Industrial hempseeds isolated protein powder and preparation method thereof

A technology of hemp seed and industrial use, applied in the preparation of protein isolate powder, industrial hemp seed protein isolate powder and its preparation field, can solve the problems of low protein content, many impurities in the powder, low nutritional value, etc., to achieve easy digestion Effect of absorbing, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

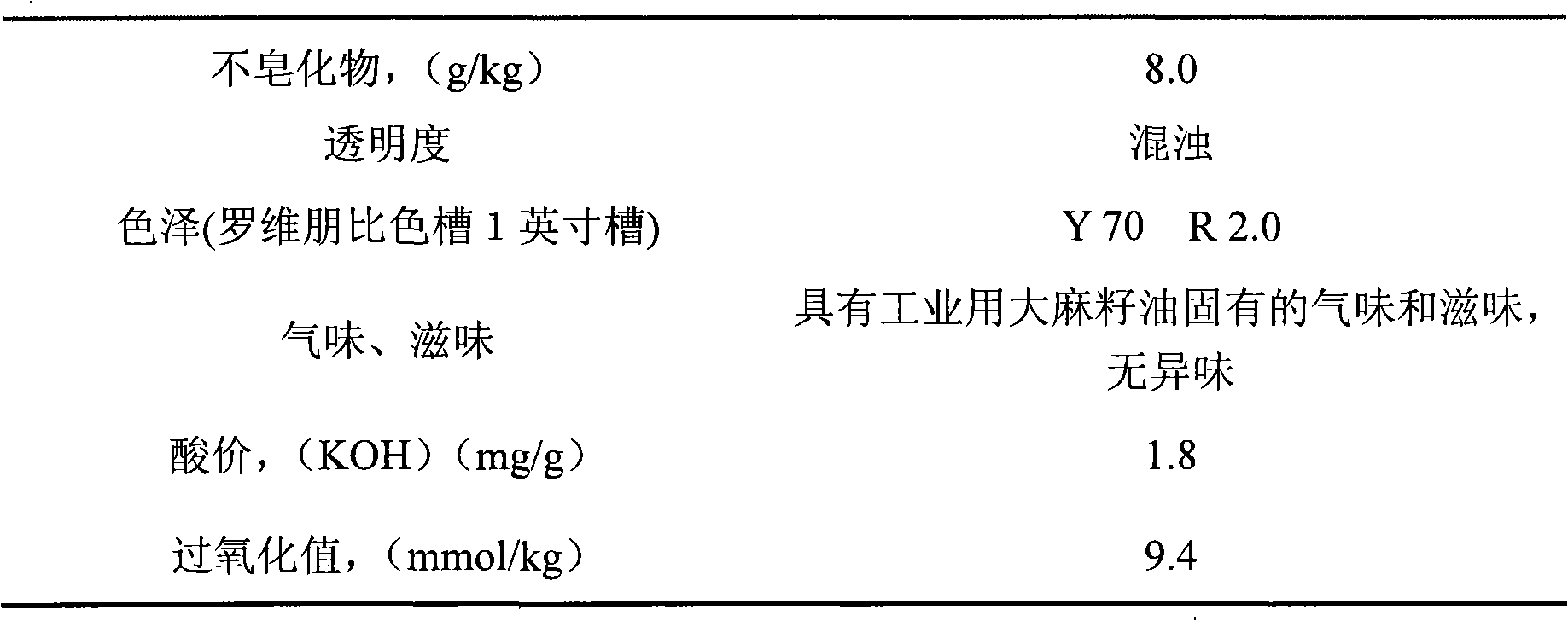

Embodiment 1

[0053] The hemp seeds for industrial use are screened to remove impurities, then graded, and then mechanically hulled and shelled; the hemp seeds obtained after shelling are subjected to carbon dioxide supercritical extraction, extracted at 43°C and 34MPa for 2 hours, and the extracted oil is extracted and the extracted product is crushed , extracted under the above conditions for another 2 hours to obtain industrial hemp seed low-temperature protein meal after oil extraction. In the low-temperature protein meal of hemp seeds for industrial use, the residual oil rate is 1.5%. The obtained low-temperature protein meal is pulverized by a pulverizer, passed through a 60-mesh sieve, and 10 kg of the sieved protein meal is taken, added to 100 kg of warm water at 50°C, stirred evenly, and the pH value is adjusted to 9.5, keep stirring for 15 minutes, vacuum filter to remove insoluble impurities, and obtain crude protein solution. Adjust the pH value of the crude protein solution to...

Embodiment 2

[0056] The hemp seeds for industrial use are screened to remove impurities, then graded, and then mechanically hulled and shelled; the hemp seeds obtained after shelling are subjected to carbon dioxide supercritical extraction, extracted at 43°C and 34MPa for 2 hours, and the extracted oil is extracted and the extracted product is crushed , extracted under the above conditions for another 2 hours to obtain industrial hemp seed low-temperature protein meal after oil extraction. In the low-temperature protein meal of hemp seeds for industrial use, the residual oil rate is 1.2%. The obtained low-temperature protein meal is pulverized with a pulverizer, passed through an 80-mesh sieve, and 10 kg of the protein meal after sieving is taken, added to 80 kg of warm water at 45° C., stirred evenly, and the pH value is adjusted to 8. Insulated and stirred for 25 minutes, vacuum filtered to remove insoluble impurities, and crude protein solution was obtained. Adjust the pH value of the ...

Embodiment 3

[0059] The hemp seeds for industrial use are screened to remove impurities, then graded, and then mechanically hulled and shelled; the hemp seeds obtained after shelling are subjected to carbon dioxide supercritical extraction, extracted at 43°C and 34MPa for 2 hours, and the extracted oil is extracted and the extracted product is crushed , extracted under the above conditions for another 2 hours to obtain industrial hemp seed low-temperature protein meal after oil extraction. In the low-temperature protein meal of hemp seeds for industrial use, the residual oil rate is 1.8%. The obtained low-temperature protein meal is pulverized by a pulverizer, passed through a 100-mesh sieve, and 10 kg of the sieved protein meal is taken, added to 110 kg of warm water at 48° C., stirred evenly, and adjusted to pH with a 28% NaOH solution by mass percent. 10. Stir with heat preservation, remove insoluble impurities by vacuum filtration, and obtain crude protein solution. Adjust the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com