Device and method for rapidly preparing high-yield activated carbon by coupling of pressure pump with microwaves

A high-yield, activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of restricting the large-scale promotion of microwave activation method, reducing the yield of solid product activated carbon, and affecting the heat transfer of pipeline exhaust furnace body, etc. problems, to achieve the effect of reducing the reaction activation energy, shortening the process operation time, increasing the yield and the degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

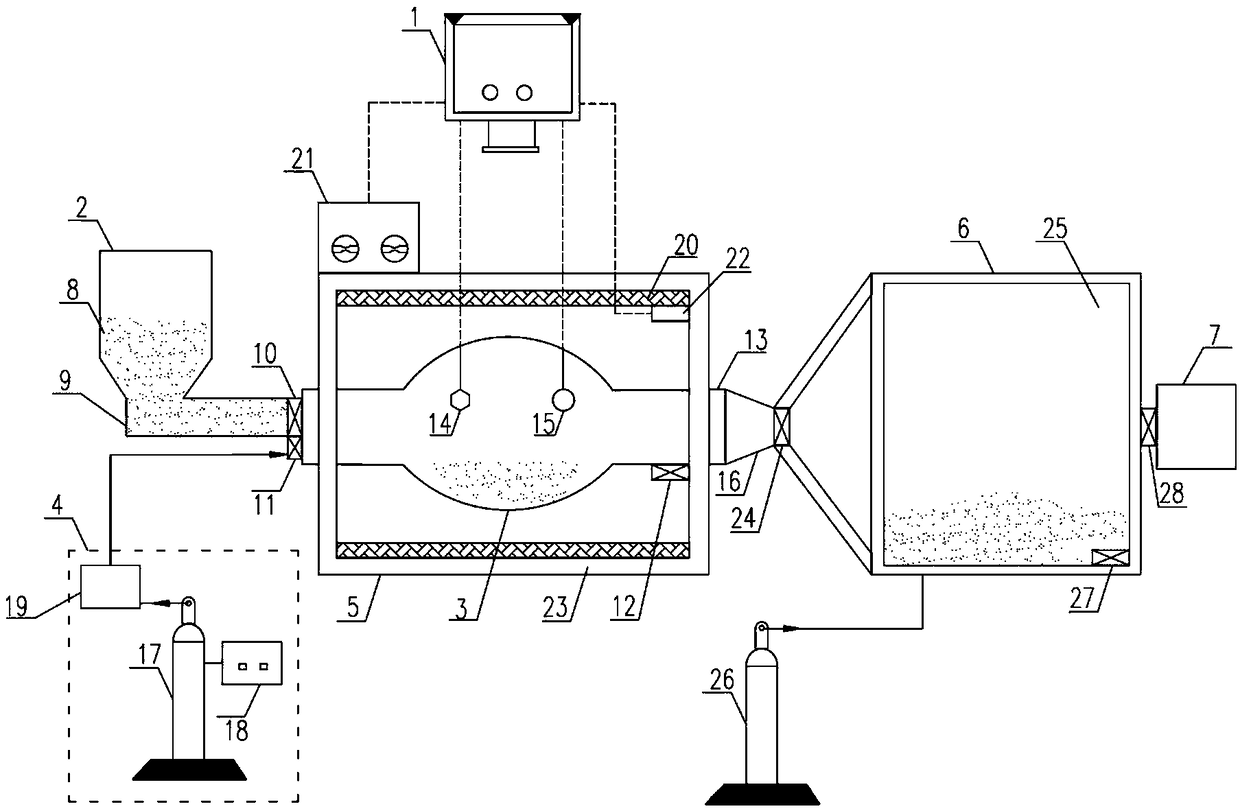

[0039] Open the feeder 9 and the feed valve 10 to transport 500g of straw powder and 500g of NaOH activator particles to the center of the reaction furnace 3 . After the feeding is completed, the feeder 9 and the feed valve 10 are closed. Open the gas storage tank 17, adjust the pressure flow controller 18 to 1000mL / min, open the inlet valve 11 to feed nitrogen into the reaction furnace 3 until the program controller shows that the high pressure in the reaction furnace 3 reaches 5MPa. Close the air storage tank 17, the pressure flow controller 18 and the intake valve 11. Start the circumferential rotation device 13, and turn on the microwave generator 20 at the same time, set the multi-level and multi-gradient heating mode through the timing-power control element 21 and the program controller 1, the specific parameters are as follows: heat with 400W power for 300s, and then increase the power To 800W, maintain 600s. Five minutes before the completion of the microwave activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com