Method for deep treatment on industrial wastewater discharged by styrene-butadiene rubber production device

A technology for advanced treatment and production equipment, which is applied in the fields of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. High problems, to achieve the effect of improving COD removal rate, convenient operation and maintenance, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

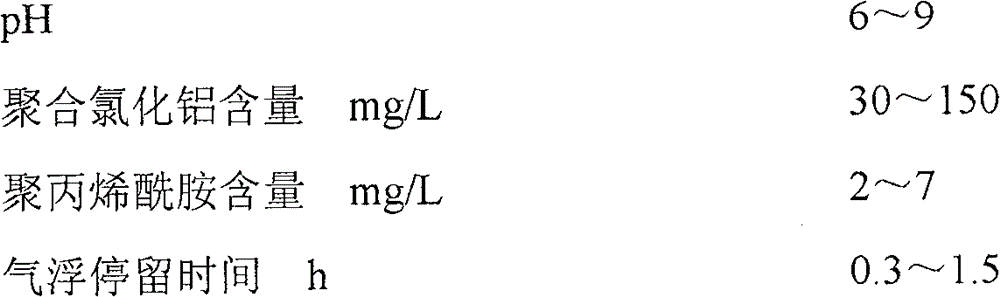

[0103] The COD concentration of a styrene-butadiene rubber production sewage is 1056mg / L, and the sewage is treated with 150m 3 The flow rate of / h enters figure 1 In the treatment process shown, the main process parameters of each treatment unit are: the pretreatment unit adds alkali to adjust the pH value to 9, the content of PAC and PAM is 250mg / L and 5mg / L respectively, and the air flotation residence time is 0.5h. COD: 771mg / L, COD removal rate 27%.

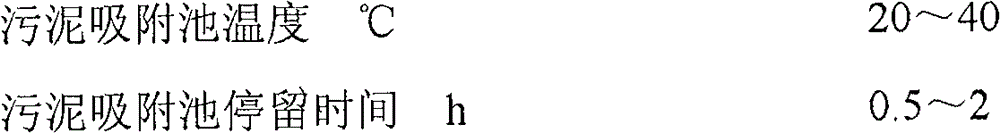

[0104] The sewage enters the sludge adsorption tank to remove the remaining suspended solids and colloidal particles in the pretreatment unit. The temperature in the pool is 35°C, and the residence time is 1h. After adsorption, the COD decreased to 470mg / L, and the COD removal rate reached 39%.

[0105] The wastewater after sludge adsorption enters the first-stage carrier fluidized bed. At this stage, the hydraulic retention time is 6h, the DO is 4.0mg / L, and the MLSS is 3000mg / L; the hydraulic retention time in the activ...

Embodiment 2

[0108] The COD concentration of a styrene-butadiene rubber production sewage is 950mg / L, and the sewage is treated with 200m 3 The flow rate of / h enters figure 1 In the shown treatment process, the main process parameters of each treatment unit are: the pretreatment unit adds alkali to adjust the pH value to 8.5, the contents of flocculant PAC and PAM are 250mg / L and 2mg / L respectively, and the air flotation residence time is 1.0h. The effluent COD of this unit is 741mg / L, and the COD removal rate is 22%.

[0109] The sewage enters the sludge adsorption tank to remove the remaining suspended solids and colloidal particles in the pretreatment unit. The temperature in the pool is 35°C, and the residence time is 1h. After adsorption, the COD dropped to 445mg / L, and the COD removal rate reached 40%.

[0110] The wastewater after sludge adsorption enters the first-stage carrier fluidized bed. At this stage, the hydraulic retention time is 8.0h, the DO is 5.5mg / L, and the MLSS i...

Embodiment 3

[0113] The COD concentration of a styrene-butadiene rubber production sewage is 761mg / L, and the sewage is treated with 120m 3 The flow rate of / h enters figure 1 In the shown treatment process, the main process parameters of each treatment unit are: the pretreatment unit adds alkali to adjust the pH value to 7.5, the contents of flocculant PAC and PAM are 150mg / L and 2mg / L respectively, and the air flotation residence time is 1h. The unit effluent COD is 533mg / L, and the COD removal rate is 30%.

[0114] The sewage enters the sludge adsorption tank to remove the remaining suspended solids and colloidal particles in the pretreatment unit. The temperature in the pool is 30°C, and the residence time is 1h. After adsorption, COD decreased to 373mg / L, and the removal rate of COD reached 30%.

[0115] The wastewater after sludge adsorption enters the first-stage carrier fluidized bed. At this stage, the hydraulic retention time is 6.5h, the DO is 4.0mg / L, and the MLSS is 2500mg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com