Full-automatic clamping device of tyres

A clamping device and fully automatic technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of low adjustment flexibility, poor dynamic stability, and high calibration requirements, and achieve precise control, low production cost, and easy mastering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

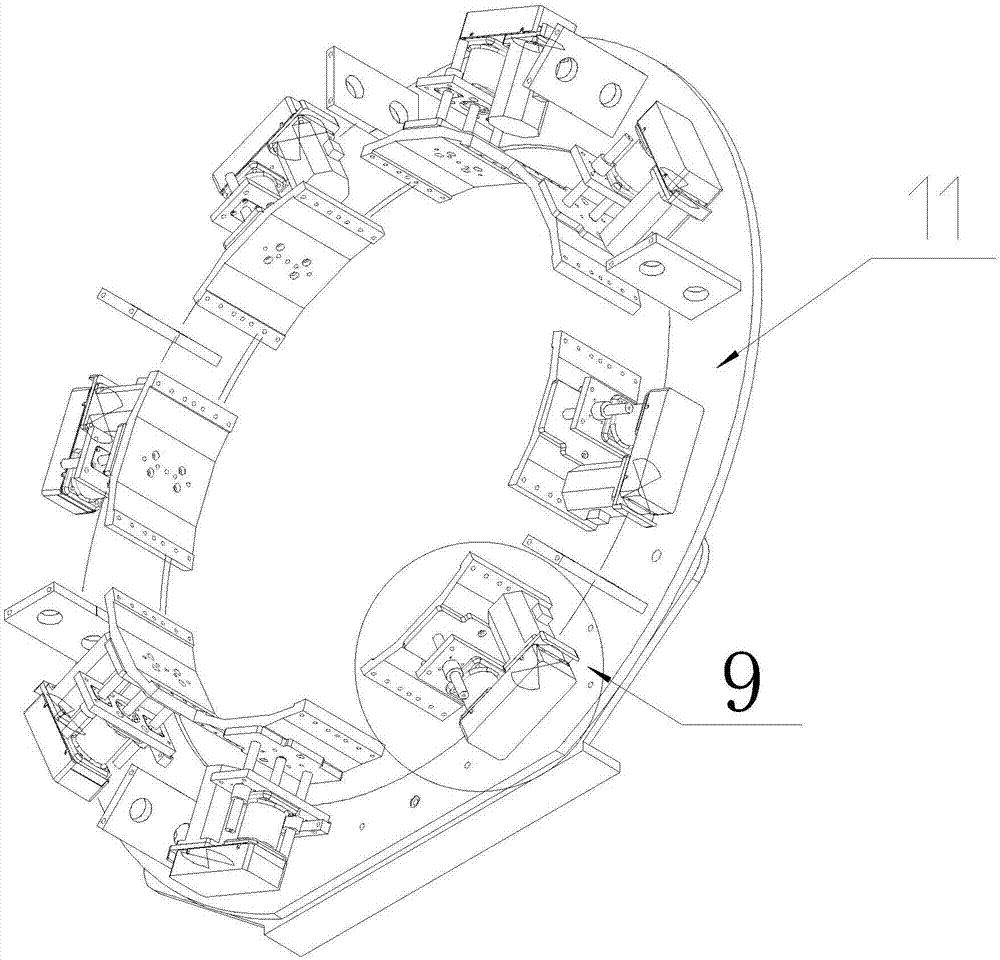

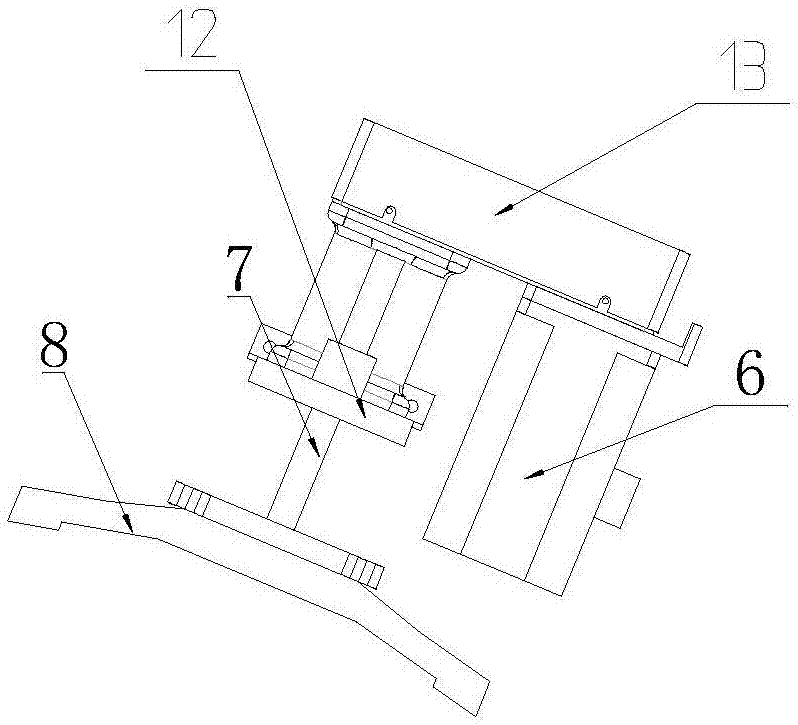

[0026] Such as Figure 1~3 As shown, a tire automatic clamping device of the present invention includes a clamping mechanism 2 and an electrical control system. The clamping and fixing base 11 and the base plate 5 fixedly connected with the clamping and fixing base 11, the clamping and fixing base 11 is fixedly installed on the tire building machine through the base plate 5, and each clamping block group 9 includes clamping The tile 8 and the tile driving device that drives the clamping tile 8 to feed linearly; the electrical control system connects all the tile driving devices and independently controls the movement of each tile driving device. Since the motor control system controls each tile driving device to move independently, all the tile driving devices are not linked, so it can better adapt to tires of different sizes during the clamping process, so that the tire a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com