Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Shorten process operation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

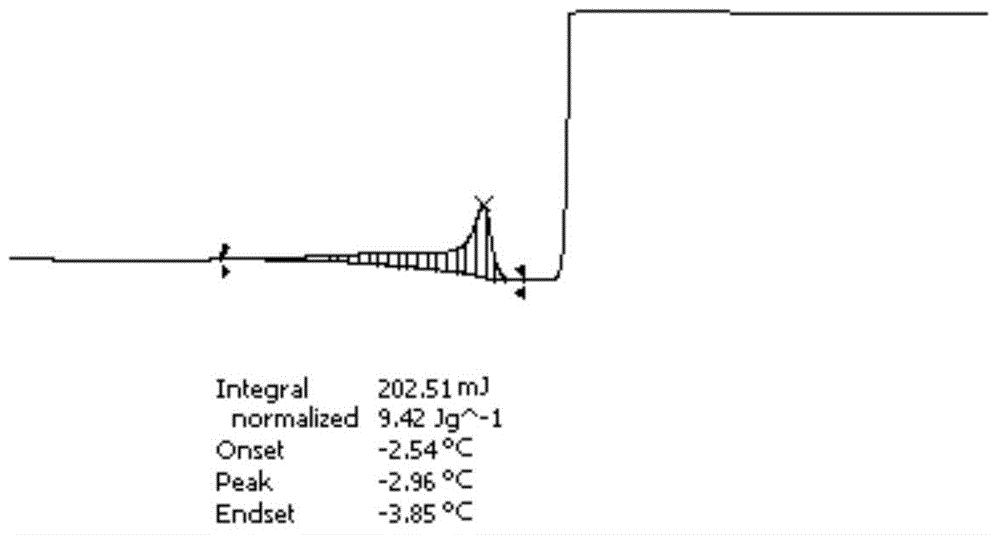

Manufacturing method of ice bag for preserving biological products

ActiveCN103194177AImprove cooling effectImprove bindingHeat-exchange elementsFreezing thawingDissolution

The invention discloses a manufacturing method of an ice bag for preserving biological products. The manufacturing method comprises the following steps: 1) adding a thickener into hot water or boiling water, and fully stirring till dissolution; 2) adding high molecular water-absorbing resin into a solution in the step 1) while hot, stirring, then standing to carry out full reaction and imbibition on the high molecular water-absorbing resin and the thickener, and forming a gelatinous solid, wherein the reaction time is 5-30minutes; and 3) bagging the gelatinous solid in the step 2), cooling, and then placing into a cold storage, a refrigerating cabinet or a refrigerator at the temperature of -10 DEG C to -20 DEG C for freezing for above 12hours. The invention provides a simple, convenient and high-efficient manufacturing method of a high molecular cold storage agent, namely the manufacturing method of the ice bag for preserving the biological products. The prepared cold storage agent has the advantages of high repeatability, great freezing-thawing phase change latent heat, long cold storage time and fast water absorption speed, and furthermore, the cost of the process is low; and by changing the added thickener, the different phase change temperatures can be obtained for meeting various different application requirements.

Owner:浙江赛灵特医药科技有限公司

Metal surface cleaning solution

The invention relates to a metal surface cleaning solution which is prepared by following raw materials of, by weight percentage, sulfuric acid, hydrochloric acid, a high polymer composite enhanced active agent, sodium dodecyl benzene sulfonate, urotropin, sodium silicate, citric acid, urea, industrial salt, triethanolamine and water. The cleaning solution can completely clean up various greasy dirt, rust and scale cinder attached on a metal surface effectively, and protective film can forms on the metal surface after being cleaned so as to prevent metal from rusting and oxidizing in a certain period. Waste water of a used cleaning solution can be reused after being recovered, precipitated and filtered.

Owner:杨恒春

Hard alloy production process

The invention relates to a hard alloy production process, in particular to a method for recycling broken materials generated in the hard alloy extrusion process. The hard alloy production process comprises the specific steps: (1) preparing a mixture: obtaining a powder material through burdening-ball grinding-drying-even crushing; (2) extruding the mixture: obtaining a semi-finished product through mixed pelleting-extruding-natural airing-heating and drying-processing and cutting; (3) sintering; (4) checking a finished product, and implementing the packaging and warehousing. The broken materials are mainly generated in the step (2), and are evenly crushed; then a component is added to implement the mixed pelleting; finally, the subsequent steps of extruding and the like are implemented. The hard alloy production process optimizes the technological process for processing the broken materials during guaranteeing the product performance, and largely reduces the cost.

Owner:杭州天石硬质合金有限公司

Fe and mixed rare earth intermediate alloy for adding rare earth into steel and preparation method for Fe and mixed rare earth intermediate alloy

The invention relates to a Fe and mixed rare earth intermediate alloy for adding rare earth into steel and a preparation method for the Fe and mixed rare earth intermediate alloy. The alloy is prepared by processing the following raw materials in percentage by weight: 70-95 percent of pure iron and 5-30 percent of mixed rare earth metal. The preparation method comprises the following steps of: performing vacuum melting in a vacuum medium frequency induction furnace crucible, wherein the vacuum degree is less than or equal to 0.1 Pa; and fully deoxidizing by using SiCaBa, and adding mixed rare earth metal into pure molten iron in the crucible when the temperature reaches 1,550-1,650 DEG C, wherein the melting and mixing time is 1-10 minutes. The invention has the advantages that: when the Fe and mixed rare earth intermediate alloy is used in a steel ladle, the rare earth adding effect is good, the rare earth adding form is novel and the rare earth can be added efficiently, the method is easy and convenient to operate, and equipment and operating workers are not added; the yield of the rare earth is greatly improved; the rare earth is uniformly distributed in molten steel; the rare earth adding amount is greatly reduced; the rare earth adding operating environment is effectively improved; the steel melting production efficiency is improved; the quality of the rare earth steel products is improved; and the comprehensive cost is reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

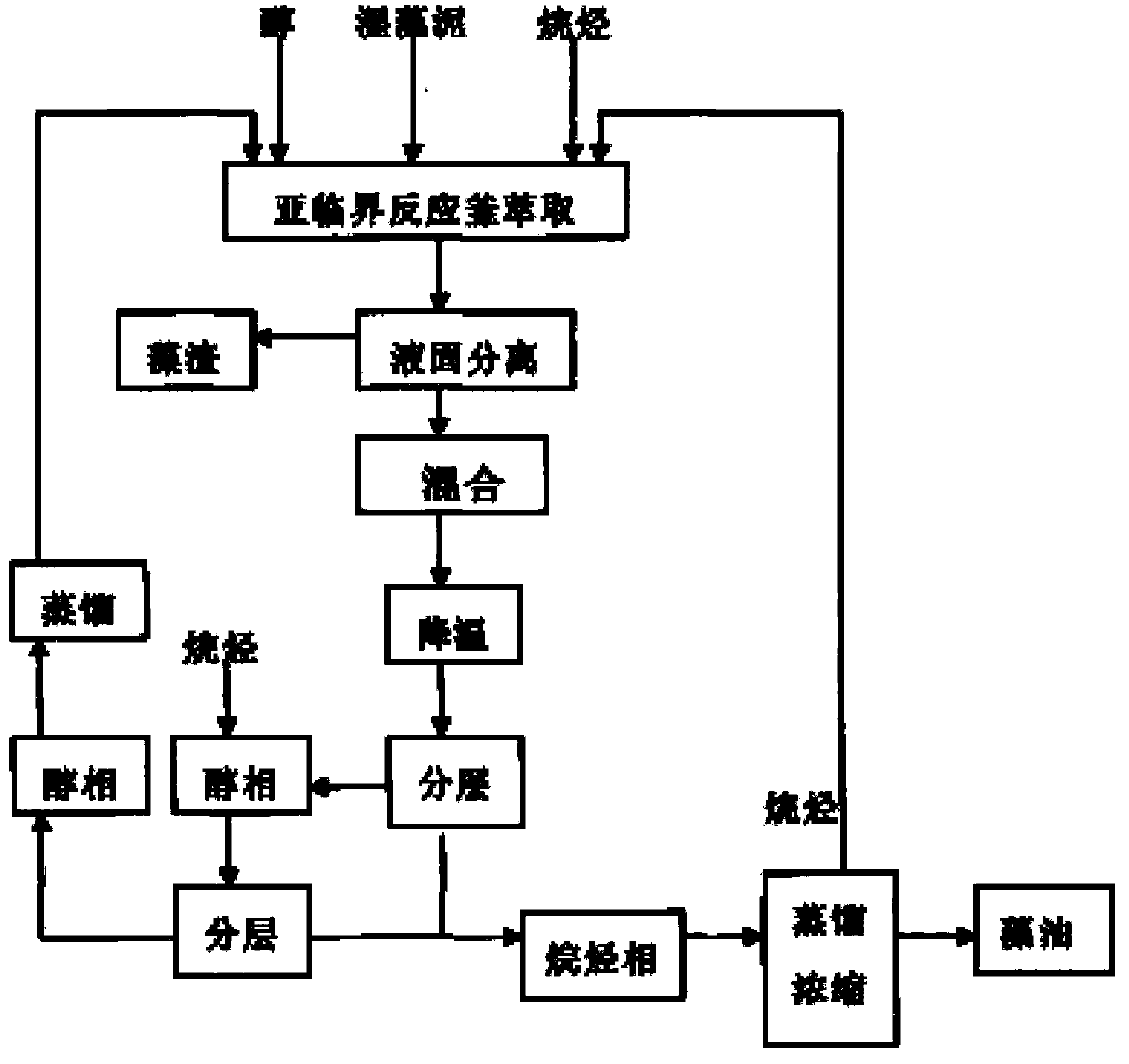

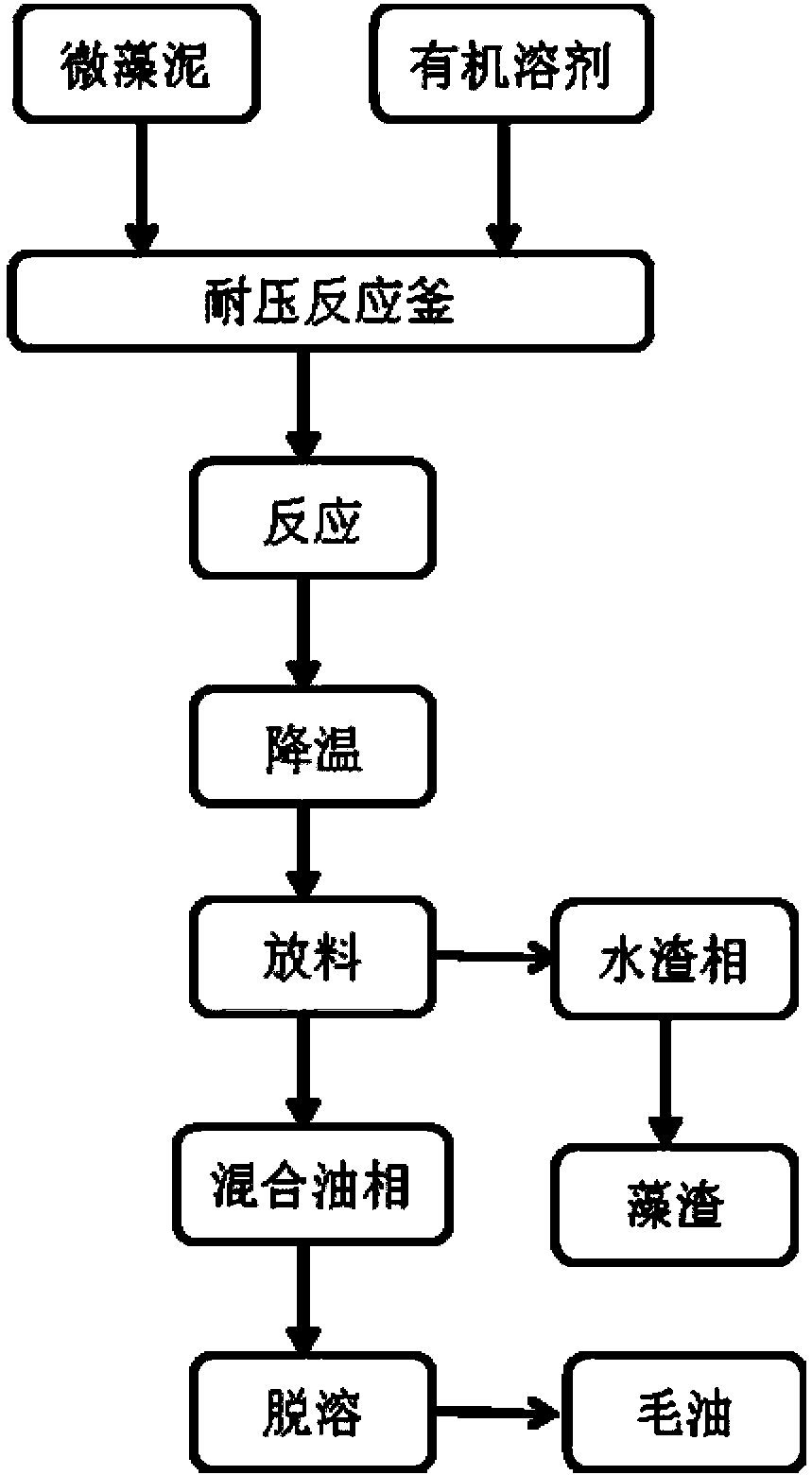

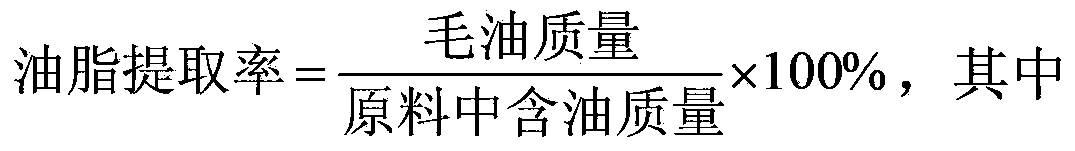

Method for extracting wet algae oil

ActiveCN103421600AReduce processing difficultyReduce dosageFatty-oils/fats productionOil and greaseOrganic solvent

The invention discloses a method for extracting wet algae oil. The method includes the following steps: (1), mixing wet algal mud of oil-producing microalgae with an organic solvent unmixable with water, adding a obtained mixture into a pressure-proof reaction kettle, sealing the reaction kettle, and starting reaction after reaching reaction temperature which refers to be above an azeotropic point of the organic solvent and water; (2), discharging after reaction is finished, respectively collecting upper-layer mixed oil phase and lower-layer water slag phase, removing a solvent from the upper-layer mixed oil phase, and obtaining crude oil. By the method, microalgae mud high in water content is directly utilized as a raw material, and algae cell drying and dehydrating are not needed, so that drying energy consumption is saved; a solvent is used in the process of extraction, so that consumption of the extraction solvent is small, easiness in recovery and separation is realized, and recovery and separation cost is lowered.

Owner:ENN SCI & TECH DEV

Process method for producing large size sculpture through resin sand removable-flask moulding

The invention relates to casting process, in particular to a process method for producing large size sculpture through resin sand removable-flask moulding. The method comprises the following technological processes: model receiving, cutting, strengthening, model placing and gating system designing, netty steel frame welding, modeling, mode dissembling, mold assembling, strengthening, pouring, sand cleaning and the like. The method is mainly characterized in that steel frames with different sizes are welded according to the sizes of casting models, and the profile-followed steel frames can be welded according to the different shapes of casting models, so that the steel frames can be reused, and the consumption of resin sand can be greatly reduced during modeling due to the welded profile-followed steel frames; the layer surface of sand is thinner, and the operation time of the whole process is shortened, so that the raw materials are saved, the production efficiency is improved, and the whole production cost is greatly reduced.

Owner:SHANXI YUDA GRP

Fe-Ce intermediate alloy for adding rare earth into steel and preparation method for Fe-Ce intermediate alloy

The invention relates to a Fe-Ce intermediate alloy for adding rare earth into steel and a preparation method for the Fe-Ce intermediate alloy. The alloy is prepared by processing raw materials with the weight percentages that: 70-95 percent of pure iron and 5-30 percent of metal Ce. The preparation method comprises the following steps of: performing vacuum melting in a vacuum medium frequency induction furnace crucible, wherein the vacuum degree is less than or equal to 0.1 Pa; and fully deoxidizing by using SiCaBa, and adding metal Ce into pure molten iron in the crucible when the temperature reaches 1550-1650 DEG C, wherein the melting and mixing time is 1-10 minutes. The invention has the advantages that: when the Fe-Ce intermediate alloy is used in a steel ladle, the rare earth adding effect is good, the rare earth adding form is novel and the rare earth can be added efficiently, the method is easy and convenient to operate, and equipment and operating workers are not added; the yield of the rare earth is greatly improved; the rare earth is uniformly distributed in molten steel; the rare earth adding amount is greatly reduced; the rare earth adding operating environment is effectively improved; the steel melting production efficiency is improved; the quality of the rare earth steel products is improved; and the comprehensive cost is reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

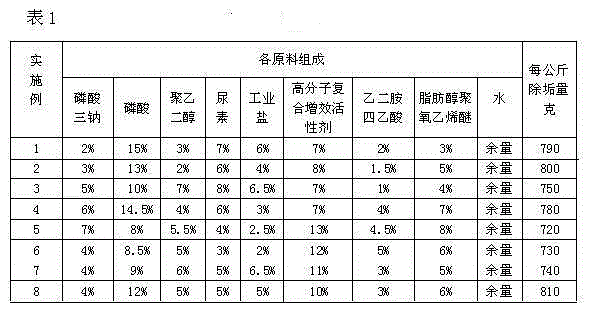

Environment-friendly multi-purpose descaling liquid

The invention discloses environment-friendly multi-purpose descaling liquid. The environment-friendly multi-purpose descaling liquid is used for removing water scales, oil scales, dirt and urine scales, and the key is that the environment-friendly multi-purpose descaling liquid is prepared from the following raw materials in percentage by weight: 2-7% of trisodium phosphate, 8-15% of phosphoric acid, 2-7% of polyethylene glycol, 3-8% of urea, 2-7% of industrial salt, 7-13% of a polymer composite synergistic active agent, 1-5% of ethylene diamine tetraacetic acid, 3-8% of fatty alcohol polyoxyethylene ether and the balance of water. The multi-purpose descaling liquid can rapidly remove the scales and has the advantages of good descaling effect, no irritation and no harm to human bodies, safety, no toxicity and no environmental pollution.

Owner:石家庄正仁环保科技有限公司

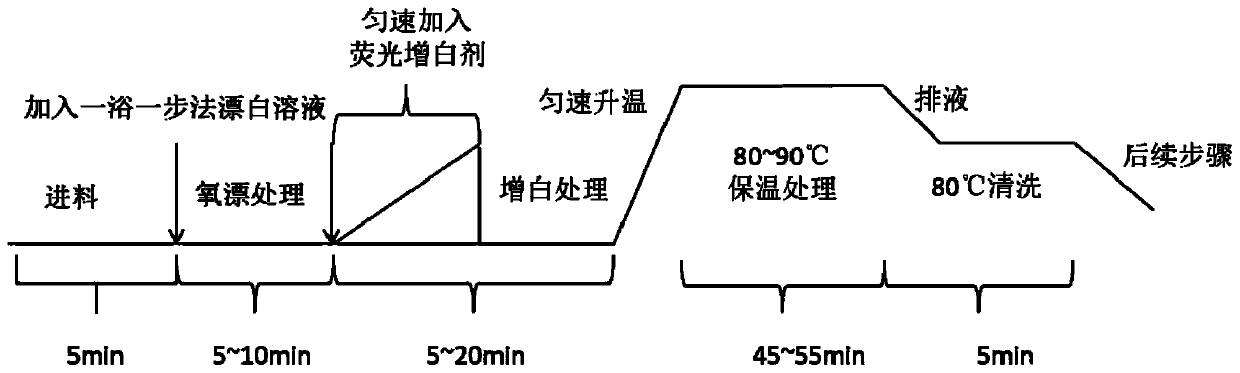

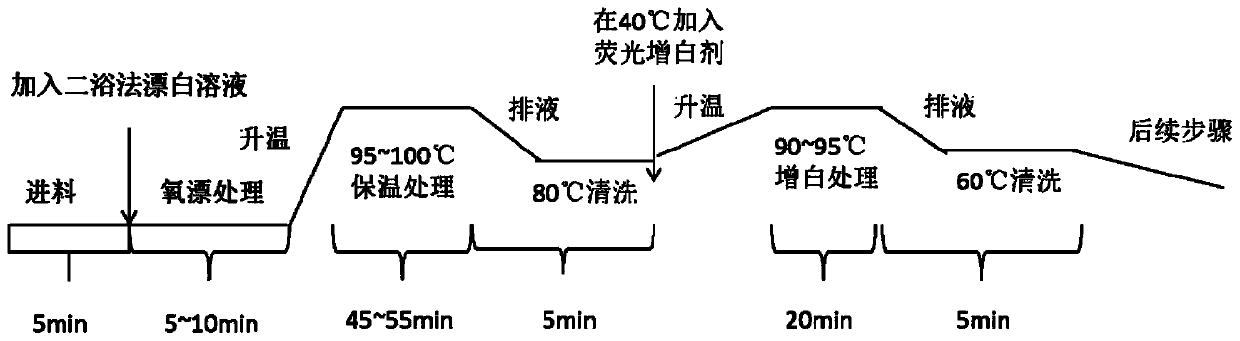

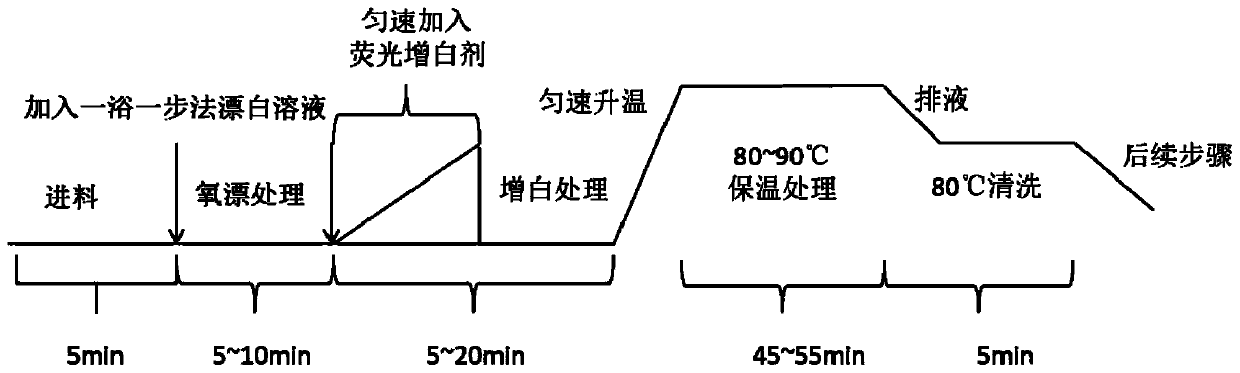

Preparation method of white fabric

ActiveCN107841866AReduce sournessNo sour tasteGrip property fibresVegetal fibresWhitening AgentsEconomic benefits

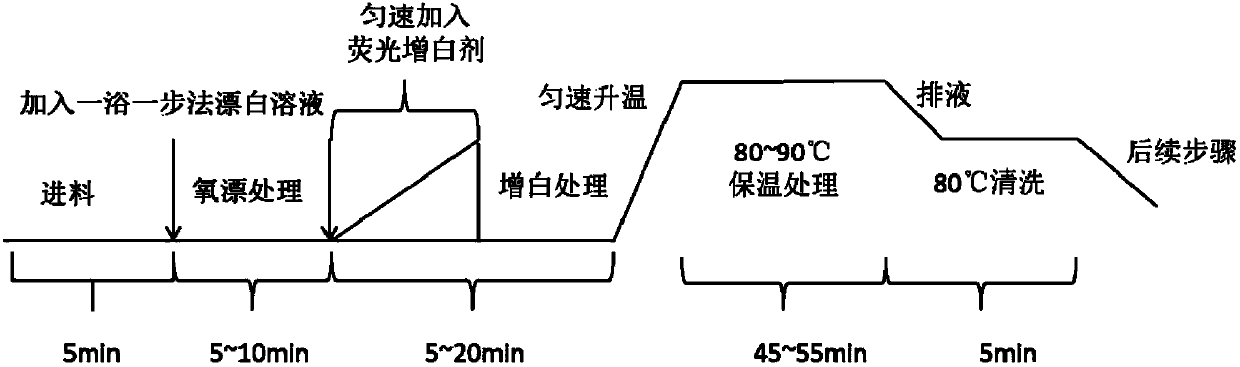

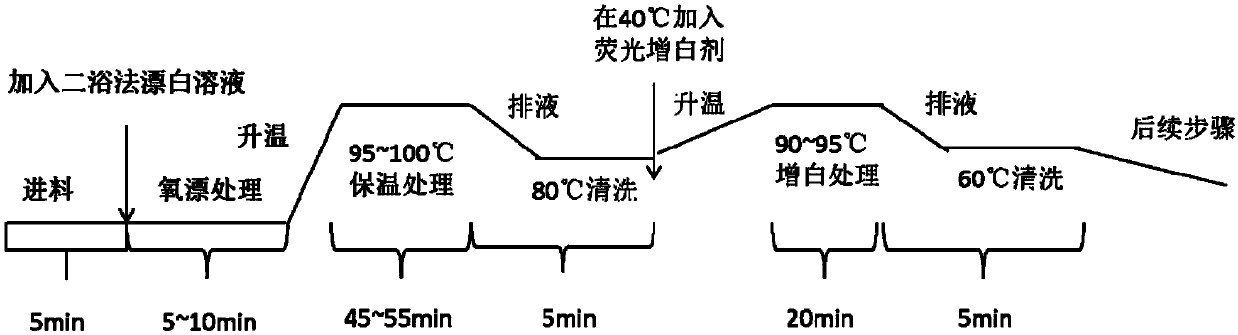

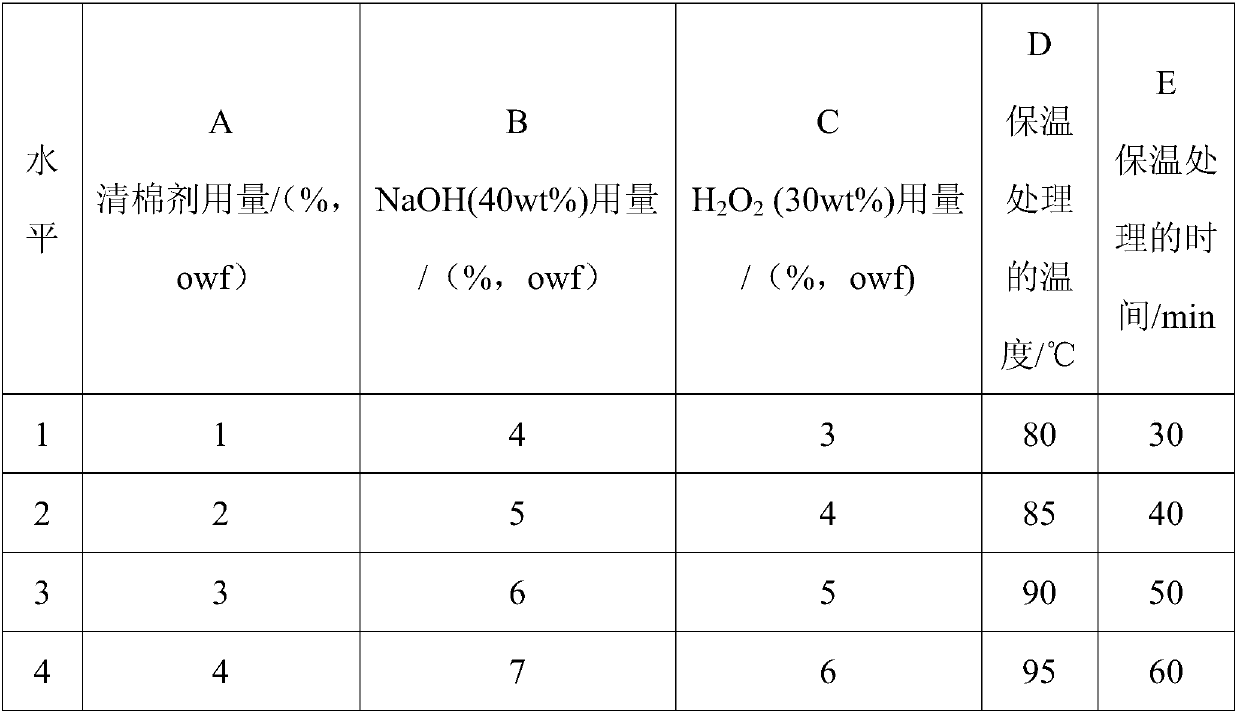

The invention relates to a preparation method of a white fabric. The method is characterized by oxygen bleaching and whitening a fabric containing cotton, and comprises the steps of adding a one-bath-one-step method bleaching solution (prepared from 1 to 2g / L of penetrating agent, 1 to 2g / L of anti-creasing agent, 2 to 7 percent (owf) of scutching agent, 2 to 9 percent (owf) of 40 percent by weight caustic soda solution, and 3 to 6 percent (owf) of 30 percent by weight hydrogen peroxide solution) with pH being 10 to 11 into the fabric for oxygen bleaching, then adding a fluorescent whitening agent for whitening, heating at a constant heating rate to 80 to 90 DEG C, carrying out insulation treatment, and cleaning, neutralizing and setting to obtain the white fabric. According to the method,a step of removing hydrogen peroxide is saved, so that the process time can be greatly saved, the water consumption is reduced, and the emission of noxious substances is reduced; the prepared white fabric is free of acidity and less in storage color change, and has a pH value stabilized in an acceptability limit from 5.5 to 7.0, and the whiteness improved by 1 to 2 or more compared with a traditional process; when preparing the white fabric with the same whiteness, the dosage of the fluorescent whitening agent can be saved by 10 to 40 percent, so that the economic benefits of enterprises canbe greatly improved.

Owner:PACIFIC (PANYU) TEXTILES LTD

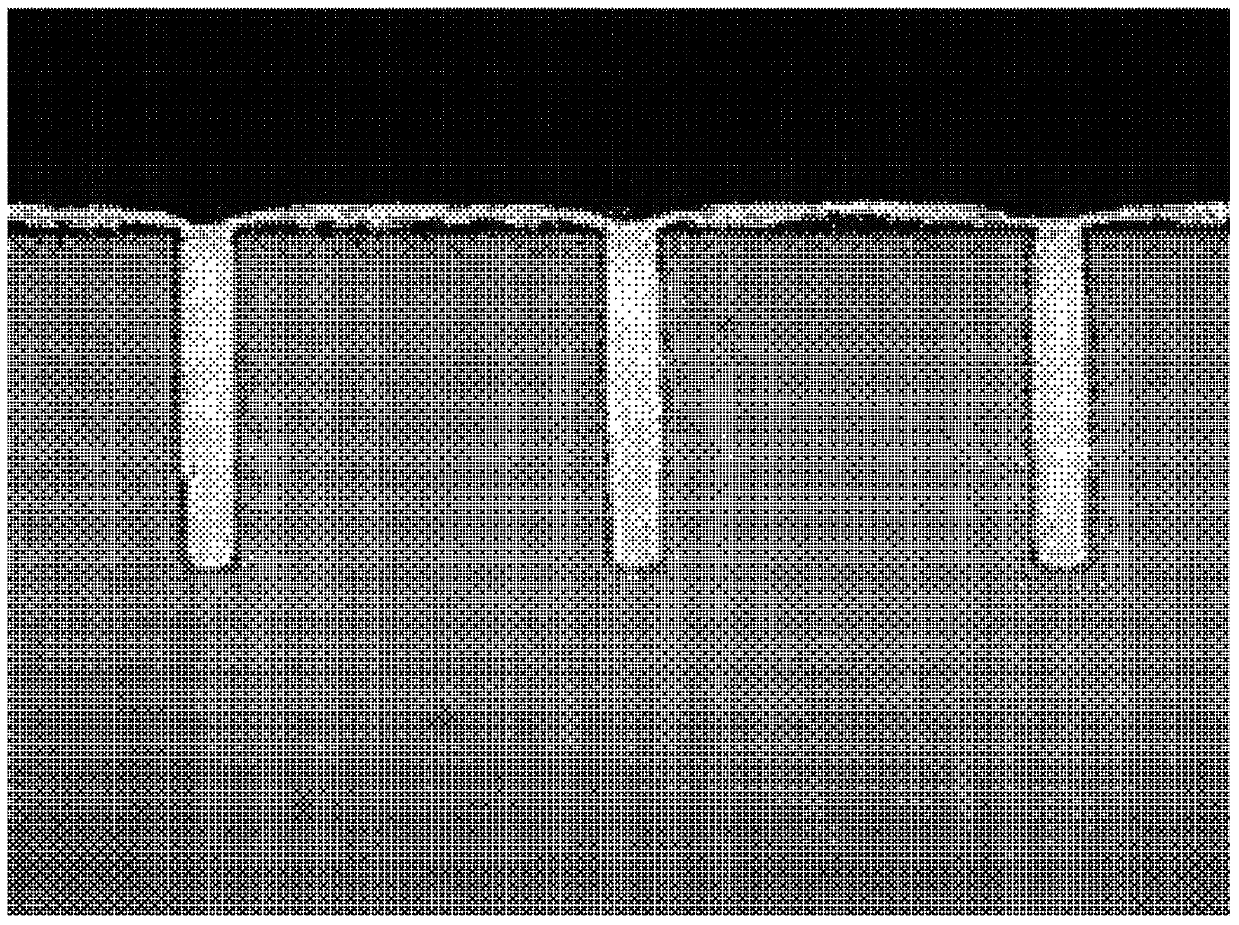

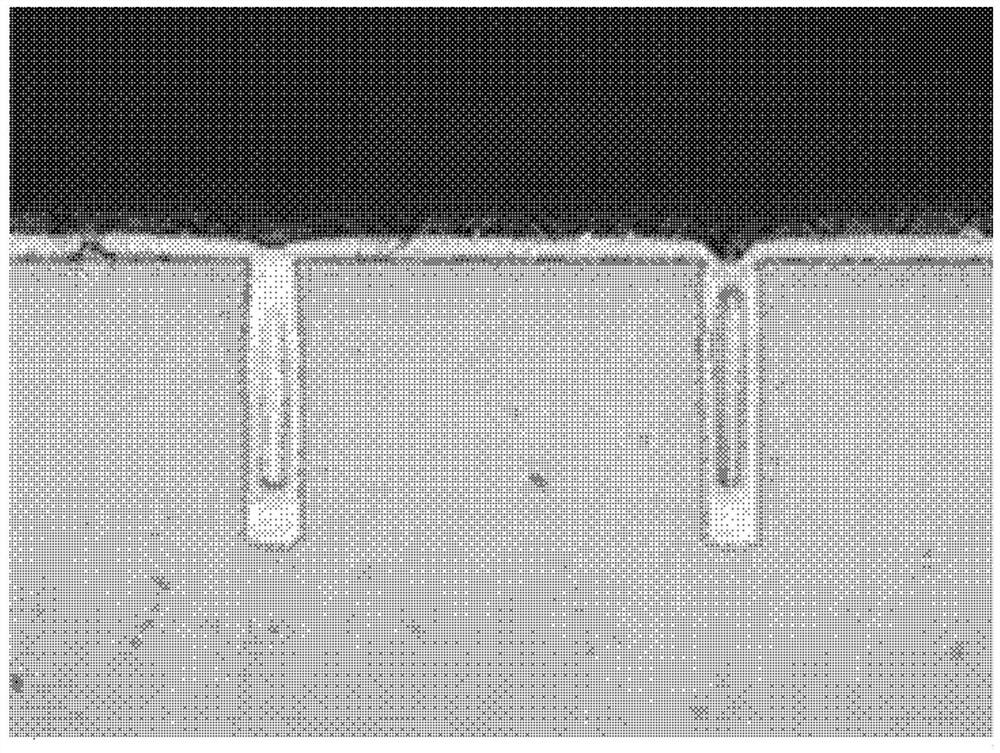

Silicon through-electrode void-free filling method and copper plating solution used in filling method

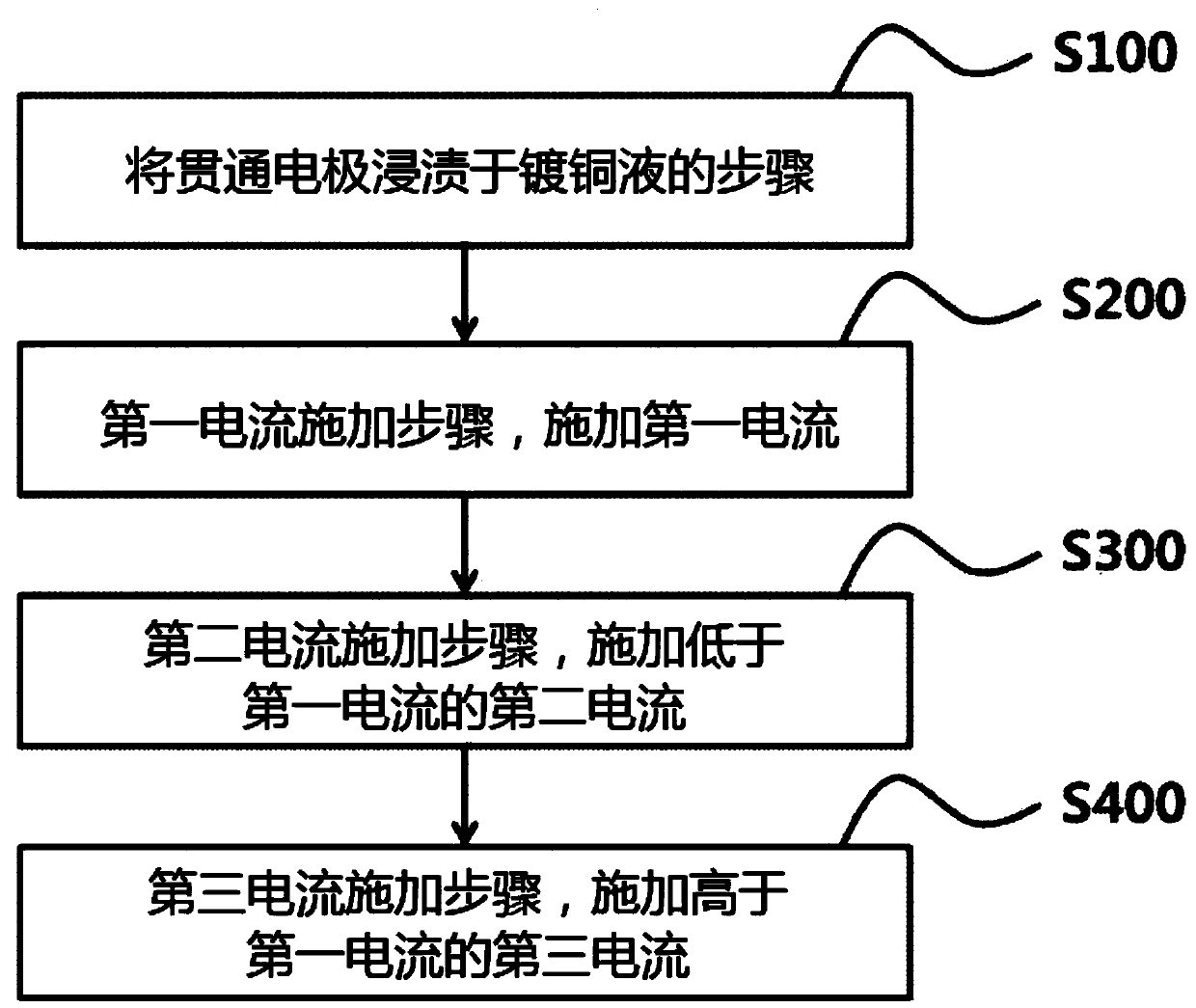

ActiveCN109863261AImprove reliabilityIncrease the first current stepCellsSemiconductor/solid-state device manufacturingCopper platingSilicon

An embodiment of the present invention provides a through-electrode filling method comprising: a step of immersing a through-electrode including a via in a copper plating solution having a leveler anda copper electrolyte; a first current applying step of applying a first current to coat an upper side surface of a via of the through-electrode in the leveler; a second current applying step of applying a second current, the magnitude of which is lower than that of the first current, to form a plating film of the copper electrolyte on the bottom of the via; and a third current applying step of applying a third current, the magnitude of which is higher than that of the first current, to fill with the copper electrolyte in a part from a surface of the plating film of the copper electrolyte to an opening of the via.

Owner:KOREA INST OF IND TECH

Lentivirus purification process

PendingCN112899242AEasy to degradeAvoid degradationRecovery/purificationReverse transcribing RNA virusesHollow fibreEnzyme digestion

The invention discloses a lentivirus purification process. The lentivirus purification process comprises the following steps: S1, clarifying and filtering a lentivirus-containing cell culture to obtain a lentivirus-containing cell culture supernatant; S2, concentrating the supernatant obtained in the step S1 by 8-15 times by adopting a hollow fiber ultrafiltration system; S3, washing and filtering the concentrated solution obtained in the step S2 by at least 10 volumes by using a first buffer solution; S4, carrying out nuclease Benzonase enzyme digestion treatment on the concentrated solution washed and filtered in the step S3, and controlling the treatment temperature to be 25-37 DEG C and the treatment time to be 30-60 minutes; S5, washing and filtering the concentrated solution in the step S4 by at least 10 volumes through a hollow fiber ultrafiltration system so as to remove nuclease Benzonase and nucleic acid fragments, and then adding a second buffer solution into the concentrated solution, wherein the second buffer solution contains Buffer for maintaining the stability of lentivirus particles; and S6, concentrating the lentiviral vector concentrated solution obtained in the step S5 to 5*10<7> TU / mL or above to obtain the purified lentivirus. The lentivirus purification process disclosed by the invention can obviously improve the recovery rate of the lentivirus and is suitable for large-scale production.

Owner:PORTON BIOLOGICS LTD

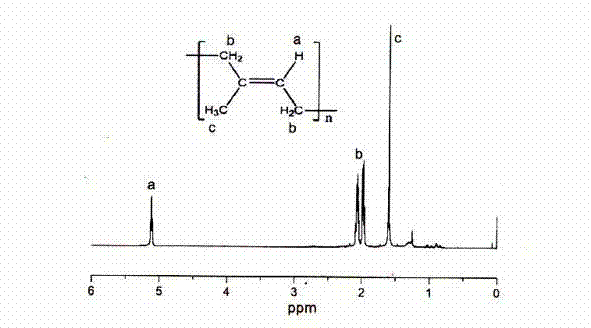

Method for preparing gutta-percha from eucommia bark

A method for preparing gutta-percha from eucommia bark comprises the steps of: first cleaning the eucommia bark with clear water; drying until water content of the eucommia bark is less than 5%; crushing the eucommia bark into particles of 10-100 mum; putting the particles into an extracting tank; adding a single solvent petroleum ether for ultrasonic countercurrent extraction; then conducting stage filtering; and finally extracting gutta-percha by a low-temperature gutta-percha crystal precipitation method. The invention has advantages of simple process, little pollution, high yield and low cost; a micro-grinding pretreatment technology and the ultrasonic countercurrent extraction are employed to realize ideal effects with extraction rate higher than 95% and the gutta-percha content reaching 99.9%.

Owner:HENAN HENGRUIYUAN IND

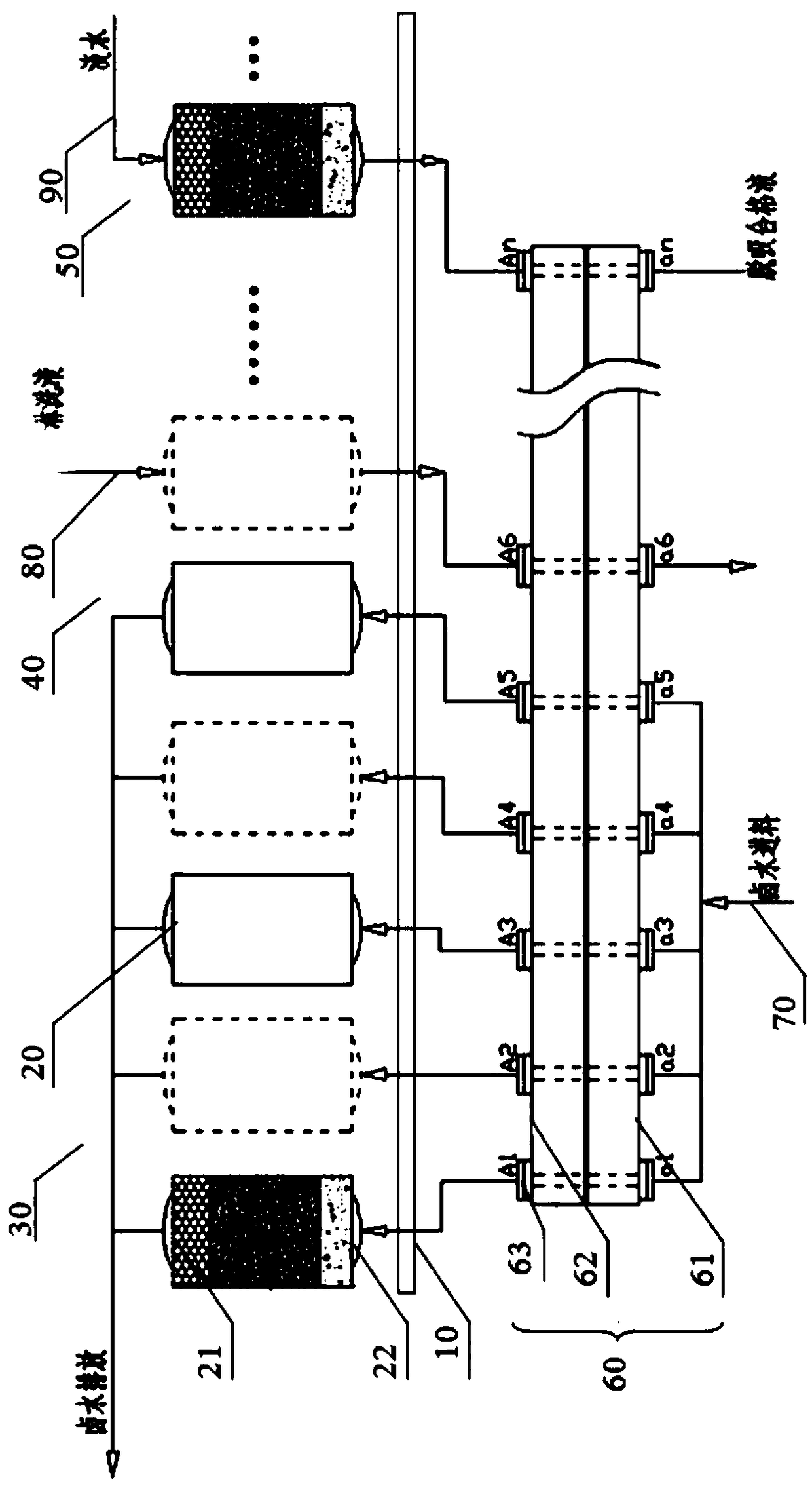

A continuous ion exchange device and lithium extraction process for extracting lithium

ActiveCN107058735BIncrease extraction rateImprove exchange efficiencyProcess efficiency improvementPhysical chemistryIon exchange

Owner:QINGHAI SALT LAKE IND

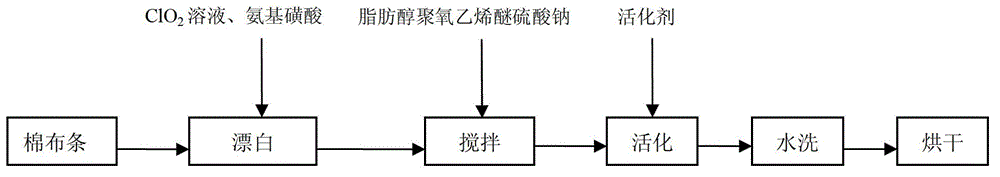

Method for bleaching cotton fabric by chlorine dioxide

InactiveCN103334291AHigh whitenessImprove bleaching effectBleaching apparatusSocial benefitsChlorine dioxide

The invention discloses a method for bleaching a cotton fabric by chlorine dioxide. The method comprises the following operating steps: 1, mixing a chlorine dioxide solution with a sulfamic acid solution according to a volume ratio of 50:1, and uniformly stirring; 2, adding cotton cloth strips to a mixed solution obtained in step 1 for fully immersing the cotton cloth strips, adding fatty alcohol polyoxyethylene ether sodium sulfate, and bleaching at 35-45DEG C through stirring for 2min by a stirrer each 30min when the pH value of the bleaching system is 3-4; 3, adding a 2mol / L activator to a solution obtained 120-150min after the bleaching treatment, and uniformly stirring; and 4, allowing a solution obtained in step 3 to stand for 30min, taking out cloth samples, washing with water, and drying in an oven at 120DEG C for 3-4h. The method has the advantages of bleaching efficiency and technological controllability increase, bleaching time shortening, wastewater treatment cost saving, environmental pollution reduction, and obvious economic and social benefits.

Owner:GUANGXI UNIV

Method of extracting gutta-percha through enzymolysis

Provided is a method of extracting gutta-percha through enzymolysis. One of natural eucommia skin or eucommia leaves or eucommia wing skin is placed in clean water to be cleaned and dried, and moisture content of the eucommia skin, the eucommia leaves, or the eucommia wing skin is enabled to be less than 5%. A compound enzyme which comprises, by mass, 0.27% of cellulose, 0.01% of pectinase, and 0.02% of protease is added, enzymolysis undergoes 1-3 days under stirring at a speed of 500 r / min under 50 DEG C. Mixture after the enzymolysis is filtered, dregs of the filtered mixture are sent to an ultrasonic extraction tank for ultrasound extraction, and glue mixed liquor is produced. The glue mixed liquor is filtered in a grading mode, impurities are eliminated, and the glue mixed liquor with the impurities eliminated is sent to a separation tank. Eventually the gutta-percha is extracted through the method that gutta-percha crystals are precipitated at a low temperature. The method is simple in process, little in pollution, high in yield rate, low in cost, and ideal in effect; the extraction rate reaches more than 95%, and the gutta-percha content reaches 99.9%; and the produced gutta-percha is long in gelatin silk, high in tensile and tearing-proofing physical strength, and capable of being applied to wide fields.

Owner:HENAN HENGRUIYUAN IND

Cleaning agent for industrial copper pipe

The invention relates to a cleaning agent for an industrial copper pipe. The cleaning agent consists of the following components in percentage by mass: 8-22 percent of glycerin monostearate, 10-25 percent of cocamidopropyl betaine, 8-25 percent of methyl acetate, 10-20 percent of 1, 3-dihydroxytoluene-5, 5-dimethylhydantolin, 6-15 percent of N-acylsarcosine sodium, 8-12 percent of polyvinyl butyral, 5-15 percent of coconut oil fatty acid and the balance of deionized water. The cleaning agent is wide in deoiling and decontamination range, capable of being separated from greasy dirt and good in cleaning effect; the cleaning agent can be used for cleaning dirt, such as lubricating oil, metal working fluid and grinding fluid on the surface of the industrial copper pipe; the cleaning agent is high in cleaning capability, high in speed, capable of being reused and free of pollution and has antirust capability. The cleaning agent can be used for rapidly removing dirt on the surface of the industrial copper pipe, cannot corrode the industrial copper pipe, can ensure that the surface of the cleaned industrial copper pipe is smooth and bright, has the cleaning efficiency being greater than 99 percent and has a remarkable effect.

Owner:张萍

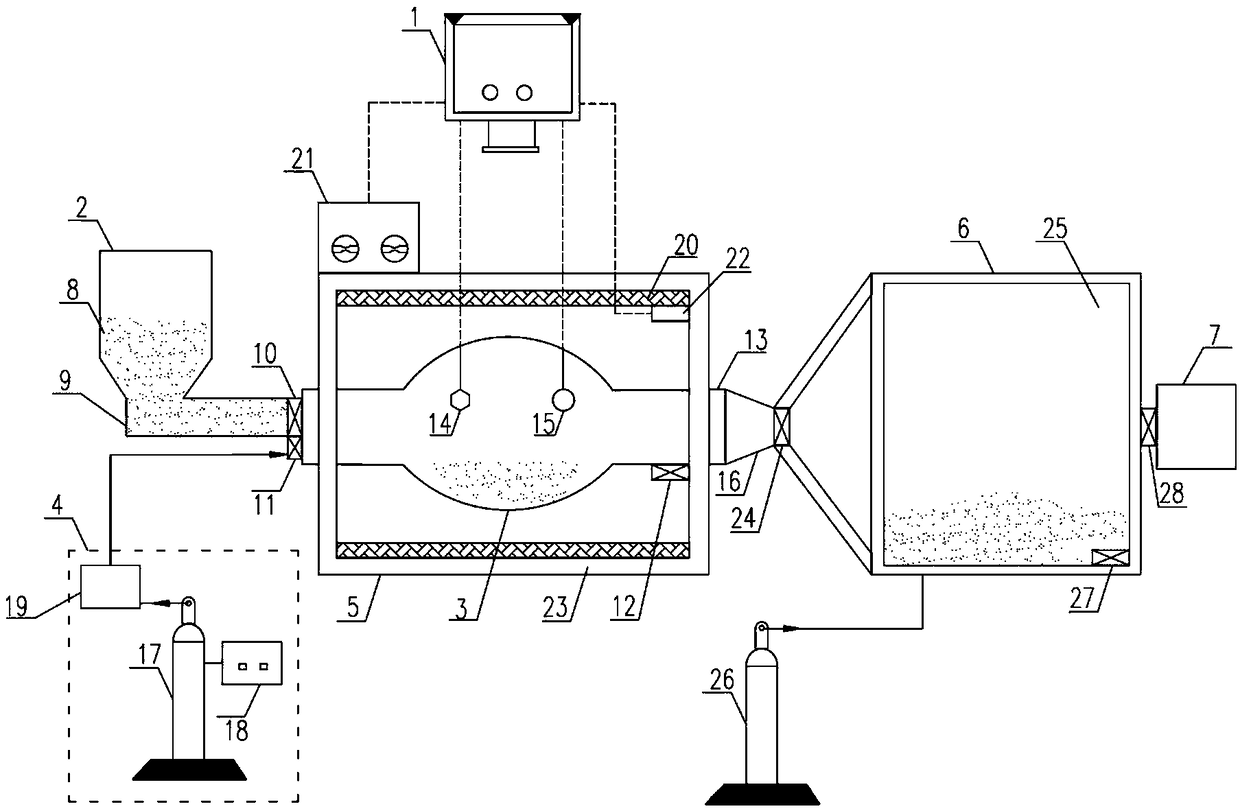

Device and method for rapidly preparing high-yield activated carbon by coupling of pressure pump with microwaves

The invention belongs to the technical field of carbon material preparation and provides a device and a method for rapidly preparing high-yield activated carbon by coupling of a pressure pump with microwaves. The device comprises a programmed controller, a feed unit, a reaction furnace, a pressure pump unit, a microwave heating unit, an explosive spraying and cooling unit and a pyrolysis gas treating unit. Friction and collision of raw material molecules are caused by the microwaves, reaction activation energy is reduced, and the process operation time is shortened greatly. Retention time of volatile matter is prolonged by pressing of the pressure pump, the volatile matter is promoted to be deposited on surface of semi-coke, and accordingly, yield of solid carbon is increased; condensationpolymerization of tar is also promoted by pressing, and production of the tar is reduced substantially or avoided. Besides, pyrolysis gas can be produced from inside of the raw materials by the aid of microwave heating, pyrolysis gas molecules retain in the raw material molecules under the pressing action to play a role of in-situ self-template and shuttle back and forth freely in the raw materials non-directionally to substantially promote pore development of the activated carbon, the instantaneous popcorn effect is beneficial to secondary pore forming of the pyrolysis gas, and the specificsurface area of a carbon material is increased.

Owner:DALIAN UNIV OF TECH

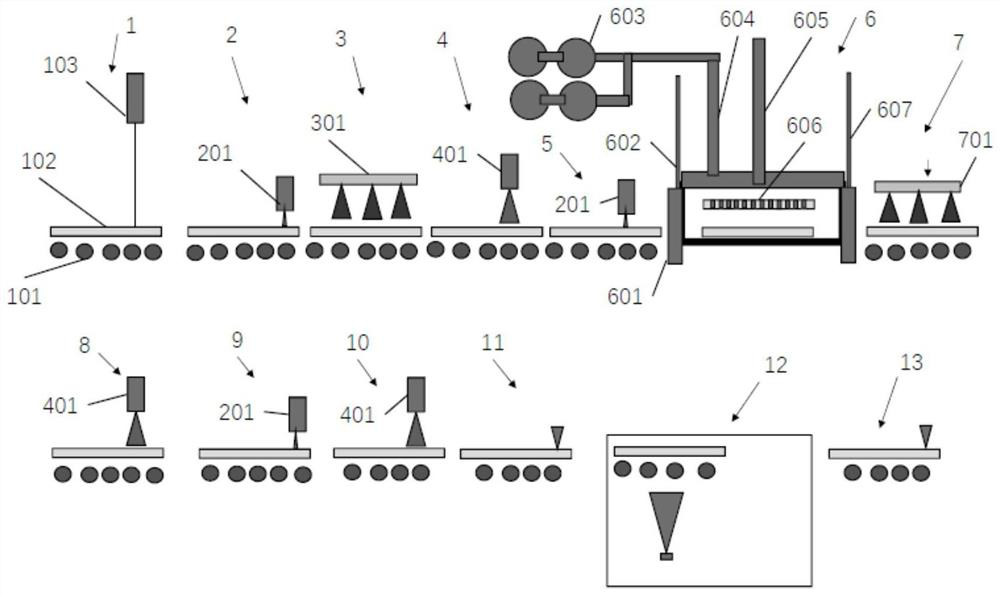

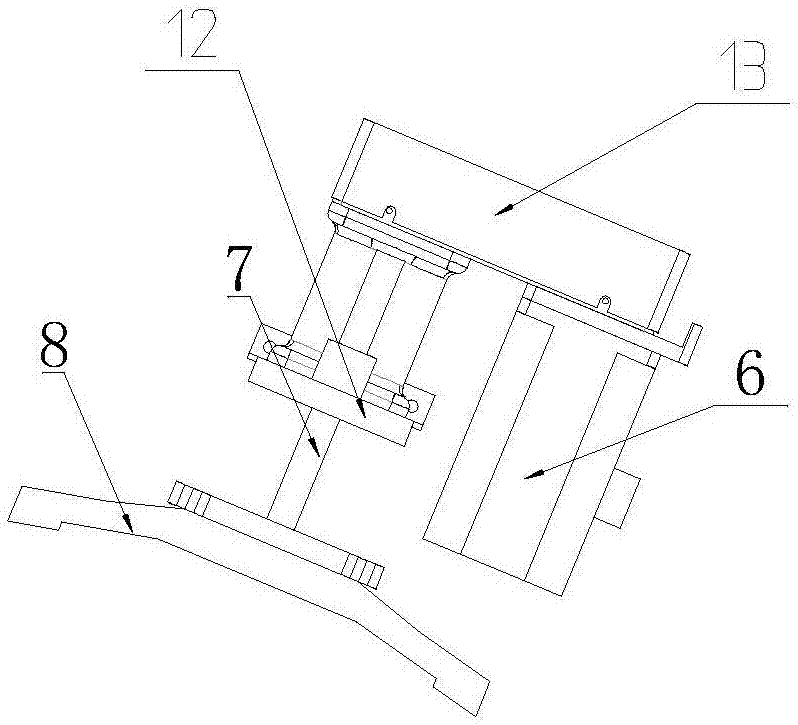

A large-area perovskite solar cell preparation device and preparation method

ActiveCN110349886BEasy to handleRealize large-scale productionFinal product manufactureSolid-state devicesPerovskite solar cellHole transport layer

The invention provides a large-area perovskite solar cell preparation device and preparation method, the device sequentially includes: FTO scribing P1 module, electron transport layer coating module, infrared radiation module, electron transport layer cooling module, perovskite Precursor solution slit coating module, perovskite wet film vacuum distillation module, composite light wave annealing module, perovskite layer cooling module, hole transport layer coating module, hole layer drying module, mechanical scribing P2 module, Electrode evaporation module and mechanical scribing P3 module, wherein the perovskite wet film vacuum distillation module includes: cavity, first transfer gate, second transfer gate, pneumatic piston and multiple sets of parallel booster pump devices, the first transfer The door and the second transfer door are respectively arranged on both sides of the cavity for the passage of the FTO glass carrier, the pneumatic piston is sealed with the cavity, and multiple sets of parallel booster pump devices are connected with the cavity. The present invention can handle the wet film and can Realize the large-scale production of perovskite solar cells.

Owner:YANGZHOU UNIV +2

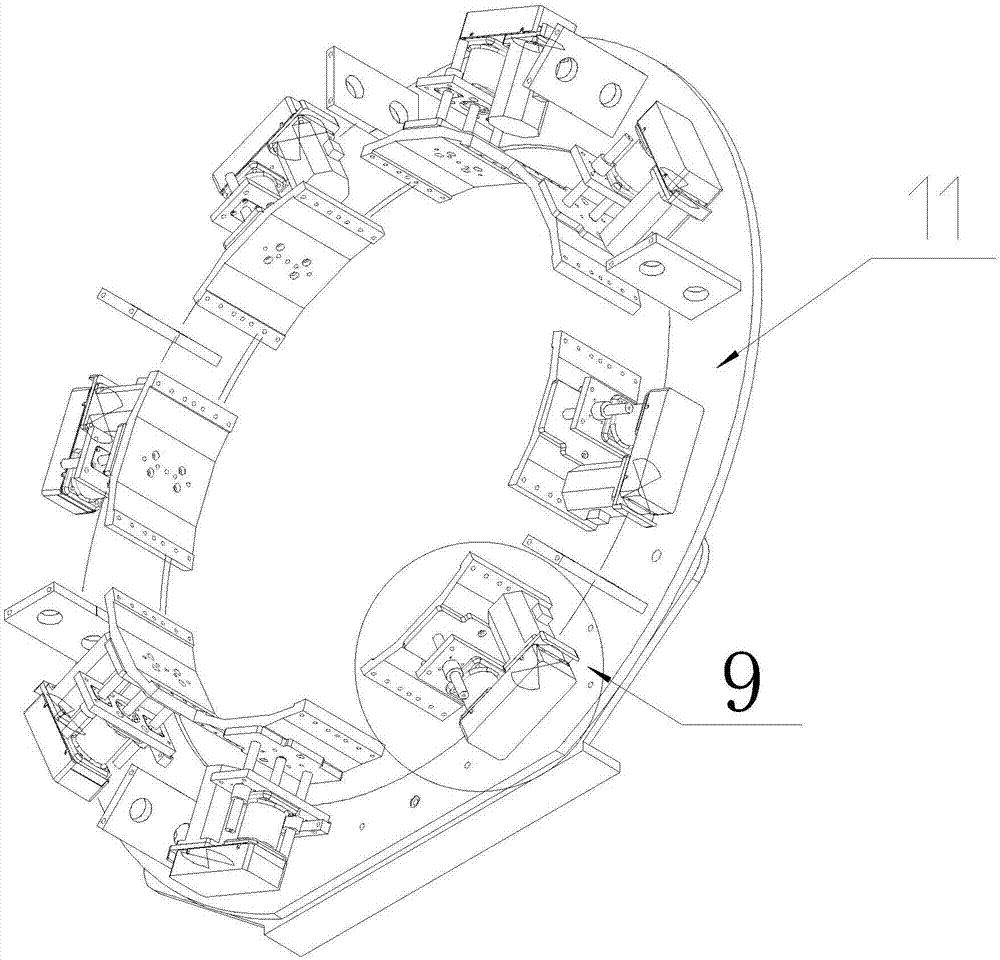

Full-automatic clamping device of tyres

The invention discloses a fully automatic clamping device for tires, which includes a clamping mechanism and an electrical control system. The clamping mechanism includes a plurality of clamping block groups, an annular clamping seat for fixing all the clamping block groups, and The clamping and fixing base is fixedly connected to the bottom plate, and the clamping and fixing base is fixedly installed on the tire building machine through the bottom plate, and each clamping block group includes clamping tiles and drives the clamping tiles to move in a straight line The given tile driving device; the electrical control system connects all the tile driving devices and independently controls the movement of each tile driving device. Each clamping tile of the present invention is independently controlled by the controller, so that the whole device has the characteristics of coaxial self-adaptation, flexible adjustment, good self-adaptability, and greatly improves the production quality and production efficiency of tires.

Owner:HANGZHOU XIANSHUN AUTOMATION TECH

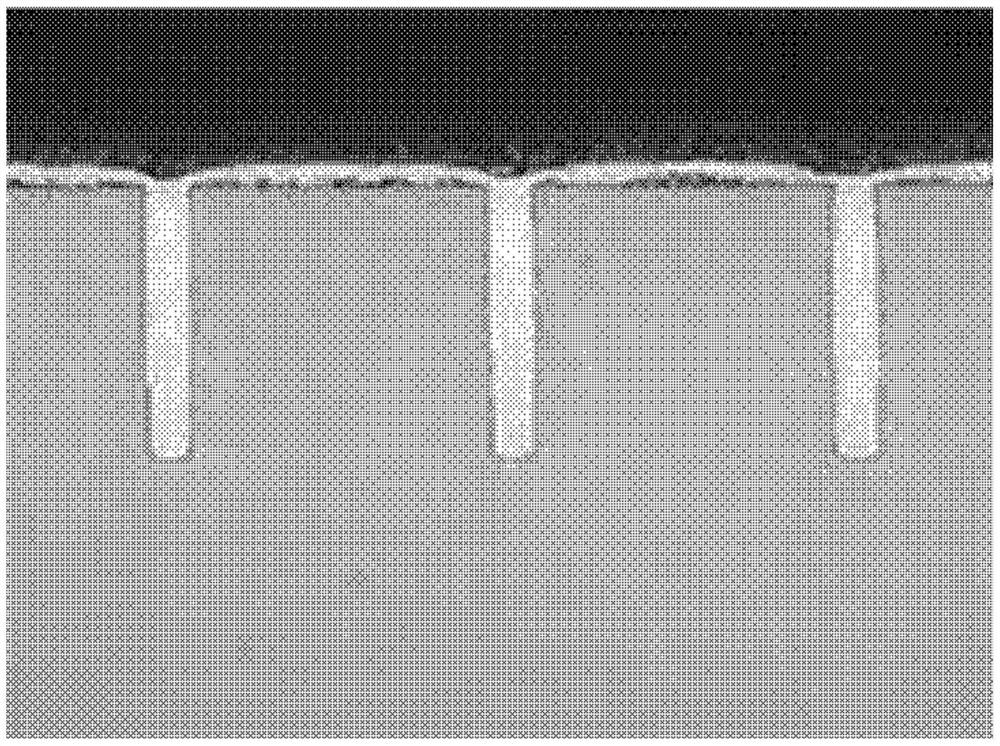

Defect-free filling method of silicon through electrode and copper plating solution used for the filling method

ActiveCN109863261BImprove reliabilityIncrease the first current stepCellsSemiconductor/solid-state device manufacturingCopper platingSilicon

An embodiment of the present invention provides a method for filling a through electrode, which includes the following steps: a step of immersing a through electrode having a through hole in a copper plating solution containing a leveling agent and a copper electrolyte; a first current applying step , applying a first current to coat the leveler on the upper side of the through hole of the through-electrode; a second current applying step, applying a second current lower than the first current, so that the forming a plating film of the copper electrolyte at the bottom of the through hole; a third current applying step, applying a third current higher than the first current, so that the copper electrolyte is filled from above the plating film of the copper electrolyte to the entrance of the through hole.

Owner:KOREA INST OF IND TECH

Automobile production pipe surface cleaning treatment agent

InactiveCN106609377AWide range of degreasing and decontaminationEasy to cleanCetyldimethylbenzylammonium chlorideSurface cleaning

The invention relates to an automobile production pipe surface cleaning treatment agent. The automobile production pipe surface cleaning treatment agent is prepared from, by mass percent, 8%-22% of turpentine, 10%-25% of oxidizing agent thiourea, 8%-25% of sodium lignin sulfonate, 10%-20% of hexadecyl dimethyl benzyl ammonium chloride, 6%-15% of trisodium phosphate, 8%-12% of butyl cellosolve, 5%-15% of benzyltriphenylphosphonium bromide and the balance deionized water. The automobile production pipe surface cleaning treatment agent is wide in oil and dirt removal range, capable of being separated from oil and dirt and good in cleaning effect; lubrication oil, metal processing liquid, grinding liquid and other dirt on the surface of an automobile production pipe can be cleaned away; the cleaning capacity is high, and the speed is high; and the automobile production pipe surface cleaning treatment agent can be repeatedly used and free of pollution and has antirust capacity. Cleaning liquid can fast remove the dirt on the surface of the automobile production pipe, and the automobile production pipe cannot be corroded.

Owner:CHONGQING YIMAN ENVIRONMENTAL PROTECTION EQUIP

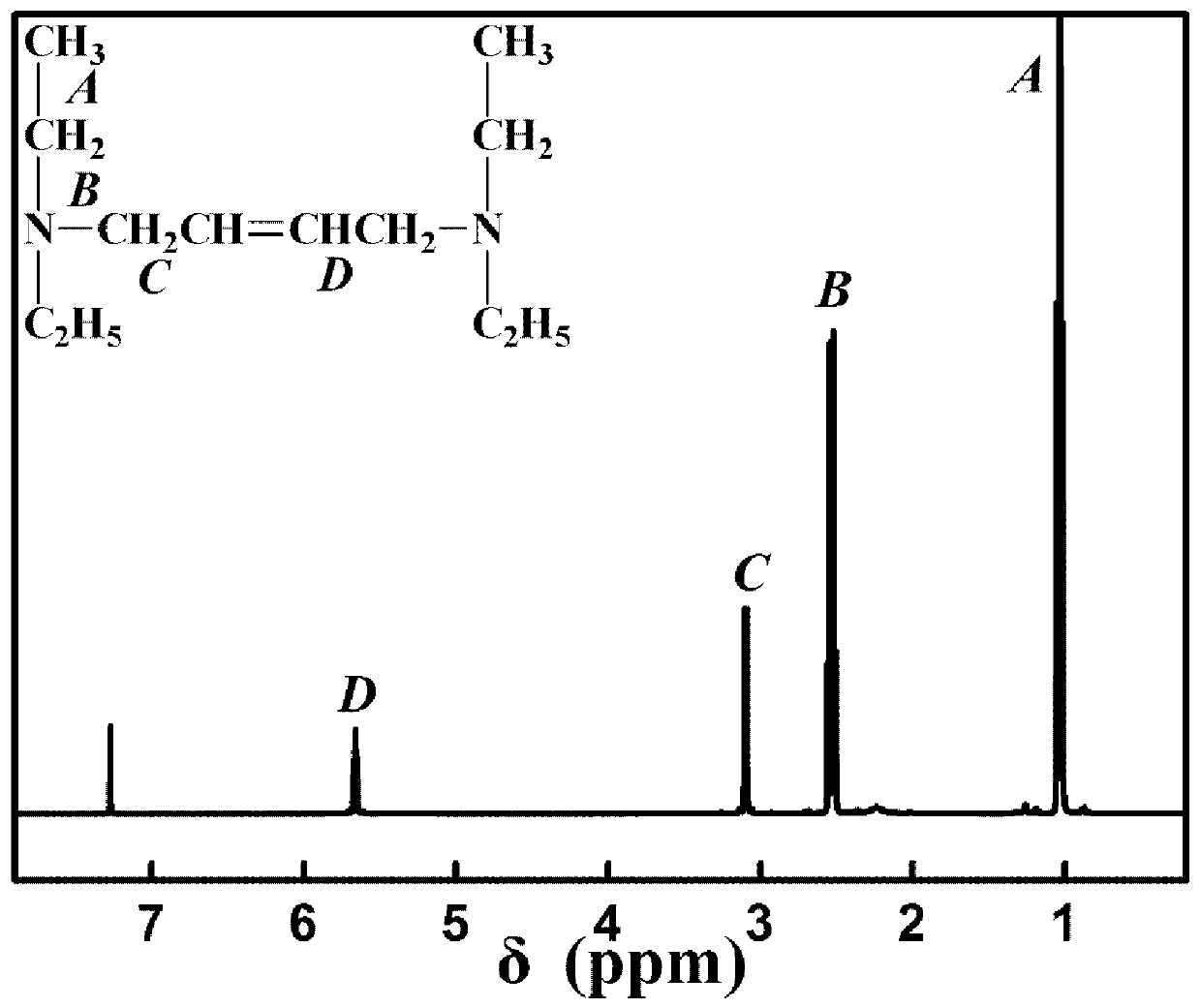

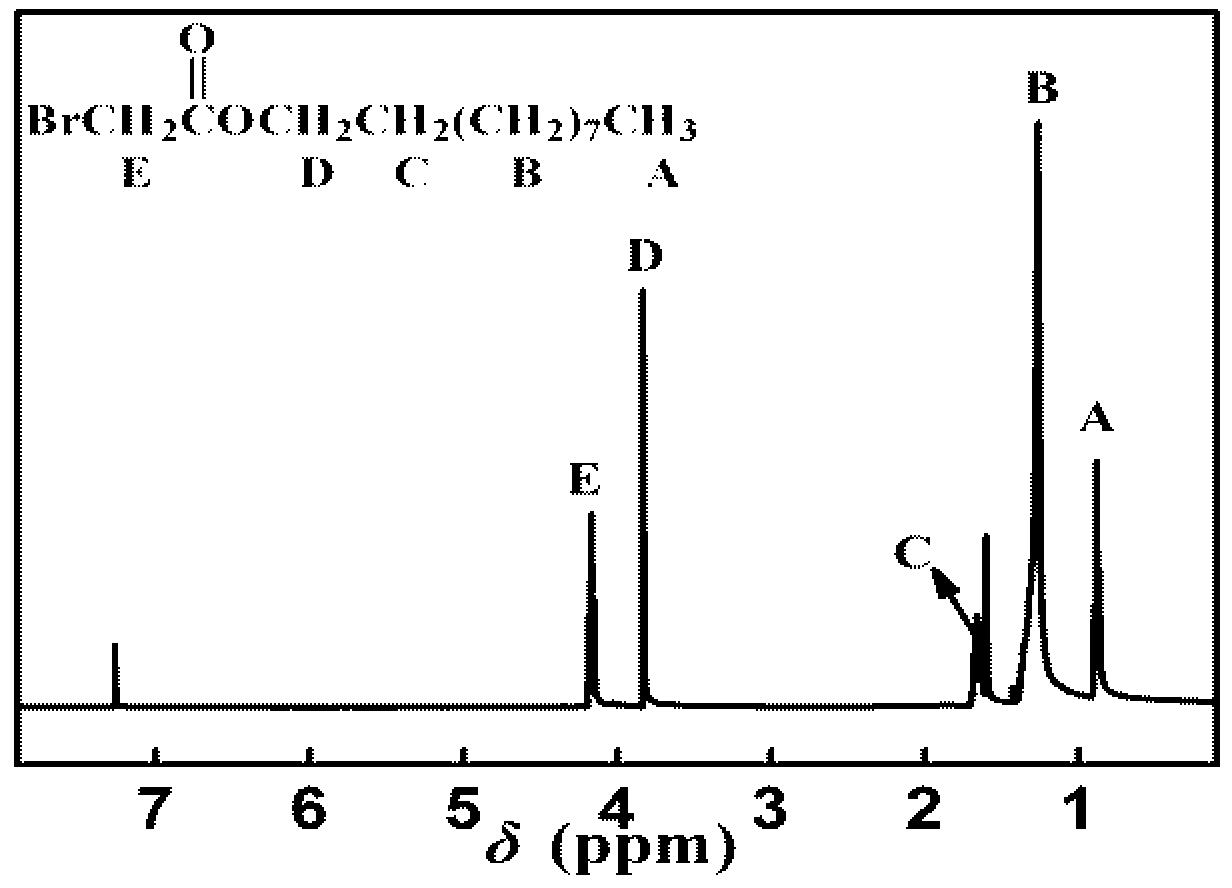

A kind of preparation method of reactive gemini quaternary ammonium salt leather fungicide

ActiveCN107805208BExtended reaction timeLow costBiocidePreparation from carboxylic acid halidesBromoacetic acidFatty alcohol

The invention discloses a preparation method of a reactive gemini quaternary ammonium salt leather bactericide. The preparation method comprises the following three steps: first step, carrying out esterification reaction on bromoacetyl bromide and fatty alcohol to generate bromine acetate; second step, carrying out nucleophilic substitution on trans-1,4-dichloro-2-butene and diethylamine to generate trans-N,N,N',N'-tetraethyl-2-butene-1,4-diamine; and third step, carrying out quaterisation on products obtained from the first two steps to obtain a reactive gemini quaternary ammonium salt. The preparation method is easy to operate, the yield of products is high, the cost of raw materials is low, the practicality is high, and moreover, a method for synthesizing diamine intermediate in the second step provides a new thinking and new method for synthesis of the gemini quaternary ammonium salt. Owing to existing of prepared bactericide molecular structure ester groups, the sterilizing property is improved, and biodegradability can be good. In addition, owing to existing of active groups C=C in the structure, the chemical activity of the gemini quaternary ammonium salt is improved, the gemini quaternary ammonium salt can be further chemically bounded into skin collagen and leather coating resin materials, and the long-lasting sterilizing property can be achieved.

Owner:SICHUAN UNIV

Manufacturing method of ice pack for preserving biological products

ActiveCN103194177BImprove cooling effectImprove bindingHeat-exchange elementsFreezing thawingDissolution

Owner:浙江赛灵特医药科技有限公司

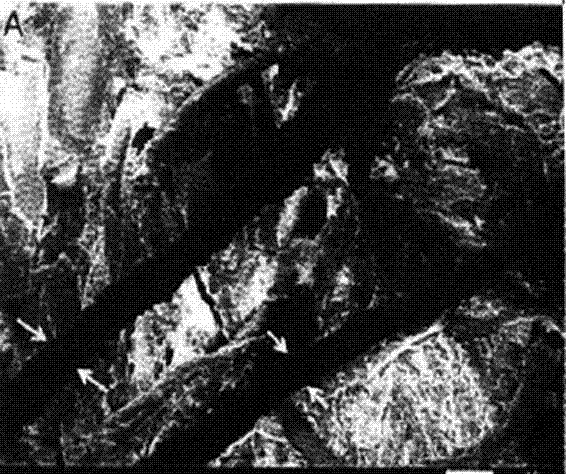

Shell biolobic material phenolic resin and its preparation method

The invention discloses a shell-organism phenol resin and its preparation method. Wherein, using smashed shell-organism active powder to replace some phenol or resorcinol; with formaldehyde and copolymerization reaction, one obtains the said product, which can be used in plastic and other industry, has advantages of no industrial secondary pollution, low cost, etc.

Owner:SOUTHWEST FORESTRY UNIVERSITY

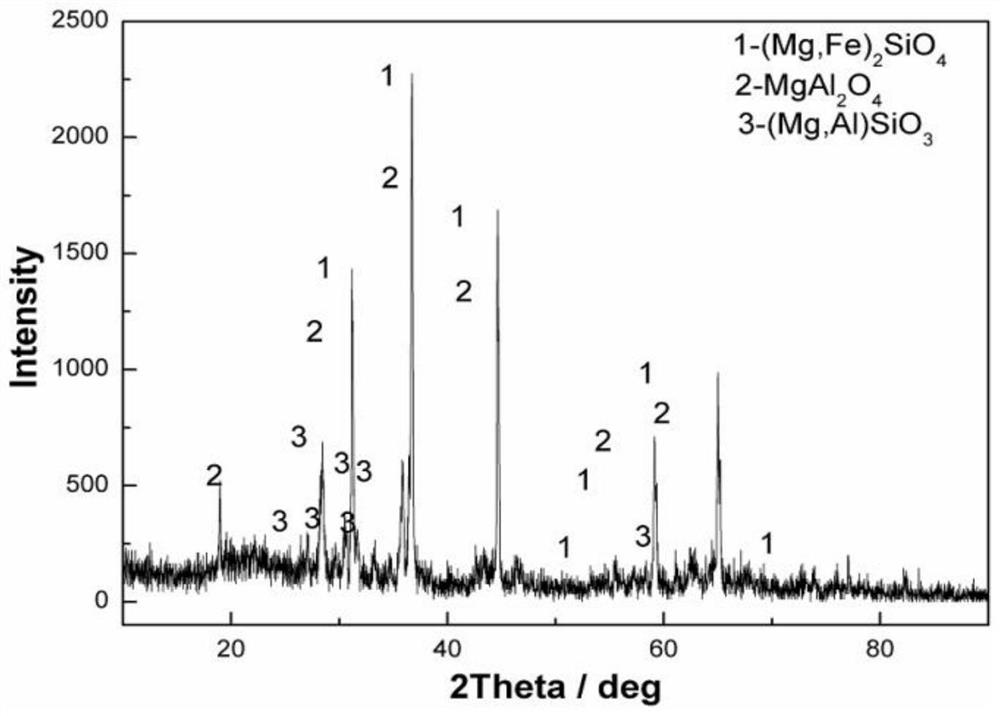

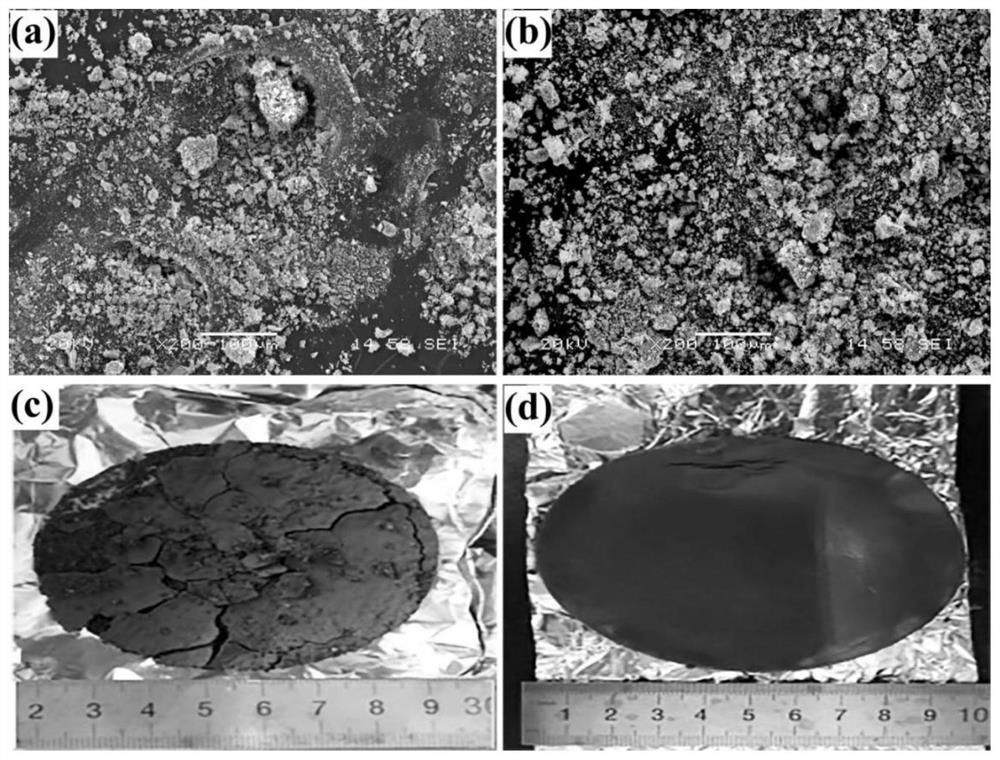

A process for preparing aluminum-silicon solution by dissolution of laterite nickel ore smelting slag

ActiveCN109467101BHigh recovery rateTake advantage ofSolid waste disposalCrystalline aluminosilicate zeolitesMetallurgical slagMetallic aluminum

Owner:UNIV OF SCI & TECH BEIJING

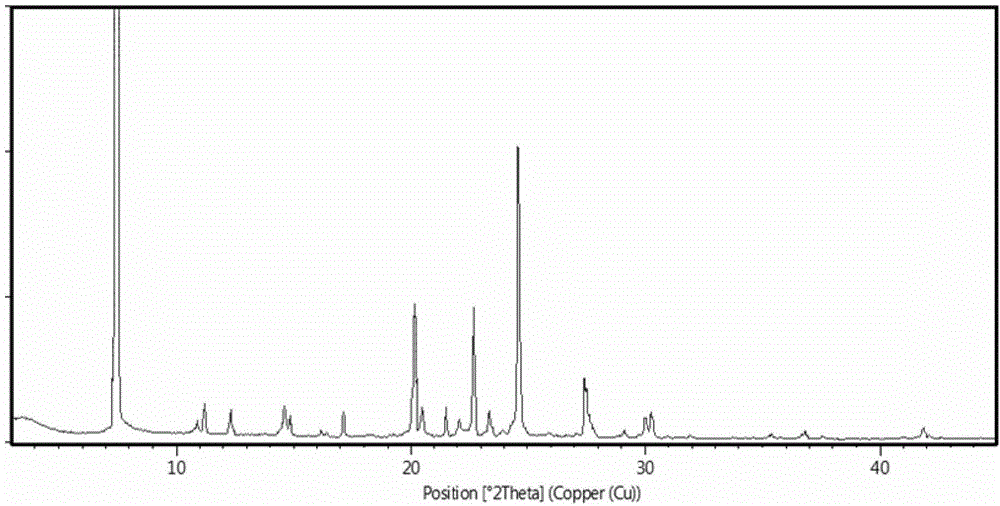

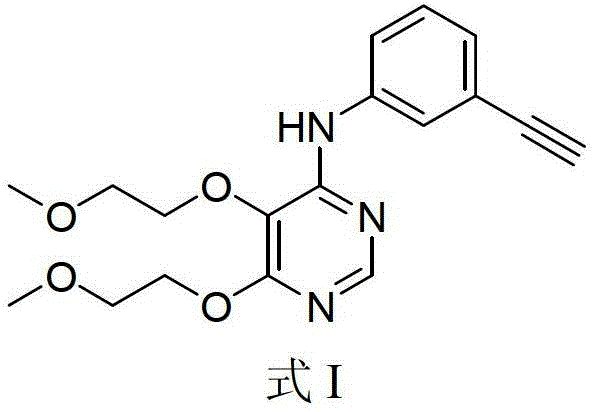

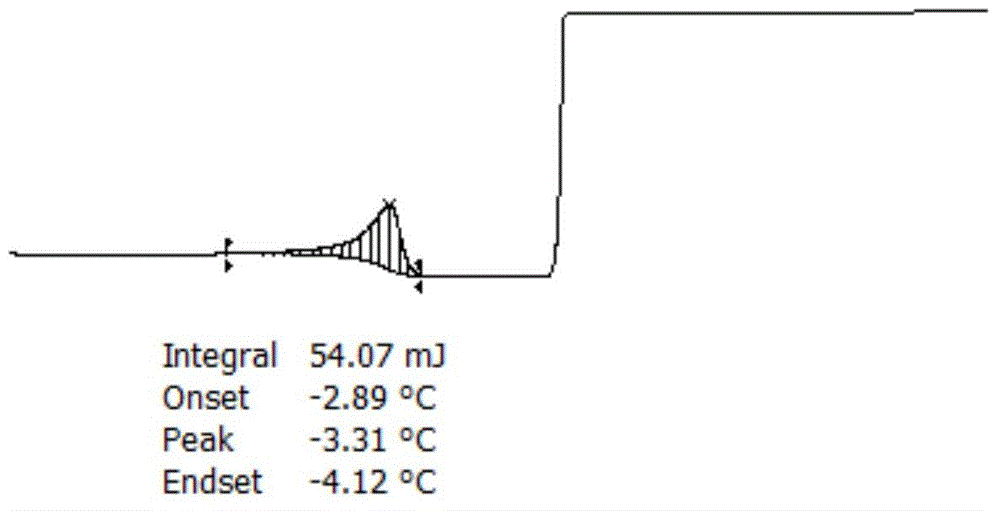

Erlotinib-hydrate crystal form I preparation method

The invention relates to an erlotinib-hydrate crystal form I preparation method. The erlotinib-hydrate crystal form I preparation method comprises the following steps of: naturally cooling an n-butyl alcohol thermal solution containing erlotinib, and reducing temperature and devitrifying to obtain the erlotinib-hydrate crystal form I. The erlotinib-hydrate crystal form I preparation method is safe and simple, has strong operability and is easy for industrial production; an obtained product has the advantages of single crystal form, high purity and good stability; and the method can be used as an erlotinib purification method for preparing high-purity erlotinib hydrochloride.

Owner:QILU PHARMA CO LTD +1

A kind of preparation method of white fabric

ActiveCN107841866BReduce sournessNo sour tasteGrip property fibresVegetal fibresColored whiteWhitening Agents

The invention relates to a preparation method of a white fabric. The method is characterized by oxygen bleaching and whitening a fabric containing cotton, and comprises the steps of adding a one-bath-one-step method bleaching solution (prepared from 1 to 2g / L of penetrating agent, 1 to 2g / L of anti-creasing agent, 2 to 7 percent (owf) of scutching agent, 2 to 9 percent (owf) of 40 percent by weight caustic soda solution, and 3 to 6 percent (owf) of 30 percent by weight hydrogen peroxide solution) with pH being 10 to 11 into the fabric for oxygen bleaching, then adding a fluorescent whitening agent for whitening, heating at a constant heating rate to 80 to 90 DEG C, carrying out insulation treatment, and cleaning, neutralizing and setting to obtain the white fabric. According to the method,a step of removing hydrogen peroxide is saved, so that the process time can be greatly saved, the water consumption is reduced, and the emission of noxious substances is reduced; the prepared white fabric is free of acidity and less in storage color change, and has a pH value stabilized in an acceptability limit from 5.5 to 7.0, and the whiteness improved by 1 to 2 or more compared with a traditional process; when preparing the white fabric with the same whiteness, the dosage of the fluorescent whitening agent can be saved by 10 to 40 percent, so that the economic benefits of enterprises canbe greatly improved.

Owner:PACIFIC (PANYU) TEXTILES LTD

Industrial cold-rolled pipe cleaning solution

The invention relates to an industrial cold-rolled pipe cleaning solution. The industrial cold-rolled pipe cleaning solution is composed of, by mass, 8-22% of 1,3-diol dimethacrylate, 10-25% of urotropine, 8-25% of thiofurfura, 10-20% of citrus oil, 6-15% of sodium metasilicate pentahydrate, 8-12% of dodecyl benzyl dimethyl ammonium chloride, 5-10% of nipagin and the balance deionized water. The cleaning solution is wide in oil removing and dirt removing range, capable of being separated from oil and dirt and good in cleaning effect; the cleaning solution can be used for removing lubrication oil, metal processing liquid, grinding fluid and other dirt on the surfaces of cold-rolled pipes; the cleaning capability is high, and the speed is high; the cleaning solution can be repeatedly used, is free of pollution and has the anti-rusting capability. The cleaning solution can quickly remove the dirt on the surfaces of the industrial cold-rolled pipes and cannot corrode the industrial cold-rolled pipes, the cleaned surfaces of the industrial cold-rolled pipes can be smooth and bright, the cleaning efficiency is higher than 99%, and the effect is obvious.

Owner:杨高林

Process method for producing large size sculpture through resin sand removable-flask moulding

ActiveCN103658523BReduce dosageReasonable designFoundry mouldsFoundry coresManufactured materialSteel frame

The invention relates to casting process, in particular to a process method for producing large size sculpture through resin sand removable-flask moulding. The method comprises the following technological processes: model receiving, cutting, strengthening, model placing and gating system designing, netty steel frame welding, modeling, mode dissembling, mold assembling, strengthening, pouring, sand cleaning and the like. The method is mainly characterized in that steel frames with different sizes are welded according to the sizes of casting models, and the profile-followed steel frames can be welded according to the different shapes of casting models, so that the steel frames can be reused, and the consumption of resin sand can be greatly reduced during modeling due to the welded profile-followed steel frames; the layer surface of sand is thinner, and the operation time of the whole process is shortened, so that the raw materials are saved, the production efficiency is improved, and the whole production cost is greatly reduced.

Owner:SHANXI YUDA GRP

Method for preparing low-temperature-resistant palm oil with high iodine value

ActiveCN103614239BReduce consumptionImprove separation efficiencyFatty-oils/fats separationWastewaterSolvent

The invention relates to a method for preparing low-temperature-resistant palm oil with high iodine value. The method comprises the following steps: (1) heating palm oil with iodine value higher than 60 at a temperature of 60-80 DEG C while stirring to completely dissolve the palm oil, then, cooling to minus 10 to 0 DEG C, and maintaining the temperature; heating up to 3-6 DEG C and maintaining the temperature; cooling to 4-8 DEG C and maintaining the temperature; and (2) transferring the palm oil obtained in the step (1) into separation equipment, centrifugally separating the palm oil at minus 15 to minus 5 DEG C until the grease is divided into a solid phase and a liquid phase, and extracting the liquid phase to obtain a palm oil product. The method for preparing low-temperature-resistant palm oil with high iodine value provided by the invention can be used for obtaining low-temperature-resistant palm oil product with iodine value higher than 75. Since such novel substances as a crystallization inhibitor, a crystallization solvent and the like are not introduced into the method provided by the invention, the separation efficiency and the separation effect are improved and the operation time of the process is greatly shortened; and no wastewater is generated in the process, the safety is good, the energy consumption in the process is low and the quality of the final product is good, so that the application prospect is wide.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com