Circulating fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation

A fluidized bed reaction and reaction device technology, applied in the direction of hydrocarbons, hydrocarbons, organic chemistry, etc., can solve problems such as toxicity and high cost, and achieve the effect of reducing polycondensation reaction and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

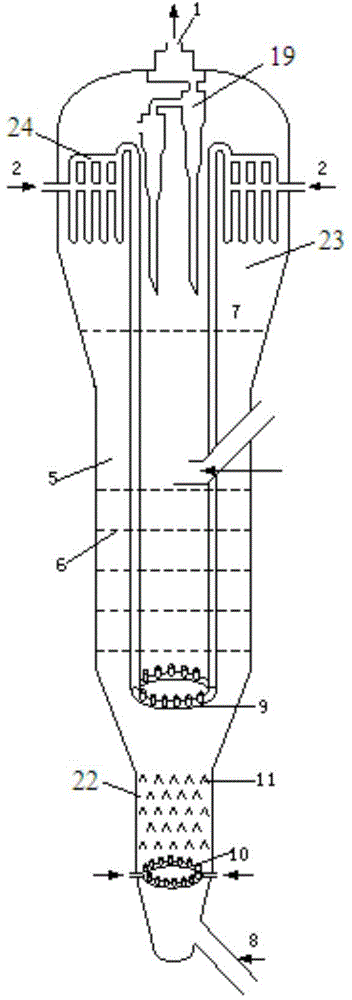

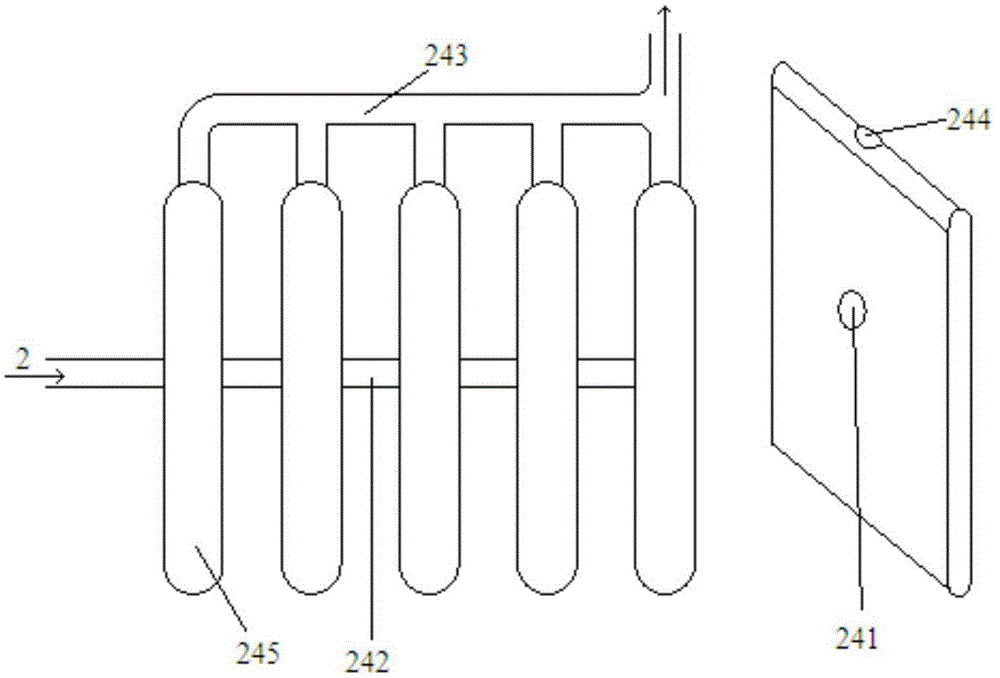

[0094] Reference attached figure 1 , the alkane dehydrogenation to olefins reaction device of the present application, the reaction device is a tank body with variable diameter, and the tank body is divided into a stripping section 22, a reaction section 5 and a catalyst settling section 23 from bottom to top, wherein the catalyst settling The diameter of the section 23 is larger than that of the reaction section 5 , and a heat exchange assembly 24 is arranged in the catalyst settling section 23 .

[0095] In this embodiment, the heat exchange assembly 24 is arranged inside the catalyst settling section 23. In the catalyst settling section 23, the raw material 2 enters the heat exchange assembly 24, and the raw material in the heat exchange assembly 24 exchanges heat with high-temperature oil and gas. Gasification and heating quickly cool down the high-temperature oil and gas, and at the same time, the raw materials use the heat energy of high-temperature oil and gas to gasif...

no. 2 approach

[0111] refer to image 3 , 4 , a dehydrogenation catalyst regenerator of the present application, comprising a regeneration section and a settling section, and the regeneration section is sequentially from bottom to top a riser lower section 16, an enlarged diameter dense phase section 21 and an upper riser section 27, and the upper riser section 27 is connected with settling section 17.

[0112] In the lower section of the riser of the dehydrogenation catalyst regenerator of the present application, most of the fuels are burned here and the coke on most of the catalysts is burned; in the dense phase section, the gas-solid two-phase heat exchange is mainly performed on the one hand, reducing Small gas-solid two-phase temperature difference transfers more energy to the catalyst, and the catalyst carries more heat to the reactor for use in the reaction. On the other hand, it promotes full contact between the oxygen in the air and the coke on the catalyst, further Burn off the c...

no. 3 approach

[0130] This embodiment is a mode in which the alkane dehydrogenation to olefins reaction device of the first embodiment is used in conjunction with the catalyst regenerator of the second embodiment. refer to image 3 , 4 .

[0131] The reaction device is connected with the catalyst regenerator through the catalyst standby inclined pipe and the catalyst regeneration inclined pipe. Reference attached image 3 , one end of the inclined tube 25 of the catalyst waiting to be born is connected to the outlet of the waiting catalyst on the reaction unit, and the outlet of the waiting catalyst is arranged between the bottom of the gas stripping section 22 of the reaction unit and the gas medium distributor 10, and the inclined tube of the waiting catalyst is The other end of 25 is connected to the spent catalyst inlet of the catalyst regenerator. One end of the catalyst regeneration inclined pipe 26 is connected with the regenerated catalyst outlet of the catalyst regenerator, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com