Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Improve processing depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbial sand-fixing dust depressor and preparation method thereof

InactiveCN103820123AFast solutionSmall sizeOther chemical processesOrganic fertilisersAging resistanceChloride

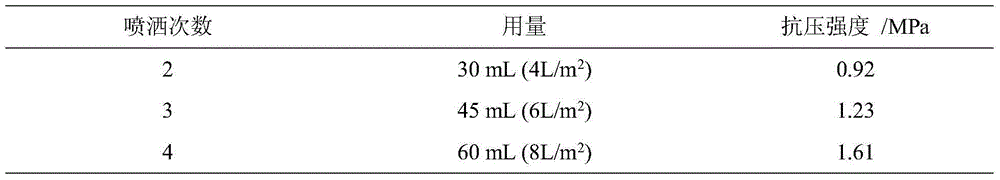

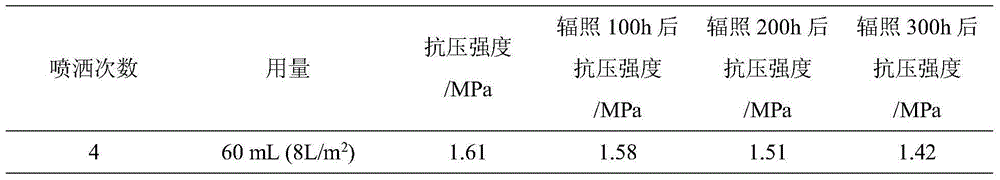

The invention provides a microbial sand-fixing dust depressor and a preparation method thereof. The microbial sand-fixing dust depressor comprises the following components in percentage by mass: 0.8-2.5% of microbial powder, 3.0-5.0% of urea, 8.1-10.1% of calcium chloride and the balance of deionized water, wherein the microorganism in the microbial sand-fixing dust depressor is bacillus pasteurii powder. The preparation method comprises the following steps: proportionally mixing the calcium chloride with the deionized water, stirring till the calcium chloride is completed dissolved, adding the urea, and after the urea is dissolved, adding the bacillus pasteurii powder till the bacillus pasteurii powder is completely dissolved, thereby obtaining a mixed solution, namely the microbial sand-fixing dust depressor. Compared with the traditional inorganic sand-fixing agent, the microbial sand-fixing dust depressor is high in permeability; compared with the traditional organic sand-fixing agent, the microbial sand-fixing dust depressor has the characteristics of high ageing resistance, simplicity in preparation, convenience in construction and the like. Proved by desert sample tests, the sand-fixing dust depressor is high in ageing resistance and wind erosion resistance and has unconfined compressive strength higher than 1MPa. Proved by raise dust sample tests, the sand-fixing dust depressor has a good dust fixing effect.

Owner:SOUTHEAST UNIV

Catalytic ozonation reactor for treatment of external circulating wastewater and wastewater treatment method

ActiveCN104478066AImprove processing depthEmission complianceWater treatment compoundsWater/sewage treatment apparatusExhaust gasSewage

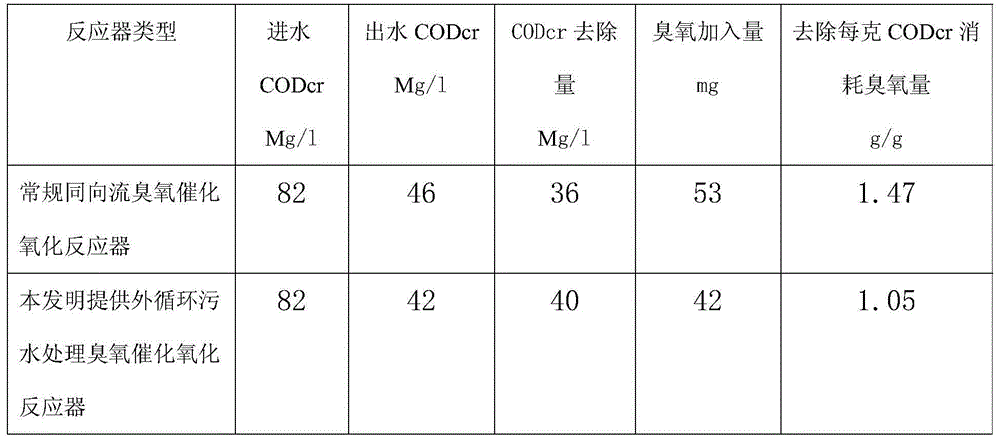

The invention discloses a catalytic ozonation reactor for treatment of external circulating wastewater. A tail gas pipe and a wastewater outlet pipe are arranged on a reactor, and are provided with reflux pipes; a tail gas reflux pipe and a wastewater reflux pipe are respectively communicated to a gas-phase inlet and a water-phase inlet of a water ejector; and an outlet of the water ejector is communicated with the inside of a reactor through a pipeline. The invention also discloses a wastewater treatment method. By virtue of the catalytic ozonation reactor for treatment of the external circulating wastewater, processed wastewater and tail gas are refluxed; and the ozone dissolved in the wastewater and the residual ozone in the tail gas are fully utilized to carry out catalytic oxidization reaction again, so that the wastewater treatment depth is improved; the ozone utilization rate is greatly improved; and the wastewater treatment depth is improved.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

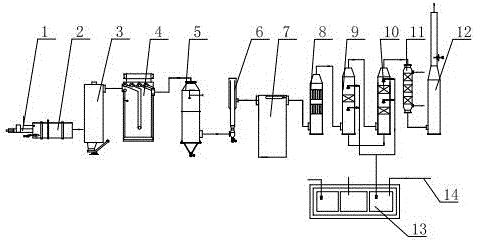

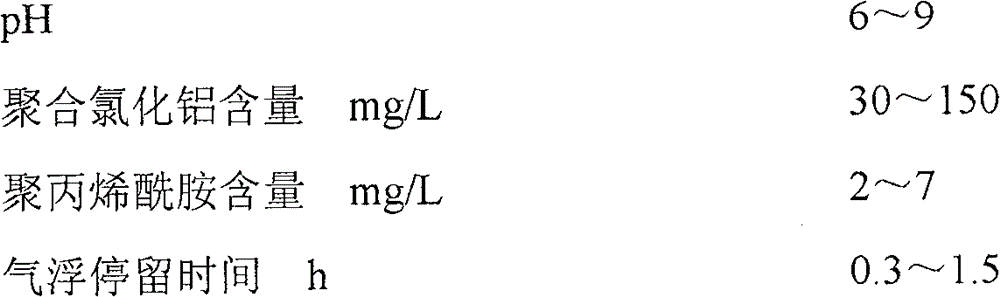

Method for deep treatment on industrial wastewater discharged by styrene-butadiene rubber production device

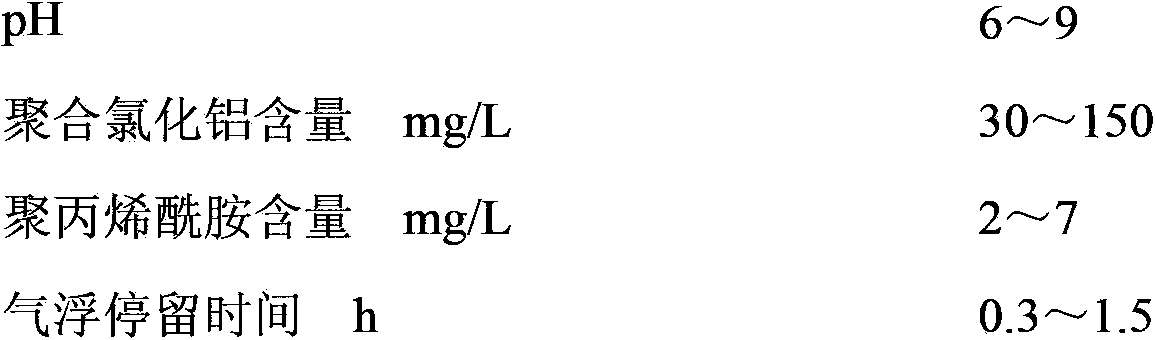

ActiveCN103723878AEasy maintenance and operationLow running costMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationTreatment effectFiltration

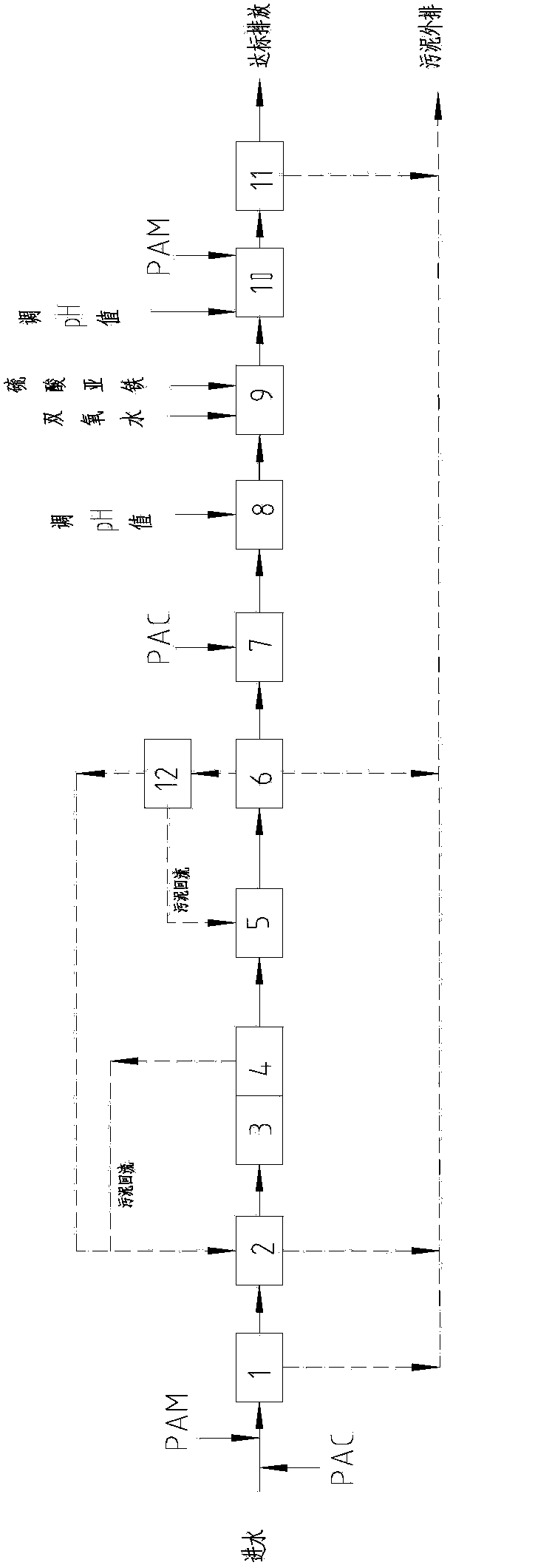

The invention relates to a method for deep treatment on industrial wastewater discharged by a styrene-butadiene rubber production device and belongs to the field of wastewater multilevel treatment. Water treatment devices such as a pre-treatment unit, a sludge adsorption unit, an aerobic biochemical treatment unit, a flocculation and filtration unit and a high-grade oxidation treatment unit are orderly connected and combined; and discharged wastewater treated by the above water treatment devices has COD less than or equal to 40mg / L and NH3-N less than or equal to 5mg / L. The method solves the problem that the prior art has a high treatment cost and poor treatment effects, is a deep treatment method having the advantages of stable, safe and reliable operation, high pollutant removal rate and low operation cost, and realizes stable and standard discharge of industrial wastewater produced by a styrene-butadiene rubber production device. Compared with the prior art, the method reduces a high-grade oxidation phase Fenton's reagent use amount by about 30%, improves treatment depth by 15% and has an industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP

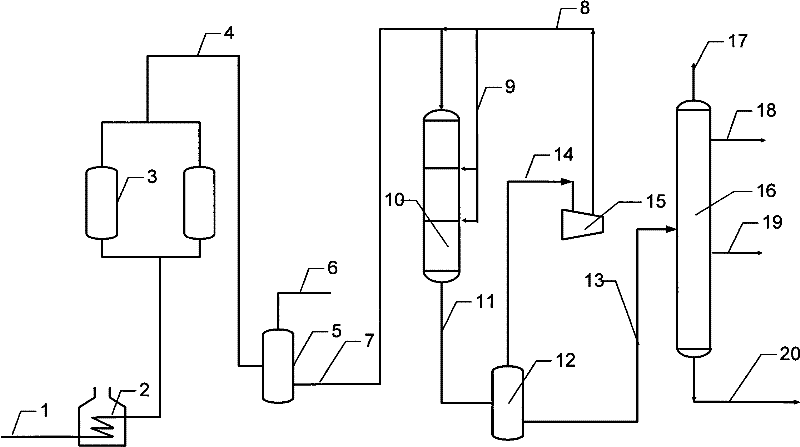

Process for preparing 1-amylene by separating C5 distillate of petroleum

ActiveCN101289362AHigh economic valuePerfect comprehensive utilization meansDistillation purification/separationPentenePetroleum

The invention discloses a method which is used for preparing 1-pentene by separating petroleum C5 fraction and takes raffinate C5 obtained after separating diolefin and isoamylene by extracting as raw materials. The process comprises that the raw materials are extracted and distilled, and the extractant is N and N-dimethylformamide, the feeding weight ratio of the raw materials and the extractant is 1:5 to 1:12, C5 saturated hydrocarbon materials are discharged from a column top, and the materials richly containing 1-pentene and the extractant are obtained in a column bottom; the materials in the column bottom obtained in the process 1 are distilled so as to recycle the extractant, the materials richly containing 1-pentene are obtained in the column top, the extractant is obtained in the column bottom, and the extractant can be recycled; the materials in the column top obtained in the process 2 are distilled and separated so as to remove heavy components, the crude product of 1-pentene are obtained from the column top, and the materials with heavy components are discharged from the column bottom; and the crude product of 1-pentene obtained in the process 3 is distilled and refined so as to remove light components, the materials in the column bottom are taken and a refined product of 1-pentene is obtained. By processing at a much deeper degree, the method of the invention solves a technical problem that 1-pentene in C5 fraction can not be utilized by the prior art.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

Process for preparing 2-amylene by separating C5 distillate of petroleum

ActiveCN101289360AImprove processing depthHigh economic valueDistillation purification/separationChemistryPentene

The invention discloses a method which is used for preparing 2-pentene by separating petroleum C5 fraction and takes raffinate C5 obtained after separating diolefin and isoamylene by extracting as raw materials. The process comprises that the raw materials are distilled and separated so as to remove light components, and the materials with light components are discharged from a column top and materials richly containing 2-pentene are obtained in a column bottom; the materials in the column bottom obtained in the process 1 are extracted and distilled, and the extractant is N and N-dimethylformamide, and the feeding weight ratio of the materials and the extractant is 1:5 to 1:12, C5 saturated hydrocarbon materials are discharged from the column top, and materials richly containing 2-pentene and the extractant are obtained in the column bottom; the materials in the column bottom obtained in the process 2 are distilled so as to recycle the extractant, and a crude product of 2-pentene is obtained in the column top, the extractant is obtained in the column bottom and the extractant can be recycled to use; and the crude product of 2-pentene obtained in the process 3 is distilled and refined so as to remove heavy components, materials in the column top are taken and a refined product of 2-pentene is obtained. By processing at a much deeper degree, the method of the invention solves a technical problem that 2-pentene in C5 fraction can not be utilized by the prior art.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

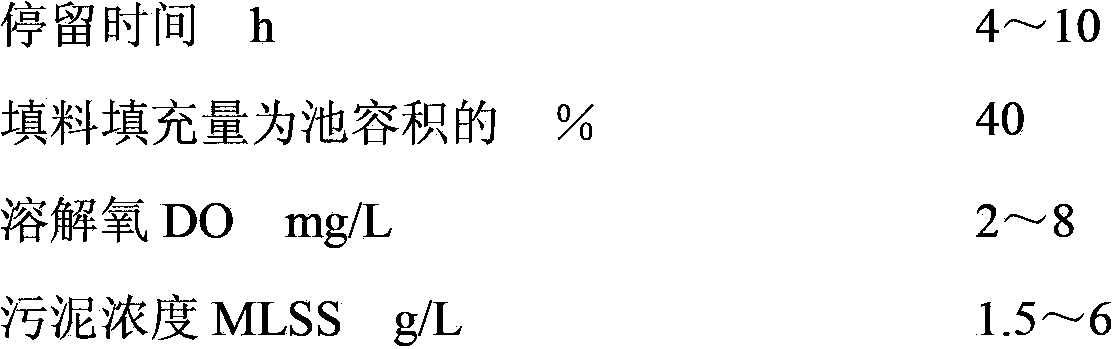

Method for cryogenic cooling absorbing-regenerative oxidation recovery and treating oil air

InactiveCN101028577AReduce the temperatureImprove recycling efficiencyDispersed particle separationResource utilizationSmall footprint

A method for recovering and treating the oil vapor generated during loading or unloading light oil by low-temp cooling-absorbing and oxidizing by accumulated heat includes such steps as absorbing the raw oil vapor by absorbing liquid and filler layer in absorption tower, heating in heat-accumulating oxidizing unit, high-temp oxidizing for decomposing to release a lot of heat, cooling by heat-accumulating bed, exhausting, and refrigerating by accumulated heat for cooling the absorbent.

Owner:TSINGHUA UNIV +1

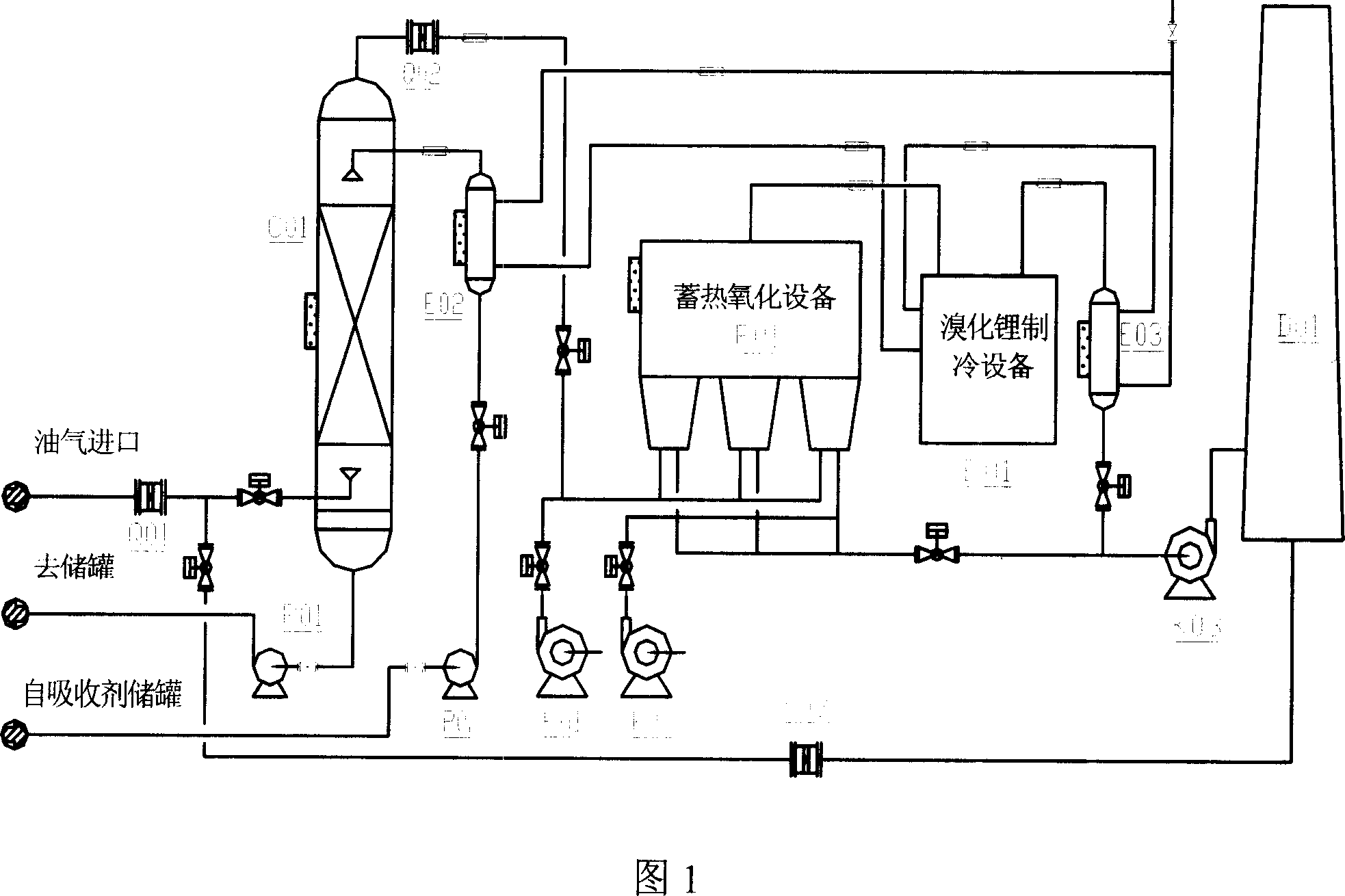

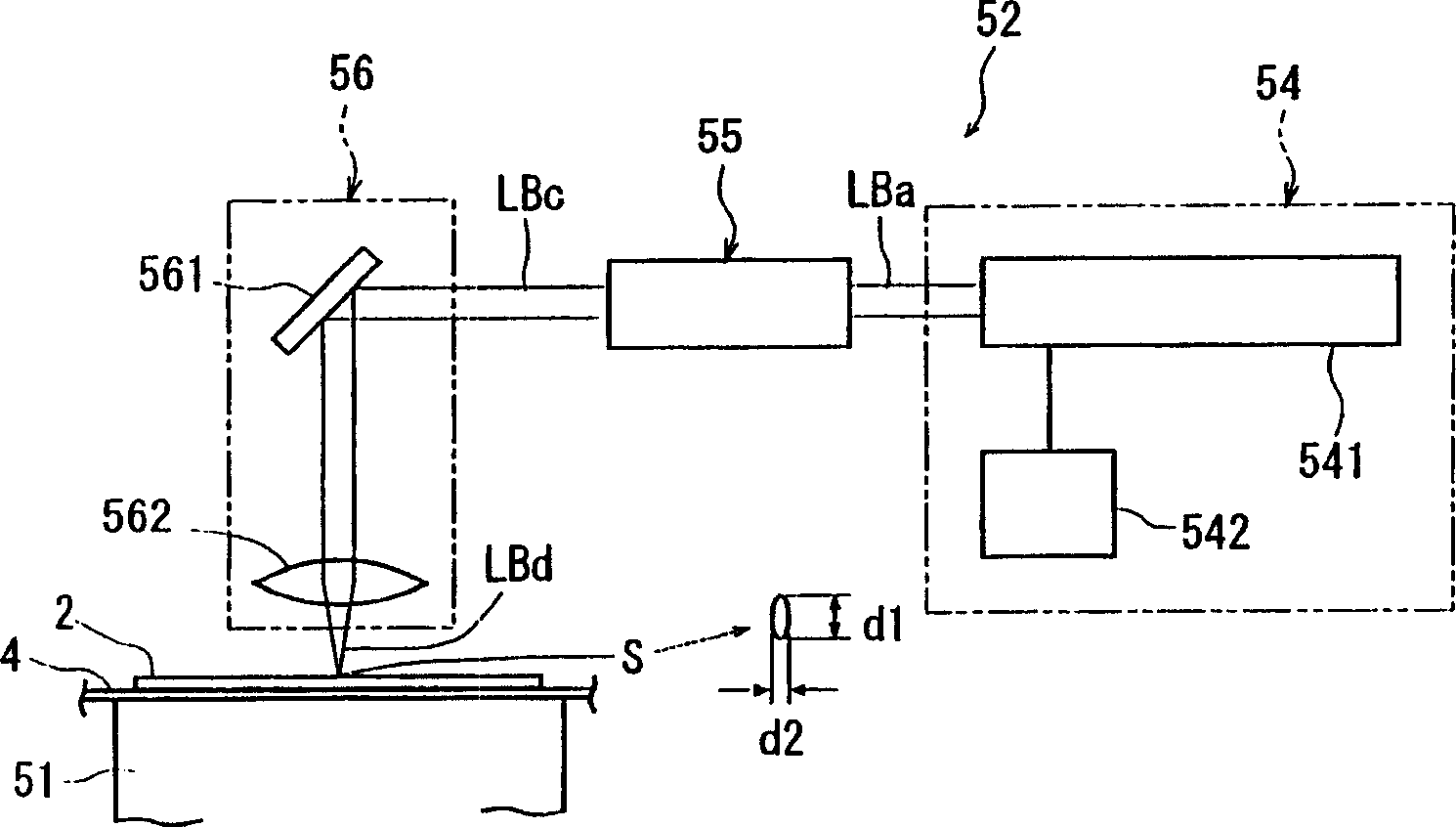

Beam splitting double-focus-point laser processing head

ActiveCN104801852ALower requirementMeets high energy density requirementsLaser beam welding apparatusLaser processingBeam splitting

The invention provides a beam splitting double-focus-point laser processing head, which comprises a light path cavity, a cavity connecting box, a servo motor and an external connecting flange, wherein the light path cavity is connected with an output shaft of the servo motor through a shaft coupler, a beam splitting mirror, a first reflecting mirror, a second reflecting mirror, a third reflecting mirror, a focusing mirror and two telescopic sleeves are arranged inside the light path cavity, the beam splitting mirror and the first reflecting mirror are respectively and fixedly arranged on the side wall of the light path cavity through a regulating mirror seat, the second reflecting mirror and the third reflecting mirror are respectively arranged on the telescopic ends of the two telescopic sleeves through a regulating mirror seat, and the fixing ends of the telescopic sleeves are arranged on the side wall of the light path cavity. The beam splitting double-focus-point laser processing head has the advantages that an incident laser beam is subjected to space beam splitting, the front focusing point and the back focusing point are realized, the relative space position between the double light beam focusing points is changed, the utilization efficiency of laser energy is improved, the laser welding plasma shielding effect can be effectively inhabited, the processing depth is improved, and the laser processing quality is improved.

Owner:WENZHOU UNIVERSITY

Laser processing method

InactiveCN1733415AImprove processing depthSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingLong axis

A laser processing method for forming a laser groove along dividing lines by applying a pulse laser beam along the dividing lines formed on a workpiece, the method comprising the steps of forming the focusing spot of the pulse laser beam in a shape of oval, positioning the long axis of the oval focusing spot along each of the dividing lines, and moving the focusing spot and the workpiece along the dividing line relative to each other.

Owner:DISCO CORP

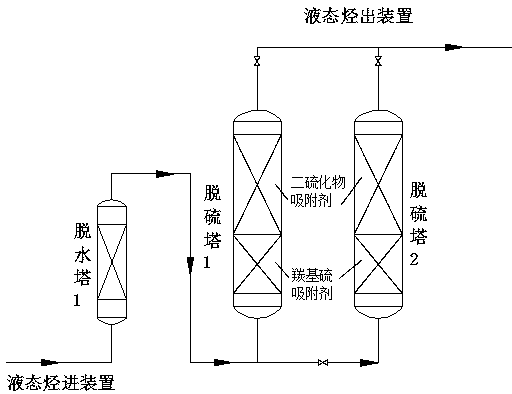

Deep desulfurization technology of refinery liquefied petroleum gas

InactiveCN103614178AImprove processing depthQuality improvementGaseous fuelsCarbonyl sulfideLiquid hydrocarbons

The invention relates to a deep desulfurization technology of a refinery liquefied petroleum gas. The technology is characterized in that an efficient selective adsorbent is used to adsorb and remove sulfides in liquid hydrocarbon or mixed C4 obtained after the mercaptan removal in a refinery in order to realize recycle. The technology selects an appropriate adsorbent to adsorb and remove carbonyl sulfide in the liquid hydrocarbon or the mixed C4 and then to remove disulfide in the liquid hydrocarbon or the mixed C4 in order to realize the deep desulfurization. The total sulfur content in the liquid hydrocarbon or the mixed C4 obtained after processing through the technology reduces to 0-20mg / m<3> from 20-400mg / m<3>. After the adsorption saturation of the adsorbent, the adsorbent can be regenerated by a regeneration medium of N2, the regeneration air speed is 100-1000h<-1>, the regeneration pressure is 0-1.0MPa, and the regeneration temperature is 180-260DEG C. After the adsorbent is regenerated 30 times, the desulfurization effect of the adsorbent still reaches 95% of the desulfurization effect of the unused adsorbent.

Owner:CHINA PETROLEUM & CHEM CORP +1

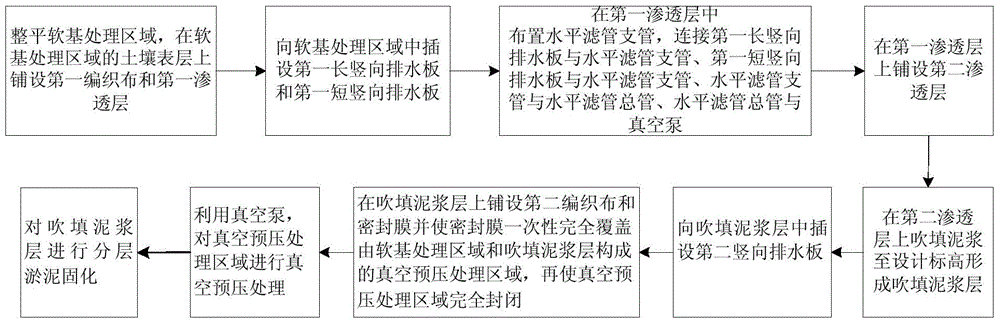

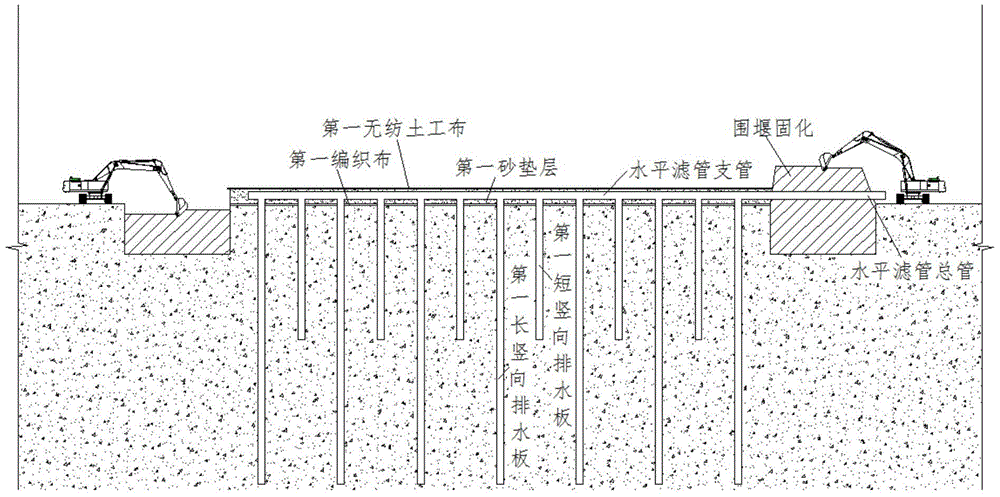

Structure and method for conducting reinforcing processing on soft foundation by combining surcharge preloading and vacuum preloading

ActiveCN104120711ASpeed up the consolidationImprove carrying capacitySoil preservationStructural engineeringSlurry

The invention discloses a structure and method for conducting reinforcing processing on a soft foundation by combining surcharge preloading and vacuum preloading. The structure comprises first woven fabric, a first pervious bed, a second pervious bed, a surcharge slurry layer, second woven fabric and a sealing film which are sequentially arranged on surface soil of a soft foundation processing region, and further comprises first long vertical drain boards, first short vertical drain boards, a horizontal branch filter tube, a horizontal master filter tube, a vacuum pump and second vertical drain boards. The first long vertical drain boards and the first short vertical drain boards are inserted into the soft foundation processing region, the horizontal branch filter tube is placed in the first pervious bed, the horizontal branch filter tube is connected with the vacuum pump through the horizontal master filter tube, and the second vertical drain boards are inserted into the surcharge slurry layer. The structure and method have the advantages that the vertical drain boards in two different lengths are inserted in the soft foundation processing region, the corresponding vertical drain boards are inserted into the surcharge slurry layer, water draining is then conducted on the vacuum condition, therefore, the solidification cycle can be shortened and the bearing capacity of the solidified foundation is high.

Owner:宁波高新区围海工程技术开发有限公司

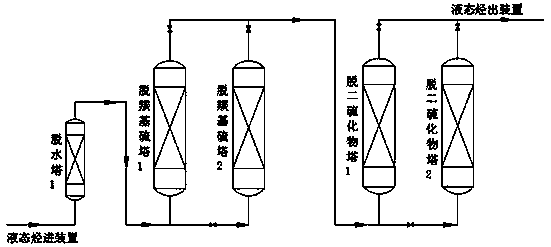

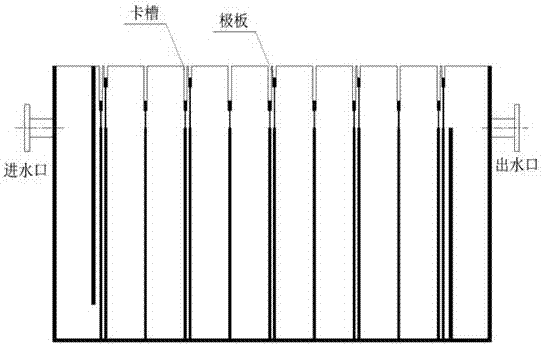

Advanced sewage treatment technology

ActiveCN104556494AReduce COD loadImprove processing depthMultistage water/sewage treatmentSuspended particlesElectrolysis

The invention belongs to the field of environmental protection and particularly relates to an advanced sewage treatment technology which comprises the following steps: after being subjected to biochemical treatment, sewage sequentially passes through a preoxidation unit, an electrolysis catalytic oxidation unit, a regeneration unit, a catalyst ultrasonic cleaning unit and a catalyst separating unit to meet the discharge standard. The static bed catalytic oxidation technology is adopted to reduce the COD load to a certain level, so that the follow-up COD load of a subsequent electrolysis catalytic oxidation unit is also reduced, the improvement on the sewage treatment depth is facilitated, and the effluent quality is better and more stable. With a static bed catalytic oxidation unit arranged in front, heavy metals and other materials in water toxic to a catalyst can be intercepted, so that a suspended particle catalyst with higher production cost can be protected, and the service life of the catalyst is prolonged. By timely adjusting the dosage of an oxidizing agent, the problem about load fluctuation can be instantly solved, the problem that the suspended particle catalyst is attached by dirt is also solved, the recycling of the suspended particle catalyst is realized, and the cost is lower.

Owner:CHINA PETROLEUM & CHEM CORP

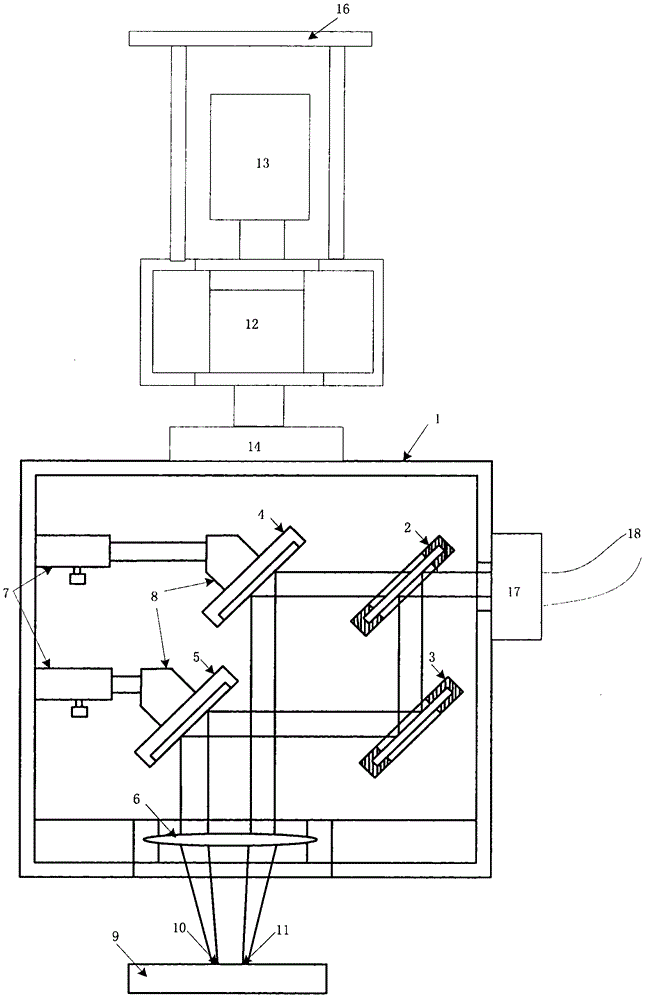

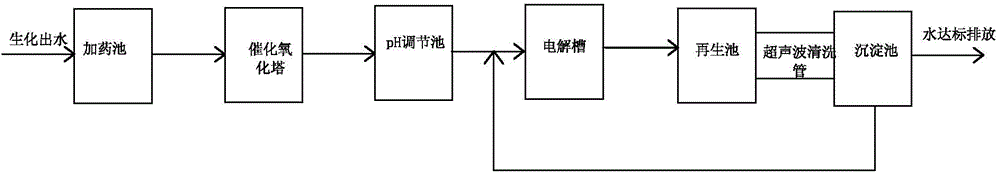

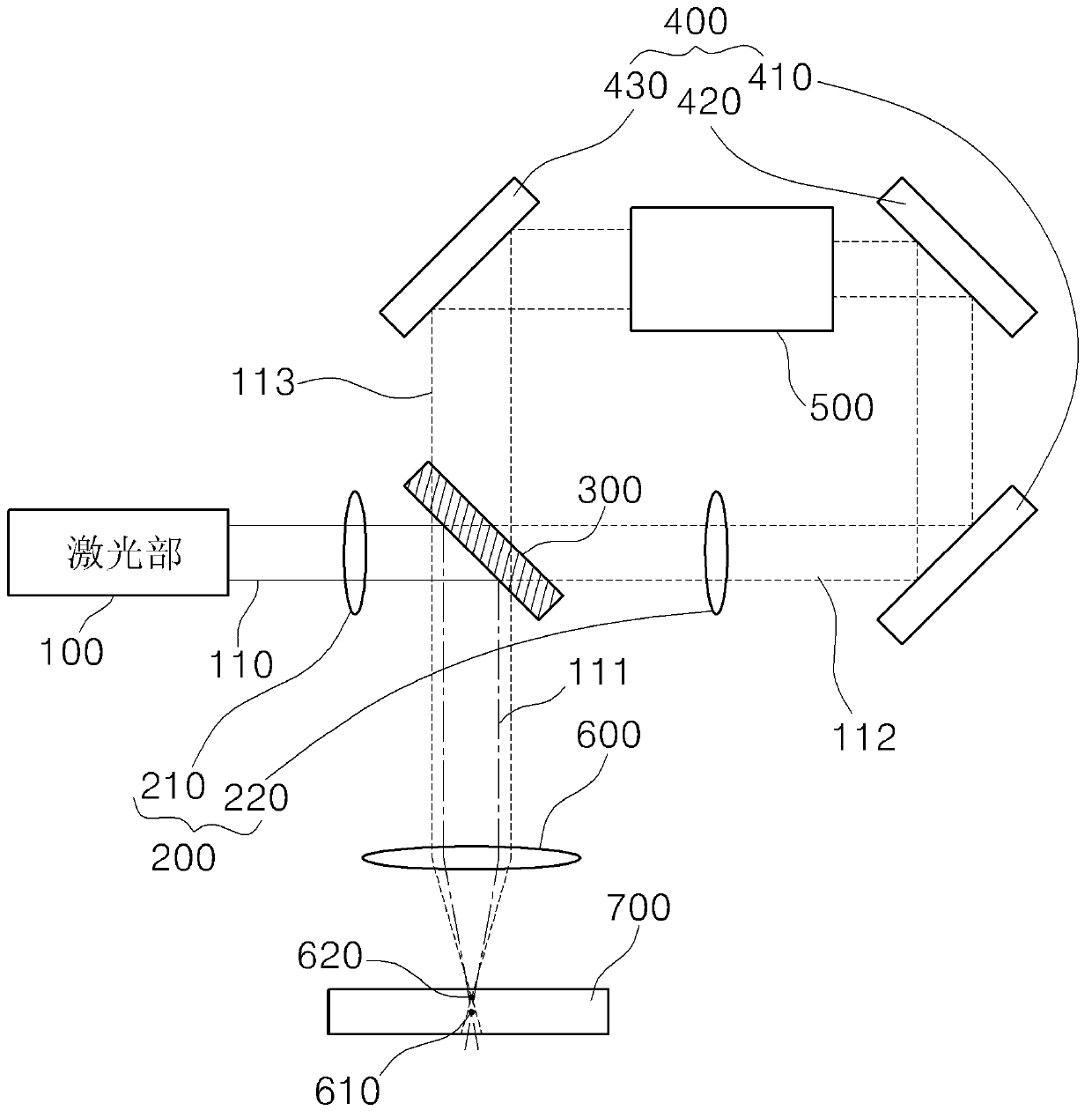

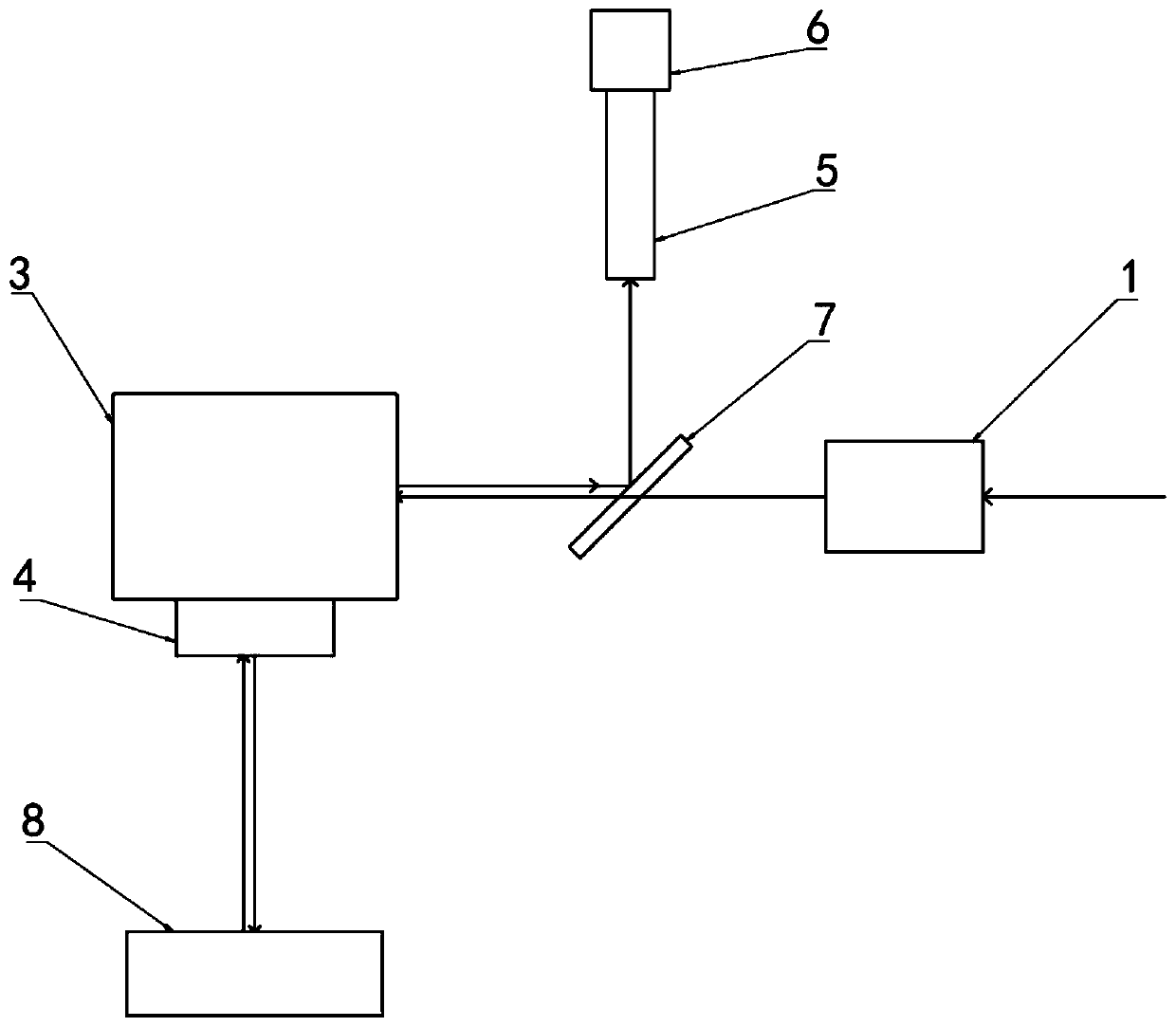

Laser processing apparatus and laser processing method

ActiveCN103212786AImprove processing depthReduce laser processing timeLaser beam welding apparatusOptoelectronicsLaser processing

The present invention relates to a laser processing apparatus and a laser processing method. The present invention relates to the laser processing apparatus, which is characterized by comprising: a laser unit (100) generating a laser beam (110); a wave plate (200) adjusting polarization direction of laser beam (110) from the laser unit (100); a polaroid (300) for dividing the laser beam (110) via the wave plate (200) into a first laser beam (111) and a second laser beam (112); a plurality of reflecting portions (400) reflecting the second laser beam (112); a laser beam amplification portion (500) amplifying the second laser beam (112); a focusing lens (600) for focusing a first laser beam (111) and a second laser beam (113) passing through the plurality of reflecting portions (400) and the laser beam amplification portion (500); and a processing unit for placing a processing target (700). The first laser beam (111) and the amplified second laser beam (113) are used respectively for processing different positions of the processing target (700).

Owner:CHARM ENG CO LTD

Saline soil area combined drain system and combined water drain forced ramming foundation treating method thereof

InactiveCN101349052AImprove foundation bearing capacity and modulusSave ground treatment costsSoil preservationProcess regionEngineering

The invention relates to a combined drainage system in a saline oil region and a method for processing the combined drainage and strongly tamping foundation. The method comprises the following steps: firstly, the combined drainage system for dredging and discharging groundwater is arranged in the foundation soil of a treatment region; the combined drainage system comprises a drainage passage combined by plastic drainage strips and dinas drainage piles; each plastic drainage strip and each dinas drainage pile are covered and a construction and operation surface layer is paved on the surface of the treatment region; the strongly tamping is carried out on the construction and operation surface layer by a tamping hammer; a tamping pit is formed in each dynamic tamping position; after groundwater in the foundation is collected in the tamping pits, pumped and discharged to the outside of a construction field; and the tamping pits are backfilled and leveled, thereby completing the first point tamping. The combined drainage system and the method solve the problem of discharging groundwater, substantially improve the bearing capacity of the foundation and the modulus, meet the requirements of constructing various buildings in the saline oil region, can save the expenses of foundation treatment by over 40 percent and shorten the construction period of the foundation treatment by more than one half.

Owner:JIAN YAN FOUND ENG

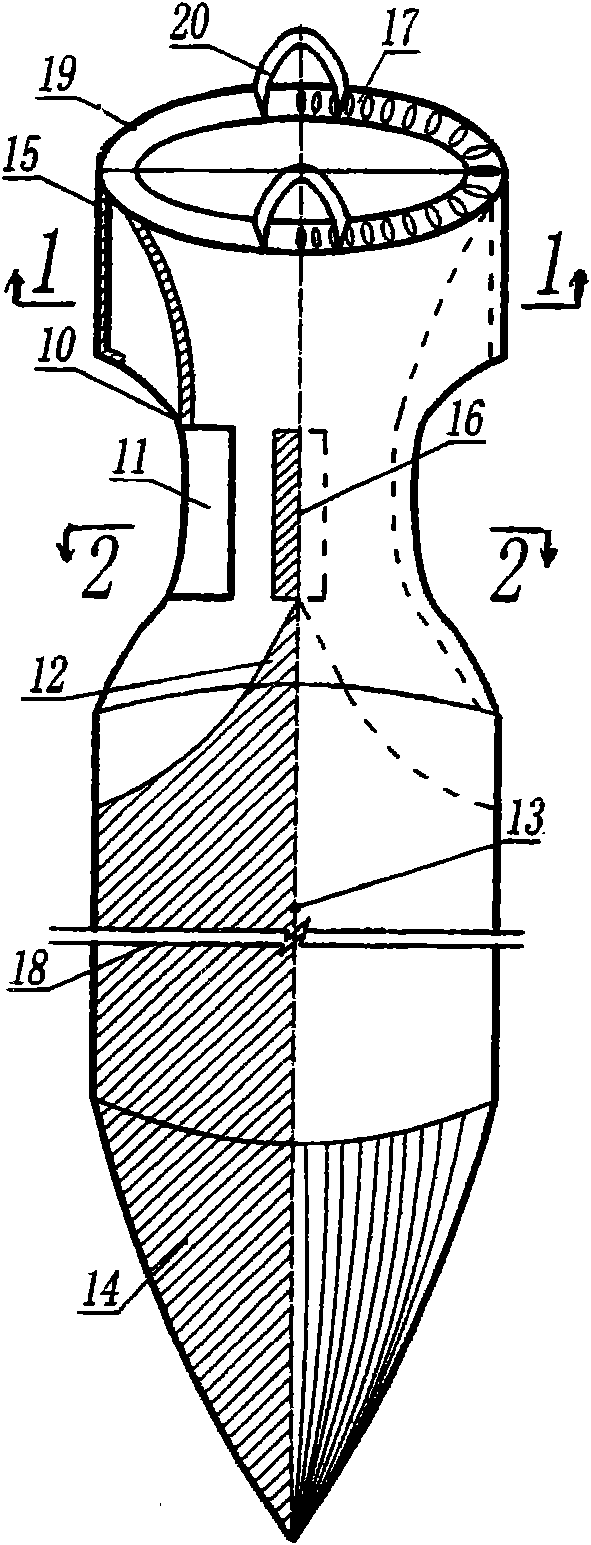

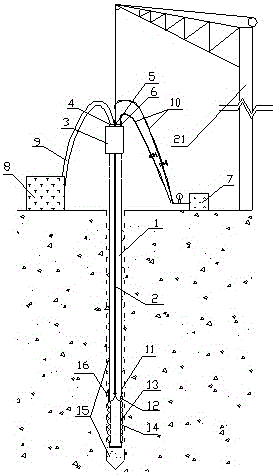

Method for realizing automatic over-pressure piling and compaction in holes

The invention relates to a method for realizing automatic over-pressure piling and compaction in holes, which comprises the following steps: making an automatic unhooking and hooking device controlled by a crane fall off and pierce a bell mouth on the upper part of an over-pressure counter weight by utilizing self weight; under the action of forces of vertical and transverse counter-force points, making the unhooking and hooking device hook hooking holes of a weight body; hoisting the counter weight to designed elevation in the air by using the crane and then making the unhooking and hooking device unhook the hooking holes of the weight body, so that the freely-falling weight body pierces a foundation hole; making the unhooking and hooking device fall off to drill and hook the weight body; repeatedly performing the steps of the hoisting of the weight body, the unhooking of the weight body, the falling-off of the weight body, the automatic weight body hooking of the unhooking and hooking device and the hoisting of the weight body, and then filling a filler with high design requirements into the foundation hole; and then repeatedly performing the steps and finally obtaining the deep foundation of a composite foundation, specific pile foundations and pre-expanded ecological pile bodies with high bearing capacity so as to fulfill the aims of processing the foundation into piles and the composite foundation and eliminating garbage contaminants.

Owner:司利利 +2

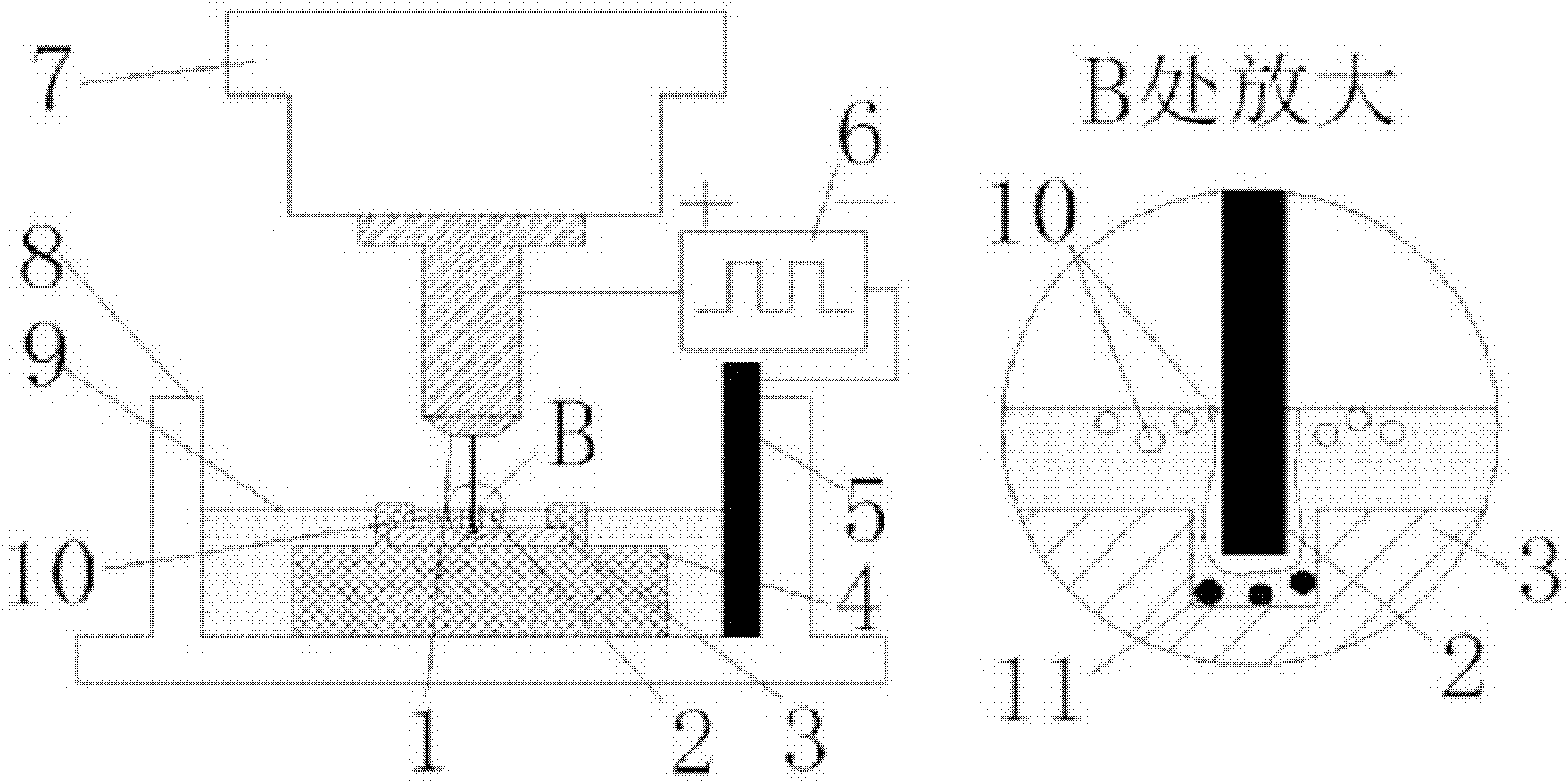

Reversed alignment electrochemical discharge machining method and device

The invention provides a reversed alignment electrochemical discharge machining (RA-ECDM) method in the field of special machining. A tool electrode is arranged below a workpiece. The tool electrode is fixed on the bottom surface of a work slot by an electrode holder and is soaked in electrolyte solution. The workpiece is connected with a feeding device of a machine tool. The feed motion in the machining process is implemented by feeding of the workpiece. The invention also provides a corresponding device. According to the invention, by changing the relative positions between the tool electrode and the workpiece, machining scraps generated in the machining process can be easily discharged under the action of gravity, so that the flowing capacity of electrolyte in a machining process in the machining process is reinforced. Moreover, due to the adoption of the reversed layout, air bubbles generated in the electrolytic reaction can be concentrated around the end part of the electrode below the machined workpiece to form a stable air film, so that the stability and the machining depth of the ECDM are effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

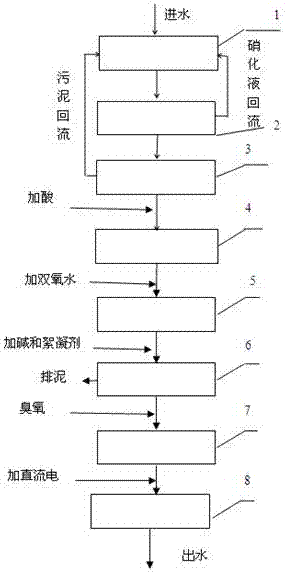

Treatment method of nanofiltration concentrated water of refuse leachate

InactiveCN107032537ADeep processingImprove processing depthMultistage water/sewage treatmentWater/sewage treatment by neutralisationIonChemistry

A treatment method of nanofiltration concentrated water of refuse leachate comprises following steps: the nanofiltration concentrated water is subjected to primary oxidation with an iron-carbon micro-electrolysis technology; after a certain amount of hydrogen peroxide is added to effluent obtained through the primary oxidation, residual acidity of the iron-carbon micro-electrolysis technology and produced ferrous ions are utilized to enable a reaction system to be converted into Fenton oxidation for secondary oxidation; alkali is added to effluent obtained after Fenton oxidation for PH back regulation, flocculent precipitate is subjected to mud-water separation, and after separation, an ozone catalyst is added to a supernatant for third-time oxidation; an electrolytic catalyst is added to effluent obtained after ozone catalytic oxidation for fourth-time oxidation, and wastewater obtained after electrolytic catalytic oxidation is discharged up to the standard. The treatment method has the advantages of deep treatment, flexible operation and low treatment cost.

Owner:SHANDONG LONGANTAI ENVIRONMENTAL PROTECTION SCI TECH CO LTD

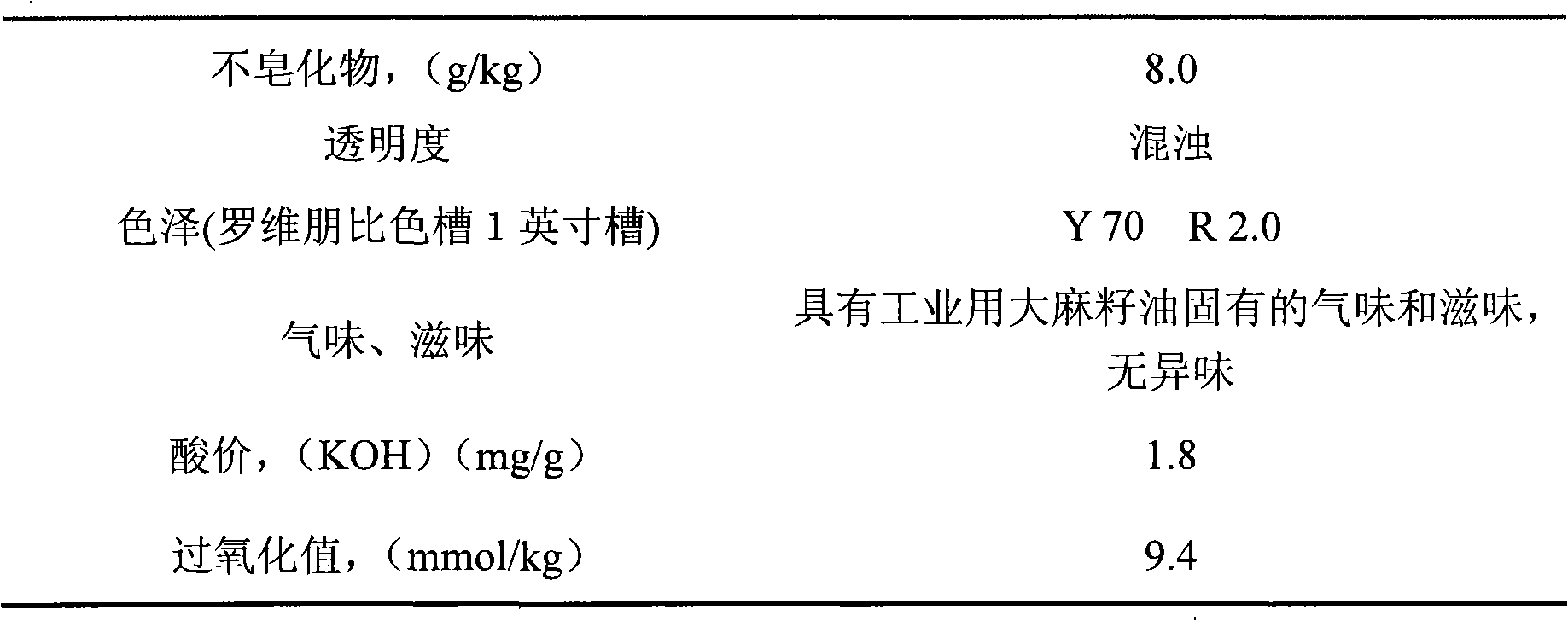

Industrial hempseeds isolated protein powder and preparation method thereof

InactiveCN101589760AAppropriate and uniform particle sizeAppropriate size and uniformProtein composition from vegetable seedsFood preparationFiberEmulsion

The invention discloses an industrial hempseeds isolate protein powder of which the protein purity is above 92%. The invention also provides a preparation method of the industrial hempseed isolated protein powder, comprising the following steps: (1) purifying and decorticating industrial hempseeds according to grading, and obtaining low temperature protein meal by CO2 supercritical fluid extraction; (2) dissolving the desolventized protein meal in alkaline liquor, adjusting the PH value to 8-10 to obtain protein emulsion, removing insoluble residue and fibre by filtering; (4) taking supernatant liquor and adding acid liquor to adjust the PH value to 4.5-5, centrifugalizing to take the precipitation; (5) adding alkaline liquor to adjust the PH value to 6-7, obtaining the industrial hempseeds isolate protein powder by spray drying. The invention has the advantages of simple process, low cost and high protein extraction efficiency. The produced industrial hempseeds isolate protein powder has high nutritional value and a wide application prospect.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

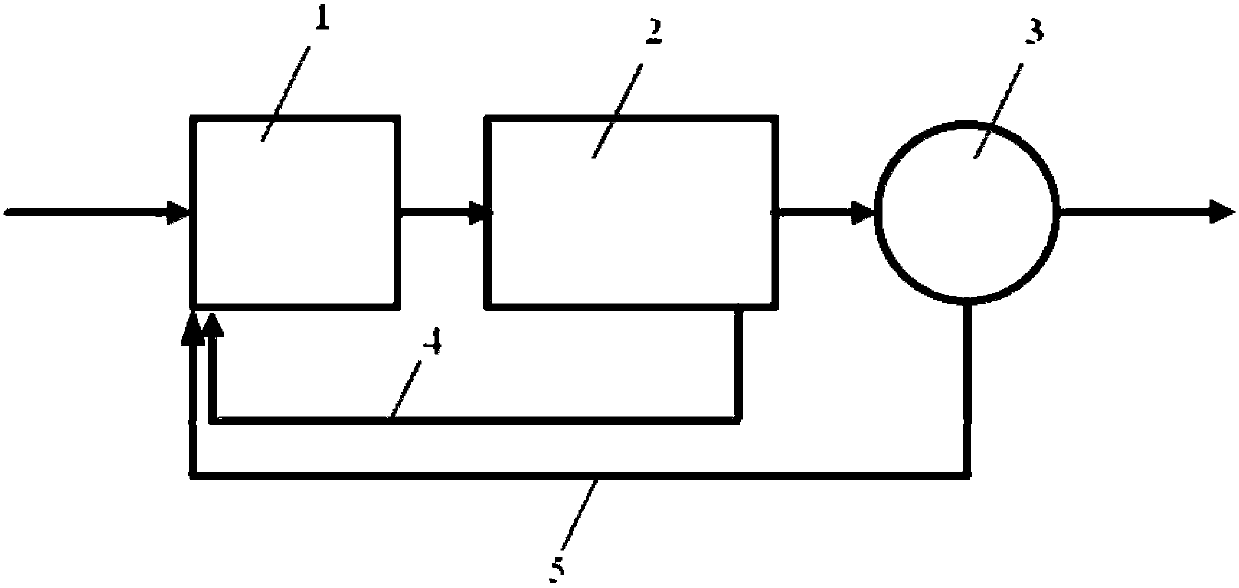

Hydrolysis/aerobic cycle suspension activated sludge process and device for deep treatment of waste water

ActiveCN103121756AReduce loadIncrease concentrationTreatment with aerobic and anaerobic processesSustainable biological treatmentActivated sludgeOxygen

The invention discloses a hydrolysis / aerobic cycle suspension activated sludge process and device for deep treatment of waste water. The hydrolysis / aerobic cycle suspension activated sludge process adopts a suspension activated sludge process and comprises the following steps of: enabling waste water to enter a hydrolysis tank to be subjected to anaerobic hydrolysis, then enabling the waste water to enter an aerobic tank to be subjected to deep treatment, and finally enabling the waste water to enter a secondary sedimentation tank to be subjected to mud-water separation, so that the waste water can be discharged, wherein backflow ratio of mixed solution of the aerobic tank returning to the hydrolysis tank is 1.0-8.0, and the backflow ratio of sludge of the secondary sedimentation tank returned to the hydrolysis tank is 0.5-2.0. The hydrolysis / aerobic cycle suspension activated sludge device comprises the hydrolysis tank, the aerobic tank and the secondary sedimentation tank, wherein the outlet of the hydrolysis tank is connected with the inlet of the aerobic tank, the outlet of the aerobic tank is connected with the inlet of the secondary sedimentation tank, a first return pipe is arranged from the aerobic tank to the hydrolysis tank, and a second return pipe is arranged from the secondary sedimentation tank to the hydrolysis tank. The treatment method disclosed by the invention has the characteristics of simple flow, easiness for operation, high treatment efficiency and low running cost.

Owner:上海心缘环境工程有限公司

Dioxin treatment system of hazardous waste incineration furnace

ActiveCN106402898AImprove adsorption capacityEffective controlEmission preventionIncinerator apparatusCombustion chamberTherapeutic effect

The invention discloses a dioxin treatment system of a hazardous waste incineration furnace. The dioxin treatment system comprises a pretreatment system, an incineration system and a smoke purification system. The incineration system comprises a rotary kiln and a secondary combustion chamber. A dry reactor is arranged between a smoke outlet of a quench tower and a bag type dust collector of the smoke purification system, and lime activated carbon is jet in the dry reactor. A plasma dioxin removing tower is arranged behind the bag type dust collector. An activated carbon powder adding device is arranged in a circulating pond, and water mixed with activated carbon powder enters a wet deacidification tower to be sprayed. Multiple equipment and process controlling points are set in the whole hazardous waste incineration furnace, dioxin type substances are effectively adsorbed and controlled, and it is ensured that tail gas emission meets the standard. The dioxin treatment system is good in treatment effect, wide in treatment range, good in universality, high in treatment depth and high in operation stability and impact resistance, and the treatment effect is good in winter and summer.

Owner:JIANGSU JINGNAN ENVIRONMENTAL PROTECTION TECH

Method for deep treatment on industrial wastewater discharged by styrene-butadiene rubber production device

ActiveCN103723878BOvercome the disadvantages of poor treatment effectStable emissionsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIndustrial waste waterSludge

The invention relates to a method for deep treatment on industrial wastewater discharged by a styrene-butadiene rubber production device and belongs to the field of wastewater multilevel treatment. Water treatment devices such as a pre-treatment unit, a sludge adsorption unit, an aerobic biochemical treatment unit, a flocculation and filtration unit and a high-grade oxidation treatment unit are orderly connected and combined; and discharged wastewater treated by the above water treatment devices has COD less than or equal to 40mg / L and NH3-N less than or equal to 5mg / L. The method solves the problem that the prior art has a high treatment cost and poor treatment effects, is a deep treatment method having the advantages of stable, safe and reliable operation, high pollutant removal rate and low operation cost, and realizes stable and standard discharge of industrial wastewater produced by a styrene-butadiene rubber production device. Compared with the prior art, the method reduces a high-grade oxidation phase Fenton's reagent use amount by about 30%, improves treatment depth by 15% and has an industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP

Device and method for treating deep seismic subsidence loess by combination of loess breakage by air injection and loess squeezing by air bag

ActiveCN105672241AImprove compactnessImprove bearing capacitySoil preservationSand blastingAir compressor

The invention discloses a device and method for treating deep seismic subsidence loess by combination of loess breakage by air injection and loess squeezing by an air bag. The device comprises an extensible double-layered steel sleeve, a top driver, an air distributing joint, a sand inlet, an air injection plug, the rubber air bag, a single-lobe non-return sand blasting opening and an adjustable gate valve, and is externally connected with an air compressor, a dry spraying machine and a lifting appliance. The method comprises the following steps: placing a device for breaking loess by air injection in seismic subsidence loess; synchronously injecting high-pressure air at a plurality of points to break macropore aerial structures of the loess; then expanding the air bag to squeeze the loose loess; releasing air in the air bag step by step after the loess is compact; refilling a hole by high-pressure sand filling; and repeating the steps piecewise so as to achieve the purpose of eliminating seismic subsidence of foundation loess finally. A process of loess breakage and a process of loess squeezing are finished continuously at a time, and the device and method are easy and convenient to operate and efficient. Moreover, owing to a water-free construction environment, possible secondary destruction caused by collapsibility of the loess meeting water is avoided, and the device and method are suitable for deep seismic subsidence loess foundations.

Owner:TAIYUAN UNIV OF TECH

Method for treatment of landfill leachate until to achieve up-to-standard direct discharging

ActiveCN107265764AReach the emission concentration limit requirementsFlexible operationWater contaminantsTreatment with aerobic and anaerobic processesTreatment effectElectrolysis

The invention belongs to the technical field of wastewater treatment, and in particular relates to a method for treatment of landfill leachate to achieve up-to-standard direct discharging. The method comprises the following steps: anaerobic biological treatment-aerobic biological treatment-iron carbon micro electrolysis-Fenton oxidation-catalytic ozonation-electrolysis catalytic oxidation. The landfill leachate is treated by the method to achieve up-to-national standard discharging, and the method has the advantages of deep wastewater treatment, flexible operation, strong water shock resistance and low processing cost. Most organic matters and total nitrogen are removed by biological methods with low processing cost, the remaining part of the organic matters are removed by the iron carbon micro electrolysis process, then hydrogen peroxide is added for Fenton oxidation, an electrode coating is used for catalytic oxidation, treatment effect is ensured, meanwhile current density between electrode plates is reduced, power consumption is reduced, and treatment cost is reduced.

Owner:SHANDONG LONGANTAI ENVIRONMENTAL PROTECTION SCI TECH CO LTD

Cylindrical electric absorption filtering apparatus by using activated carbon fiber as electric absorption material

InactiveCN105217744AIncrease the adsorption rateImprove adsorption capacityDispersed particle separationElectricityActivated carbon

The present invention provides a cylindrical electric absorption filtering apparatus by using activated carbon fiber as an electric absorption material, and belongs to the field of water pollution control in environment engineering. The cylindrical electric absorption filtering apparatus is provide with a liquid inlet, a liquid outlet and an electric absorption filtering component that is filled in a housing of a conductive layer, wherein the inner wall of the housing is a conductive layer. The assembly method of the inner electric absorption filtering component is as follows: a cylindrical conductor is a mandrel that is positioned in the center of the apparatus, and the activated carbon fiber is filled between the cylindrical conductor and the conductive layer, wherein the activated carbon fiber is used as a working electrode, and insulating layers are arranged between electrodes that are used as the conductive layers for the inner wall of the housing, or between the cylindrical conductor and working electrode that are in the center of the apparatus, and between electrodes. The cylindrical conductor and the conductive layer are connected with an electrode extending line respectively, the electrode extending line is extended through the housing and is sealed connection with the housing. According to the present invention, an electric absorption technology is coupled into a filter process, and the electric absorption technology is used for improving the adsorption rate and adsorption capacity of a traditional filter, and improving water purification depth.

Owner:DALIAN UNIV OF TECH

Grape skin residue and yam fruit vinegar powder and preparation method thereof

The invention relates to grape skin residue and yam fruit vinegar powder and a preparation method thereof, belonging to the technical field of fruit vinegar production and processing. The grape skin residue and yam fruit vinegar powder is prepared by the steps of fermenting 20-30 parts of yam powder and 70-80 parts of fine grape skin residue powder after gelatinization to prepare a vinegar solution and carrying out spray-drying. The grape skin residue and yam fruit vinegar powder is high in acidity, unique in flavor, free from cyclodextrin, good in mouth feel and rich in nutrition, can be used for preventing hypertension and hyperlipidemia, removing fatigue and the like, and greatly improves a healthcare function of fruit vinegar; grape skin residues and yams are all utilized and the utilization rate of the edible parts of the grape skin residues and the yams increases to 99%; cellulose, starch and other macromolecular substances in the grape skin residues and the yams are structurally degraded in a fermenting process, thereby shortening the fermenting time and facilitating digestion of absorption of an organism to the grape skin residue and yam fruit vinegar powder.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Dyeing and finishing wastewater treatment system and technology

PendingCN107117778AImprove biodegradabilityIncrease processing depthWater treatment parameter controlSpecific water treatment objectivesProcess engineeringWater use

The invention discloses a dyeing and finishing wastewater treatment system which comprises a first-level treatment unit, a first-level precipitation unit, at least one set of second-level treatment unit and a second-level precipitation unit, wherein the second-level treatment unit is connected with a corresponding second-level precipitation unit; the first-level treatment unit comprises a grid pool and a wastewater regulating pool; the first-level precipitation unit comprises a coagulative precipitation tank; the second-level treatment unit comprises a hydrolytic acidification cell, a first aerobic contact oxidation cell, a second aerobic contact oxidation cell and a reaction buffering pool which are connected in sequence; the second-level precipitation unit comprises a second-level precipitation pool and a reverse multi-element filtering pool; and the reverse multi-element filtering pool is connected with a clean water pool. The invention also discloses a wastewater treatment technology adopting the dyeing and finishing wastewater treatment system. According to the dyeing and finishing wastewater treatment system and technology disclosed by the invention, the textile wastewater can be deeply treated, the wastewater can reach the standard of recycled water, multiple effects of reducing wastewater discharge, saving water resources and protecting environment can be achieved, and the dyeing and finishing wastewater treatment system can meet the market requirement of the textile dyeing and finishing industry.

Owner:福建省万德环境工程有限公司

Dry gas hydrogen manufacturing cogeneration methanol technics

InactiveCN101161613AImprove processing depthEliminate pollutionOrganic compound preparationHydroxy compound preparationSyngasSocial benefits

The invention relates to an auxiliary process for oil refinery, in particular to a process of hydrogen production by dry gas and methanol co-production. The technical proposal is that: the methanol is produced by the following procedures of: (1) the preparation of synthetic gas which comprises dry gas desulphurization, compression, fine desulphurization, hydrocarbonsííconversion and waste recovery; (2) the synthesis of the methanol which comprises the compression of the synthetic gas, methanol synthesis and methanol separation; (3) the rectification of the methanol. The invention has the advantages that: the dry gas in the invention is not simply taken as the fuel for heating furnace, but becomes the important chemical raw material, and can create higher economical benefit and social benefit.

Owner:汤广德

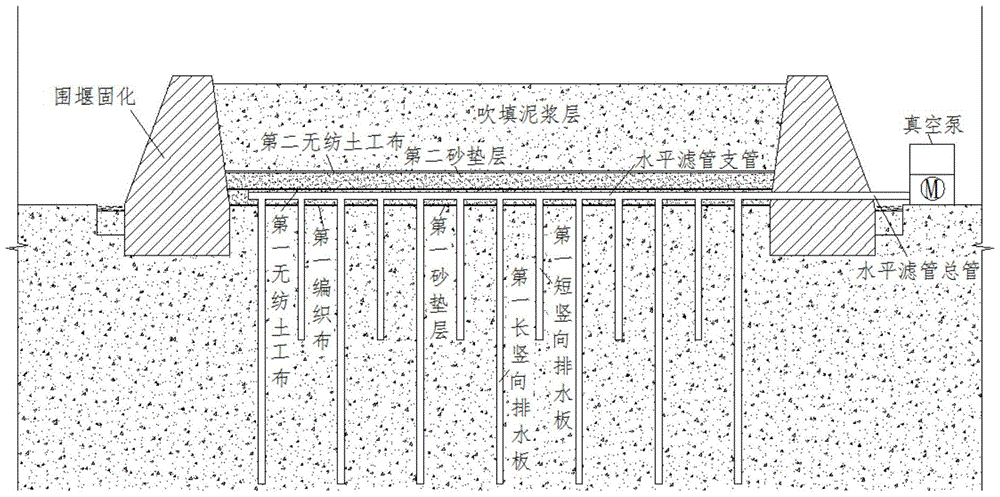

Soft foundation reinforcement treatment method of vacuum preloading combined with dredging and filling mud

ActiveCN104120710BSpeed up the consolidationShorten the consolidation cycleSoil preservationSludgeStructural engineering

The invention discloses a soft foundation reinforcement treatment method of vacuum preloading combined with dredging and filling mud. First, a first woven cloth and a first permeable layer are laid on the soil surface layer of the soft foundation treatment area; and then inserted into the soft foundation treatment area. Set up the first long vertical drainage board and the first short vertical drainage board, connect the horizontal filter pipe, and connect the vacuum pump; then lay the second permeable layer on the first permeable layer, according to the design elevation of the soft ground treatment area in the second The dredging and filling mud layer is formed on the permeable layer to the design elevation; then the second vertical drainage board is inserted into the dredging and filling mud layer; the second woven cloth and sealing film are laid in sequence on the dredging and filling mud layer; finally The vacuum preloading treatment area is vacuumed, and after the vacuuming is completed, the layered sludge solidification is carried out on the drained dredging mud layer; the advantage is that the consolidation period is short, and the bearing capacity of the treated dredged mud layer is high, which is convenient for construction The equipment works on it, and the treated foundation has a high bearing capacity and a high treatment depth.

Owner:宁波高新区围海工程技术开发有限公司

Laser scanning system and laser engraving system with same

PendingCN110421253ARealize real-time dynamic compensationAchieve real-time acquisitionLaser beam welding apparatusOptical axisLaser engraving

The invention provides a laser scanning system and a laser engraving system with the same. The laser scanning system comprises a Z-axis unit, a galvanometer assembly, a field lens and an imaging unit,wherein the Z-axis unit is positioned on an optical axis of a laser beam and is used for changing the position of a focal point in the Z-axis direction, and the optical axis is defined as a first optical axis; the galvanometer assembly is positioned on the first optical axis on one side of Z-axis unit, the laser beam is deflected into a second optical axis from the first optical axis after passing through the galvanometer assembly, and the galvanometer assembly is used for changing the position of the focal point in the X-axis direction and the Y-axis direction; the field lens is positioned on the second optical axis between the galvanometer assembly and a workpiece and is used for focusing the laser beam deflected by the galvanometer assembly to form the focal point; and the imaging unitis used for collecting illuminating beam reflected by the workpiece for imaging. According to the laser scanning system and the laser engraving system with the same, the imaging unit is additionallyarranged in the three-axis galvanometer, the image information on the surface of the workpiece is acquired so that the workpiece can be conveniently observed and the workpiece can be positioned on thebasis of the image, and therefore the laser scanning system has the advantages of being large in machining depth, high in machining precision and high in machining accuracy during machining of the workpiece.

Owner:LANGFANG SUPOWER DIAMOND TECH

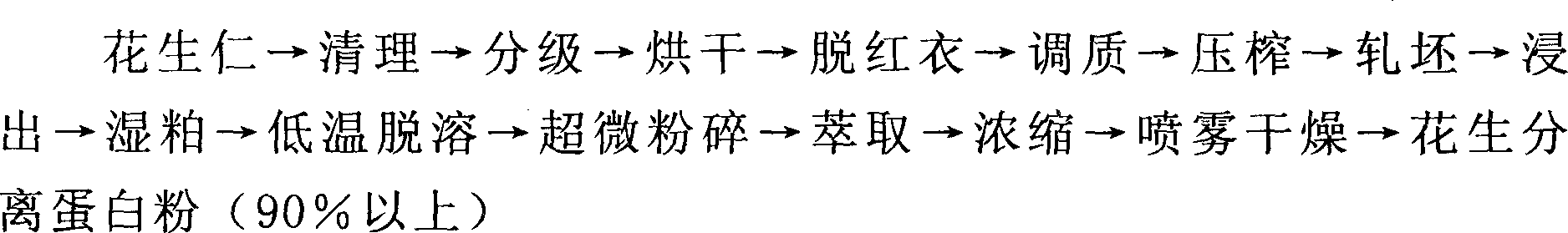

Method for separating protein powder of peanut

InactiveCN1899077ADoes not affect oil yieldQuality is not affectedVegetable proteins working-upSolventDeep processing

The present invention relates to peanut deep processing technology, and is especially method of separating protein powder from peanut. The special peanut protein powder separating process includes the following steps: 1. stoving peanut kernel at 55-65deg.c for 30 min to eliminate over 98 % of peanut coat; 2. low temperature pre-squeezing and puffing; 3. leaching; 4. low temperature solvent eliminating at temperature lower than 78deg.c; and 5. twice extraction, acid precipitation, neutralization, modifying, spray drying to separate peanut protein powder.

Owner:菏泽丹盟港龙农副产品开发有限公司

Combined process for delayed coking and hydrotreating

ActiveCN101638588BImprove processing depthReduce yieldTreatment with hydrotreatment processesLiquid productWax

The invention discloses a combined process for delayed coking and hydrotreating, which comprises the following steps that: a coking raw material is heated to enter a coking tower to react, oil gas escapes from the top of the coking tower, gas components and liquid components are separated, and the cycle ratio in a coking process is 0; and the liquid components are mixed with hydrogen to react in a hydrogenation reactor, then the obtained hydrogenated reaction effluent is distilled to obtain hydrogenated naphtha, hydrogenated diesel oil and hydrogenated wax oil, and the hydrogenated wax oil used as a high-quality raw material is fed into a catalytic cracking device or a hydrocracking device. By adopting the process flow of zero circulation of a coking device, the method provided by the invention furthest improves the yield of a liquid product, improves the processing depth of heavy oil, saves a coking fractionating tower, and achieves the aims of optimizing the flow and reducing the investment; and by adopting reasonable graduation of a hydrogenation catalyst, the method can furthest take account of the running period and the refining depth of each coking product fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com