Method for separating protein powder of peanut

A technology of peanut protein powder and protein powder, which is applied in the direction of vegetable protein processing, etc., can solve the problems of particle fineness limitation, high oil content of peanuts, difficult industrial application, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

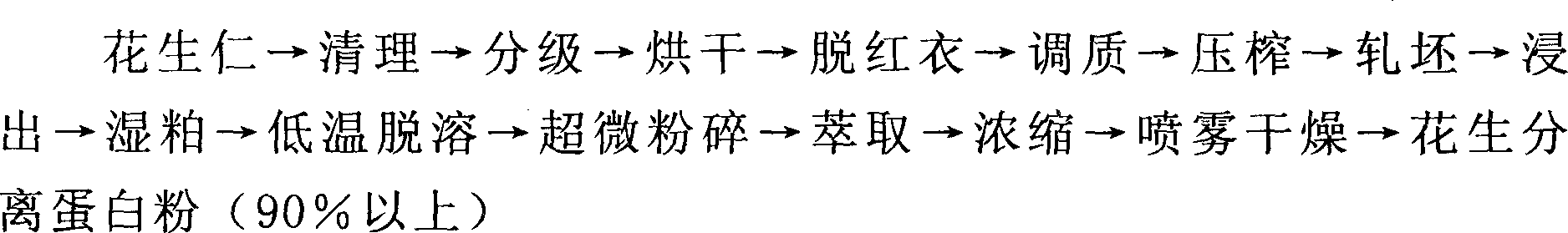

Image

Examples

Embodiment 1

[0019] Accompanying drawing is a kind of specific embodiment of the present invention. The method of this embodiment is as follows: the material discharged from the baking oven is subjected to cold water rapid cooling, and the peanuts are removed from the red seed coat. The unqualified peanut kernels are selected, and the peanut kernels that have not been stripped of the seed coat enter the stripper again to remove the seed coat. The peanut kernels that have been removed from the red seed coat are put into the crusher to crush 7-8 petals, and the broken cake can be pre-pressed at low temperature (81°C) and extruded. The temperature of the extruder outlet material is 95°C. grade peanut oil. Peanuts enter the extractor for leaching, and then the low-denatured defatted meal after low-temperature desolventization, and then undergoes two extractions, acid precipitation, neutralization, modification, and spray drying to obtain the product. The product is in powder form, contains m...

Embodiment 2

[0021] This embodiment comprises the following steps: (1) the roasting temperature of the peanut kernels before removing the red seed coating is 55° C. for 30 minutes, and the rate of removing the red seed coating of the peanut kernels is more than 98%; (2) then proceeding at 78° C. Low-temperature pre-pressing and puffing, the outlet temperature of the puffing machine is 95°C; (3) The extruded peanut meal is extracted at a temperature of 53°C for 90 minutes; (4) The low-temperature precipitation temperature is controlled at 75°C, The fat content is about 1%; (5) Ultrafine grinding is carried out to make peanut protein powder with a particle size of 200-300 mesh. After two extractions, acid precipitation, neutralization, modification, and spray drying, the content of isolated peanut protein powder is 90 %above.

Embodiment 3

[0023] This embodiment comprises the following steps: (1) the roasting temperature of the peanut kernels before removing the red seed coating is 65° C. for 30 minutes, and the rate of removing the red seed coating of the peanut kernels is more than 98%; (2) then proceed at 75° C. Low-temperature pre-pressing and puffing, the outlet temperature of the puffing machine is 90°C; (3) The extruded peanut meal is extracted at a temperature of 56°C for 90 minutes; (4) The low-temperature precipitation temperature is controlled at 78°C, The fat content is about 1%; (5) After two extractions, acid precipitation, neutralization, modification, and spray drying, the content of the isolated peanut protein powder is above 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com