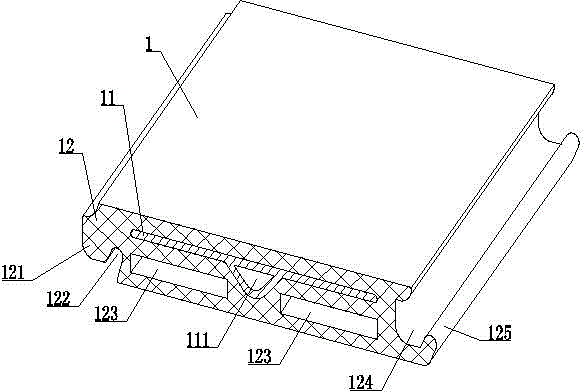

Aluminum-plastic-coextrusion heat-conducting floor

The invention discloses an aluminum-plastic-coextrusion heat-conducting floor which comprises a floor body (1). The aluminum-plastic-coextrusion heat-conducting floor is characterized in that the floor body (1) comprises an aluminum core (11) and a wrapping layer (12) which wraps the outer surface of the aluminum core (11), a triangular hole (111) is formed in the aluminum core (11), two parallel rectangular holes (123) are formed in the core part of the wrapping layer (12), the left end of floor body (1) is provided with a large elbow (121) and a small groove (122), and the right end of the floor body (1) is provided with a large groove (124) and a small elbow (125). The aluminum-plastic-coextrusion heat-conducting floor is easy to splice, good in heat conducting performance, high in strength, environmental friendly, attractive, low in cost and long in service life.

Owner:HUANGSHI ZHIYUN ELECTROMECHANICAL TECH INST

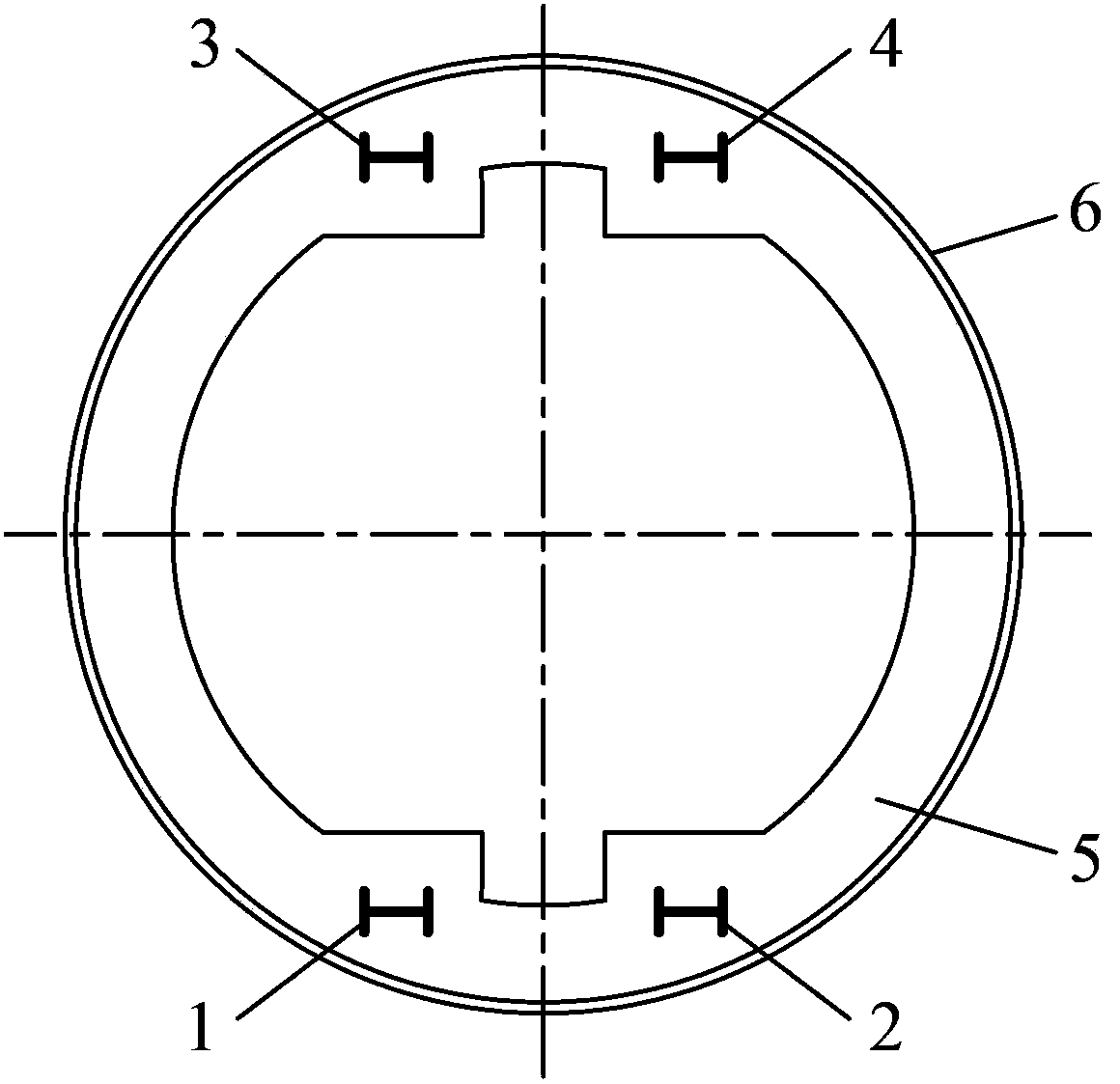

Double-wall large elbow pipe structure

ActiveCN113565632AImprove sealingEasy to disassembleGas turbine plantsLeakage preventionMechanicsBolt connection

The invention discloses a double-wall large elbow pipe structure, which belongs to the technical field of aero-engines and comprises a large elbow pipe outer wall, a large elbow pipe inner wall and a pin, wherein the pin penetrates through the large elbow pipe outer wall and is fixedly connected with the large elbow pipe outer wall, and the end part of the pin abuts against the large elbow pipe inner wall to form a gap between the large elbow pipe outer wall and the large elbow pipe inner wall. One end of the inner wall and the outer wall of a double-wall large elbow is designed into an L-shaped structure, a bolt connection mode is adopted, the inner wall of the large elbow at the other end is designed into a structure with a U-shaped groove and a bolt hole in a straight edge, the corresponding end of the outer wall of the large elbow is designed into a straight section which is inserted into the U-shaped groove in the inner wall of the large elbow, the bolt hole is used for axial and circumferential positioning of the large elbow, is easy to disassemble and assemble, and moreover, the joint is firm and reliable, and the sealing effect is good. The distance between the outer wall of the large elbow and the inner wall of the large elbow can be adjusted by adjusting the length of the pin between the outer wall of the large elbow and the inner wall of the large elbow.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Device for automatically welding 90-degree large elbow

InactiveCN102489836BRealize fully automatic weldingSmooth motionArc welding apparatusEngineeringWinch

The invention relates to a device for automatically welding a 90-degree large elbow. The device comprises a welding gun, a submerged arc welding trolley and winches and is characterized by also comprising an elbow turning rest, wherein struts are respectively arranged on the two sides of the elbow turning rest; pulleys are arranged at the tops of the struts; one sides of the two struts are respectively provided with one winch; an elbow is fixed on the elbow turning rest; the two ends of the elbow are respectively connected with the winches by virtue of steel wire ropes; one ends of the steel wire ropes are fixed on the winches and the other ends of the steel wire ropes are fixedly connected with the elbow by bypassing the pulleys; a rail is arranged on the welding line of the elbow; and the submerged arc welding trolley is put on the rail and is provided with the welding gun. The device runs stably and is high in welding efficiency; and the welding gun can be always vertical to the welding line so as to avoid reducing the welding line quality because a molten pool is affected by the gravity, thus obtaining the high-quality welding line.

Owner:WUXI HANSHEN ELECTRIC

Preparation technology of forging elbow

ActiveCN101603614BUniform wall thicknessSimple processEngine componentsRigid pipesMaterials scienceHeat treated

The invention relates to the elbow preparation technical field, in particular to a preparation technology of forging elbow. The technology is characterized in that: (1) forging a pipe, namely a forging rod is fixed and forged into a forging pipe, and the eccentricity of the forging pipe is 4-6% of the wall thickness of a finished elbow; (2) bending, namely half-round thin pipe wall of the forgingpipe formed by eccentricity is made into the inner ring of an elbow while the half-round thick pipe wall is made into the outer ring of the elbow after the forging pipe is subject to heat treatment, thus the forging pipe is bent into the elbow. Compared with the prior art, the invention has simple technology, large elbow can be bent by adopting the technology, and the wall thickness of the inner ring and the out ring of the elbow can be ensured to be relatively uniform.

Owner:SHANGHAI CHANGQIANG POWER

Large-diameter elbow grinding equipment

InactiveCN112355877AAchieve surface grindingImprove work efficiencyEdge grinding machinesPolishing machinesGear wheelElectric machinery

The invention relates to the field of grinding materials, in particular to large-diameter elbow grinding equipment which comprises a box body. A motor is arranged in the box body, a worm and gear cavity is formed in the box body, a transmission cavity is formed in the box body, and the motor is in power connection with a motor shaft which extends rightwards to penetrate through the worm and gear cavity to the interior of the transmission cavity; and a large shaft sleeve capable of sliding left and right is arranged in the transmission cavity in a spline fit manner, and sliding gears are arranged on the large shaft sleeve in a left-right symmetry manner. According to the large-diameter elbow grinding equipment, surface grinding of a large elbow can be achieved; and the inner surface and theouter surface of the large elbow make full contact with grinding materials, and under vibration of the grinding materials, the grinding process of the inner surface and the outer surface of the elbowis completed, so that the working time is saved while the working efficiency is improved.

Owner:福州堡徐翁科技有限公司

Equipment for automatically welding longitudinal arched seam of large elbow

InactiveCN100525992CPrevent fallingGuarantee job securityWelding/cutting auxillary devicesAuxillary welding devicesLarge elbowEngineering

Automatic welding equipment for longitudinal arched seams of large elbows, including a power unit, a large elbow positioning device, a welding head positioning device and a brake device, wherein the large elbow positioning device includes several pieces fixed on the drum with automatic centering and welding. The clamping plate with seam centering function, the machine head positioning device for the longitudinal arch weld in the large elbow adopts a special machine head bracket, which can fix the machine head directly above the weld seam to ensure good welding quality. The device can immediately brake the entire welding equipment when the power is stopped or cut off, and continue welding from the power-off position after the power is turned on to ensure safe production. The automatic welding equipment for longitudinal arched seams of large elbows provided by the present invention cleverly changes the longitudinal arched welds of large elbows of workpieces into circumferential welds, breaking through the problem that the longitudinal arched welds of large elbows cannot be welded automatically.

Owner:李文秀

Double Wall Big Elbow

ActiveCN113175688BAvoid strength problems such as fatigue cracksAchieving a sealed connectionContinuous combustion chamberThermal dilatationDouble wall

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com