Microbial sand-fixing dust depressor and preparation method thereof

A technology of dust suppressant and microorganism, applied in chemical instruments and methods, fertilizer mixtures, other chemical processes, etc., to achieve good water permeability, strong adaptability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) According to the mass percentage, add 9.3% calcium chloride to 85% water, stir until it is completely dissolved, then add 5.0% urea to it, and then add 1.7% urea after it is completely dissolved. Bacillus subtilis bacteria powder, stir until it dissolves completely, then the sand-fixing agent of the present invention can be obtained. The whole reaction process was carried out at normal temperature.

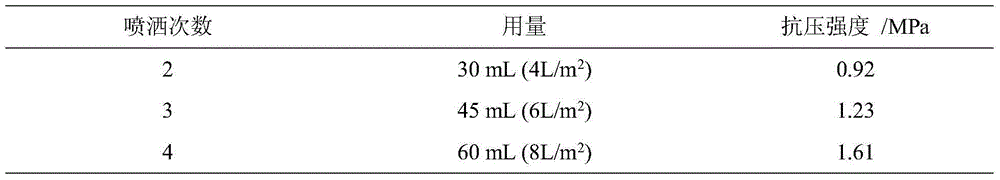

[0018] (2) Consolidated layer hardness and unconfined compressive strength tests were carried out on the sand-fixing agent prepared in this example.

[0019] ①Consolidated layer hardness test

[0020] The hardness of the cured sand samples was tested by LX-D Shore hardness tester. The method is as follows: Take 100g of sand samples (with a particle size of 0.15-0.30mm), put them into a petri dish with a diameter of 95mm, spread them flat and compact them. Then measure 15mL of microbial sand-fixing and dust-suppressing agent and spray evenly on the surface of the sand...

Embodiment 2

[0030] (1) In terms of mass percentage, add 10.1% calcium chloride to 84% water, stir until it is completely dissolved, then add 3.0% urea, and then add 2.5% urea after it is completely dissolved. Bacillus subtilis bacteria powder, stir until it dissolves completely, then the sand-fixing agent of the present invention can be obtained. The whole reaction process was carried out at normal temperature.

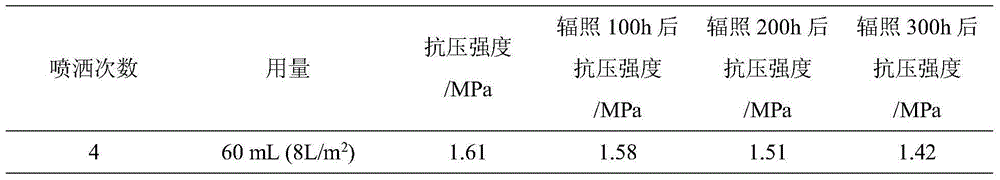

[0031] (2) Carry out an aging resistance test on the sand-fixing agent prepared in this example.

[0032] Take 33g of sand samples (with a particle size of 0.15-0.30mm), put them into a syringe with a diameter of 3cm, spread them flat and compact them. Then measure 15mL of microbial sand-fixing and dust-suppressing agent and spray evenly on the surface of the sand sample. After the penetration is complete, repeat the spraying of the microbial sand-fixing and dust-suppressing agent. Then put it in an oven (60°C), and take it out after 48 hours to smooth the surface to be tested...

Embodiment 3

[0037] (1) In terms of mass percentage, add 8.3% calcium chloride to 85% water, stir until it is completely dissolved, then add 4.9% urea, and then add 2.0% urea after it is completely dissolved. Bacillus subtilis bacteria powder, stir until it dissolves completely, then the sand-fixing agent of the present invention can be obtained. The whole reaction process was carried out at normal temperature.

[0038] (2) Conduct a wind erosion test on the sand-fixing agent prepared in this example.

[0039] Take 3000g of sand samples (with a particle size of 0.15-0.30mm), put them into a square iron pan with a size of 32cm×22cm×4.8cm, and spread them flat and compact them. Then measure 500mL of microbial sand-fixing and dust-suppressing agent and evenly spray it on the surface of the sand sample. After the penetration is complete, repeat the spraying of the microbial sand-fixing and dust-suppressing agent. Then put it in an oven (60°C), after drying, place it in front of an industria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com