Stand for welding machine head of equipment for automatically welding large elbow

A technology of automatic welding and welding head, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of undiscovered and automatic welding difficulties, achieve low manufacturing cost, improve welding quality, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

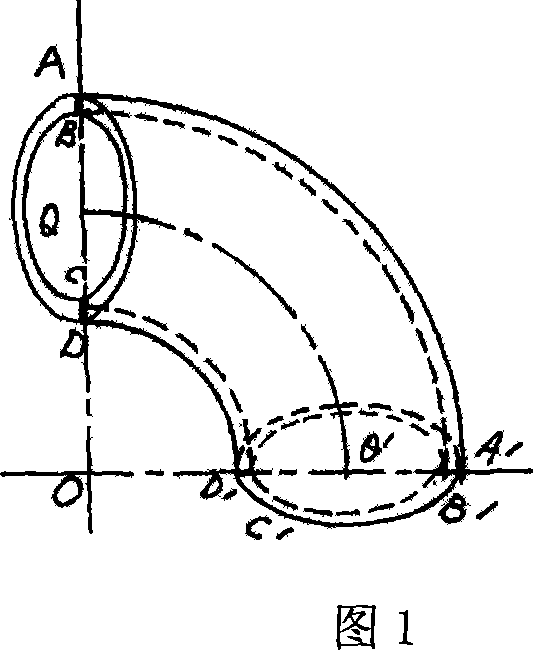

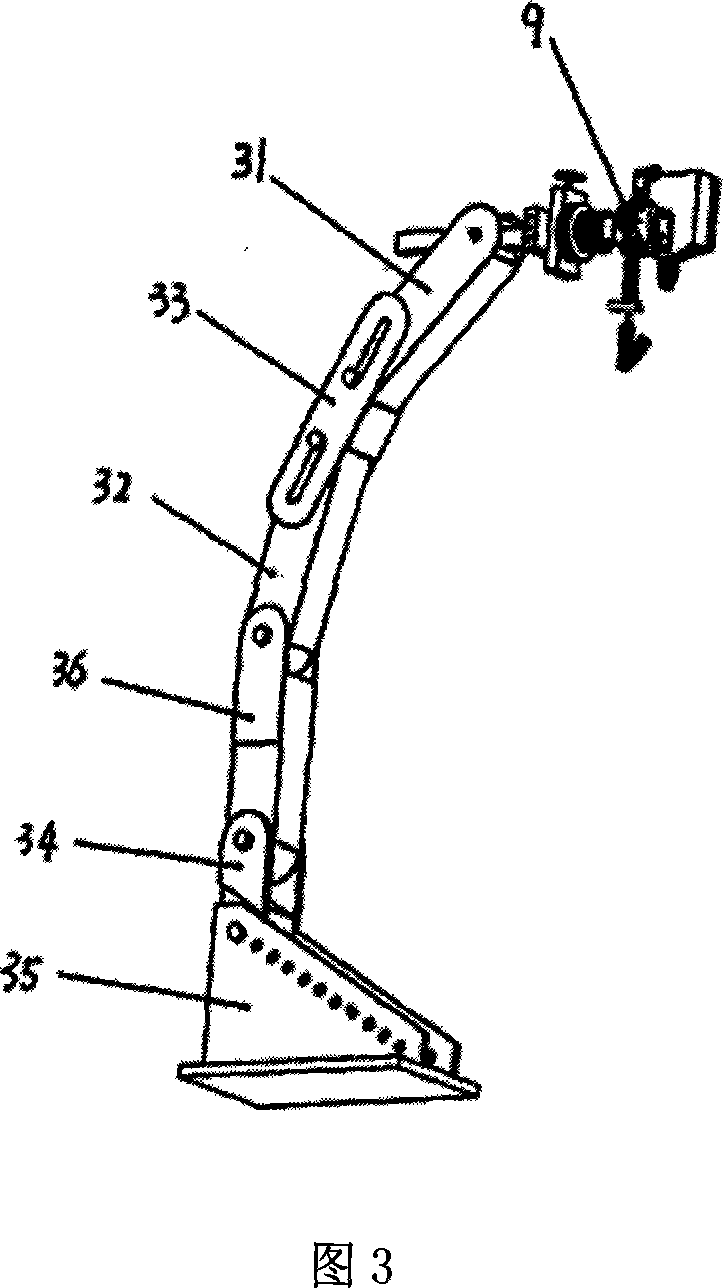

[0029] As shown in Fig. 3 and Fig. 10, the head support 30 comprises a first section 31, an intermediate section 32, a secondary intermediate section 36, an adjusting plate 33, a distal section 34 and a base 35, the first section 31, an adjusting plate 33, an intermediate section 32, a secondary The middle section 36 and the end section 34 are connected into an arc shape, and the center of the arc coincides with the center of the motion track of the weld seam of the workpiece. The center of the seam movement trajectory coincides, that is, the radius of the head support is 1.5D, and D is the maximum diameter of the cross-section of the large elbow of the workpiece, and the straight line length of AD shown in Figure 1.

[0030] First section 31 is used for installing machine head, and structure as shown in Figure 4, comprises upper cover plate 311, lower cover plate 312, connecting plate 313, connecting plate 314, mounting hole 315 and installation shaft 316, upper and lower cove...

Embodiment 2

[0039]As shown in Figure 11, it is the same as Embodiment 1, the difference is that the base 5 fixes the entire head support on the synchronization device, the synchronization device rotates synchronously with the main shaft of the workpiece power device, and the synchronization device drives the head support to rotate to drive The welding head and the workpiece rotate synchronously, which can realize the automatic welding of the inner welding seam.

[0040] When the welding operation of the inner concave weld seam is carried out to the large elbow workpiece, the welding head of the inner longitudinal concave seam BB' arc (as shown in Figure 1) is automatically welded by the large elbow inner weld seam provided by the present invention The welder head bracket is fixed to the outer end of the inner concave weld of the workpiece, aligned with the arc of the inner weld BB', and the movement trajectory of the welding spot on the longitudinal inner concave weld BB' arc forms a traje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com