Coal liquefaction catalyst and coal liquefaction method using coal liquefaction catalyst

A catalyst and coal liquefaction technology, applied in the field of coal chemical industry, can solve the problems of low catalytic efficiency, achieve high catalytic efficiency, highlight catalytic activity, and increase oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

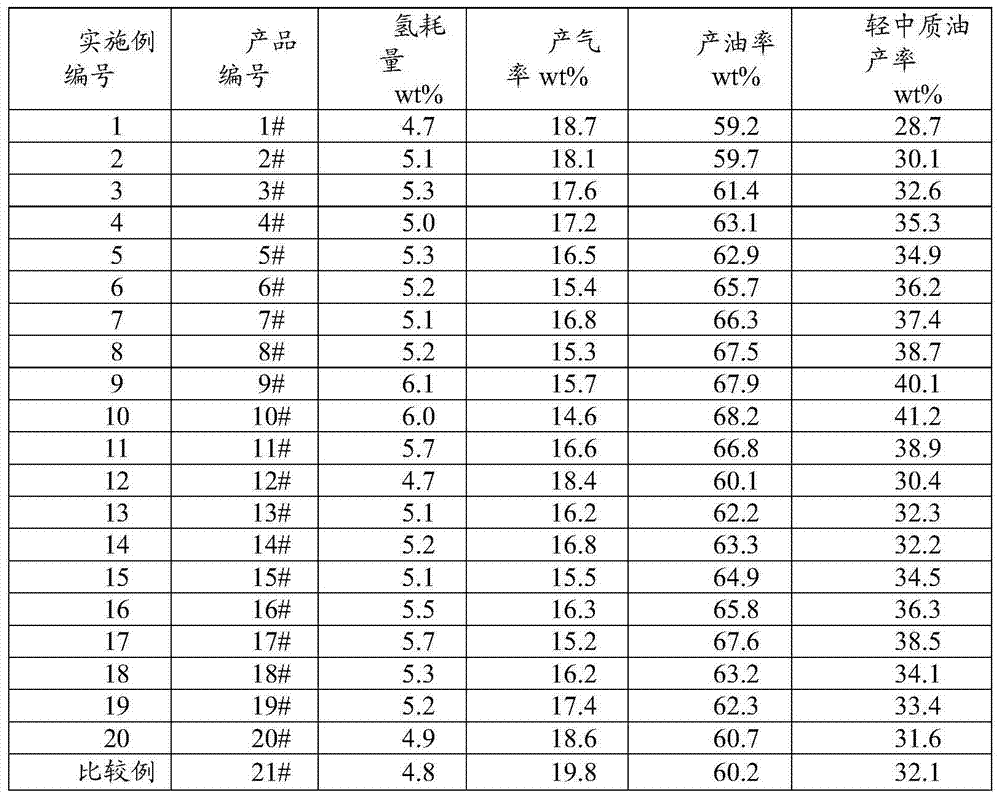

Examples

Embodiment 1

[0044] Weigh 1g of iron oxyhydroxide and 99g of iron sulfide, wherein the sulfur in iron sulfide accounts for 45wt% of the total mass of the catalyst, mix them uniformly, and pulverize to a particle size of 200 mesh to obtain the coal liquefaction catalyst 1#.

Embodiment 2

[0046] Weighed 99g of iron oxyhydroxide and 1g of iron sulfide, wherein the sulfur in iron sulfide accounted for 0.46wt% of the total mass of the catalyst, mixed them uniformly, and crushed to a particle size of 200 mesh to obtain the coal liquefaction catalyst 2#.

Embodiment 3

[0048] Weigh 50g of iron oxyhydroxide and 950g of iron sulfide, wherein the sulfur in iron sulfide accounts for 43wt% of the total mass of the catalyst, mix them uniformly, and pulverize to a particle size of 200 mesh to obtain the coal liquefaction catalyst 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com