Method for treating dispersant low-temperature domestic sewage by floating stuffing segregating technique

A technology for suspended fillers and domestic sewage, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of small number of microbial strains and poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

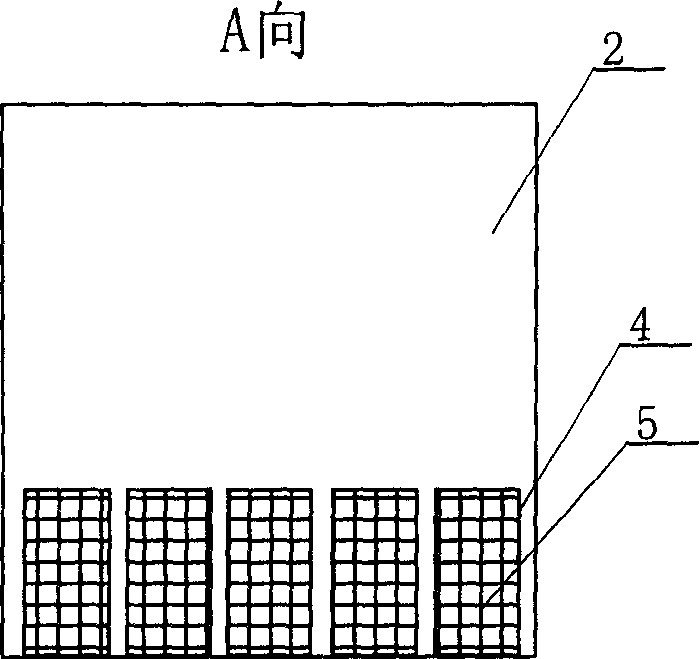

[0005] Specific implementation mode 1: In this embodiment, the treatment process of the dispersed low-temperature domestic sewage by the suspended packing grid process is as follows: water absorption well - lifting pump - suspended packing grid PCSBR reaction tank - effluent. The treatment method is as follows: a. Bury the reaction tank 1 underground, and the upper end of the reaction tank 1 is 0.5m away from the ground surface; b. The process of controlling each operation cycle of the reaction tank 1 is as follows: water inflow for 6 hours, aeration while water inflow , the water inflow to the reaction tank adopts non-restrictive aeration method, and the water is aerated while entering the water. The water level in the reaction tank is controlled by a liquid level gauge, and the aeration device adopts a microporous aerator; stage, the denitrifying bacteria present in the deep anaerobic layer of the biofilm and the anaerobic layer at the bottom of the activated sludge denitrify...

specific Embodiment approach 2

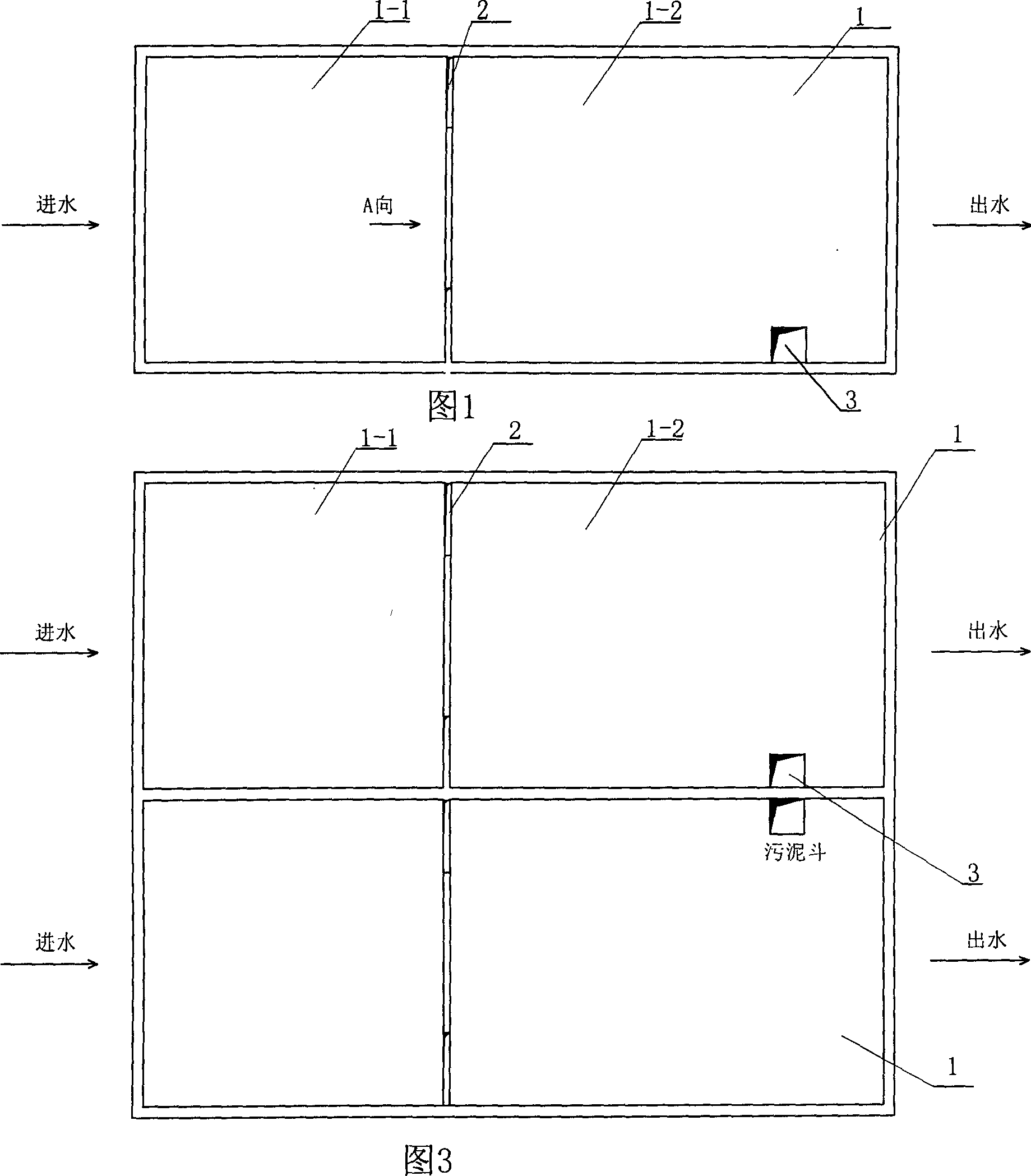

[0006] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the number of reaction pools 1 is two, referring to Fig. The operation period of the pond is 8 hours, among which, water is fed for 4 hours, aeration is carried out at the same time, then static sedimentation is performed for 2 hours, and then decanting and sludge discharge are performed. The decanting and sludge discharge time is 1.5 hours, and finally idle for 0.5 hours. Each reaction pool 1 runs intermittently in time sequence and space sequence.

specific Embodiment approach 3

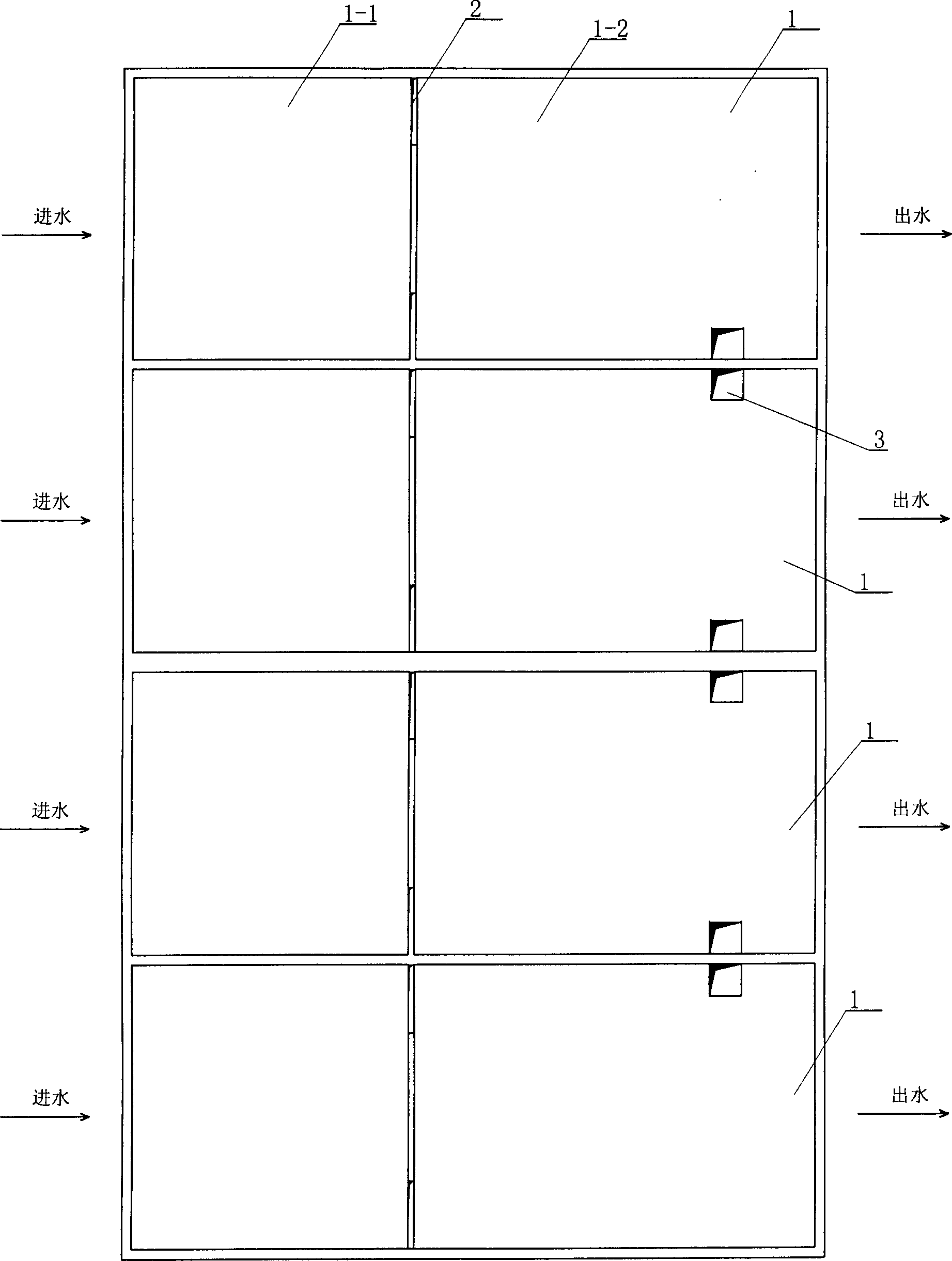

[0007] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the number of reaction pools 1 is four, refer to Figure 4 , in which the operation cycle of a single tank is 6 hours, of which, water intake is 4 hours, aeration is carried out at the same time as water intake, and then static sedimentation is performed for 0.5 hours, and then decanting and sludge discharge are performed. The decanting and sludge discharge time is 1 hour, and finally idle for 0.5 Hour. Several reaction pools 1 are operated intermittently in time sequence and space sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com