Equipment for automatically welding longitudinal concave seam of large elbow

A welding equipment and automatic seam technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as undiscovered, automatic welding difficulties, etc., to improve welding quality, good welding quality, and ensure work safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

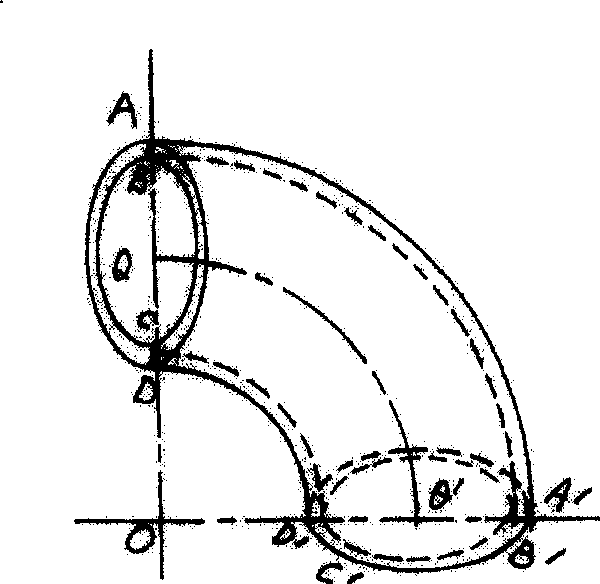

[0051] Such as Figure 16 As shown, the automatic welding equipment for the longitudinal concave seam of a large elbow includes a power unit 1, a large elbow positioning device 2, a welding head positioning device 3, and a brake device 4.

[0052] The power unit 1 includes a motor, a reducer, a transmission component, a main shaft 13 and a flat plate 14 fixedly connected to the main shaft. The end of the main shaft is wound with a wire rope 41 fed by a brake device. The flat plate 14 is fixedly connected to the large elbow positioning device 2 and the motor is connected. After the power is turned on, the reducer is driven to rotate, the reducer drives the main shaft to rotate through the transmission component, and the main shaft drives the flat plate and the large elbow positioning device to rotate around the main shaft. The transmission component can be a chain, belt or gear transmission.

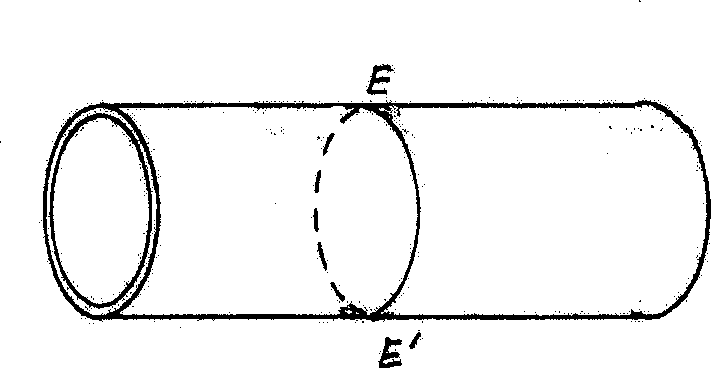

[0053] 20 rounds of R-shaped threads are machined on the outer circumference of the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com